The global concrete gutter market is experiencing steady growth, driven by rising infrastructure development and increased demand for durable drainage solutions in residential, commercial, and industrial construction. According to Grand View Research, the global rainwater drainage systems market was valued at USD 5.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030, with concrete-based systems maintaining a strong foothold due to their longevity and structural resilience. Similarly, Mordor Intelligence projects continued expansion in the building materials sector, citing urbanization and government-led infrastructure initiatives as key growth drivers—factors that directly benefit manufacturers specializing in precast and cast-in-place concrete gutters. As demand grows, a select group of manufacturers has emerged at the forefront, combining innovation, scalability, and product reliability to meet evolving market needs. Below is a data-informed look at the top 9 concrete gutter manufacturers shaping the industry today.

Top 9 Concrete Gutter Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wilbert Precast Inc.

Domain Est. 1999 | Founded: 1906

Website: wilbertprecast.com

Key Highlights: We’ve been in business since 1906. After more than a century of concrete, we’ve seen — and cast — it all. We match our innovative, always improving methods ……

#2 SI Precast Concrete

Domain Est. 2004

Website: siprecast.com

Key Highlights: SI Precast is your go-to source for custom and precast concrete products. With 50 manufacturing plants and 400 trucks on the road every day….

#3 GOMACO Corporation

Domain Est. 1997

Website: gomaco.com

Key Highlights: GOMACO Corporation manufactures curb and gutter machines, concrete slipform pavers, placer/spreaders, trimmer/placers, cylinder finishers, canal machinery ……

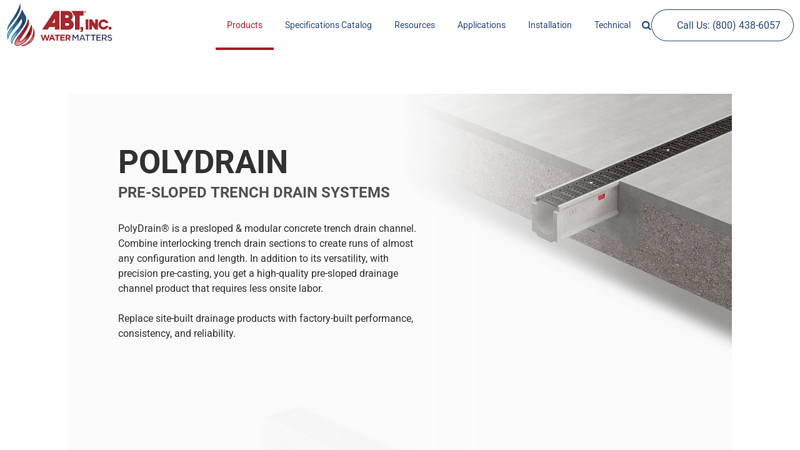

#4 Presloped & Modular Concrete Trench Drain Channels

Domain Est. 1997

Website: abtdrains.com

Key Highlights: ABT Drains’ pre-sloped trench drain systems are modular concrete drainage solutions that can create a huge variety of configurations and lengths….

#5 ABC Supply

Domain Est. 1998

Website: abcsupply.com

Key Highlights: Rain Gutters, Guards & Downspouts · Aluminum Rain Gutters, Guards … Concrete & Clay Roof Tiles · Cedar Shakes & Shingles · Metal Roofing · Composite ……

#6 Advanced Drainage Systems

Domain Est. 2000

Website: adspipe.com

Key Highlights: Advanced Drainage Systems provides high-performing, durable pipe and innovative stormwater management solutions. Discover our industry-leading products ……

#7 Products

Domain Est. 2004

Website: theturnerco.com

Key Highlights: The Turner Company supplies precast concrete aerobic and anaerobic sewage treatment systems from the Rhone facility or through local distributors….

#8 Keystone Concrete Products

Domain Est. 2007

Website: keystoneconcreteproducts.com

Key Highlights: Keystone Concrete Products is dedicated to both the Agriculture and Commercial Precast concrete needs. We specialize in a large variety of Precast T & L shape ……

#9 Concrete Splash Blocks

Domain Est. 2011

Website: nitterhousemasonry.com

Key Highlights: In stock $150 deliveryWe manufacture our concrete gutter splash block products with 8,500-psi concrete to meet the highest quality and durability standards with a maximum of 6% ……

Expert Sourcing Insights for Concrete Gutter

H2: 2026 Market Trends for Concrete Gutters

The global concrete gutter market is poised for steady growth by 2026, driven by increasing urbanization, infrastructure development, and a rising emphasis on durable stormwater management solutions. As cities expand and climate-related weather events become more frequent, the demand for robust drainage systems—particularly concrete gutters—is expected to rise significantly. This analysis explores key trends shaping the concrete gutter market through 2026.

1. Infrastructure Investment and Urban Development

Governments and private developers worldwide are investing heavily in urban infrastructure, including roads, highways, and residential complexes. Concrete gutters are a critical component of roadside drainage systems, and their use is mandated in many public works projects due to their longevity and load-bearing capacity. Emerging economies in Asia-Pacific (e.g., India, Indonesia) and Africa are expected to lead demand, where rapid urbanization necessitates large-scale construction.

2. Shift Toward Sustainable and Durable Materials

Compared to alternatives like plastic or aluminum, concrete offers superior durability, fire resistance, and minimal maintenance. With sustainability becoming a key criterion in construction, the long lifecycle of concrete gutters reduces replacement frequency and resource consumption. Innovations in eco-friendly concrete—such as low-carbon cements and recycled aggregates—are enhancing the environmental profile of concrete gutters, aligning them with green building standards.

3. Technological Advancements in Manufacturing

Pre-cast concrete gutter production is benefiting from automation and modular design, improving efficiency and consistency. 3D modeling and Building Information Modeling (BIM) are being integrated into planning and installation, enabling precise customization for complex infrastructure projects. These advancements reduce waste and shorten construction timelines, making concrete gutters a more attractive option.

4. Climate Resilience and Flood Management

With climate change increasing the frequency of heavy rainfall and flooding, municipalities are prioritizing resilient drainage systems. Concrete gutters, especially those with high flow capacity and structural strength, are being adopted in flood-prone areas. Integration with permeable pavements and smart stormwater systems is also emerging, positioning concrete gutters as part of broader climate adaptation strategies.

5. Regional Market Dynamics

North America and Europe will maintain steady demand, driven by road maintenance and retrofitting projects. However, the fastest growth is expected in the Asia-Pacific region, where government-led infrastructure initiatives (e.g., India’s Smart Cities Mission, China’s sponge city program) are boosting the use of concrete drainage solutions. The Middle East and Latin America are also witnessing increased adoption due to expanding transportation networks.

6. Competitive Landscape and Market Consolidation

The market is moderately fragmented, with a mix of multinational construction material suppliers and regional pre-cast manufacturers. Strategic partnerships, mergers, and expansion into emerging markets are key strategies among leading players. Companies are also investing in R&D to differentiate products through improved design, faster installation, and enhanced aesthetics.

Conclusion

By 2026, the concrete gutter market will be shaped by the convergence of infrastructure growth, sustainability mandates, and climate resilience needs. While facing competition from lightweight alternatives, concrete gutters will retain a dominant position in heavy-duty and long-life applications. Stakeholders who innovate in materials, production efficiency, and system integration will be best positioned to capitalize on the expanding global demand.

Common Pitfalls When Sourcing Concrete Gutters (Quality and Intellectual Property)

Sourcing concrete gutters involves several potential risks, particularly concerning material quality and intellectual property (IP) considerations. Avoiding these pitfalls is crucial for ensuring long-term performance, compliance, and legal safety.

Poor Material Quality and Workmanship

One of the most frequent issues is receiving concrete gutters that do not meet required durability or structural standards. Substandard mix designs, inadequate curing, or use of low-grade reinforcement can lead to cracking, spalling, or premature failure. Buyers should verify compliance with relevant standards (e.g., ASTM, BS, or local codes) and request test reports or certifications.

Inconsistent Dimensional Accuracy

Concrete gutters require precise dimensions to ensure proper installation and water flow. Poorly manufactured units may have deviations in length, depth, or slope, leading to fitting issues, leaks, or inefficient drainage. Always review tolerance specifications and inspect samples before bulk ordering.

Lack of Reinforcement or Corrosion Protection

Reinforced concrete gutters must include appropriate steel rebar or mesh to handle load and thermal stress. Inadequate reinforcement or failure to use corrosion-resistant coatings (especially in coastal or high-moisture areas) can drastically reduce service life. Confirm reinforcement details and corrosion protection methods with suppliers.

Insufficient Testing and Certification

Suppliers may claim compliance without providing third-party test results for compressive strength, water absorption, or freeze-thaw resistance. Relying solely on supplier assurances can lead to performance issues. Insist on certified lab reports and, if possible, conduct independent quality audits.

Intellectual Property Infringement

Some concrete gutter designs—especially proprietary profiles, connection systems, or drainage technologies—are protected by patents or design rights. Sourcing generic copies of patented systems can result in legal liability, shipment seizures, or costly litigation. Always verify whether a product design is IP-protected and ensure licensing agreements are in place if required.

Unverified Manufacturing Origin and Traceability

Sourcing from unknown or unverified manufacturers increases the risk of counterfeit or non-compliant products. Lack of traceability makes it difficult to address quality issues or recall defective items. Establish clear supplier credentials, factory audit processes, and material traceability protocols.

Inadequate Warranty and After-Sales Support

Some suppliers offer limited or vague warranties that exclude common failure modes. Without strong after-sales support, resolving quality issues becomes difficult and expensive. Negotiate clear warranty terms covering structural integrity, material defects, and performance under expected conditions.

By proactively addressing these pitfalls—through due diligence, quality checks, and IP verification—buyers can ensure they source reliable, compliant, and legally safe concrete gutter systems.

Logistics & Compliance Guide for Concrete Gutters

Concrete gutters are essential components in drainage and civil infrastructure projects, requiring careful planning in logistics and adherence to multiple compliance standards. This guide outlines key considerations for the safe, efficient, and compliant transportation, handling, and installation of precast concrete gutters.

Product Specifications and Handling Requirements

Concrete gutters are typically precast units made from reinforced or unreinforced concrete, designed to channel surface water. They come in various shapes (e.g., U-shaped, trapezoidal) and sizes. Due to their weight and brittleness, proper handling is critical to prevent cracking or structural damage. Always use lifting points or approved slings during loading and unloading—never drag or drop units.

Transportation and Load Securing

Transport concrete gutters using flatbed trucks or low-bed trailers with adequate load capacity. Units must be stacked securely with timber dunnage between layers to prevent chipping. Use chains or straps to secure loads, complying with local road transport regulations (e.g., U.S. DOT, EU Road Transport Rules). Overhang should not exceed legal limits, and warning signs must be used if necessary. Route planning should avoid roads with low bridges or weak infrastructure.

Storage On-Site

Store gutters on a level, compacted surface to prevent tipping or cracking. Stack no higher than recommended by the manufacturer (typically 2–3 layers). Keep units protected from excessive moisture and freeze-thaw cycles if stored long-term. Maintain clear access routes for lifting equipment and ensure fire lanes remain unobstructed.

Regulatory and Safety Compliance

Adhere to OSHA (U.S.) or equivalent workplace safety standards (e.g., HSE in the UK) when handling heavy concrete units. Workers must wear PPE including steel-toed boots, gloves, and high-visibility vests. Lifting operations should follow safe rigging practices, and cranes or forklifts must be operated by certified personnel. Conduct risk assessments for manual handling and implement control measures.

Environmental and Sustainability Standards

Ensure manufacturing and transport processes comply with environmental regulations such as EPA (U.S.) or EU Environmental Directives. Use sustainable practices where possible—recycled aggregates, low-carbon concrete mixes, and fuel-efficient transport. Dispose of packaging and damaged units according to local waste management laws. Consider LEED or BREEAM credits if applicable to the project.

Quality Assurance and Documentation

Each batch of concrete gutters should be supplied with a certificate of conformity, including mix design, compressive strength (e.g., 30 MPa minimum), and test results (ASTM C478, BS EN 1433, or equivalent). Maintain records of delivery notes, inspection reports, and installation logs for audit and compliance purposes.

Installation and Final Compliance

Installation must follow engineering specifications and local building codes. Ensure proper bedding and alignment, and conduct inspections prior to backfilling. Final compliance may require sign-off from municipal authorities or third-party inspectors, especially for stormwater management systems regulated under NPDES (U.S.) or similar programs.

By following this guide, stakeholders can ensure the safe, legal, and effective deployment of concrete gutters in infrastructure projects.

In conclusion, sourcing concrete gutters requires careful consideration of factors such as material quality, durability, cost, supplier reliability, and compliance with project specifications. Concrete gutters offer long-term benefits including strength, resistance to environmental elements, and low maintenance, making them a suitable choice for various drainage applications. Conducting thorough research, comparing multiple suppliers, evaluating lead times, and ensuring adherence to local standards will contribute to a successful procurement process. By prioritizing quality and sustainability in sourcing decisions, project stakeholders can ensure effective water management solutions that support infrastructure longevity and performance.