The global construction lumber market is experiencing steady expansion, driven by rising residential and commercial building activities, urbanization, and the growing preference for sustainable building materials. According to a 2023 report by Mordor Intelligence, the market was valued at approximately USD 320 billion in 2022 and is projected to grow at a CAGR of over 5.8% through 2028. Key growth drivers include increased infrastructure development in emerging economies and the resurgence of wood as an eco-friendly alternative to carbon-intensive materials like steel and concrete. North America and Europe remain dominant markets due to stringent environmental regulations and strong demand for timber-frame construction, while Asia-Pacific is anticipated to witness the fastest growth, fueled by rapid urbanization in countries like China and India. As demand surges, a select group of manufacturers have emerged as leaders, combining scale, sustainability certifications, and advanced production technologies to meet evolving global needs. Here’s a data-driven look at the top 10 construction lumber manufacturers shaping the industry.

Top 10 Construction Lumber Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Boise Cascade Wood Products Building Materials

Domain Est. 1994

Website: bc.com

Key Highlights: We make and deliver building materials for the residential and commercial construction industry … The industry’s top-performing engineered wood solutions….

#2 Weyerhaeuser

Domain Est. 1995

Website: weyerhaeuser.com

Key Highlights: Weyerhaeuser manages the most sustainable, versatile resource on earth: forests. We’re experts at using trees to make products people need, and we do it the ……

#3 84 Lumber: Lumber Yard

Domain Est. 1996

Website: 84lumber.com

Key Highlights: 84 Lumber is your source for building supplies, building materials and all your construction needs. Find a store or request a quote online today!…

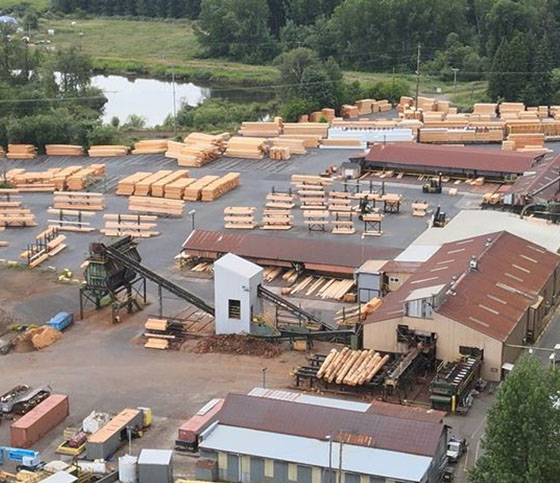

#4 Stimson Lumber

Domain Est. 1996

Website: stimsonlumber.com

Key Highlights: Stimson Lumber produces high-quality wood products from environmentally certified forests in Oregon, Idaho, Montana, and Washington….

#5 Lumber, Plywood, MDF Boards

Domain Est. 1996

Website: timberproducts.com

Key Highlights: Timber Products has the expertise to provide top quality lumber, plywood, MDF boards and more! 100+ years of industry leadership!…

#6 Carter Lumber

Domain Est. 1997

Website: carterlumber.com

Key Highlights: Carter Lumber is dedicated to providing exceptional service and quality building materials at competitive prices to our family of customers….

#7 West Fraser Timber Co.

Domain Est. 1997

Website: westfraser.com

Key Highlights: From lumber to engineered wood products, West Fraser delivers high-quality, naturally renewable building materials to the world. Explore Our Products….

#8 Builders FirstSource

Domain Est. 1998

Website: bldr.com

Key Highlights: Builders FirstSource is the nation’s largest supplier of structural building products, value-added components and services to the professional market….

#9

Domain Est. 2002

Website: uslumber.com

Key Highlights: US LUMBER was founded in Birmingham, Alabama and has grown into a highly-trusted, privately held distributor of specialty building materials….

#10 Hood Distribution

Domain Est. 2006

Website: hooddistribution.com

Key Highlights: Our five mills strategically located across the Eastern United States from Massachusetts to Alabama provide value-added services of the highest quality….

Expert Sourcing Insights for Construction Lumber

H2: 2026 Market Trends for Construction Lumber

As we approach 2026, the construction lumber market is poised for notable shifts driven by economic conditions, supply chain dynamics, housing demand, sustainability initiatives, and technological advancements. The second half of the decade is expected to bring stabilization after years of volatility, with several key trends shaping the industry.

1. Moderating Prices Amid Improved Supply Chain Resilience

Following the extreme price fluctuations seen during and after the pandemic, lumber prices in 2026 are anticipated to stabilize. Increased domestic mill capacity, improved logistics, and better inventory management have reduced supply bottlenecks. However, regional disparities may persist due to localized demand surges or transportation constraints. Prices are expected to remain above pre-2020 levels due to higher production and labor costs but will be less volatile than in previous years.

2. Housing Market Rebound Fuels Demand

The U.S. and several international markets are projected to experience a modest rebound in single-family home construction in 2026. Declining mortgage rates compared to 2023–2024 levels, coupled with a persistent housing shortage, are driving new builds. This renewed activity is increasing demand for dimensional lumber, particularly spruce-pine-fir (SPF) and southern yellow pine. Multi-family urban developments are also incorporating more mass timber, supporting demand for engineered wood products.

3. Growth in Mass Timber and Sustainable Construction

Environmental regulations and green building certifications (e.g., LEED, Living Building Challenge) are accelerating the adoption of mass timber—such as cross-laminated timber (CLT) and glued laminated timber (glulam)—in mid-rise and commercial construction. By 2026, North America is expected to have expanded mass timber production capacity, reducing reliance on imports from Europe. This shift supports lower carbon construction and aligns with government incentives for sustainable development.

4. Technological Integration and Efficiency Gains

Digitalization is transforming lumber production and distribution. Advanced sawmill automation, AI-driven yield optimization, and blockchain-enabled supply chain tracking are improving efficiency and traceability. Builders increasingly use Building Information Modeling (BIM) to reduce waste and optimize framing designs, which affects lumber purchasing patterns—favoring precision-cut and prefabricated components.

5. Trade Policies and Geopolitical Factors

The long-standing softwood lumber dispute between the U.S. and Canada remains a factor, though new trade agreements or tariff adjustments by 2026 may ease tensions. Additionally, export policies from major producers like Russia (post-sanctions) and new sourcing from South America and Eastern Europe could alter global supply flows. U.S. import reliance on Canadian lumber is expected to remain high but may diversify slightly.

6. Climate Change and Resource Management

Wildfire risks, droughts, and changing forest health due to climate change are impacting timber availability, particularly in the western United States and Canada. Sustainable forestry practices and increased investment in reforestation are being prioritized by industry leaders and governments to ensure long-term supply security. Certifications like FSC and SFI are gaining importance among environmentally conscious buyers.

Conclusion

The construction lumber market in 2026 reflects a maturing response to past disruptions, with greater emphasis on sustainability, efficiency, and resilience. While demand remains closely tied to housing starts and interest rates, innovation in materials and processes is reshaping traditional usage patterns. Stakeholders who adapt to these trends—particularly in mass timber, digital supply chains, and environmental stewardship—are likely to gain competitive advantage in the evolving landscape.

Common Pitfalls When Sourcing Construction Lumber: Quality and Intellectual Property Concerns

Sourcing construction lumber involves more than just securing the lowest price. Overlooking key quality and intellectual property (IP) issues can lead to project delays, cost overruns, legal disputes, and compromised structural integrity. Below are critical pitfalls to avoid.

Poor Lumber Quality and Grading Misrepresentation

One of the most frequent issues in lumber sourcing is receiving material that does not meet specified quality standards. Suppliers may provide lower-grade lumber than contracted—such as substituting construction-grade with utility-grade wood—leading to warping, splitting, or inadequate load-bearing capacity. Misrepresentation of grading stamps or failure to adhere to standards like those from the American Lumber Standard Committee (ALSC) or equivalent international bodies can compromise safety and code compliance.

Inadequate Moisture Content Control

Lumber with improper moisture content can cause serious problems post-installation, including shrinkage, swelling, cracking, or mold growth. Sourcing wood without verified kiln-drying documentation or failing to specify acceptable moisture levels (typically 15–19% for exterior use, 6–12% for interior) risks long-term performance issues. Always require moisture test reports and on-site verification.

Lack of Chain-of-Custody and Sustainability Certification

Using lumber without proper chain-of-custody documentation (e.g., FSC or PEFC certification) can lead to reputational damage, especially in green building projects or public contracts requiring sustainable sourcing. Failure to verify sustainable forestry practices may also expose companies to regulatory penalties or consumer backlash.

Non-Compliance with Regional Building Codes

Lumber properties vary by region and species, and not all wood is suitable for every climate or structural application. Sourcing without confirming compliance with local building codes (e.g., wind load, fire resistance, or seismic requirements) can result in rejected materials or unsafe construction. Always validate species, treatment type (e.g., pressure-treated for ground contact), and regional suitability.

Intellectual Property Infringement in Engineered Wood Products

When sourcing engineered lumber (such as Laminated Veneer Lumber (LVL), I-joists, or structural insulated panels), be wary of counterfeit or unlicensed products. Many proprietary systems are protected by patents and trademarks. Using unauthorized copies not only violates intellectual property rights but may also fail performance and warranty standards, leading to liability in case of structural failure.

Unclear or Missing Documentation for Traceability

Failing to obtain proper mill certifications, grade stamps, treatment records, or test reports limits traceability. In the event of a defect or recall, lack of documentation makes it difficult to identify the source, assign responsibility, or claim warranties. Always require complete paperwork as part of the procurement contract.

Overreliance on Unverified Suppliers

Sourcing from suppliers without thorough due diligence—especially in international markets—increases the risk of receiving substandard or misrepresented products. Unverified vendors may lack consistent quality control or ethical sourcing practices. Conduct site audits, request references, and verify industry affiliations before committing.

Avoiding these pitfalls requires proactive specification, third-party inspections, and clear contractual terms that define quality standards, compliance requirements, and IP protections. Due diligence at the sourcing stage protects both structural integrity and legal standing.

Logistics & Compliance Guide for Construction Lumber

Transporting and handling construction lumber involves careful planning to ensure product integrity, regulatory compliance, and operational efficiency. This guide outlines key considerations for logistics and compliance throughout the lumber supply chain.

Regulatory Compliance

Compliance with local, national, and international regulations is essential when sourcing, transporting, and using construction lumber. Failure to adhere to these standards can result in fines, shipment delays, or project disruptions.

Timber Sourcing Standards

Ensure lumber is sourced from legal and sustainable forests. Key certifications include:

– FSC (Forest Stewardship Council): Verifies responsible forest management.

– PEFC (Programme for the Endorsement of Forest Certification): Promotes sustainable forest practices globally.

– SFI (Sustainable Forestry Initiative): North American standard for sustainable forestry.

Documentation such as chain-of-custody certificates must accompany shipments, particularly for public or environmentally sensitive projects.

International Trade Regulations

When importing or exporting lumber:

– Comply with Lacey Act (USA): Prohibits trade in illegally sourced wood.

– Provide phytosanitary certificates to meet International Plant Protection Convention (IPPC) standards.

– Use ISPM 15-compliant wood packaging (heat-treated or fumigated wood pallets).

– Classify lumber correctly under HS codes (e.g., 4407 for sawn wood) for accurate customs declarations.

Building Codes and Standards

Verify that lumber meets regional construction standards, such as:

– ASTM D1990 (USA): Standard for establishing allowable properties for visually graded lumber.

– CSA O86 (Canada): Engineering design standard for wood structures.

– Eurocode 5 (EU): Design of timber structures.

Grades, moisture content, and species must align with project specifications and local building authority requirements.

Transportation and Handling

Efficient and safe logistics are critical to minimize damage, reduce waste, and ensure timely delivery.

Loading and Securing

- Use flatbed or enclosed trailers suited for long, heavy loads.

- Stack lumber evenly with dunnage between layers to allow airflow and prevent warping.

- Secure loads with straps, chains, or load locks to prevent shifting during transit.

- Follow FMCSA (Federal Motor Carrier Safety Administration) or local load securement rules.

Moisture and Weather Protection

- Cover loads with waterproof tarps to prevent rain exposure.

- Avoid direct ground contact to reduce moisture absorption; use pallets or skids.

- Store lumber under cover upon delivery; ideal moisture content for framing is 12–19%.

Dimensional and Weight Considerations

- Standard dimensional lumber (e.g., 2×4, 2×6) has defined nominal and actual sizes.

- Account for vehicle weight limits; a full load of kiln-dried softwood can exceed 20,000 lbs.

- Check bridge laws and permit requirements for oversized loads.

Storage and Site Management

Proper on-site storage prevents damage and ensures lumber remains usable.

On-Site Storage Best Practices

- Store lumber on level, well-drained ground using stringers or pallets.

- Keep stacks covered and elevated; allow space between boards for air circulation.

- Separate treated and untreated lumber to avoid contamination.

- Rotate stock using FIFO (First In, First Out) to prevent aging and degradation.

Safety Considerations

- Stack lumber no higher than 16 feet unless secured properly.

- Maintain clear walkways and use PPE when handling.

- Train personnel in safe lifting and material handling techniques.

Documentation and Traceability

Maintain accurate records to ensure compliance and support quality assurance.

Required Documentation

- Mill certificates (including species, grade, moisture content)

- Certificates of origin

- FSC/PEFC chain-of-custody documentation

- Inspection reports and test results (e.g., for treated lumber)

- Bill of lading and delivery receipts

Digital tracking systems can enhance traceability from mill to job site.

Environmental and Sustainability Compliance

Green building standards often require responsible lumber sourcing.

LEED and Other Green Building Programs

- Earn LEED credits through use of certified sustainable wood.

- Document regional materials (extracted and manufactured within 500 miles).

- Minimize waste through accurate ordering and recycling scrap.

Emissions and Waste Management

- Recycle wood waste through chipping or biomass programs.

- Properly dispose of treated lumber (e.g., ACQ, CCA) per EPA or local hazardous waste guidelines.

By adhering to these logistics and compliance practices, construction professionals can ensure the safe, legal, and efficient use of lumber in building projects while supporting sustainability goals.

In conclusion, sourcing construction lumber requires careful consideration of quality, sustainability, cost, and supply chain reliability. Selecting the right type of lumber—whether softwood, hardwood, or engineered wood—depends on the specific requirements of the project, including structural needs, environmental conditions, and budget constraints. It is essential to work with reputable suppliers who adhere to industry standards and provide certification for sustainable forestry practices, such as FSC or PEFC, to ensure environmental responsibility. Additionally, factoring in lead times, transportation logistics, and potential market fluctuations can help mitigate delays and cost overruns. By taking a strategic and informed approach to sourcing lumber, construction professionals can ensure the durability, efficiency, and sustainability of their projects while maintaining cost-effectiveness and compliance with regulatory standards.