The global concrete floor scrubber machine market is experiencing steady growth, driven by rising demand for efficient cleaning solutions in commercial, industrial, and institutional facilities. According to Grand View Research, the global floor cleaning equipment market was valued at USD 7.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is largely attributed to increased hygiene standards, urbanization, and the expansion of large retail spaces, warehouses, and healthcare facilities—all of which require high-performance concrete maintenance equipment. Additionally, the shift toward eco-friendly, battery-operated scrubber machines aligns with global sustainability trends, further fueling market adoption. As demand surges, a number of manufacturers have emerged as industry leaders, combining innovation, durability, and advanced cleaning technology. Based on market presence, product range, technological integration, and customer reviews, we’ve identified the top 10 concrete scrubber machine manufacturers shaping the future of floor maintenance.

Top 10 Concrete Scrubber Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Concrete grinder, Floor Grinder,floor scrubber,ride on floor scrubber …

Domain Est. 2016

Website: ronlonfloorsystem.com

Key Highlights: A professional manufacturer of floor grinders, floor scrubbers, and industrial vacuum cleaners in China! It is an innovative enterprise integrating R&D, ……

#2 Sioux Corporation

Domain Est. 1997 | Founded: 1939

Website: sioux.com

Key Highlights: Since 1939, Sioux Corporation has provided durable industrial cleaning equipment, water heaters, & steam generators, all built in the USA….

#3 EDCO Inc: High

Domain Est. 1997

Website: edcoinc.com

Key Highlights: We are a manufacturer of world-class surface preparation, floor grinding, removal, vacuum systems and professional sawing equipment….

#4 Floor Cleaner Machines

Domain Est. 1998

Website: minutemanintl.com

Key Highlights: Minuteman International offers industrial and commercial floor cleaning machines for retail, manufacturing & distribution, office buildings, and much more….

#5 BW Manufacturing

Domain Est. 2000

Website: bwmanufacturing.com

Key Highlights: BW Manufacturing manufacturers concrete shot blasters, scarifiers and diamond grinders with an industry leading interchangeable attachment design….

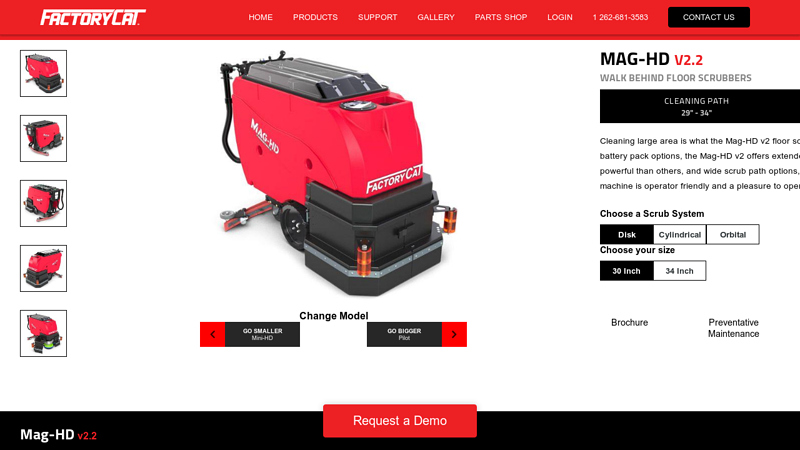

#6 Powerful Concrete Floor Scrubber for Tough Jobs

Domain Est. 1997

Website: factorycat.com

Key Highlights: The Mag-HD v2 offers extended scrub times and covers a lot of square footage per hour. Equipped with scrub motors more powerful than others, and wide scrub ……

#7 Concrete Cleaning Machines, Cement Floor Cleaning Equipment

Domain Est. 2002

#8 Floor Scrubber Machines & Concrete Floor Cleaner Collection

Domain Est. 2009

Website: xtremepolishingsystems.com

Key Highlights: 3-day delivery 15-day returns…

#9 Amano Pioneer Eclipse

Domain Est. 2011

Website: pioneereclipse.com

Key Highlights: A leader and innovator in floor care systems, with an emphasis on propane powered equipment, electric and battery powered equipment, innovative floor coatings….

#10 Grinding and polishing machines

Domain Est. 2013 | Founded: 2001

Website: lavina-eu.com

Key Highlights: Lavina Superabrasive has been producing grinding (planetary grinders) and polishing machines since 2001. Lavina ELITE planetary grinders are a new line of ……

Expert Sourcing Insights for Concrete Scrubber Machine

2026 Market Trends for Concrete Scrubber Machine

Growing Demand in Construction and Renovation Sectors

The global market for concrete scrubber machines is poised for significant growth by 2026, driven primarily by rising construction and renovation activities across both developed and emerging economies. With urbanization accelerating in regions such as Asia-Pacific, Latin America, and parts of Africa, there is an increased need for efficient surface preparation and cleaning in large-scale infrastructure projects. Concrete scrubber machines—known for their ability to clean, grind, and prepare concrete surfaces without excessive water usage—are becoming essential tools on construction sites, particularly where dust control and speed are critical.

Technological Advancements and Automation

By 2026, technological innovation is expected to redefine the concrete scrubber machine market. Manufacturers are increasingly integrating automation, smart sensors, and IoT (Internet of Things) capabilities into their machines. These advancements allow for real-time monitoring of machine performance, predictive maintenance alerts, and optimized cleaning patterns. Automated scrubbers with programmable navigation and enhanced battery life are gaining traction, especially in industrial and commercial applications such as warehouses, manufacturing plants, and airports. This shift toward smart machinery is expected to improve operational efficiency and reduce labor costs.

Emphasis on Eco-Friendly and Sustainable Equipment

Environmental regulations and sustainability initiatives are shaping product development in the concrete scrubber machine industry. By 2026, demand for eco-friendly machines with low emissions and energy-efficient motors is expected to surge. Electric and battery-powered scrubbers are replacing diesel and gasoline models, particularly in enclosed environments where air quality is a concern. Additionally, water recycling systems and dust collection technologies are being incorporated to minimize environmental impact and comply with green building standards such as LEED and BREEAM.

Expansion in Industrial and Commercial Applications

Beyond traditional construction, concrete scrubber machines are finding expanded use in industrial maintenance, food processing, logistics, and retail sectors. Facilities require regular cleaning and surface maintenance to ensure safety, hygiene, and aesthetic standards. The versatility of modern scrubber machines—capable of handling coatings, adhesives, paint, and heavy grime—makes them ideal for large flooring areas. The growth of e-commerce, for example, is boosting warehouse construction and maintenance demand, further fueling adoption of high-performance scrubbing equipment.

Regional Market Dynamics

Asia-Pacific is expected to emerge as the fastest-growing market for concrete scrubber machines by 2026, led by countries such as China, India, and Indonesia. Government investments in infrastructure, smart cities, and industrial parks are creating substantial opportunities. North America and Europe will maintain strong market positions, driven by aging infrastructure rehabilitation projects and strict occupational health and safety regulations. In these regions, demand is shifting toward high-capacity, operator-friendly machines with advanced safety features.

Competitive Landscape and Market Consolidation

The concrete scrubber machine market is becoming increasingly competitive, with key players focusing on product differentiation, strategic partnerships, and geographic expansion. Companies such as Tennant, Daimer, Karcher, and Nilfisk are investing in R&D to launch compact, multifunctional models tailored to specific industry needs. Mergers and acquisitions are likely to increase as firms aim to broaden their technology portfolios and distribution networks in anticipation of rising global demand.

Conclusion

By 2026, the concrete scrubber machine market will be shaped by technological innovation, environmental considerations, and expanding applications across industries. With increasing emphasis on efficiency, sustainability, and automation, manufacturers and end-users alike are adapting to a new era of surface maintenance solutions. The convergence of these trends positions the market for robust growth, particularly in rapidly urbanizing regions and industrialized economies seeking smarter, cleaner, and more cost-effective cleaning technologies.

Common Pitfalls When Sourcing a Concrete Scrubber Machine (Quality & Intellectual Property)

Sourcing a concrete scrubber machine—especially from international or unfamiliar suppliers—can present significant challenges. Overlooking key aspects related to quality and intellectual property (IP) can lead to costly delays, performance issues, and legal risks. Below are common pitfalls to avoid:

Poor Build Quality and Material Selection

Many low-cost suppliers use substandard materials such as thin-gauge steel, inferior motors, or non-durable brushes and seals. This leads to premature wear, frequent breakdowns, and higher maintenance costs. Always verify material specifications and request third-party quality certifications (e.g., ISO 9001).

Inadequate Performance Testing and Validation

Some suppliers provide performance claims without real-world testing data. Machines may fail to meet promised cleaning efficiency, water usage, or throughput rates under actual site conditions. Request documented test reports or arrange for on-site demonstrations before finalizing a purchase.

Lack of Compliance with Safety and Environmental Standards

Concrete scrubbers must comply with regional safety and environmental regulations (e.g., OSHA, CE, EPA). Sourcing non-compliant equipment risks fines, project delays, or operational shutdowns. Confirm that the machine meets all applicable standards for your region.

Absence of Intellectual Property Verification

When sourcing from manufacturers—particularly in regions with weak IP enforcement—there’s a risk of purchasing machines that infringe on patented designs or technologies. This can lead to legal liability, shipment seizures, or forced equipment removal. Conduct due diligence by reviewing patent databases and requiring suppliers to certify IP ownership or licensing.

Copycat or Counterfeit Equipment

Some suppliers market machines that are close replicas of well-known branded models. These “knock-offs” often mimic appearance but lack performance, reliability, and safety features. Be wary of suspiciously low prices and insist on technical documentation and original design validation.

Limited After-Sales Support and Spare Parts Availability

Even high-quality machines can fail without access to spare parts and technical support. Suppliers may disappear or lack service networks, especially in remote regions. Confirm service capabilities, parts inventory, and warranty terms before procurement.

Incomplete or Ambiguous Technical Documentation

Poorly translated or missing manuals, schematics, and maintenance guides hinder safe and efficient operation. Ensure all documentation is comprehensive, accurate, and available in your required language.

Failure to Conduct Factory Audits or Site Visits

Relying solely on brochures and online communication increases the risk of misrepresentation. Whenever possible, conduct a factory audit or third-party inspection to verify manufacturing processes, quality control, and IP practices.

Avoiding these pitfalls requires thorough due diligence, clear contractual agreements, and proactive verification of both quality and intellectual property rights.

Logistics & Compliance Guide for Concrete Scrubber Machine

This guide outlines key considerations for the safe, efficient, and compliant transportation, handling, and operation of Concrete Scrubber Machines.

Regulatory Compliance

Ensure the Concrete Scrubber Machine meets all relevant international, national, and local regulations. This includes adherence to environmental protection standards (e.g., EPA, EU Emissions Directives), electrical safety certifications (e.g., CE, UL, CSA), and noise emission limits. Operators must comply with local wastewater discharge regulations when cleaning the machine, as runoff may contain concrete residue and chemicals. Always dispose of slurry and wash water in accordance with environmental guidelines, typically via approved settling tanks or waste management services.

Transportation Requirements

Transport the Concrete Scrubber Machine using a flatbed truck or trailer rated for its weight and dimensions. Secure the unit with heavy-duty straps or chains to prevent shifting during transit. Ensure the machine is turned off, all fluids are drained or properly contained, and moving parts (e.g., brushes, augers) are locked or blocked. Provide proper documentation including a bill of lading, equipment specifications, and any required hazardous materials declarations (if applicable, e.g., for hydraulic fluids).

Handling and Site Preparation

Prior to delivery, ensure the job site is accessible and prepared with a level, stable surface capable of supporting the machine’s operational weight. Clear the area of debris, overhead obstructions, and underground utilities. Use lifting equipment with appropriate slings or forklift pockets (if equipped) to offload the machine—never drag or roll it unexpectedly. Follow manufacturer instructions for setup, including leveling, grounding, and connection to power and water sources.

Operational Safety and Training

Only trained and authorized personnel should operate the Concrete Scrubber Machine. Provide comprehensive training on startup, shutdown, emergency stops, and routine maintenance. Operators must wear appropriate personal protective equipment (PPE), including eye protection, gloves, hearing protection, and steel-toed boots. Establish safety zones around the machine during operation to prevent unauthorized access.

Maintenance and Documentation

Perform routine maintenance as specified in the manufacturer’s manual, including inspection of brushes, pumps, filters, and hydraulic systems. Keep detailed logs of maintenance, repairs, and safety inspections. Retain all compliance documents, operator certifications, and service records for audit purposes. Regularly verify that safety guards, emergency stops, and warning labels are in place and legible.

Environmental and Waste Management

Collect all wash water and slurry using containment systems such as berms or portable settling tanks. Never allow contaminated water to enter storm drains or natural waterways. Recycle reusable water when possible and dispose of solid waste at licensed facilities. Monitor local environmental regulations for changes in permissible discharge levels or disposal methods.

Conclusion for Sourcing a Concrete Scrubber Machine:

After a thorough evaluation of various suppliers, equipment specifications, cost considerations, and operational requirements, sourcing a concrete scrubber machine is a strategic investment that enhances surface preparation efficiency, improves concrete finish quality, and supports compliance with environmental and safety standards. The selected machine balances performance, durability, and cost-effectiveness, aligning with project demands and long-term maintenance goals. By partnering with a reputable supplier offering reliable technical support and after-sales service, the organization can ensure optimal equipment uptime and a strong return on investment. Moving forward, proper operator training and routine maintenance will be essential to maximize the machine’s lifespan and performance, ultimately contributing to higher productivity and superior project outcomes.