The global concrete edger machine market is experiencing steady growth, driven by rising infrastructure development, increased residential and commercial construction activities, and a growing emphasis on surface finishing quality. According to Grand View Research, the global construction equipment market—under which concrete finishing tools fall—was valued at USD 173.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Mordor Intelligence projects similar momentum, noting robust demand in emerging economies and advancements in machine efficiency and ergonomics as key growth catalysts. With such expansion, identifying leading manufacturers of concrete edger machines has become crucial for contractors, distributors, and procurement professionals seeking reliable, high-performance equipment. The following list highlights the top 10 manufacturers shaping the industry through innovation, durability, and global reach.

Top 10 Concrete Edger Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 China Cement Curbing Machine Manufacturers, Suppliers, Factory

Domain Est. 2020

Website: ranchengmachine.com

Key Highlights: As one of the leading cement curbing machine manufacturers and suppliers in China, we warmly welcome you to buy cost-efficient cement curbing machine for ……

#2 Top

Domain Est. 2016

Website: curbmachines.com

Key Highlights: Trust the latest technology with The Best Curb Machines by Curb Dog Equipment for easy curbing solutions. Upgrade your equipment today!…

#3 Curbing Machines

Domain Est. 2017

Website: borderlineusa.com

Key Highlights: We manufacturer in North Dakota the best concrete curbing machines on the market. Start a Curb Business Today!…

#4 Concrete Curb Machines for Commercial & Sidewalk Construction

Domain Est. 1997

Website: powercurbers.com

Key Highlights: Power Curbers designs and manufactures commercial concrete curb machines and slipform paving equipment built for precision, durability, and productivity….

#5 Curb & Gutter

Domain Est. 1997

Website: gomaco.com

Key Highlights: We sell more curb and gutter than any other. Select any of the below photos to learn more about GOMACO’s extensive curb and gutter lineup. GT-3600 Hybrid….

#6 Curb Machine

Domain Est. 1998

Website: curb-king.com

Key Highlights: Curb King has the most technologically advanced curb machines and curbing equipment in the industry. We have features and patents that you will not find in any ……

#7 Concrete Edging Machine

Domain Est. 1999

Website: lilbubba.com

Key Highlights: Our curb equipment and trailers are designed specifically for professional concrete curbing businesses. Developed by industry professionals for unsurpassed ……

#8 Curb Depot

Domain Est. 2006

Website: curbdepot.com

Key Highlights: Get everything you need to start your own curbing business with top-of-the-line equipment and expert training and support….

#9 Concrete Roller Screeds

Domain Est. 2007

Website: curbroller.com

Key Highlights: Concrete shaping solutions for curb, flatwork, and custom jobs that boost production, reduce labor, and pay off on day one….

#10 Curb Fox: Curb Machine

Domain Est. 2007

Website: curbfox.com

Key Highlights: Curb Fox is a leading provider of curb machine, curb & gutter machine, concrete paving machine, concrete curbing machines, curb forming machines & equipment ……

Expert Sourcing Insights for Concrete Edger Machine

H2: 2026 Market Trends for Concrete Edger Machines

The global concrete edger machine market is poised for steady growth leading into 2026, driven by rising construction activities, infrastructure development, and technological advancements in construction equipment. As urbanization accelerates across emerging economies and developed regions alike, demand for efficient, precision-oriented concrete finishing tools continues to climb. This analysis explores key trends shaping the concrete edger machine market in 2026.

1. Increased Demand in Infrastructure and Residential Construction

A major driver for the concrete edger machine market in 2026 is the global surge in infrastructure projects, including roads, highways, airports, and commercial buildings. Governments in regions such as Asia-Pacific, North America, and the Middle East are investing heavily in public works, fueling demand for construction equipment. Additionally, the growth of residential construction, especially in developing countries, supports the need for cost-effective and time-efficient concrete finishing solutions, positioning edger machines as essential tools on job sites.

2. Technological Advancements and Product Innovation

Manufacturers are increasingly integrating advanced features into concrete edger machines to improve performance and user experience. By 2026, innovations such as ergonomic designs, vibration-dampening handles, and compatibility with multiple blade types are becoming standard. Additionally, electric and battery-powered edgers are gaining traction as contractors seek quieter, more environmentally friendly alternatives to traditional gas-powered models. Smart features, such as real-time performance feedback and modular attachments, are also beginning to emerge in premium models.

3. Shift Toward Rental and Equipment-as-a-Service (EaaS) Models

The construction industry is witnessing a growing preference for equipment rental over ownership, especially among small and medium-sized contractors. In 2026, rental companies are expected to expand their fleets of concrete edger machines to meet short-term project needs. This trend is supported by the rise of Equipment-as-a-Service (EaaS) platforms, which offer flexible access to high-quality edging tools with maintenance and support included, reducing upfront costs and improving operational efficiency.

4. Regional Market Dynamics

Asia-Pacific is anticipated to lead the market in 2026 due to rapid urbanization in countries like India, China, and Indonesia. North America remains a key market, supported by ongoing infrastructure modernization and private construction activity. Europe shows moderate growth, driven by green building initiatives and renovation projects. Latin America and the Middle East are emerging as high-potential regions due to government-led construction programs and investments in transportation networks.

5. Sustainability and Regulatory Influences

Environmental regulations are pushing manufacturers to reduce emissions and improve fuel efficiency in gas-powered edgers. In response, many companies are shifting toward cleaner technologies, such as electric motors powered by lithium-ion batteries. Additionally, standards for noise pollution and worker safety are influencing machine design, with more emphasis on low-emission, low-noise models that comply with regional regulations.

6. Competitive Landscape and Market Consolidation

The concrete edger machine market in 2026 is becoming increasingly competitive, with key players such as Wacker Neuson, Multiquip, Husqvarna, and Allen Engineering focusing on product differentiation, global distribution, and after-sales support. Mergers, acquisitions, and strategic partnerships are expected to rise as companies aim to expand their market reach and integrate complementary technologies.

In conclusion, the 2026 concrete edger machine market is characterized by innovation, regional growth disparities, and evolving customer preferences. As construction practices become more efficient and environmentally conscious, concrete edger machines will continue to play a critical role in delivering high-quality, durable concrete finishes across diverse applications.

Common Pitfalls When Sourcing a Concrete Edger Machine: Quality and Intellectual Property Issues

Sourcing a concrete edger machine—especially from international suppliers—can be cost-effective, but it comes with risks. Two critical areas where buyers often encounter problems are product quality and intellectual property (IP) concerns. Understanding these pitfalls can help avoid costly setbacks and legal complications.

Quality-Related Pitfalls

Inconsistent Build Standards

Not all manufacturers adhere to the same engineering or material standards. Machines sourced from low-cost suppliers may use subpar steel, bearings, or engines, leading to premature wear, frequent breakdowns, and reduced job site efficiency.

Lack of Testing and Certification

Many suppliers, particularly in emerging markets, do not provide third-party testing reports or certifications (e.g., CE, ISO). Without verifiable performance data, buyers risk receiving machines that fail under real-world conditions.

Poor Assembly and Calibration

Even with quality components, improper assembly can compromise performance. Concrete edgers require precise blade alignment and motor calibration—issues that are hard to detect during a factory inspection but become apparent on the job site.

Inadequate After-Sales Support and Spare Parts Availability

Lower-priced machines may come from suppliers who lack a support network. When parts break or maintenance is needed, delays in sourcing replacements can lead to costly downtime.

Intellectual Property (IP) Concerns

Counterfeit or Copycat Designs

Some manufacturers produce machines that closely mimic patented designs from reputable brands. While they may appear identical, these clones often infringe on intellectual property rights, exposing the buyer to legal risks—especially when importing into countries with strict IP enforcement.

Unauthorized Use of Brand Logos and Trademarks

Suppliers may label machines with well-known brand names or logos without authorization. Purchasing such equipment, even unknowingly, can result in seizure by customs or legal action from the rightful IP holder.

Gray Market and Warranty Voidance

Machines produced under license but sold outside authorized distribution channels may lack warranty coverage. Buyers risk investing in equipment that cannot be serviced or supported through official channels.

Lack of Design Innovation and Documentation

Cloned machines rarely come with original technical documentation or innovation. This limits customization, integration with other tools, and the ability to verify design integrity or safety compliance.

How to Mitigate These Risks

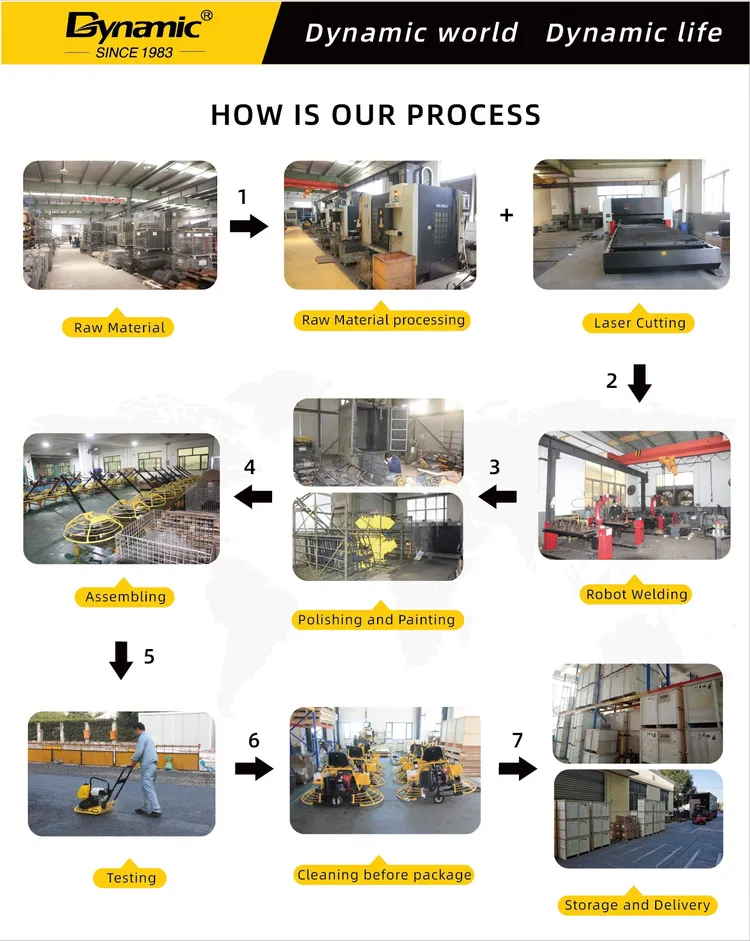

- Request product samples and conduct on-site inspections.

- Verify certifications and demand test reports.

- Work with legal counsel to review supplier agreements and IP disclaimers.

- Use trusted sourcing platforms with IP protection policies.

- Partner with suppliers who offer transparent manufacturing processes and after-sales support.

Avoiding these common pitfalls ensures you source a reliable, legally compliant concrete edger machine that delivers long-term value.

Logistics & Compliance Guide for Concrete Edger Machine

This guide outlines key considerations for the safe, efficient, and compliant transportation, handling, and operation of a Concrete Edger Machine.

Shipping and Transportation

Ensure the concrete edger machine is securely crated or strapped to a pallet using industrial-grade tie-downs. Use corner protectors to prevent damage during transit. Confirm that all loose components (handles, blades, fuel containers) are removed and packed separately. Choose a freight carrier experienced in handling heavy construction equipment and verify that weight and dimensions comply with road transport regulations. Provide clear shipping labels indicating “Fragile,” “This Side Up,” and “Heavy Equipment.”

Import/Export Compliance

Verify applicable Harmonized System (HS) codes for concrete edgers—commonly under 8479.89 or similar machinery classifications—based on your region. Ensure compliance with destination country regulations, including customs documentation, import duties, and potential product certification requirements (e.g., CE, UKCA, or EPA standards for engines). For machines with internal combustion engines, confirm adherence to emissions regulations such as EPA Tier 4 or EU Stage V.

Safety Standards and Certifications

The concrete edger machine must meet relevant safety standards such as ANSI B71.4 (for concrete finishing equipment) and OSHA requirements in the U.S., or equivalent regional standards like EN 13866 in Europe. Electric models should comply with IEC 60335 for safety of household and similar electrical appliances. Machines with gasoline engines must include proper labeling for fuel type, noise levels, and vibration emissions, and comply with local environmental safety directives.

On-Site Handling and Assembly

Use appropriate lifting equipment such as forklifts or overhead cranes with slings rated for the machine’s weight during unloading. Never lift by handles or non-designated points. Follow the manufacturer’s assembly instructions precisely. Inspect all components for transit damage before assembly. Ensure operators are trained in equipment handling and that required safety gear (gloves, steel-toe boots, eye protection) is available.

Operational Compliance

Operators must be trained and familiar with the manufacturer’s operating manual. Machines with internal combustion engines must be operated in well-ventilated areas to prevent carbon monoxide buildup. Adhere to local noise regulations, especially in residential zones or during restricted hours. Regularly inspect safety features such as blade guards, emergency stop mechanisms, and vibration-dampening systems to ensure they remain functional.

Maintenance and Documentation

Maintain a log of all maintenance activities, including blade sharpening, engine servicing, and safety inspections. Keep compliance documents—such as conformity declarations, safety data sheets (SDS) for fuels and lubricants, and user manuals—readily accessible. Follow manufacturer-recommended service intervals to ensure ongoing compliance with safety and emissions standards.

Environmental and Disposal Regulations

Dispose of used engine oil, fuel, and worn blades in accordance with local environmental regulations. Used blades may be classified as metal waste and should be recycled appropriately. For machines reaching end-of-life, follow WEEE (Waste Electrical and Electronic Equipment) directives if applicable, particularly for models with electronic components or electric motors.

In conclusion, sourcing a concrete edger machine requires careful consideration of several key factors including machine type (manual vs. power edgers), material quality, blade type, ease of use, maintenance requirements, and overall cost. It is essential to match the machine specifications with the scale and nature of your concrete finishing projects to ensure optimal performance and longevity. Evaluating supplier reliability, warranty terms, and availability of after-sales support will further contribute to a successful procurement decision. By conducting thorough research and prioritizing durability and efficiency, you can source a concrete edger machine that enhances productivity, delivers professional-quality edges, and provides a strong return on investment for your construction or landscaping operations.