The global compression fitting market, driven by increasing demand in plumbing, HVAC, and industrial applications, is projected to grow at a CAGR of 5.8% from 2024 to 2030, according to Grand View Research. With galvanized steel pipes still widely used in water supply and gas distribution systems—especially in retrofitting and rural infrastructure—the need for reliable, leak-proof connections has elevated the importance of high-performance compression fittings. As industries prioritize durability and ease of installation, manufacturers specializing in compression fittings for galvanized pipes are seeing heightened demand. This growth is further fueled by ongoing infrastructure development and stringent safety standards across North America, Europe, and Asia Pacific. In this evolving landscape, identifying top manufacturers who combine precision engineering, corrosion resistance, and compliance with international standards becomes crucial. Based on market presence, product innovation, and application reliability, the following seven companies stand out as leaders in producing compression fittings tailored for galvanized pipe systems.

Top 7 Compression Fitting For Galvanized Pipe Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Galvanized compression fittings aka dresser fittings

Domain Est. 1995

Website: plumbingsupply.com

Key Highlights: Galvanized Male Compression Adapter · NPT male threads · Compression side fits both IPS sized metal pipes and Schedule 40 plastic pipes · Maximum 125 PSI at ……

#2 Compression Couplings

Domain Est. 1997

Website: morriscoupling.com

Key Highlights: The “Original” Morris compression coupling designed to join pipe and tubing for pneumatic conveying systems. Easy to install; Pipe and tube sizes 1/2″ through ……

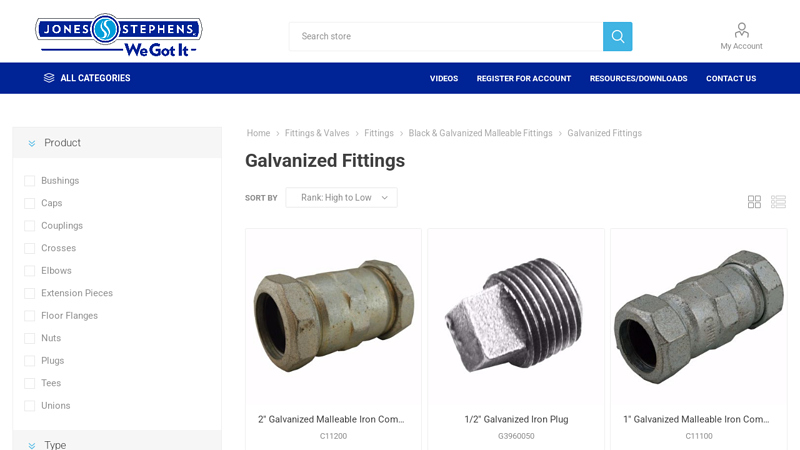

#3 Galvanized Fittings

Domain Est. 1999

Website: jonesstephens.com

Key Highlights: 2″ Galvanized Malleable Iron Compression Coupling, Long Pattern. C11200. Picture of 1/2″ Galvanized Iron Plug. 1/2″ Galvanized Iron Plug. G3960050….

#4 GCCL2

Domain Est. 2000

Website: braxtonharris.com

Key Highlights: 4-1/2″ LENGTH. MADE OF MALLEABLE IRON. 125 PSI 120 DEGREES FAHRENHEIT. COMES WITH RUBBER GASKETS & METAL WASHERS. ALL COMPRESSION COUPLING MUST BE RESTRAINED ON ……

#5 GF Industry and Infrastructure Flow Solutions

Domain Est. 2001

Website: gfps.com

Key Highlights: PRIMOFIT is a full end-load resistant compression fitting made of malleable cast iron, which is suitable for the connection of steel, PE and lead pipes with a ……

#6 Galvanized Compression Coupling

Domain Est. 2020

Website: asc-es.com

Key Highlights: Pipe Joining Systems · Pipe Fittings · Plumbing Specialties · PVC; Galvanized Compression Coupling. FIG SERIES 2948 Galvanized Compression Coupling. Comp ……

#7 Galvanized steel compression fittings

Domain Est. 2023

Website: nexaparts.com

Key Highlights: 6-day deliveryNexaparts sells galvanized steel compression fittings in all shapes and sizes, so we always have a fitting that perfectly suits your application….

Expert Sourcing Insights for Compression Fitting For Galvanized Pipe

H2: Projected Market Trends for Compression Fittings for Galvanized Pipe in 2026

As the global infrastructure and construction sectors continue to evolve, the market for compression fittings for galvanized pipe is expected to undergo notable shifts by 2026. While galvanized steel pipe remains a staple in plumbing, HVAC, and industrial applications—particularly in regions with legacy systems and cost-sensitive projects—the demand for compatible compression fittings is being influenced by technological advancements, regulatory changes, and material substitution trends.

-

Steady Demand in Repair and Retrofit Markets

By 2026, a significant portion of demand for compression fittings for galvanized pipe is projected to come from maintenance, repair, and overhaul (MRO) activities. Aging infrastructure in North America and parts of Europe will continue to rely on galvanized piping systems, especially in rural or low-pressure water supply applications. Compression fittings are favored in these scenarios due to their ease of installation without welding, making them ideal for quick repairs and system modifications. -

Competition from Alternative Materials

The long-term use of galvanized pipes is being challenged by corrosion issues over time, leading to a gradual shift toward alternatives such as PEX, CPVC, and stainless steel piping. This transition may suppress growth in new installations using galvanized pipes, indirectly affecting the demand for related compression fittings. However, the need for transition fittings that connect galvanized systems to modern piping materials is expected to create a niche but growing segment within the compression fitting market. -

Regional Market Variations

Emerging economies in Asia-Pacific, Africa, and Latin America are expected to sustain demand for galvanized pipe systems due to lower material costs and established supply chains. In these regions, compression fittings compatible with galvanized pipe will remain relevant, particularly in municipal water distribution and industrial projects. China and India, in particular, may see continued use in rural water supply and agricultural irrigation systems. -

Focus on Corrosion-Resistant Fittings

As galvanized pipe is prone to internal rust and scaling, manufacturers of compression fittings are anticipated to emphasize compatibility with aged systems and improved seal technologies. By 2026, expect increased innovation in brass and nickel-plated brass fittings that offer better resistance to galvanic corrosion when used with galvanized pipe, ensuring longer service life and leak prevention. -

Regulatory and Environmental Pressures

Environmental regulations restricting lead content in plumbing components (e.g., NSF/ANSI 61 and Lead-Free legislation in the U.S.) will continue to influence material choices. Compression fitting manufacturers will need to ensure compliance, driving a shift toward lead-free brass and recyclable materials. These regulatory standards may also accelerate the adoption of alternative piping systems, indirectly pressuring the galvanized pipe ecosystem. -

Digitalization and Supply Chain Optimization

By 2026, digital procurement platforms and B2B e-commerce are expected to streamline the distribution of compression fittings. Contractors and suppliers will increasingly rely on online catalogs with compatibility filters, enabling quick identification of fittings for galvanized pipes. This will enhance market efficiency but also increase price transparency and competition.

Conclusion:

While the overall market for new galvanized pipe installations may decline due to material advancements, the compression fitting segment for existing galvanized systems will remain resilient through 2026. Growth will be driven by maintenance needs, transitional applications, and regional demand in developing markets. Manufacturers who adapt by offering corrosion-resistant, compliant, and versatile fittings will be best positioned to capture value in this mature but enduring niche.

Common Pitfalls When Sourcing Compression Fittings for Galvanized Pipe (Quality and IP Considerations)

Sourcing compression fittings for use with galvanized pipes requires attention to both quality standards and intellectual property (IP) concerns. Overlooking key factors can lead to performance failures, safety hazards, or legal complications. Below are common pitfalls to avoid:

Poor Material Quality and Inadequate Standards Compliance

One of the most frequent issues is selecting compression fittings made from substandard materials. Galvanized pipes operate in environments prone to corrosion and high pressure, so the fitting must match these demands. Low-grade brass or incompatible alloys can lead to leaks, cracking, or accelerated deterioration. Always verify that fittings comply with recognized standards such as ASTM, ISO, or ASME. Lack of proper certification may indicate poor quality control.

Incompatibility with Galvanized Pipe Surface

Galvanized pipes have a rough, zinc-coated exterior that differs from smooth tubing. Standard compression fittings designed for copper or plastic may not create a proper seal on galvanized surfaces. Using incompatible fittings can result in thread damage or leakage. Ensure the fitting is specifically rated for use with galvanized pipe, and check for correct thread type (typically NPT for threaded connections).

Misunderstanding Compression vs. Threaded Fitting Types

A common confusion arises between true compression fittings and threaded fittings marketed as “compression-style.” True compression fittings use a ferrule and nut to compress onto the pipe, but galvanized pipes are typically joined using threaded connections. Applying a standard compression fitting to a galvanized pipe without proper adapters can compromise the joint integrity. Confirm the fitting type and application method with the manufacturer.

Lack of Intellectual Property Verification

When sourcing from overseas suppliers or third-party vendors, there’s a risk of purchasing counterfeit or IP-infringing products. Some manufacturers replicate patented designs without authorization, particularly in regions with lax IP enforcement. Using such components may expose your project or company to legal liability. Always request documentation proving design legitimacy and verify trademarks or patents with relevant IP databases.

Inadequate Pressure and Temperature Ratings

Fittings must be rated for the system’s maximum operating pressure and temperature. Sourcing fittings without verifying these specs—especially for industrial or high-demand applications—can lead to catastrophic failures. Check manufacturer datasheets and ensure ratings exceed the expected operational conditions.

Insufficient Corrosion Resistance

Even though galvanized pipes are corrosion-resistant, the fitting material must also withstand similar environments. Brass fittings that aren’t dezincification-resistant (DZR) can degrade quickly in wet or aggressive conditions. Specify DZR brass or stainless steel fittings when appropriate, particularly in potable water or outdoor installations.

Overlooking Certification and Traceability

Reputable suppliers provide traceable certifications (e.g., mill test reports, compliance certificates). The absence of documentation is a red flag. Without traceability, it’s impossible to verify material composition or manufacturing processes, increasing the risk of failure and non-compliance with industry regulations.

By being aware of these pitfalls—ranging from material quality and compatibility to legal IP concerns—you can make informed decisions when sourcing compression fittings for galvanized pipe applications.

Logistics & Compliance Guide for Compression Fitting For Galvanized Pipe

This guide outlines essential logistics considerations and compliance requirements for the procurement, transportation, storage, and use of compression fittings designed for galvanized steel pipes. Adhering to these guidelines ensures product integrity, regulatory compliance, and operational safety.

Product Identification and Specifications

Ensure all compression fittings are clearly identified with the following specifications:

– Material: Typically brass, stainless steel, or plastic (confirm compatibility with galvanized pipe)

– Size: Nominal pipe size (e.g., 1/2″, 3/4″) and thread type (e.g., NPT)

– Pressure and Temperature Rating: Must meet or exceed system requirements

– Standards Compliance: Marked per relevant industry standards (e.g., ASTM, ASME, NSF, ANSI)

– Manufacturer and Model Number: For traceability and warranty purposes

Regulatory and Industry Compliance

Compression fittings used with galvanized pipe must comply with applicable regulations and standards, including but not limited to:

– ASME B1.20.1: Standard for Pipe Threads, General Purpose (Inch)

– ASTM B62 / B63: Specifications for bronze and brass casting alloys

– NSF/ANSI 61: Drinking Water System Components – Health Effects (required for potable water applications)

– IPC (International Plumbing Code): Governs installation practices in plumbing systems

– OSHA Regulations: For workplace safety during handling and installation

– RoHS and REACH: Environmental and chemical safety compliance (especially for exports to EU)

Verify that all fittings have appropriate certification marks (e.g., NSF, UPC, CSA) when required by jurisdiction or application.

Packaging and Labeling Requirements

To maintain product quality and ensure regulatory compliance:

– Use protective packaging to prevent thread damage, corrosion, and contamination

– Label packages with:

– Product description and part number

– Quantity per package

– Manufacturer name and contact information

– Compliance markings (e.g., NSF, ASTM)

– Handling instructions (e.g., “Fragile”, “Protect from Moisture”)

– Include Safety Data Sheets (SDS) if applicable (e.g., for lubricants or coatings)

Shipping and Transportation Logistics

- Use carriers with experience in handling plumbing and industrial components

- Protect against moisture, extreme temperatures, and physical shock during transit

- Ensure proper stacking and securing in containers or trucks to prevent damage

- Maintain chain-of-custody documentation for traceability

- Comply with transportation regulations for hazardous materials if applicable (rare for dry fittings)

Storage and Inventory Management

- Store in a dry, temperature-controlled environment to prevent corrosion, especially important when in contact with galvanized surfaces prone to galvanic corrosion

- Keep fittings in original packaging until ready for use

- Implement FIFO (First In, First Out) inventory rotation

- Protect from dust, dirt, and contaminants that could affect sealing surfaces

- Segregate by size, material, and certification to avoid mix-ups

Import/Export and Customs Compliance

For international shipments:

– Classify fittings under the correct HS Code (e.g., 7412.20 for copper pipe fittings)

– Provide commercial invoices, packing lists, and certificates of origin

– Include compliance documentation (e.g., NSF certification, test reports)

– Comply with destination country’s plumbing code requirements and import regulations

– Verify tariffs, duties, and restrictions (e.g., lead content limits under U.S. Safe Drinking Water Act)

Installation and Field Use Compliance

- Follow manufacturer’s installation instructions to ensure leak-free joints and system integrity

- Use only with compatible pipe materials; avoid direct brass-to-galvanized steel connections without dielectric unions to prevent galvanic corrosion

- Ensure fittings are installed by licensed or qualified personnel where required by local code

- Inspect for damage prior to installation; do not use compromised fittings

Documentation and Traceability

Maintain comprehensive records including:

– Purchase orders and supplier certifications

– Certificates of Conformance (CoC)

– Test reports and compliance documentation

– Batch/lot numbers for traceability

– SDS (if applicable)

Environmental and Disposal Considerations

- Dispose of damaged or obsolete fittings in accordance with local recycling and environmental regulations

- Recycle metal components (brass, steel) through certified recyclers

- Avoid landfill disposal when recycling options are available

Adhering to this logistics and compliance guide ensures that compression fittings for galvanized pipe meet safety, performance, and regulatory standards throughout their lifecycle.

In conclusion, sourcing compression fittings for galvanized pipes requires careful consideration of compatibility, material quality, and application requirements. While compression fittings offer ease of installation and do not require soldering, they are generally not recommended for direct use with galvanized pipes due to potential leakage risks caused by the uneven outer diameter and rough surface of galvanized piping. For reliable performance, it is advisable to transition to a more suitable piping system (such as copper or PEX) or use threaded, flared, or push-to-connect fittings specifically designed for galvanized pipe connections. When compression fittings are necessary, ensure they are rated for use with galvanized pipes, made from durable materials like brass or stainless steel, and sourced from reputable suppliers to maintain system integrity and longevity. Proper installation and adherence to local plumbing codes are essential to ensure safety, performance, and compliance.