The global hole saw market is experiencing steady expansion, driven by rising demand in construction, plumbing, and industrial fabrication. According to Mordor Intelligence, the global hole saw market was valued at approximately USD 425 million in 2023 and is projected to grow at a CAGR of 4.8% over the forecast period (2023–2028). This growth is fueled by increasing infrastructure development and the widespread use of power tools in both professional and DIY applications. Among the various sizes, 4-inch concrete hole saws are particularly sought after for their efficiency in cutting through masonry, concrete, and reinforced materials in large-scale construction projects. As demand for precision and durability intensifies, manufacturers are investing in carbide and diamond-tipped technologies to improve performance and tool life. In this competitive landscape, a select group of manufacturers have emerged as leaders, combining innovation, quality materials, and global distribution to dominate the concrete hole saw segment.

Top 8 Concrete 4 Inch Hole Saw Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 CORDED ROTARY HAMMERS

Domain Est. 1995

Website: makitatools.com

Key Highlights: Makita USA: The Leader In Cordless with 18V LXT Lithium-Ion. The best in class for cordless power tool technology. A leader in power tool technology for the ……

#2 Champion Cutting Tool

Domain Est. 1998

Website: championcuttingtool.com

Key Highlights: Hole Saw Pilot Drills · Drill Gauge · Step Drills · Step Drill Sets · Hex Shank Step Drills · Straight Shank Step Drills · Hole Cutters / Hole Saws · Hole ……

#3 Concrete Cutting Tools, Diamond Blades & Equipment

Domain Est. 2001

Website: deltadiamond.com

Key Highlights: Free delivery over $99 30-day returnsHigh-performance dry diamond blades, continuous rim blades, core drilling tools, and concrete cutting equipment for contractors. Shop 14-inch b…

#4 Hole Saws

Domain Est. 2002

Website: irwintools.com

Key Highlights: IRWIN Bi-Metal hole saws and hole saw kits feature patented Weldtec 4.5/5.5 variable tooth design for longer life and improved cutting performance….

#5 DHSAR375

Domain Est. 2004

Website: diablotools.com

Key Highlights: These radical new hole saws provide ultimate cutting length to bore deeper holes in a single pass, tool-free plug ejection and Variable Tooth Design for faster ……

#6 Products

Domain Est. 2004

Website: sangtools.com

Key Highlights: China best 4 inch concrete hole saw provider is here!Our company has engaged in 4 inch concrete hole saw for more than 26 years experience,call us now!…

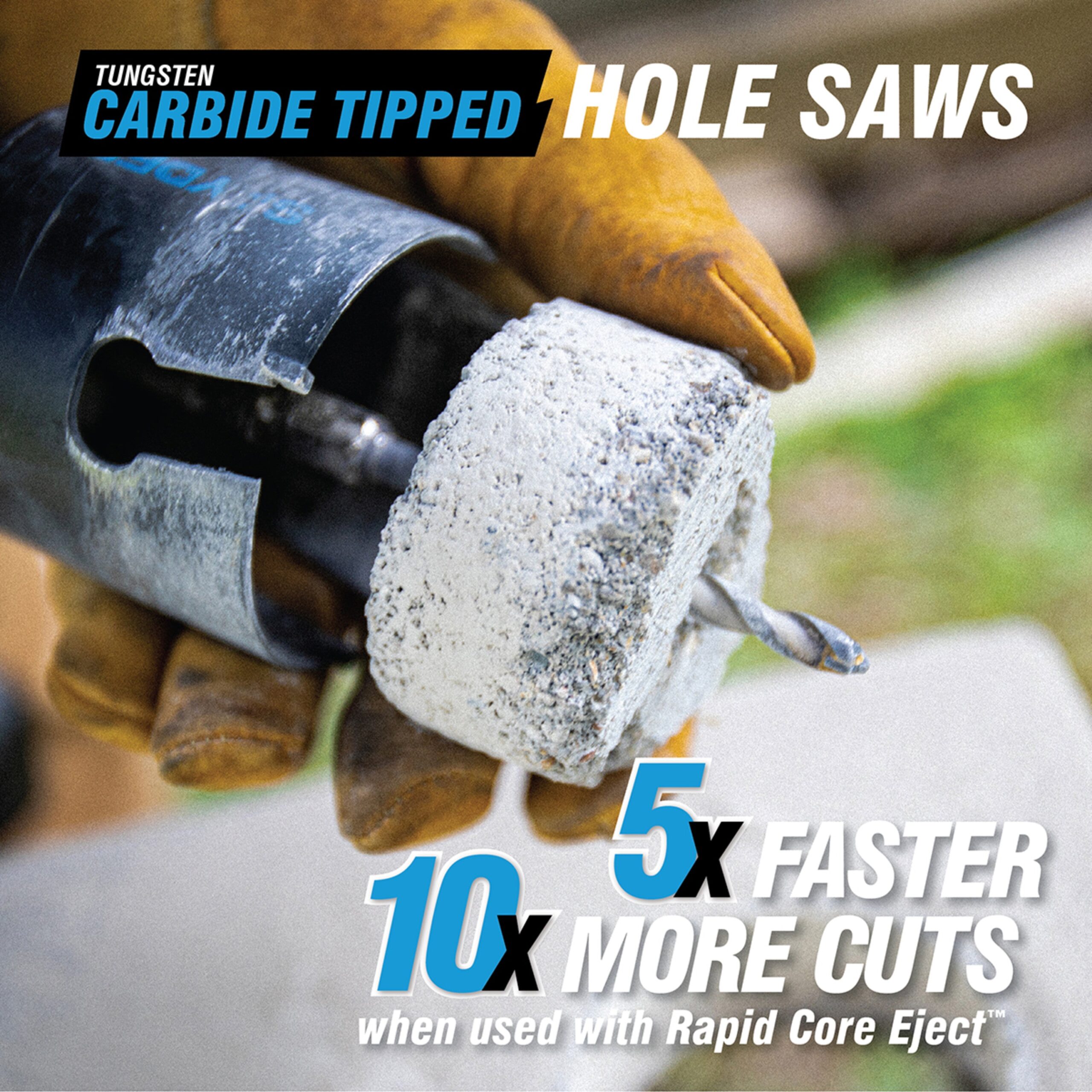

#7 4″ Deep Cut Tungsten Carbide Tipped Hole Saw

Domain Est. 2010

Website: spyderproducts.com

Key Highlights: This extended cutting depth makes Spyder’s Deep Cut hole saws excellent for stacked materials, deeper cuts, and for drilling through brick and concrete block….

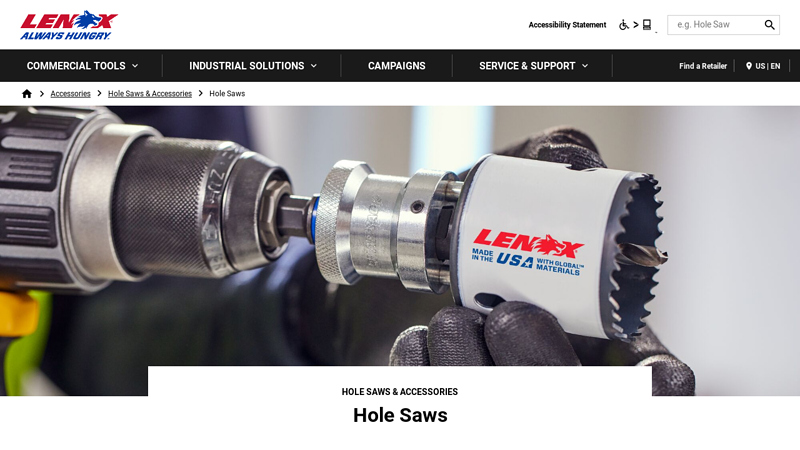

#8 Hole Saws

Domain Est. 2017

Website: cutwithlenox.com

Key Highlights: SNAP-BACK® Quick Change Hole Saw Arbors 2L 12.7mm 32 – 210mm · Options available. 5.0. (7). 5.0 out of 5 stars. 7 reviews. Plumber Hole Saw Kit (9 pc.)….

Expert Sourcing Insights for Concrete 4 Inch Hole Saw

2026 Market Trends for Concrete 4-Inch Hole Saw

The market for 4-inch concrete hole saws in 2026 is poised for significant evolution, driven by technological advancements, shifting construction demands, and sustainability imperatives. Key trends shaping this niche tool segment include:

Growing Demand from Infrastructure and Renovation Sectors

A surge in global infrastructure modernization projects—including smart city developments, transit expansions, and utility upgrades—is driving demand for efficient core drilling tools. Concurrently, the rise in building retrofitting and renovation, especially for HVAC, electrical, and plumbing upgrades in existing concrete structures, is increasing the need for large-diameter (4-inch) hole saws. This trend is amplified by urban densification, where adding systems to older concrete buildings requires precise, minimally invasive tools.

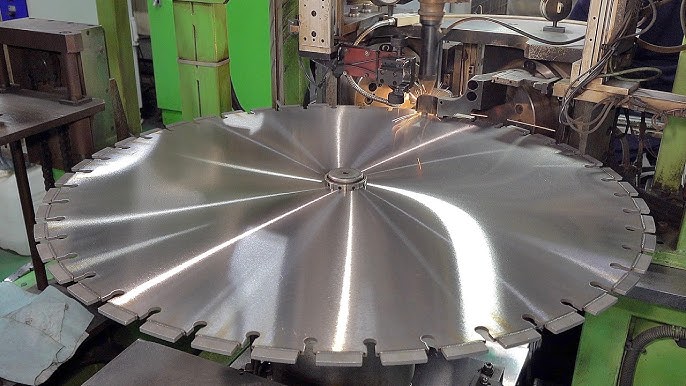

Advancements in Diamond-Tipped and Hybrid Cutting Technology

By 2026, diamond-impregnated and segmented rim hole saws will dominate the 4-inch concrete category due to their superior durability and faster cutting speeds. Manufacturers are investing in advanced bonding technologies and optimized segment geometries to extend tool life and improve performance in reinforced concrete. Additionally, hybrid designs combining carbide and diamond elements are emerging, offering cost-effective solutions for mixed-material applications while maintaining efficiency in pure concrete.

Increased Focus on Dust Control and Operator Safety

Stricter occupational health and safety regulations, particularly in North America and Europe, are pushing demand for hole saw systems integrated with dust extraction. Wet-cutting and vacuum-compatible 4-inch hole saws are becoming standard, driven by OSHA and EU directives limiting silica dust exposure. Tool designs now emphasize ergonomic features, vibration reduction, and compatibility with cordless hammer drills, enhancing user safety and productivity on job sites.

Rise of Cordless Power Tool Ecosystems

The rapid adoption of high-torque 18V and 20V cordless hammer drills is reshaping accessory markets. In 2026, 4-inch concrete hole saws are increasingly engineered for compatibility with cordless systems, featuring optimized arbor designs and heat dissipation for prolonged battery-powered operation. This shift supports mobile workflows, especially in high-rise and remote locations where power access is limited.

Sustainability and Circular Economy Initiatives

Environmental concerns are influencing product development. Leading manufacturers are introducing recyclable packaging, longer-lasting tool designs to reduce waste, and take-back programs for worn diamond segments. Additionally, the use of recycled materials in non-cutting components of hole saw bodies is becoming more prevalent, aligning with green building certifications like LEED and BREEAM.

Expansion in Emerging Markets

Rapid urbanization in Asia-Pacific, Latin America, and Africa is creating new demand for construction tools. As local building codes evolve and professional contractor bases grow, there is increasing adoption of specialized tools like 4-inch concrete hole saws. Regional distribution networks and localized pricing strategies are enabling broader market penetration by global and regional tool brands.

Digital Integration and Smart Tool Features

While still in early stages, some premium 4-inch hole saw systems are beginning to incorporate smart features—such as RFID tags for tool tracking, usage analytics, or compatibility with digital work management platforms. These innovations support fleet management for large contractors and contribute to predictive maintenance, reducing downtime.

In summary, the 2026 market for 4-inch concrete hole saws is characterized by innovation in materials and design, heightened regulatory and environmental awareness, and strong demand from infrastructure and renovation sectors. Manufacturers who prioritize performance, safety, and sustainability will lead this evolving landscape.

H2. Common Pitfalls When Sourcing a 4-Inch Concrete Hole Saw (Quality and Intellectual Property)

Logistics & Compliance Guide: Concrete 4-Inch Hole Saw

Product Overview

The Concrete 4-Inch Hole Saw is a specialized drill bit designed for cutting precise, clean holes in masonry, concrete, brick, and block materials. Typically constructed with diamond or tungsten carbide tips, this tool is commonly used in construction, plumbing, electrical, and HVAC applications for installing conduits, pipes, and fixtures.

Packaging & Labeling Requirements

- Primary Packaging: Hole saws should be individually packaged in protective plastic sleeves or clamshell packaging to prevent tip damage.

- Secondary Packaging: Packaged in sturdy cardboard boxes with cushioning material (e.g., foam inserts or corrugated dividers) to prevent movement during transit.

- Labeling:

- Product name and size (e.g., “4-Inch Concrete Hole Saw”)

- Material composition (e.g., “Diamond-Tipped” or “Tungsten Carbide”)

- Manufacturer name and part number

- Safety warnings (e.g., “Wear eye and respiratory protection”)

- Country of origin

- UPC/EAN barcode for inventory and retail tracking

- Compliance marks (e.g., CE, RoHS where applicable)

Shipping & Transportation

- Weight & Dimensions: Typical unit weight: 0.5–1.0 lbs (0.23–0.45 kg). Dimensions: ~4.5″ diameter × 2″ depth per unit. Palletized shipments should follow standard U.S. pallet dimensions (48″ × 40″).

- Shipping Methods:

- Small orders: Couriers (e.g., FedEx, UPS) with ground or express service.

- Bulk orders: LTL (Less Than Truckload) or FTL (Full Truckload) freight.

- Hazard Classification: Non-hazardous. No special handling required under DOT, IATA, or IMDG regulations.

- Export Considerations: No ITAR or EAR restrictions. Confirm destination country import regulations for power tool accessories.

Import & Customs Compliance

- HS Code: 8207.50.60 – Tools for working in the hand, with parts suitable for use with tools of heading 8202–8205, of base metal, for working stone, ceramics, concrete, etc.

- Import Duties: Varies by country. In the U.S., typically duty-free under HTSUS 8207.50.60. Confirm local tariff regulations in destination markets.

- Documentation:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin (preferably Form A for GSP-eligible countries)

- Customs Clearance: Ensure accurate product description, value declaration, and country of origin to avoid delays.

Regulatory & Safety Compliance

- OSHA (U.S.): Operators must follow proper PPE requirements when using the tool (safety glasses, gloves, dust mask/respirator).

- REACH (EU): Confirm no restricted substances (e.g., lead, cadmium) exceed allowable limits in metal components.

- RoHS (EU): Applies to electrical components; generally not applicable to standalone hole saws unless part of a motorized kit.

- CE Marking: Required for sale in the EU. Must comply with Machinery Directive 2006/42/EC if part of a tool system; standalone cutting tools may be exempt but should still meet safety standards.

- ANSI B7.1 (U.S.): Safety requirements for the use of abrasive products (relevant if diamond-coated).

Environmental & Disposal Guidelines

- End-of-Life: Metal components (steel body, carbide/diamond tips) are recyclable. Segregate for metal recycling where available.

- Waste Classification: Non-hazardous waste when discarded.

- Dust Generation: During use, produces silica dust. Comply with OSHA silica exposure standards (29 CFR 1926.1153) by using water suppression or HEPA vacuum systems.

Storage & Handling

- Storage Conditions: Store in a dry, temperature-controlled environment to prevent rust or degradation of coatings.

- Shelf Life: Indefinite if stored properly. Inspect for corrosion or damage before use.

- Handling: Use gloves to avoid cuts from sharp cutting edges. Avoid dropping to prevent tip chipping.

Warranty & Returns

- Warranty Period: Typically 1 year against manufacturing defects.

- Return Logistics: Unused, undamaged items in original packaging accepted within 30 days. Coordinate via RMA (Return Merchandise Authorization).

- Reverse Logistics: Use same carrier as original shipment or designated courier. Include return label and documentation.

Additional Notes

- Training & Instructions: Include multilingual safety and usage instructions with bulk shipments.

- Sustainability: Consider recyclable packaging materials and supplier certifications (e.g., ISO 14001).

By adhering to this guide, distributors, importers, and users can ensure safe, compliant, and efficient handling of the Concrete 4-Inch Hole Saw throughout its supply chain lifecycle.

In conclusion, sourcing a 4-inch concrete hole saw requires careful consideration of several key factors to ensure optimal performance, durability, and value. Compatibility with your existing drilling equipment—particularly the arbor and drill type (hammer drill recommended)—is essential. Choosing the right material, such as diamond-coated or carbide-tipped segments, will significantly impact cutting efficiency and tool life, especially when working with dense or reinforced concrete.

Additionally, evaluating reputable suppliers, comparing prices, and checking for warranties or customer reviews can help secure a reliable product. While cost is a factor, investing in a high-quality hole saw may reduce long-term expenses by minimizing replacements and downtime. Safety and proper usage practices should also not be overlooked to protect both the operator and the tool.

Ultimately, selecting a well-made 4-inch concrete hole saw from a trusted source ensures clean, accurate cuts and enhances productivity on construction, plumbing, or electrical projects involving concrete materials.