The global wood products market continues to expand, driven by rising demand for sustainable building materials and innovative wood-based solutions across construction, furniture, and landscaping sectors. According to a 2023 report by Mordor Intelligence, the global wood market is projected to grow at a CAGR of 5.8% from 2023 to 2028, fueled by increasing urbanization and environmentally conscious consumer preferences. As demand for specialty wood products rises, cone-shaped wood components—used in everything from acoustic diffusers to decorative elements—have gained traction among designers and manufacturers seeking both aesthetic appeal and functional performance. With North America and Europe leading in technological adoption and sustainable forestry practices, a select group of manufacturers have emerged as industry leaders in precision-crafted cone wood products. Based on production capacity, market presence, innovation, and customer reach, the following nine companies represent the top players shaping the future of this niche yet growing segment.

Top 9 Cone Wood Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Cone Machinery

Domain Est. 1999

Website: conemachinery.com

Key Highlights: Cone Machinery, Inc. manufactures a complete line of sawmill machinery, including chipping edgers, saw edgers, optimized edger infeeds, log turners and ……

#2 Disposable Wooden Cone

Domain Est. 2017

Website: anchengfoodservice.com

Key Highlights: Disposable Wooden Cone offered by China manufacturer Ancheng Bamboo&Wood. Buy high quality Disposable Wooden Cone right now!…

#3 Pine Cone Lumber

Domain Est. 1999

Website: pineconelumber.com

Key Highlights: We have over six decades of experience providing Sunnyvale and South Bay professional builders with the materials you need….

#4 Premium Wood Bowls & Cones for Food Presentation

Domain Est. 2004

Website: uniquemanufacturing.com

Key Highlights: Our wood bowls and cones are perfect for caterers, food trucks, and charcuterie displays. Single-use, food-safe options for impressive plating….

#5 RAW Cone Creator • RAWthentic

Domain Est. 2004

Website: rawthentic.com

Key Highlights: This little RAW Cone Creator is the perfect tool for making your own cones on-the-go! Just roll a tip and slip it into the hole. Then wrap your RAW paper….

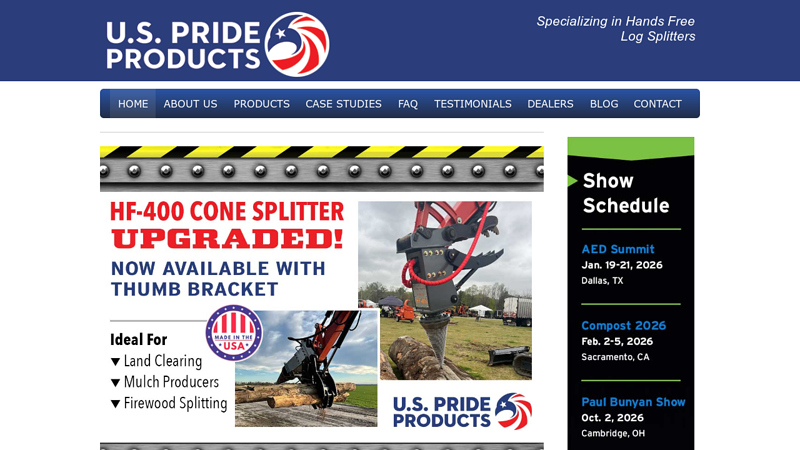

#6 U.S. Pride Products

Domain Est. 2006

Website: usprideproducts.com

Key Highlights: US Pride Products designs and builds cone screw splitters to do one thing; split big logs – quickly, safely and efficiently….

#7 Pine Wood Medium Cones Belix

Domain Est. 2010

Website: gfifoods.com

Key Highlights: Made from natural pine wood, these cones provide a rustic and charming alternative to traditional serving ware. Ideal for appetizers, desserts, single-serve ……

#8 Wooden Tip Cones & Tubes

Domain Est. 2022

Website: conesworld.com

Key Highlights: ConesWorld is your go-to destination for premium customized cones crafted to perfection. We specialize in providing high-quality pre-rolled cones, rolling ……

#9 Ashford Wheels and Looms

Founded: 1934

Website: ashford.co.nz

Key Highlights: Made in New Zealand since 1934. Trusted by hand crafters the world over. Explore the range ……

Expert Sourcing Insights for Cone Wood

H2 2026 Market Trends Outlook for Cone Wood

As of mid-2026, the market for cone wood—timber harvested from coniferous trees such as pine, spruce, fir, and cedar—is experiencing a complex mix of demand shifts, supply constraints, and evolving sustainability pressures. Below is an analysis of key trends shaping the cone wood market in H2 2026:

1. Increased Demand in Construction and Renovation

H2 2026 continues to see strong demand for structural softwood (a primary component of cone wood) driven by resilient residential construction, particularly in North America and Northern Europe. Government incentives for energy-efficient housing have boosted the use of engineered wood products (like CLT and glulam), which rely heavily on high-grade spruce and pine. Additionally, post-pandemic remote work trends have sustained demand for home expansions and backyard office structures, further supporting cone wood consumption.

2. Supply Chain Stabilization with Regional Variations

After years of volatility, global supply chains for cone wood have largely stabilized. However, regional imbalances persist:

– North America: Sawmill production has rebounded, but labor shortages and transportation bottlenecks in the U.S. Pacific Northwest are causing localized delays.

– Nordic Countries: Strong export volumes from Sweden and Finland are meeting European demand, though tighter forestry regulations are limiting harvest growth.

– Russia and Eastern Europe: Sanctions and logistical challenges continue to restrict Russian softwood exports, redirecting European buyers toward Baltic and Scandinavian suppliers.

3. Sustainability and Certification Pressures Intensify

Environmental, Social, and Governance (ESG) criteria are now central to procurement decisions. In H2 2026, demand for certified cone wood (FSC, PEFC) has surged, especially in the EU, where the revised Timber Regulation (EUTR) mandates full traceability. Companies are investing in digital tracking systems and blockchain solutions to verify sustainable sourcing. Non-certified or high-risk origin wood faces increasing market resistance, particularly in green building projects.

4. Pricing Moderation After Volatility

After the price spikes of 2021–2023, cone wood prices have moderated into H2 2026 due to improved supply and tempered housing starts. However, prices remain above pre-pandemic levels. Premiums are observed for kiln-dried, stress-graded, and sustainably sourced lumber. Market watchers anticipate slight downward pressure in Q4 due to seasonal slowdowns, but any extreme weather disruptions (e.g., wildfires in Canada) could trigger short-term price surges.

5. Innovation in Wood Products and Circular Use

There is growing adoption of mass timber and prefabricated wood components in commercial construction, supported by updated building codes. Concurrently, the circular economy is gaining traction—reclaimed cone wood from demolition sites is being repurposed into furniture and design elements, creating a niche but expanding secondary market. This trend is particularly strong in urban centers with sustainability mandates.

6. Climate Change Impacts on Supply

Climate-related challenges are affecting cone wood availability. Increased frequency of bark beetle infestations (linked to warmer winters) and wildfires in Canadian and U.S. forests have reduced usable timber yields. These ecological pressures are prompting longer-term investments in forest resilience, including reforestation with climate-adapted conifer species and improved pest management.

Conclusion

H2 2026 presents a cautiously optimistic outlook for the cone wood market. While structural demand remains robust and supply chains are more resilient, long-term success will depend on adapting to sustainability mandates, climate risks, and technological innovation. Stakeholders who prioritize traceability, invest in value-added wood products, and adopt adaptive forestry practices are best positioned to thrive in this evolving landscape.

Common Pitfalls Sourcing Cone Wood (Quality, IP)

Sourcing Cone Wood—a term sometimes used informally or regionally for specific types of coniferous timber such as pine, spruce, or fir—can present several challenges, particularly concerning quality consistency and intellectual property (IP) considerations, especially when used in proprietary products or designs. Below are common pitfalls to watch for:

Quality Inconsistencies

One of the primary risks in sourcing Cone Wood is variability in material quality. Factors such as growth conditions, harvesting methods, and processing standards can lead to significant differences in density, grain structure, moisture content, and durability. Buyers may receive batches with warping, knots, or uneven coloration, impacting the final product’s performance and aesthetics. Lack of standardized grading or certification (e.g., FSC, PEFC) increases the risk of subpar material, especially when sourcing from regions with less stringent forestry practices.

Misrepresentation of Species and Origin

Suppliers may label wood generically as “Cone Wood” without specifying the exact species (e.g., Pinus sylvestris vs. Picea abies), leading to confusion and mismatched expectations. This ambiguity can affect mechanical properties and suitability for intended applications. Additionally, undisclosed or falsified country of origin raises concerns about illegal logging and non-compliance with environmental regulations, exposing buyers to reputational and legal risks.

Lack of Traceability and Sustainability Claims

Many suppliers make broad sustainability claims without providing verifiable documentation. Without proper chain-of-custody certification, it’s difficult to confirm whether the Cone Wood was harvested legally and sustainably. This opacity undermines corporate social responsibility goals and may lead to non-compliance with regulations such as the EU Timber Regulation (EUTR) or the U.S. Lacey Act.

Intellectual Property Risks in Design and Processing

When Cone Wood is used in finished goods—especially in furniture, architectural elements, or consumer products—there’s potential for IP infringement if the design, treatment process, or finishing technique is protected. Sourcing partners might use patented wood treatments, coatings, or manufacturing methods without proper licensing. Furthermore, if a supplier replicates a proprietary design provided by the buyer, it may lead to disputes over ownership, especially in cross-border transactions without clear contractual IP clauses.

Inadequate Contractual Safeguards

Failure to include detailed specifications, quality benchmarks, and IP indemnification clauses in supply agreements leaves buyers vulnerable. Ambiguous contracts may not address who owns design adaptations, how disputes are resolved, or liability for using protected technologies. This is particularly critical when co-developing products or sharing technical drawings with overseas manufacturers.

Conclusion

To mitigate these pitfalls, buyers should insist on species-specific sourcing, third-party certifications, transparent supply chains, and robust legal agreements that clearly define quality standards and IP rights. Due diligence and ongoing supplier audits are essential to ensure both material integrity and compliance.

Logistics & Compliance Guide for Cone Wood

This guide outlines the key logistics and compliance considerations for the legal and sustainable sourcing, transportation, and handling of cone wood. Cone wood—typically derived from coniferous trees such as pine, spruce, or fir—is commonly used in landscaping, mulch production, biomass fuel, and artisanal crafts. Ensuring proper logistics and regulatory compliance is critical to avoid legal issues, environmental harm, and supply chain disruptions.

Regulatory Compliance

CITES and Endangered Species Regulations

Although most conifer species are not listed under CITES (Convention on International Trade in Endangered Species), certain rare or regionally protected conifers may be regulated. Verify species identification and check CITES appendices before cross-border transport, especially when sourcing from biodiverse regions.

National and Regional Timber Regulations

Comply with national forestry laws such as the U.S. Lacey Act, the EU Timber Regulation (EUTR), and similar frameworks in other countries. These require proof of legal harvest and chain-of-custody documentation. Ensure suppliers provide harvest permits, land-use rights, and transportation licenses.

Phytosanitary Standards

Cone wood, especially when transported internationally, must meet phytosanitary requirements to prevent the spread of pests and diseases (e.g., bark beetles, fungal pathogens). Obtain an International Phytosanitary Certificate (IPPC mark) when exporting. Heat treatment or fumigation may be required for wood packaging or raw logs.

Environmental and Land-Use Compliance

Harvesting must comply with local environmental regulations, including protected area restrictions, watershed protections, and sustainable forestry practices. Avoid sourcing from ecologically sensitive zones or areas with active conservation designations.

Sustainable Sourcing Practices

Forest Management Certification

Prioritize suppliers certified under recognized standards such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification). These certifications ensure sustainable harvesting and responsible forest management.

Chain-of-Custody Documentation

Maintain clear records from harvest to end-user, including supplier invoices, harvest dates, locations, transportation logs, and processing records. This supports traceability and compliance audits.

Seasonal Harvesting and Replanting Policies

Coordinate harvesting with seasonal cycles to minimize ecological impact. Support reforestation initiatives where applicable, especially if cones or seeds are collected for propagation.

Transportation & Handling

Domestic and International Shipping

Use carriers experienced in handling raw wood materials. Clearly label shipments with species name, origin, treatment status (e.g., heat-treated), and compliance documentation. For international shipments, ensure adherence to ISPM 15 standards for wood packaging.

Storage and Moisture Control

Store cone wood in dry, ventilated areas to prevent mold growth and insect infestation. Elevate materials off the ground and cover if exposed to weather. Monitor moisture levels, especially if intended for biomass or mulch applications.

Safety Protocols

Train personnel in safe handling practices. Use appropriate PPE when processing or transporting wood, particularly when dealing with sharp cones or dusty byproducts. Ensure vehicles and equipment are well-maintained and operated by licensed staff.

Documentation & Record-Keeping

Required Paperwork

Maintain the following documents for each shipment:

– Harvest permit or forestry authorization

– Bill of lading

– Phytosanitary certificate

– Proof of legal origin (e.g., FSC certificate)

– Transport licenses and customs declarations (for cross-border movement)

Audit Preparedness

Regularly review compliance records and conduct internal audits. Be prepared for inspections by forestry departments, customs agencies, or environmental regulators.

Conclusion

Effective logistics and compliance for cone wood require diligence in regulatory adherence, sustainable sourcing, and transparent documentation. By following this guide, businesses can minimize legal risks, support environmental stewardship, and maintain reliable supply chains. Always consult local authorities or legal experts to ensure up-to-date compliance with regional and international regulations.

In conclusion, sourcing cone wood requires careful consideration of sustainability, legality, and environmental impact. As cone wood—typically derived from coniferous trees such as pine, spruce, or fir—is often used in specialty applications like incense, crafts, or small-scale construction, it is essential to ensure that harvesting practices do not contribute to deforestation or habitat degradation. Responsible sourcing involves obtaining wood from certified sustainable forests (e.g., FSC or PEFC certified), supporting local and ethical suppliers, and prioritizing fallen or naturally deceased trees when possible. Additionally, exploring alternative materials or recycled wood can further reduce ecological footprints. Ultimately, a commitment to environmentally sound and socially responsible practices ensures the long-term availability of cone wood while protecting forest ecosystems for future generations.