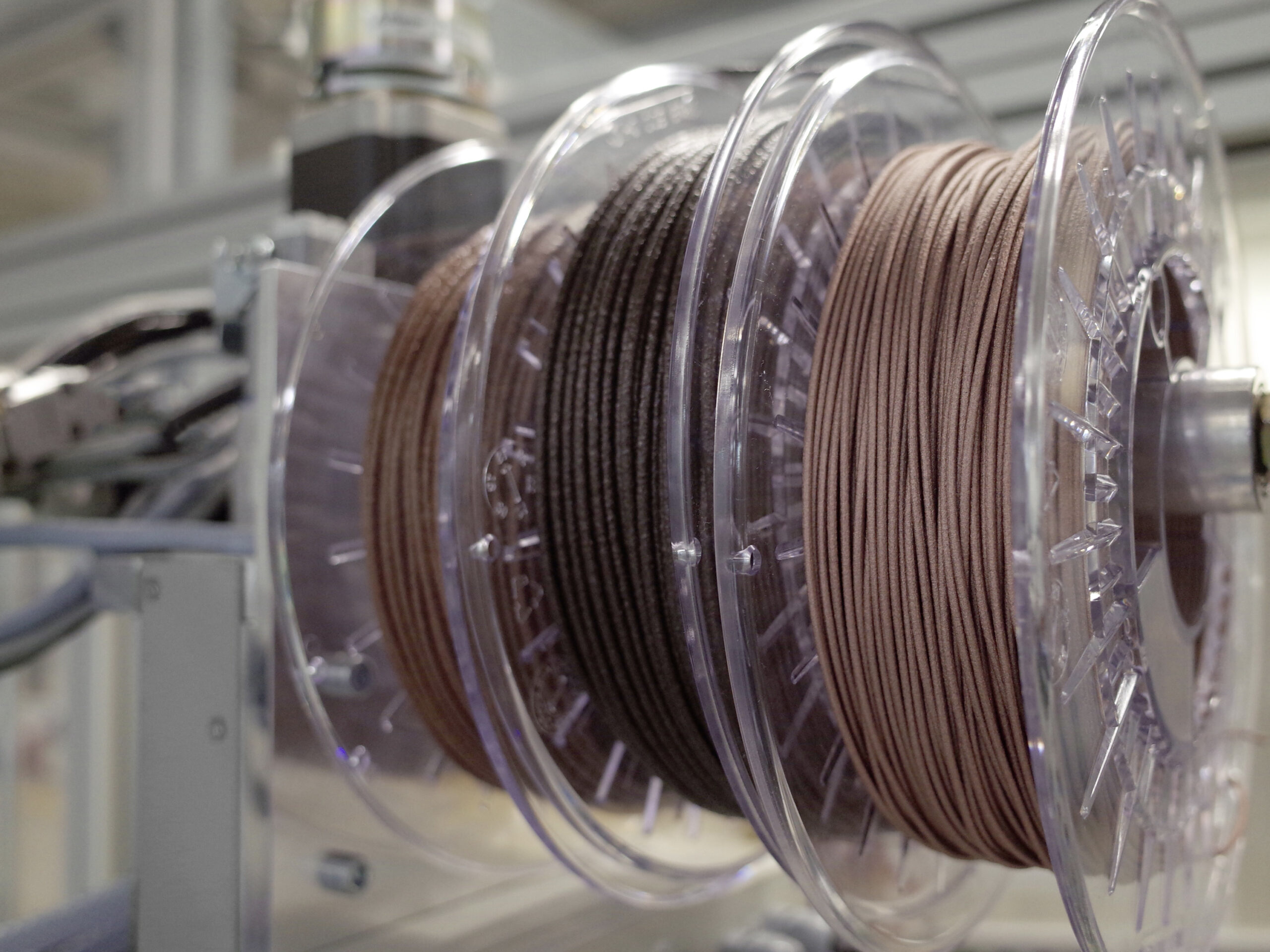

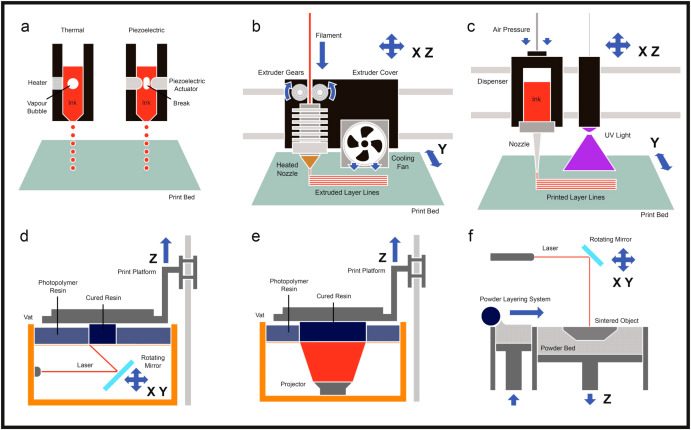

The global conductive 3D printing filament market is experiencing robust growth, driven by increasing demand for functional and smart components across industries such as electronics, automotive, aerospace, and healthcare. According to a report by Mordor Intelligence, the global 3D printing materials market—which includes conductive filaments—is projected to grow at a CAGR of over 18.5% from 2023 to 2028. Conductive filaments, typically enhanced with additives like carbon nanotubes, graphene, or metal particles, are pivotal in enabling embedded circuits, EMI shielding, and static dissipation in printed parts. Grand View Research further supports this trajectory, noting that the expanding adoption of 3D printing in prototyping and low-volume production is accelerating innovation in specialized materials, with conductive filaments representing one of the fastest-growing segments. As industrial and commercial applications push beyond form and into function, the need for reliable, high-performance conductive filaments has intensified—elevating the strategic importance of manufacturers at the forefront of material science and print compatibility.

Top 8 Conductive 3D Filament Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 NinjaTek Advanced 3D Printing Filaments

Domain Est. 1998

Website: ninjatek.com

Key Highlights: NinjaTek leverages 50 years of extrusion experience to provide industry-leading rigid and flexible 3D printer filaments. Shop our TPU filament….

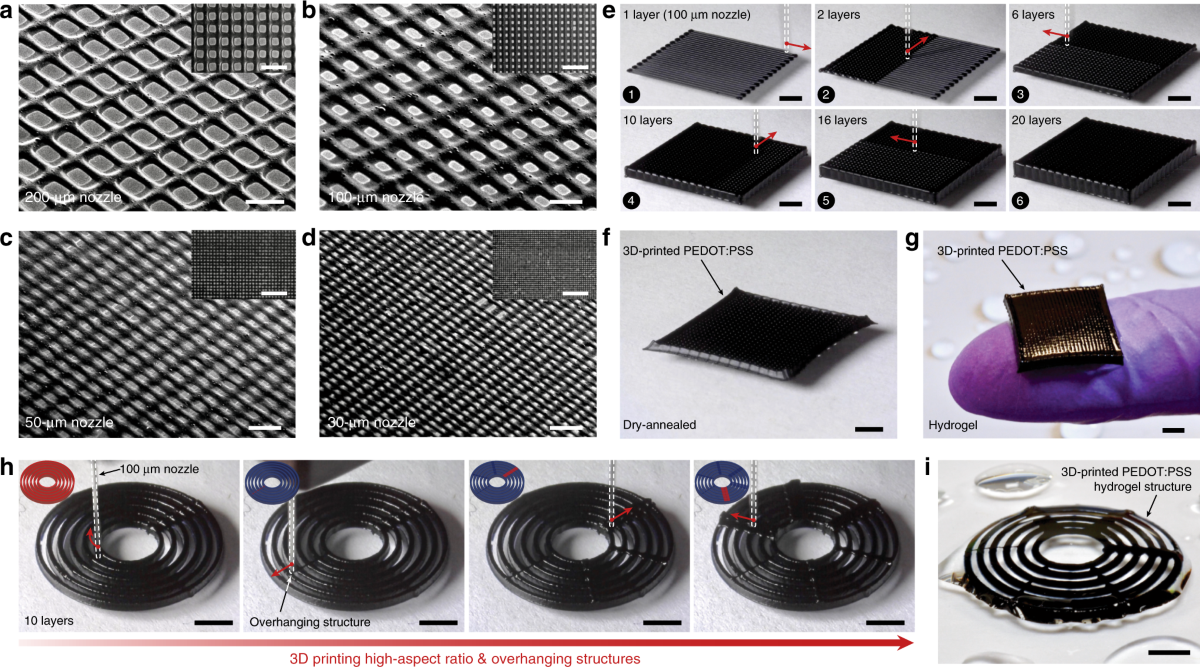

#2 3D Printed Conductive Materials

Domain Est. 2010

Website: 3dalt.com

Key Highlights: Conductive 3D printing materials are revolutionizing additive manufacturing by enabling the direct integration of electrical pathways into printed objects….

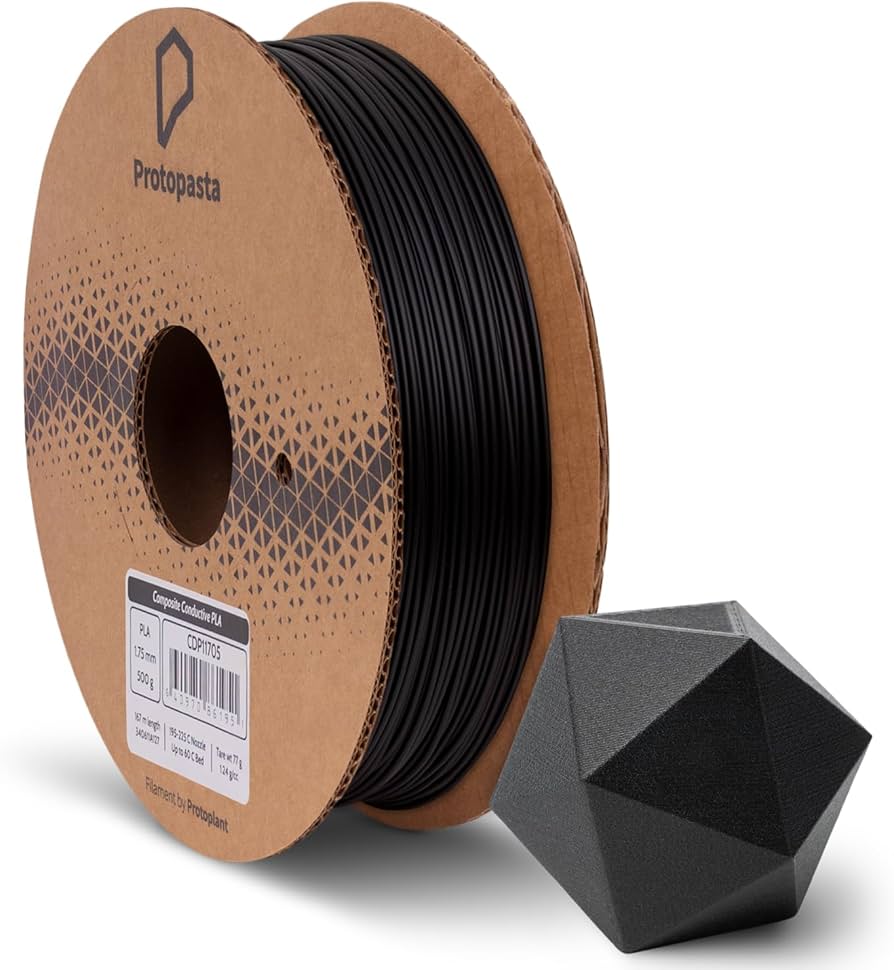

#3 Electrically Conductive Composite PLA

Domain Est. 2013

Website: proto-pasta.com

Key Highlights: In stock Rating 4.8 (45) Protopasta Conductive PLA is the perfect material for you! Use as a resistor. Typical resistance for 10 cm of 1.75 mm filament is 2.0-3.5 kohm….

#4 Conductive Filaflex TPU Filament Electrically Conductive

Domain Est. 2013

Website: recreus.com

Key Highlights: Rating 5.0 (3) · 4–12 day deliveryConductive Filaflex is the electrically conductive TPU filament, ideal for the manufacture of electrically conductive parts or components….

#5 Fiberthree Super Conductive Filament, 1.75mm

Domain Est. 2013

Website: 3dchimera.com

Key Highlights: In stock $25 deliveryEngineered in Germany for excellence, the Fiberthree Super Conductive Filament is a game-changer for FFF/FDM 3D printing. This best-in-class material is ……

#6 PLA Electrically Conductive

Domain Est. 2015

#7 Conductive PLA Filament for 3D Printing Prototypes

Domain Est. 2015

Website: vexmatech.com

Key Highlights: Conductive PLA is a specialized filament used in FDM 3D printing that combines the convenience of PLA with electrical conductivity properties….

#8

Domain Est. 2016

Website: tcpoly.com

Key Highlights: Our 3D printing capabilities, including the world’s first thermally conductive filaments and a farm of high speed 3D printers, allow our customers to validate ……

Expert Sourcing Insights for Conductive 3D Filament

H2: 2026 Market Trends for Conductive 3D Filament

The global conductive 3D filament market is poised for significant transformation by 2026, driven by converging technological advancements, expanding industrial applications, and evolving material science. Key trends shaping the market include:

1. Surge in Electronics and Prototyping Integration:

By 2026, conductive filaments will see heightened adoption in rapid electronics prototyping, particularly in printed circuit boards (PCBs), embedded sensors, and custom connectors. The demand for agile, low-volume production in R&D and startups will fuel growth, with filaments featuring improved conductivity (approaching 1–10 S/cm) enabling functional prototypes without traditional electronics assembly.

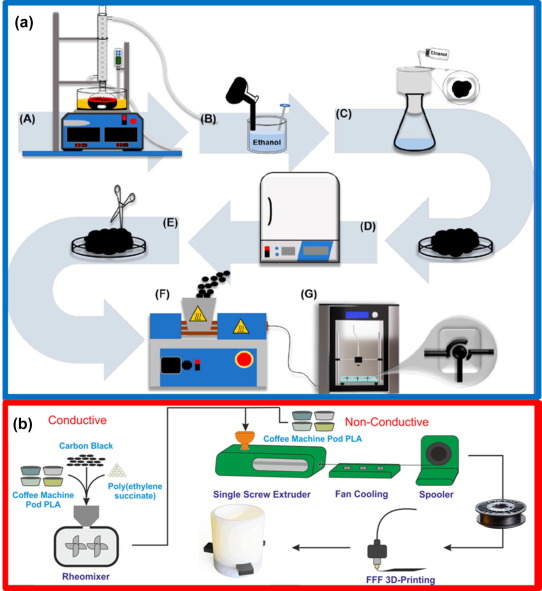

2. Advancement in Material Composition and Performance:

Innovations will shift focus from basic carbon black-infused PLA to hybrid formulations incorporating graphene, carbon nanotubes (CNTs), and metal-coated polymers. These next-gen composites will offer superior conductivity, mechanical strength, and thermal stability, broadening applicability in aerospace, automotive, and IoT devices. Multi-material printing compatibility will also improve, allowing seamless integration with insulating filaments.

3. Expansion into Smart Manufacturing and Industry 4.0:

Conductive filaments will play a pivotal role in developing smart components with built-in sensing and data transmission capabilities. Applications such as EMI shielding enclosures, wearable health monitors, and condition-sensing industrial tools will gain traction, supported by digital twin and IoT integration strategies across manufacturing sectors.

4. Growth in Healthcare and Wearable Technology:

The medical and wearable tech sectors will increasingly adopt conductive 3D printing for custom biosensors, ECG electrodes, and therapeutic devices. Biocompatible conductive filaments will emerge as a niche but high-growth segment, driven by personalized medicine and remote patient monitoring trends.

5. Sustainability and Recycling Challenges:

Environmental concerns will prompt R&D into recyclable conductive composites and bio-based conductive polymers. However, recycling complexities due to filler dispersion will remain a barrier, pushing the industry toward closed-loop systems and standardized material certifications by 2026.

6. Regional Market Diversification and Competitive Landscape:

North America and Europe will maintain leadership in R&D and high-end applications, while Asia-Pacific (especially China and South Korea) will dominate volume production and consumer electronics integration. Increased competition will drive price reductions and standardization, making conductive filaments more accessible to SMEs and educational institutions.

In summary, by 2026, the conductive 3D filament market will evolve from a niche prototyping tool to a critical enabler of functional, smart, and integrated manufacturing solutions—anchored by improved materials, broader industrial adoption, and a push toward sustainability.

Common Pitfalls When Sourcing Conductive 3D Filament (Quality & IP)

Sourcing conductive 3D filament introduces unique challenges beyond standard filaments, particularly concerning material quality and intellectual property (IP) risks. Overlooking these aspects can lead to failed prints, inconsistent performance, legal complications, and project delays.

Inconsistent Material Quality and Performance

One of the most frequent issues is variability in conductivity and mechanical properties across batches or suppliers. Conductive filaments typically blend base polymers (like PLA or ABS) with conductive additives such as carbon black, graphene, or carbon nanotubes. Poor dispersion of these additives results in inconsistent electrical resistance, making reliable circuit printing difficult. Additionally, filament diameter tolerances may exceed standard specifications, leading to extrusion problems and print failures. Some suppliers may overstate conductivity claims without providing verifiable test data, so relying on datasheets alone can be misleading.

Lack of Standardized Testing and Documentation

Many conductive filament suppliers fail to provide comprehensive, standardized testing reports. Without independent verification of resistivity, tensile strength, and thermal stability, users risk purchasing subpar materials. Absence of batch-specific certificates of analysis (CoA) further complicates quality control, especially in regulated or industrial applications. This lack of transparency can undermine reproducibility and scalability in production environments.

Intellectual Property and Design Infringement Risks

Using conductive filament for functional electronic prototypes or end-use parts may inadvertently infringe on existing patents. Several companies hold IP on conductive 3D printing materials, methods, and applications—particularly in embedded electronics and printed circuits. Sourcing filament from unknown or unlicensed manufacturers increases exposure to IP litigation, especially if the material formulation or its application violates patented processes. Additionally, using open-source designs that incorporate conductive elements may still pose legal risks if those designs build upon protected innovations.

Supply Chain and Vendor Reliability

Smaller or newer filament manufacturers may lack the infrastructure for consistent large-scale production. This can lead to supply disruptions or reformulations without notice, affecting long-term project viability. Moreover, some vendors rebrand filament from third-party producers without disclosing the original source, obscuring traceability and accountability for quality or IP issues.

Mitigation Strategies

To avoid these pitfalls, conduct due diligence by requesting sample testing, reviewing independent material certifications, and verifying supplier transparency. Consult legal counsel when developing commercial products to assess IP landscape risks. Prefer vendors who openly share material composition (within reasonable confidentiality), provide batch traceability, and align with industry standards such as ASTM or ISO for additive manufacturing materials.

Logistics & Compliance Guide for Conductive 3D Filament

Overview

Conductive 3D filament, typically made from materials such as carbon-infused PLA, ABS, or specialized polymers with embedded conductive fillers (e.g., graphene, carbon nanotubes, or metal particles), introduces unique handling, shipping, and regulatory considerations. This guide outlines essential logistics and compliance requirements for the safe and legal transport, storage, and use of conductive 3D filament.

Classification & Hazard Assessment

Conductive 3D filaments may not always be classified as hazardous under standard shipping regulations (e.g., IATA, IMDG, ADR) if they are in solid form and non-reactive. However, due to the presence of conductive additives, certain formulations may fall under specific hazard classes:

– UN3077 (Environmentally hazardous substance, solid, n.o.s.) – May apply if carbon-based nanoparticles are present and meet criteria for environmental toxicity.

– Combustible Dust Risk – Fine particles generated during printing or handling may pose a dust explosion hazard under specific conditions (ATEX/IECEx).

– Electrostatic Discharge (ESD) Risk – Spools may accumulate static charge, requiring grounding during handling in sensitive environments.

Regulatory Compliance

Ensure compliance with the following regulatory frameworks:

– REACH (EU) – Verify that conductive additives (e.g., carbon black, graphene) are registered and do not contain restricted substances above thresholds.

– RoHS (EU) – Confirm absence of restricted heavy metals (e.g., lead, cadmium) in filament composition.

– TSCA (USA) – Ensure chemical substances are listed or exempt under the Toxic Substances Control Act.

– GHS/CLP Labeling – Use appropriate hazard pictograms and safety phrases on packaging if applicable. Even non-hazardous filaments should include handling instructions.

Packaging & Labeling

- Anti-Static Packaging: Use static-dissipative or shielded bags to prevent electrostatic buildup.

- Moisture Protection: Seal filament in vacuum or dry bags with desiccant, as moisture can degrade print quality and alter conductivity.

- Labeling Requirements:

- Product name and batch number

- Net weight and dimensions

- Conductive properties (e.g., resistivity in ohms/cm)

- Storage conditions (e.g., “Store in dry, cool place”)

- Safety warnings (e.g., “Avoid inhalation of fumes during printing”)

- Regulatory compliance marks (e.g., CE, RoHS)

Storage Conditions

- Temperature: Store between 15–25°C (59–77°F); avoid extreme heat or cold.

- Humidity: Maintain relative humidity below 50%; use dry boxes or sealed containers with desiccants.

- Static Control: Store away from high-static areas; use grounded shelving in ESD-sensitive environments.

- Segregation: Keep separate from flammable materials and reactive chemicals.

Transportation Guidelines

- Domestic (USA): Typically non-hazardous if solid and not classified as dangerous goods; standard parcel shipping acceptable.

- International Air (IATA): Conduct a formal hazard classification. Most conductive filaments ship as “Not Restricted” under Special Provision A152 if they are solids and not classified as hazardous. Documentation should include a safety data sheet (SDS).

- Maritime (IMDG): Similar assessment as air; ensure proper classification and documentation.

- EU Road (ADR): Generally exempt from hazardous goods regulations for consumer quantities unless nanoparticle concentration triggers classification.

Safety Data Sheet (SDS) Requirements

An up-to-date SDS per GHS standards must be available and provided to customers. Key sections:

– Section 3 (Composition): List conductive additives and concentrations.

– Section 7 (Handling & Storage): Include ESD and dust control measures.

– Section 8 (Exposure Controls): Recommend ventilation and PPE (e.g., respirator for fine dust).

– Section 11 (Toxicological Information): Detail potential health effects of nanoparticles if applicable.

End-of-Life & Environmental Considerations

- Recycling: Most conductive filaments are not recyclable through standard municipal streams due to additives. Offer take-back programs or partner with specialized recyclers.

- Disposal: Dispose as non-hazardous solid waste unless local regulations classify nanoparticle-containing waste as hazardous.

- Waste Electrical Equipment (WEEE): Products made from conductive filament may fall under WEEE when discarded; ensure proper labeling and take-back compliance.

Import/Export Documentation

- HS Code: Typically 3916.20 (Plastic rods, bars, and profiles) or 3917.29 (Other plastic line, cable, or profile shapes). Confirm based on composition.

- Certificates: Provide certificates of compliance (RoHS, REACH) upon request.

- Customs Declarations: Accurately describe product as “Conductive 3D printing filament, non-hazardous, for additive manufacturing.”

Best Practices for Distributors & Users

- Train staff on ESD-safe handling procedures.

- Use filament dryers before printing to maintain performance.

- Monitor regulatory updates, especially concerning nanomaterials.

- Maintain traceability via batch records for compliance audits.

By adhering to this guide, businesses can ensure the safe, compliant, and efficient logistics of conductive 3D filament across global supply chains.

Conclusion for Sourcing Conductive 3D Filament

Sourcing conductive 3D filament requires a careful balance between electrical performance, mechanical properties, printability, and cost. While several manufacturers offer conductive filaments—typically filled with carbon black, graphene, or carbon nanotubes—performance can vary significantly between brands and formulations. It is crucial to define the specific application requirements, such as resistivity range, durability, and flexibility, to identify the most suitable material.

Through evaluation, filaments like Proto-pasta, Essentium, and自制 (in-house or specialty suppliers) have demonstrated reliable conductivity and print consistency, though often at a higher cost than standard filaments. Additionally, post-processing techniques—such as sanding or applying conductive coatings—can enhance performance but add complexity.

In conclusion, successful sourcing involves:

1. Prioritizing application-specific electrical and mechanical needs,

2. Testing samples from multiple suppliers to assess print quality and conductivity,

3. Considering total cost of use, including printer maintenance and failure rates, and

4. Staying informed on emerging materials, such as graphene-enhanced composites, for improved performance.

Ultimately, while conductive 3D filaments are now accessible and increasingly viable for prototyping and functional parts, a strategic and iterative sourcing approach is essential to achieve optimal results.