The global fiber optic cable market is experiencing robust expansion, driven by rising demand for high-speed data transmission, the proliferation of 5G networks, and increasing investments in broadband infrastructure. According to Mordor Intelligence, the fiber optic cable market was valued at USD 10.5 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 8.6% through 2029. This surging demand has amplified the need for reliable conduit systems that protect and support fiber optic cables in diverse environments—from urban underground networks to rugged industrial installations. As deployment scales worldwide, manufacturers specializing in high-performance conduits play a critical role in ensuring network durability, signal integrity, and long-term operational efficiency. The following list highlights the top nine conduit manufacturers shaping the backbone of modern fiber optic infrastructure, selected based on market presence, technological innovation, product breadth, and industry recognition.

Top 9 Conduit For Fiber Optic Cable Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

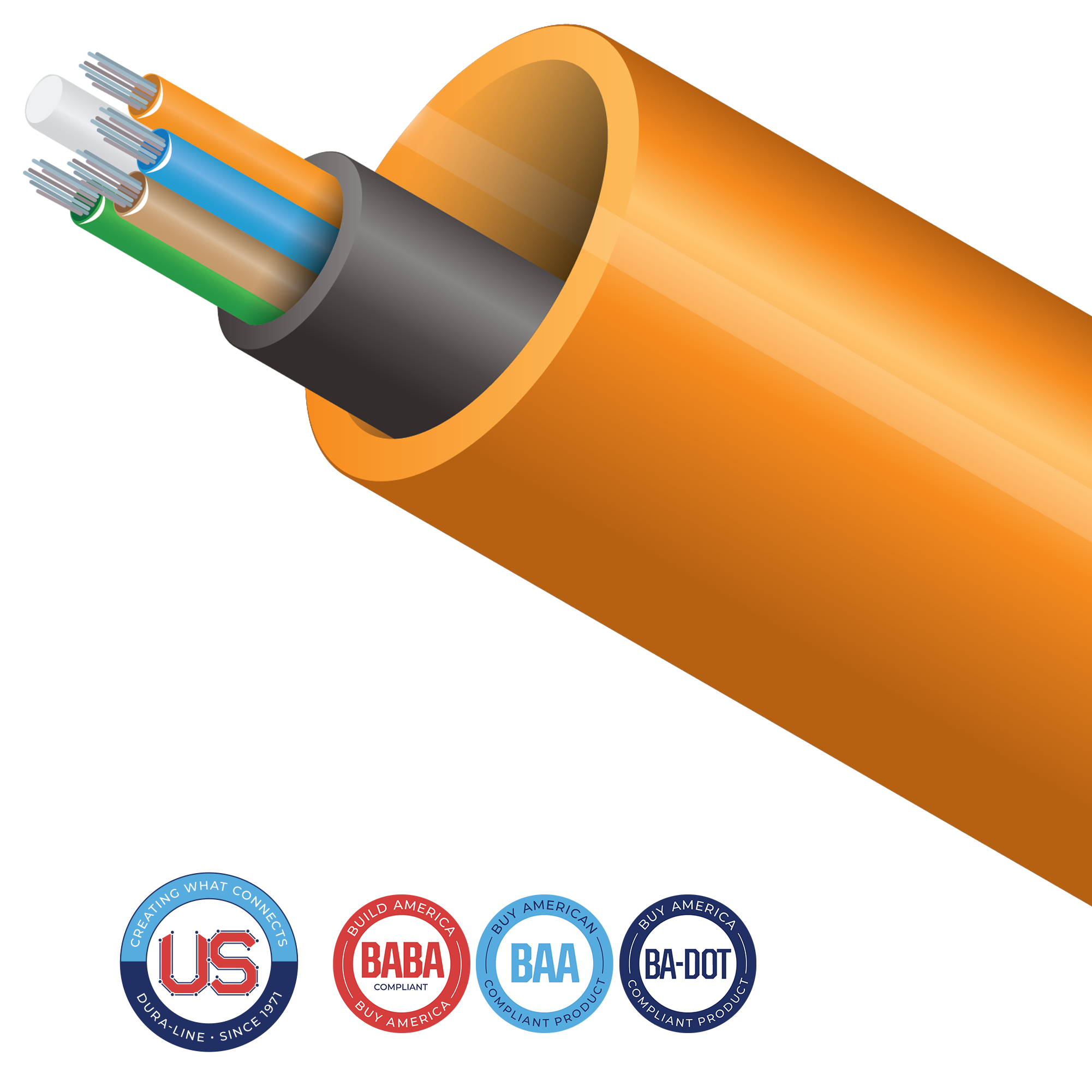

#1 Dura

Domain Est. 1995

Website: duraline.com

Key Highlights: Our lives depend on clear, consistent, reliable communication. Discover how Dura-Line High, a global manufacturer of HDPE conduits creates what connects us….

#2 Fiber Optic Cables

Domain Est. 1991

Website: corning.com

Key Highlights: Duct Cables. Ducts (or conduits) offer a highly protective environment for fiber-optic cables. They are typically buried, and then the cables are air-blown ……

#3 Empty Conduit

Domain Est. 1994

Website: commscope.com

Key Highlights: Our ConQuest conduit products protect your underground cables by offering exceptional resistance to chemicals as well as a lower moisture ……

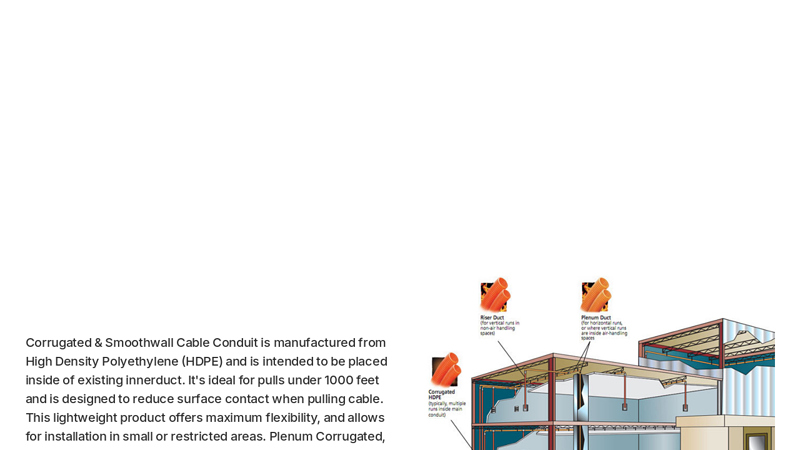

#4 Innerduct Conduit

Domain Est. 2002

Website: store.cablesplususa.com

Key Highlights: 4–11 day delivery 30-day returnsCorrugated & Smoothwall Cable Conduit is manufactured from High Density Polyethylene (HDPE) and is intended to be placed inside of existing innerduc…

#5 Underground & Pipeline Fiber Optic Cables

Domain Est. 2002

Website: ofsoptics.com

Key Highlights: Conduits are used to bury fiber optic cable, which is typically done between 3 and 4 feet down, or 36 and 48 inches underground. A minimum depth of 42 inches is ……

#6 Channell Commercial Corporation

Domain Est. 2003

Website: channell.com

Key Highlights: Optisquid Hardened Connectors · Green Hornet Splitters · Fused Biconic Couplers · Optimus Fiber Hub Splitter Module · Conduit Caps · Fiber Closures….

#7 Cable in Conduit

Domain Est. 2004

Website: bdiky.com

Key Highlights: BDI HDPE conduit is available in a variety of sizes, colors, dimensions and lengths. … Blue Diamond has the capacity for extruding the pipe over power, CATV and ……

#8 AFL

Domain Est. 2008

Website: aflglobal.com

Key Highlights: Engineered for aerial distribution power lines, it can also be used in underground duct applications, delivering versatile performance across your network….

#9 HDPE fiber optic conduit

Domain Est. 2018

Website: phtopindustry.com

Key Highlights: HDPE fiber optic conduit is a pipe used to protect optical fibers and cables, with the following advantages: 1. High strength and pressure resistance….

Expert Sourcing Insights for Conduit For Fiber Optic Cable

H2: Projected Market Trends for Conduit for Fiber Optic Cable in 2026

As global demand for high-speed internet and robust telecommunications infrastructure continues to surge, the market for conduit used in fiber optic cable deployment is poised for significant growth by 2026. Several key trends are expected to shape the industry landscape, driven by technological advancements, government initiatives, and evolving consumer demands.

1. Expansion of Fiber-to-the-Home (FTTH) and 5G Networks

The widespread rollout of FTTH and the continued deployment of 5G infrastructure are primary drivers for increased demand for fiber optic conduit. 5G networks require dense networks of small cells connected via fiber, necessitating extensive underground conduit systems. Countries across North America, Europe, and Asia-Pacific are investing heavily in national broadband plans, which include laying millions of miles of conduit to support last-mile fiber connectivity. By 2026, this trend is expected to accelerate, especially in emerging markets where digital infrastructure is being built from the ground up.

2. Shift Toward Microduct and Pre-Installed Conduit Systems

Innovations such as microduct conduit systems—small, flexible tubes installed within larger conduits—are gaining traction due to their scalability and ease of fiber installation and upgrades. Pre-installed conduit bundles with multiple microducts allow network operators to deploy fiber incrementally without repeated excavation, reducing long-term costs and environmental impact. By 2026, these advanced conduit solutions are projected to capture a larger market share, particularly in urban and smart city developments.

3. Increased Focus on Sustainability and Durability

Environmental regulations and sustainability goals are influencing material choices in conduit manufacturing. High-density polyethylene (HDPE) remains the dominant material due to its durability, flexibility, and recyclability. However, by 2026, an uptick in the use of recycled plastics and bio-based polymers in conduit production is anticipated, driven by corporate ESG (Environmental, Social, and Governance) commitments and regulatory pressure. Additionally, conduits with enhanced resistance to moisture, crushing, and chemical exposure will be in higher demand to ensure long-term reliability in diverse climates.

4. Growth in Smart City and Underground Utility Projects

The global rise of smart cities is catalyzing integrated underground utility corridors that house fiber conduits alongside power, water, and data lines. Municipalities are prioritizing underground cabling to reduce visual clutter and improve disaster resilience. By 2026, public-private partnerships (PPPs) are expected to play a crucial role in funding large-scale conduit infrastructure, particularly in regions like Southeast Asia, the Middle East, and Latin America.

5. Regional Market Divergence and Investment Hotspots

While North America and Europe maintain mature fiber markets with ongoing upgrades, the fastest growth in conduit demand is expected in Asia-Pacific, particularly in India, Indonesia, and Vietnam, where national digitalization programs are in full swing. Africa is also emerging as a high-potential region, with initiatives like the Africa Digital Transformation Strategy spurring cross-border fiber backbone projects that require extensive conduit networks.

6. Supply Chain Optimization and Localized Manufacturing

Ongoing geopolitical tensions and supply chain disruptions have prompted companies to localize production. By 2026, more conduit manufacturers are expected to establish regional production facilities near high-growth markets to reduce lead times and logistics costs. Automation and digital twin technologies will also be increasingly adopted in manufacturing to improve quality control and output efficiency.

In conclusion, the conduit for fiber optic cable market in 2026 will be characterized by technological innovation, sustainability imperatives, and strong alignment with global digital infrastructure goals. As fiber becomes the backbone of modern connectivity, the conduit market will continue to evolve as a critical enabler of next-generation communication networks.

Common Pitfalls Sourcing Conduit for Fiber Optic Cable (Quality, IP)

Sourcing the right conduit for fiber optic cable installations is critical to ensuring long-term network reliability, safety, and performance. However, several common pitfalls can compromise quality and lead to problems down the line—especially when considering Ingress Protection (IP) ratings and material standards. Avoid these key issues:

Choosing Low-Quality or Non-Compliant Materials

Opting for cheaper conduits made from substandard polyethylene (PE) or polyvinyl chloride (PVC) can lead to brittleness, cracking, or deformation over time. Poor-quality materials may not meet industry standards such as IEC, ASTM, or EN, resulting in reduced durability, UV resistance, or mechanical protection. Always verify material certifications and compliance with relevant standards to ensure long-term integrity.

Ignoring Ingress Protection (IP) Ratings

Fiber optic conduits must prevent water, dust, and other contaminants from entering, especially in outdoor or underground installations. Failing to select conduits with appropriate IP ratings (e.g., IP65, IP66, or IP68) can result in moisture ingress, which damages cables and causes signal loss. Ensure that conduit systems—including joints and fittings—maintain the required IP rating throughout the entire run.

Overlooking UV and Environmental Resistance

Conduits exposed to sunlight require UV-stabilized materials. Non-UV-resistant conduits degrade quickly when exposed to direct sunlight, leading to embrittlement and structural failure. Always confirm that outdoor conduits are rated for prolonged UV exposure and suitable for the local climate (e.g., extreme temperatures or chemical exposure).

Mismatching Conduit Diameter and Bend Radius

Using undersized conduits or those with excessively tight bends can damage fiber optic cables during installation or cause micro-bending losses. Ensure the conduit’s inner diameter allows adequate space for cable pulling and respects the minimum bend radius specified by the cable manufacturer. Poorly designed pathways can increase friction and installation difficulty.

Neglecting Mechanical Protection Requirements

In high-traffic or industrial areas, standard conduits may not provide sufficient crush or impact resistance. Failing to assess installation environment risks (e.g., heavy vehicles, rodent activity, or construction zones) can lead to conduit failure. Consider using heavy-wall, armored, or encased conduits where mechanical stress is expected.

Using Incompatible or Poorly Sealed Fittings

Even high-quality conduit is compromised by low-grade or improperly installed couplings, connectors, and end caps. These components must maintain the same IP rating and mechanical strength as the conduit itself. Inadequate sealing leads to water ingress and pest infestation, which can damage fiber cables.

Skipping Proper Testing and Certification Documentation

Always request and verify test reports, certificates of conformity (CoC), and third-party validation (e.g., UL, CE, or TÜV). Absence of documentation may indicate non-compliance with safety, quality, or environmental standards. This is particularly important for projects requiring regulatory approval or insurance coverage.

By addressing these common pitfalls during the sourcing process, you ensure a robust, future-proof fiber optic infrastructure that meets both quality expectations and required IP protection levels.

Logistics & Compliance Guide for Conduit for Fiber Optic Cable

Overview

Conduit for fiber optic cable plays a critical role in protecting and organizing fiber lines during installation and throughout their operational life. Proper logistics and compliance management ensure safe, efficient deployment and adherence to regulatory standards. This guide outlines key considerations for handling, transporting, storing, and complying with applicable regulations for conduit systems used in fiber optic networks.

Regulatory & Industry Standards

Conduit used for fiber optic applications must meet specific national and international standards to ensure durability, safety, and compatibility. Key standards include:

- NEC (National Electrical Code) – Article 770: Governs the installation of fiber optic cables and associated raceways, including conduit use, fill capacity, and separation from power conductors.

- UL 651 / UL 1 (Standard for Safety for Rigid Metal Conduit): Applies to metallic conduits; ensures mechanical strength and fire resistance.

- UL 651A / UL 1685 (Nonmetallic Conduit Standards): Covers PVC, HDPE, and other nonmetallic conduits; includes flame spread and smoke emission testing.

- ANSI/NECA 700 (Standard for Installing Commercial Building Fiber Optic Cabling): Provides best practices for conduit use and cable pulling.

- OSHA Regulations: Ensure worker safety during handling and installation, particularly for trenching and confined spaces.

- RoHS & REACH Compliance: Required for conduit materials exported to or used in the EU; restricts hazardous substances.

Verify that all conduit products carry appropriate certifications (e.g., UL Listed, CSA, CE Mark) based on project location and application.

Material Handling & Transportation

Conduit Types and Handling Requirements

Common conduit types include:

- PVC (Polyvinyl Chloride): Lightweight but sensitive to UV and temperature extremes. Store indoors or under cover.

- HDPE (High-Density Polyethylene): Flexible and UV-resistant; ideal for direct burial. Avoid kinking during transport.

- EMT (Electrical Metallic Tubing): Rigid and crush-resistant. Protect ends to prevent deformation.

- Rigid Metal Conduit (RMC/IMC): Heavy; requires secure bracing during transit to prevent damage.

Loading & Securing

- Use cradles or racks to prevent rolling or crushing of coiled conduit (e.g., HDPE on reels).

- Secure straight lengths with straps and edge protectors to avoid shifting.

- Avoid dropping or dragging conduit, which can cause cracks, dents, or internal deformation.

Storage Guidelines

Environmental Controls

- Store conduit indoors when possible, away from direct sunlight and extreme temperatures.

- Keep PVC conduit below 140°F (60°C) to prevent softening or warping.

- Elevate materials off the ground using pallets to prevent moisture absorption and contamination.

Organization & Inventory

- Label conduit by type, diameter, length, and certification.

- Group by project or phase to streamline distribution.

- Rotate stock using FIFO (First In, First Out) principles to prevent aging.

Installation Compliance

Fill Capacity & Bend Radius

- Adhere to NEC fill capacity limits: maximum 40% fill for multiple cables in a single conduit run.

- Maintain minimum bend radius (typically 10–12 times the conduit diameter) to avoid stress on fiber cables during pulling.

Grounding & Bonding (Metallic Conduit)

- Bond metallic conduit systems to ground in accordance with NEC Article 250.

- Use listed connectors and grounding bushings to ensure continuity.

Sealing & Environmental Protection

- Seal conduit ends in outdoor or underground applications to prevent water, dust, and pest intrusion.

- Use approved firestop systems where conduit penetrates fire-rated walls or floors (per NFPA 101 and IBC).

Documentation & Traceability

Required Documentation

- Product cut sheets with specifications and compliance certifications.

- Material Safety Data Sheets (MSDS/SDS), especially for PVC or treated conduits.

- Certificates of Conformance (CoC) from manufacturers.

- As-built drawings showing conduit routing, depth, and connections.

Record Retention

Maintain logs of delivery dates, inspection results, and installation records for audits and warranty claims. Retain for minimum of 5–7 years, or per local regulatory requirements.

Sustainability & Disposal

Recycling & End-of-Life

- HDPE and PVC conduits are recyclable; coordinate with certified recyclers.

- Follow local regulations for disposal of non-recyclable or contaminated materials.

- Avoid open burning, which releases toxic fumes (especially from PVC).

Sustainable Sourcing

- Prioritize conduit made from recycled content where performance allows.

- Choose manufacturers with environmental management systems (e.g., ISO 14001).

Conclusion

Effective logistics and compliance management for fiber optic conduit ensures long-term network reliability, regulatory adherence, and worker safety. By following industry standards, proper handling practices, and maintaining accurate documentation, project stakeholders can mitigate risks and support efficient, sustainable deployments.

Conclusion on Sourcing Conduit for Fiber Optic Cable:

Sourcing the appropriate conduit for fiber optic cable installation is a critical step in ensuring the long-term reliability, protection, and scalability of the network infrastructure. Based on evaluation of material options, installation environment, regulatory requirements, and cost considerations, high-density polyethylene (HDPE) conduit emerges as the preferred choice for most applications due to its durability, flexibility, resistance to moisture and corrosion, and ability to support future cable upgrades through pull-string or blown-fiber techniques.

When sourcing conduit, it is essential to consider factors such as conduit diameter (with adequate fill ratio), length of runs, bend radius requirements, and compatibility with existing infrastructure. Working with reputable suppliers who provide compliant, high-quality materials and proper certifications (e.g., NEC, Telcordia, or local standards) ensures adherence to safety and performance standards.

Additionally, engaging with experienced contractors during the planning phase can help avoid installation issues and reduce lifecycle costs. Ultimately, investing in the right conduit system not only protects the fiber optic cables from physical and environmental damage but also supports network scalability and minimizes maintenance and downtime over time. A strategic, forward-looking approach to conduit sourcing lays a strong foundation for reliable, future-ready fiber optic networks.