The global concrete anchor bolts market is experiencing steady expansion, driven by rising construction activities and infrastructure development worldwide. According to Mordor Intelligence, the market was valued at USD 3.8 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. This growth is fueled by increasing demand in commercial, industrial, and residential construction, particularly in emerging economies. Additionally, stringent building codes and a growing emphasis on structural safety are boosting the adoption of high-performance anchor bolts. As the construction industry evolves with more sustainable and resilient building practices, manufacturers are innovating to deliver durable, corrosion-resistant, and load-optimized anchoring solutions. Against this backdrop, identifying the leading concrete anchor bolt manufacturers becomes crucial for industry stakeholders seeking reliability, performance, and compliance with international standards.

Top 10 Concrete Anchor Bolts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Anchor Fasteners Industrial co., Ltd.

Domain Est. 1998 | Founded: 1986

Website: anchorfast.com.tw

Key Highlights: For more than 30 years since 1986, Anchor has been dedicated in manufacturing high quality fasteners for the Construction, Automotive and Electronic industries….

#2 Portland Bolt

Domain Est. 1998 | Founded: 1912

Website: portlandbolt.com

Key Highlights: Portland Bolt has manufactured and distributed the highest-quality anchor bolts and nonstandard construction fasteners since 1912….

#3 Concrete and Masonry Anchor Manufacturers Association

Domain Est. 1999

Website: concreteanchors.org

Key Highlights: CAMA is the voice of the concrete and masonry anchor industry, establishing standards, codes, criterion and principals for the design, use, and testing of ……

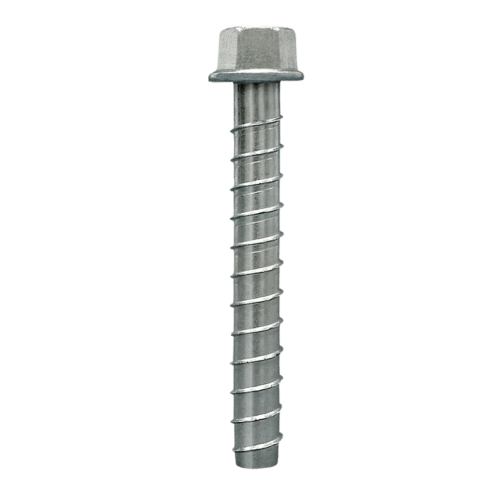

#4 Titen HD® Heavy

Domain Est. 1995

Website: strongtie.com

Key Highlights: A high-strength screw anchor for use in cracked and uncracked concrete, as well as uncracked masonry. The Titen HD offers low installation torque and ……

#5 Fasteners

Domain Est. 1995

Website: hilti.com

Key Highlights: Shop all products · Mechanical anchors · Chemical anchors · Anchor rods & elements · Cast-in anchors · Cast-in anchor channels · Screws · Nails · Threaded studs & ……

#6 Cobra Anchors

Domain Est. 1999

Website: cobraanchors.com

Key Highlights: Discover Cobra Anchors’ strong, easy-to-install anchors and hanging hardware for drywall, masonry, concrete, and other projects….

#7 Concrete Anchors, Tapcon, Bits, American Made Anchors

Domain Est. 2000

Website: concretefasteners.com

Key Highlights: Free delivery over $35Purchase Concrete Fasteners, Tapcons, Bits and American Made Anchors online and save; free freight, in stock for immediate shipment….

#8 Concrete and Masonry

Domain Est. 2002

Website: mitek-us.com

Key Highlights: Installation · Select appropriate AB Anchor Bolt. · Use concrete with minimum compressive strength of 2,500 psi at 28 days. · Nuts and washers are included….

#9 Bolt anchor

Domain Est. 2010

Website: fischerfixingsusa.com

Key Highlights: The anchors are made from normal steel, hot-dip galvanised steel, A4 stainless steel, and highly corrosion-resistant steel. They safely introduce the loads into ……

#10 Concrete Anchor Bolts

Domain Est. 2023

Website: concreteanchorbolts.com

Key Highlights: Concrete Anchor Bolts offers retrofit solutions to replace corroded J-bolts and tie straps. Call 623-305-3319 for fast, durable results….

Expert Sourcing Insights for Concrete Anchor Bolts

H2: 2026 Market Trends for Concrete Anchor Bolts

The global concrete anchor bolts market is poised for steady growth through 2026, driven by advancements in construction technologies, rising infrastructure investments, and increasing demand for high-performance fastening solutions. Several key trends are shaping the industry landscape:

-

Growth in Construction and Infrastructure Development

Urbanization and government-led infrastructure projects—especially in emerging economies across Asia-Pacific, Latin America, and Africa—are major drivers. Countries like India, Indonesia, and Brazil are investing heavily in transportation, commercial buildings, and smart city initiatives, boosting demand for reliable anchoring systems. -

Shift Toward High-Strength and Corrosion-Resistant Materials

There is a growing preference for anchor bolts made from stainless steel, hot-dip galvanized steel, and other corrosion-resistant alloys. This trend is particularly strong in coastal regions and industrial environments where exposure to moisture and chemicals is high. Manufacturers are focusing on enhancing product durability to meet stringent building codes and sustainability standards. -

Adoption of Post-Installed and Chemical Anchors

Post-installed mechanical and adhesive (chemical) anchor systems are gaining traction due to their flexibility in retrofit applications and ease of installation. Chemical anchors, in particular, offer superior load capacity and performance in cracked concrete, making them ideal for seismic-prone areas. -

Stringent Safety and Regulatory Standards

Building codes such as ICC-ES, ETA (European Technical Assessment), and ISO standards are becoming more rigorous, especially concerning seismic resilience and fire resistance. Compliance with these regulations is pushing manufacturers to innovate and certify their products, ensuring reliability and safety. -

Sustainability and Green Building Initiatives

The rise of green construction practices is influencing material selection. Anchor bolt producers are developing low-carbon manufacturing processes and recyclable products to align with LEED and BREEAM certification requirements. Lifecycle durability is increasingly valued over initial cost. -

Digitalization and Smart Construction Technologies

Integration with Building Information Modeling (BIM) and digital project management tools enables precise anchor bolt placement and inventory tracking. Some companies are exploring smart anchor systems with embedded sensors for structural health monitoring—especially in bridges and high-rise buildings. -

Regional Market Dynamics

- North America remains a mature market with steady demand, supported by infrastructure renewal programs.

- Europe emphasizes high safety standards and sustainable construction, favoring certified and eco-friendly products.

-

Asia-Pacific is the fastest-growing region due to rapid urbanization and industrial construction in China, India, and Southeast Asia.

-

Consolidation and Innovation Among Key Players

Major manufacturers like Hilti, Fischer Group, Simpson Strong-Tie, and ITW are investing in R&D to launch innovative anchor solutions, including fire-rated and high-vibration resistance systems. Strategic partnerships and acquisitions are expected to increase market consolidation.

In conclusion, the concrete anchor bolts market in 2026 will be defined by innovation, regulatory compliance, and sustainability. Companies that prioritize product performance, adapt to regional construction trends, and embrace digital tools will be best positioned for long-term success.

Common Pitfalls When Sourcing Concrete Anchor Bolts (Quality, IP)

Sourcing concrete anchor bolts involves more than just matching dimensions and strength grades. Overlooking critical quality and intellectual property (IP) aspects can lead to structural failures, safety hazards, legal issues, and project delays. Below are key pitfalls to avoid:

Poor Material Quality and Non-Compliance

One of the most frequent issues is receiving anchor bolts made from substandard materials or failing to meet required industry standards (e.g., ASTM A307, ASTM F1554, or ISO 898-1). Suppliers—especially low-cost offshore manufacturers—may use inferior steel, incorrect heat treatment, or inaccurate thread rolling, resulting in bolts with reduced tensile strength, ductility, or corrosion resistance. Always verify mill test reports and insist on third-party certification.

Lack of Traceability and Certification

Reputable projects require full traceability of materials, including heat numbers and test certifications. Many suppliers fail to provide proper documentation, making it impossible to verify compliance with project specifications. This is particularly critical in construction and infrastructure where audits or inspections may be required. Without proper certification, anchor bolts may be rejected on-site, causing costly delays.

Counterfeit or Non-Genuine Products

In markets with weak IP enforcement, counterfeit anchor bolts bearing fake certifications or mimicking branded products (e.g., fake Hilti or Powers labels) are common. These products may look identical but lack the engineered performance and reliability of genuine items. Sourcing from unauthorized distributors or gray market channels increases the risk of receiving counterfeit goods, exposing projects to liability and safety risks.

Intellectual Property Infringement

Some suppliers manufacture anchor bolts that replicate patented designs (such as specialized undercut or expansion mechanisms) without licensing. Using such infringing products can expose the buyer to legal action, especially in regions with strong IP protections like the EU or U.S. Always ensure that proprietary designs are properly licensed and that technical data is from authorized sources.

Inadequate Corrosion Protection

Anchor bolts used in harsh environments (e.g., coastal areas or chemical plants) require proper corrosion protection such as hot-dip galvanizing, mechanical galvanizing, or duplex coatings. A common pitfall is receiving bolts with insufficient or poorly applied coatings. For example, post-galvanizing after threading can damage coating integrity. Verify coating thickness and adherence to standards like ASTM A153 or ISO 1461.

Dimensional and Thread Accuracy Issues

Off-spec thread pitch, incorrect embedment lengths, or deviations in diameter can prevent proper installation or reduce load capacity. Poor thread quality may also damage nuts or fail torque requirements. Ensure dimensional conformity through sample inspections and request first-article testing when sourcing from new suppliers.

Misrepresentation of Load Capacity

Some suppliers exaggerate load ratings based on ideal lab conditions rather than real-world performance (e.g., cracked concrete, edge distances, or installation torque). This can compromise structural safety. Always refer to recognized engineering guidelines (e.g., ACI 318, ETAG 001) and demand installation-specific performance data, including pull-out and shear test reports.

Inconsistent Quality Control Processes

Suppliers without robust quality management systems (e.g., ISO 9001 certification) may deliver inconsistent batches. Without in-process inspections and final testing, defects can go undetected. Request evidence of the supplier’s QC procedures and conduct periodic audits or third-party inspections.

Avoiding these pitfalls requires due diligence: vet suppliers thoroughly, demand documentation, conduct sample testing, and work with reputable, certified vendors. Proper sourcing ensures structural integrity, regulatory compliance, and long-term project success.

Logistics & Compliance Guide for Concrete Anchor Bolts

Product Overview and Classification

Concrete anchor bolts are specialized fasteners designed to secure structural and non-structural elements to concrete substrates. They are commonly used in construction, infrastructure, and industrial applications. These bolts fall under construction hardware and are subject to specific transportation, storage, and regulatory requirements based on material composition, load rating, and intended use.

Regulatory and Standards Compliance

Anchor bolts must comply with international and regional standards to ensure structural integrity and safety. Key compliance requirements include:

– ASTM Standards (USA): ASTM A307, ASTM F1554 (Grades 36, 55, 105), ASTM A193 (for high-strength applications)

– ISO Standards: ISO 898-1 (mechanical properties of bolts), ISO 15630 (testing methods)

– European Norms (EN): EN 1993-1-8 (Eurocode 3), ETA (European Technical Assessment) for post-installed anchors

– Building Codes: Compliance with IBC (International Building Code), ACI 318 (American Concrete Institute) for design and installation

– CE Marking: Required for sale within the European Economic Area (EEA), indicating conformity with health, safety, and environmental protection standards

Manufacturers must provide certification documentation (e.g., Mill Test Reports, Declaration of Performance) for traceability and compliance audits.

Packaging and Handling Requirements

Proper packaging ensures product integrity during transit and storage:

– Anchor bolts should be bundled and secured with rust-inhibiting paper or VCI (Vapor Corrosion Inhibitor) wrapping

– Use moisture-resistant packaging, especially for galvanized or stainless steel variants

– Label each package with product specifications, lot number, ASTM/EN standard, and handling instructions (e.g., “Protect from Moisture”)

– Palletize loads securely using edge protectors and stretch-wrapping to prevent shifting during transport

– Handle with non-abrasive equipment to avoid damaging protective coatings

Transportation and Shipping Guidelines

Anchor bolts are typically transported via truck, rail, or sea freight. Key considerations include:

– Domestic Shipping (e.g., USA, EU): Follow DOT (Department of Transportation) or ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road) regulations as applicable (note: anchor bolts are generally non-hazardous)

– International Shipping: Comply with IMDG Code for sea freight and IATA regulations if air freight is used (though uncommon due to weight)

– Load Securing: Use dunnage and load locks to prevent movement; steel bundles must not exceed safe load limits per pallet or container

– Documentation: Include commercial invoice, packing list, certificate of compliance, and bill of lading. For exports, provide HS Code (e.g., 7318.15 for bolts and screws of iron or steel)

Storage Conditions and Shelf Life

To maintain quality, anchor bolts must be stored under controlled conditions:

– Store indoors in a dry, well-ventilated area with relative humidity below 60%

– Elevate pallets off the floor using wooden skids to prevent moisture absorption

– Segregate by grade, size, and coating type to avoid mix-ups

– Avoid contact with corrosive chemicals or salt-laden environments

– Shelf life: Indefinite if stored properly, but inspect periodically for signs of corrosion or coating degradation (especially for zinc-plated or hot-dip galvanized bolts)

Import/Export and Customs Compliance

When shipping across borders:

– Verify destination country’s import regulations (e.g., CBP requirements in the USA, UKCA marking post-Brexit)

– Ensure accurate product classification under the Harmonized System (HS) codes

– Provide necessary documentation: Certificate of Origin, Import License (if required), and Test Reports

– Be aware of anti-dumping duties or trade restrictions on steel products in certain regions

– Use licensed customs brokers for efficient clearance and tariff classification

Environmental and Safety Considerations

- Anchor bolts made from recyclable steel contribute to sustainable construction

- Coatings (e.g., zinc, epoxy) must comply with RoHS and REACH regulations in the EU

- Provide Safety Data Sheets (SDS) if requested, especially for coated or chemically treated bolts

- Ensure workplace safety during handling—use PPE (gloves, safety glasses) due to sharp edges and heavy weight

Quality Assurance and Traceability

Establish a traceability system to support compliance and recalls:

– Maintain batch/lot tracking from raw material to final product

– Conduct periodic third-party testing for tensile strength, thread accuracy, and coating thickness

– Retain documentation for a minimum of 10 years for structural applications

– Implement a non-conformance reporting (NCR) process for defective shipments

Conclusion

Effective logistics and compliance management for concrete anchor bolts ensures product reliability, regulatory adherence, and customer satisfaction. By following standardized packaging, transport, storage, and documentation practices, suppliers and distributors can minimize risk and support safe, code-compliant construction projects worldwide.

Conclusion for Sourcing Concrete Anchor Bolts:

Sourcing concrete anchor bolts requires careful consideration of project specifications, environmental conditions, load requirements, and compliance with relevant standards. Selecting the appropriate type—such as cast-in-place, wedge, or sleeve anchors—ensures structural integrity and long-term performance. It is essential to partner with reputable suppliers who provide high-quality, certified products and maintain consistent supply chain reliability. Additionally, factors like material (carbon steel, stainless steel, or hot-dip galvanized), diameter, embedment depth, and installation methods must align with engineering designs to ensure safety and durability. A well-planned sourcing strategy that balances cost-efficiency with quality and technical support ultimately contributes to the success and safety of construction and infrastructure projects.