The global compression driver market is experiencing steady growth, driven by rising demand for high-fidelity audio systems across professional sound reinforcement, commercial installations, and live entertainment sectors. According to a 2023 report by Mordor Intelligence, the global loudspeaker market—of which compression drivers are a critical component—is projected to grow at a CAGR of approximately 5.8% from 2023 to 2028. This expansion is fueled by technological advancements in driver materials, increasing adoption in outdoor and public address systems, and the proliferation of premium audio solutions in emerging economies. Additionally, Grand View Research valued the global loudspeaker market at USD 11.7 billion in 2022, with continued growth anticipated due to integration in smart audio devices and commercial infrastructure development. As demand for efficient, high-SPL (sound pressure level) transducers rises, compression driver manufacturers are focusing on innovation in phase plugs, diaphragm materials, and thermal management to meet evolving performance standards. Against this backdrop, the following list highlights the top 10 compression driver manufacturers leading the industry in technology, reliability, and market presence.

Top 10 Compression Driver Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 [PDF] S & ERS CONE TRANSDUCERS & COMPRESSION DRIVERS

Domain Est. 1996

Website: jblpro.com

Key Highlights: Incorporates JBL’s patented Super Vented Gap™ technology for improvement in power handling capability while minimizing power compression. 2426H/J. 25MM 1″ EXIT ……

#2 Compression Driver Horn Drivers

Domain Est. 1994

Website: newark.com

Key Highlights: Free delivery over $150 · 60-day returnsFind a huge range of Compression Driver Horn Drivers at Newark Electronics. We stock a wide range of Horn Drivers, such as Horn Driver, Com…

#3 Compression Drivers

Domain Est. 1995

Website: celestion.com

Key Highlights: Our lightest weight, high frequency compression driver provides 40W continuous power handling (20Wrms AES standard) and 104dB sensitivity….

#4 Transducers

Domain Est. 1996

Website: rcf.it

Key Highlights: FERRITE COMPRESSION DRIVERS Professional compression drivers with precision-built ceramic magnetic design, advanced molding and assembly technologies….

#5 Drivers Archives

Domain Est. 1997

Website: lowellmfg.com

Key Highlights: 12 inch Coaxial Compression Speaker. 12P150. $573.00 MSRP · Compare · 12Q250: 12″ 250W Coaxial Compression Driver. 12 inch Coaxial Compression Speaker. 12Q250….

#6 Compression Drivers

Domain Est. 2000

#7 STHF-007T

Domain Est. 2000

Website: soundtown.com

Key Highlights: In stock Rating 5.0 4 The compression driver comes with a 30-oz magnet and has a power handling capability of 125W RMS with a sensitivity of 105dB….

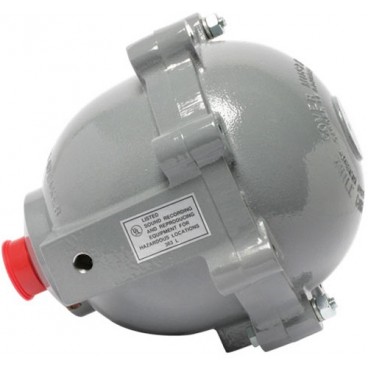

#8 Environment

Domain Est. 2007

#9 SB Audience

Domain Est. 2019

Website: sbaudience.com

Key Highlights: SB Audience is spawned from the heavyweight manufacturing of Sinar Baja Electric Indonesia, with well over 44 years of experience in development and ……

#10 News

Domain Est. 1999

Website: bcspeakers.com

Key Highlights: Come check out our latest products including the HLX and DCX series compression drivers from B&C, the ND2T driver and NTLS woofers from 18 Sound, and more from ……

Expert Sourcing Insights for Compression Driver

H2: 2026 Market Trends for Compression Drivers

The global compression driver market is poised for notable transformation by 2026, driven by advancements in audio technology, increased demand for high-efficiency sound systems, and expanded applications across commercial, professional, and consumer sectors. Compression drivers—key components in high-frequency loudspeakers used in professional audio, public address systems, and live sound reinforcement—are experiencing a shift influenced by technological innovation, material science improvements, and evolving end-user requirements.

One of the dominant trends shaping the 2026 landscape is the integration of neodymium magnet technology, which allows for lighter, more compact, and energy-efficient compression drivers. This shift supports the growing demand for portable and high-performance audio systems in live events, touring, and outdoor installations. Manufacturers are increasingly focusing on reducing weight without compromising acoustic output, making neodymium-based drivers a standard in premium product lines.

Additionally, the adoption of advanced diaphragm materials such as titanium, aluminum, and composite polymers is enhancing high-frequency clarity and durability. These materials offer superior thermal and mechanical resilience, crucial for sustained high-volume operation. By 2026, expect broader use of hybrid and multi-material diaphragms to optimize performance across frequency ranges.

Another significant trend is the rise of digitally optimized and smart audio systems. Compression drivers are being designed to work seamlessly with digital signal processing (DSP) and networked audio platforms like Dante and AVB. This enables precise control over sound dispersion, equalization, and system calibration, particularly in large-scale installations such as stadiums, airports, and corporate venues.

The expansion of the commercial audio market—especially in emerging economies—fuels demand for cost-effective yet reliable compression drivers. As urbanization and infrastructure development continue in regions like Asia-Pacific and Latin America, public address and emergency alert systems are increasingly incorporating high-efficiency drivers, driving market growth.

Furthermore, sustainability and manufacturing efficiency are becoming key differentiators. Leading manufacturers are investing in eco-friendly production techniques and recyclable materials to align with global environmental standards, a factor that will influence procurement decisions among environmentally conscious buyers by 2026.

In summary, the 2026 compression driver market is characterized by technological miniaturization, material innovation, integration with digital ecosystems, and geographic market expansion. These trends collectively point toward a more efficient, versatile, and intelligent generation of compression drivers, meeting the escalating demands of modern audio applications.

Common Pitfalls Sourcing Compression Drivers (Quality, IP)

Sourcing high-performance compression drivers requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these aspects can lead to subpar audio performance, reliability issues, and potential legal risks. Below are key pitfalls to avoid:

1. Prioritizing Cost Over Quality Components

One of the most common mistakes is selecting compression drivers based solely on price. Low-cost units often use inferior materials—such as cheap diaphragms, low-grade adhesives, or undersized voice coils—which degrade sound quality, reduce power handling, and shorten lifespan. These compromises become evident in distorted output, limited frequency response, and failure under sustained use.

Solution: Evaluate specifications critically—look for drivers with titanium or advanced polymer diaphragms, high-temperature voice coils, and robust phase plugs. Request test reports or third-party certifications (e.g., THD, power compression data) to verify performance claims.

2. Inadequate Environmental Protection (IP Rating Misinterpretation)

Compression drivers used in outdoor or harsh environments require proper Ingress Protection (IP) ratings. A frequent pitfall is assuming all “weather-resistant” drivers meet IP55 or IP65 standards. Some suppliers exaggerate protection levels or omit testing documentation.

Solution: Verify actual IP ratings with test reports. Ensure seals, gaskets, and housing materials are designed for long-term moisture and dust resistance. Confirm that both the driver and its mounting flange are protected, not just the front waveguide.

3. Ignoring Manufacturing Consistency and Tolerances

Even if a driver’s design is sound, inconsistent manufacturing processes can result in unit-to-unit variations. Poor quality control leads to mismatched drivers in multi-unit arrays, causing phase issues and uneven sound coverage.

Solution: Source from manufacturers with documented quality management systems (e.g., ISO 9001). Request batch testing data and consider conducting incoming inspections.

4. Overlooking Intellectual Property Risks

Using or sourcing compression drivers that infringe on patented technologies (e.g., waveguide designs, phase plug geometry, cooling systems) exposes buyers to legal liability. Some suppliers, especially in less-regulated markets, produce clones of established OEM designs.

Solution: Conduct due diligence on the supplier’s design origins. Prefer vendors who license technology or have their own patented innovations. Include IP indemnification clauses in procurement contracts.

5. Relying Solely on Datasheet Specifications

Datasheets often present idealized performance under laboratory conditions. Real-world factors like thermal compression, long-term material fatigue, and mounting constraints are rarely reflected.

Solution: Request real-world performance data, including power compression curves over time, and conduct field testing under expected operating conditions. Engage in sample trials before large-scale procurement.

6. Poor Supply Chain Transparency

Lack of visibility into the supply chain increases risks of counterfeit components, inconsistent quality, and disruption. Some distributors obscure the original manufacturer or source from multiple unvetted factories.

Solution: Work directly with OEMs or authorized distributors. Require full traceability of components and manufacturing locations.

By addressing these pitfalls proactively, buyers can ensure they source compression drivers that deliver reliable performance, meet environmental demands, and avoid legal complications.

Logistics & Compliance Guide for Compression Driver

Product Classification & Regulatory Overview

Compression drivers, used in professional audio systems, are electro-acoustic transducers that require adherence to both logistics standards and regulatory requirements. These components are typically classified under Harmonized System (HS) codes related to loudspeakers or electro-acoustic transducers (e.g., 8518.21 or 8518.29, depending on specifications). Compliance with international trade regulations, product safety standards, and environmental directives is essential for global distribution.

Packaging & Handling Requirements

Proper packaging is critical to prevent damage during transit. Compression drivers should be packed in rigid, corrugated cardboard boxes with internal cushioning (e.g., foam inserts or molded pulp) to protect the diaphragm, phase plug, and terminals. Avoid stacking heavy items on packed units. Label packages with “Fragile,” “This Side Up,” and any applicable handling icons. Ensure all packaging materials are recyclable and compliant with regional environmental regulations such as the EU Packaging Waste Directive.

Import/Export Documentation

Accurate documentation is required for customs clearance. Essential documents include a commercial invoice, packing list, bill of lading or air waybill, and a certificate of origin. For destinations requiring conformity assessment, provide technical documentation, including product specifications, circuit diagrams, and user manuals. Where applicable, include an Export Control Classification Number (ECCN) to verify no ITAR or dual-use restrictions apply.

Safety & Electromagnetic Compliance

Compression drivers must comply with electrical safety and electromagnetic compatibility (EMC) standards in target markets. In the European Union, adherence to the Low Voltage Directive (LVD) and EMC Directive is mandatory, often demonstrated via CE marking. In the United States, compliance with FCC Part 15 (for unintentional radiators) may be required if the driver is part of an active system. While standalone drivers typically do not emit significant EMI, integration context must be considered.

Environmental & Substance Regulations

Ensure compliance with restrictions on hazardous substances. The EU’s RoHS (Restriction of Hazardous Substances) Directive limits the use of lead, mercury, cadmium, and other substances in electrical equipment. Provide a RoHS compliance declaration or material declaration (e.g., using IPC-1752 standards). Additionally, comply with REACH regulations regarding chemical substances, and consider conflict minerals reporting if applicable under the U.S. Dodd-Frank Act.

Labeling & Marking Requirements

Each unit or packaging must include permanent labeling with key information: manufacturer name, model number, electrical ratings (impedance, power handling), and compliance marks (e.g., CE, UKCA, or FCC). Avoid misleading claims. Labels must be legible, durable, and placed in accordance with local regulatory requirements.

Transportation & Shipping Considerations

Use carriers experienced in handling sensitive electronic components. Avoid extreme temperatures and high humidity during transit. For air freight, comply with IATA Dangerous Goods Regulations if batteries or other regulated materials are included in a complete assembly. Sea freight containers should be sealed and protected against moisture, especially for extended voyages.

End-of-Life & Recycling Compliance

In markets such as the EU, producers may be responsible for end-of-life take-back under the WEEE (Waste Electrical and Electronic Equipment) Directive. Register with national WEEE compliance schemes and provide take-back information to customers. Design for disassembly and recyclability to support circular economy goals.

Recordkeeping & Audit Preparedness

Maintain comprehensive records of compliance certifications, test reports, supply chain due diligence, and customer communications for a minimum of 10 years, as required in some jurisdictions. Be prepared for audits by regulatory authorities or certification bodies to demonstrate ongoing compliance.

Regional Compliance Variations

Account for regional differences:

– North America: FCC and UL certification may be required for full systems.

– European Union: CE marking with technical file and EU Declaration of Conformity.

– United Kingdom: UKCA marking for Great Britain; CE still accepted in Northern Ireland.

– China: CCC certification may apply if the driver is part of a regulated audio product.

Verify specific requirements with local regulatory experts before market entry.

Conclusion for Sourcing Compression Drivers

In conclusion, sourcing compression drivers requires a strategic approach that balances performance requirements, cost efficiency, supplier reliability, and long-term supply chain sustainability. Through evaluation of technical specifications—such as sensitivity, power handling, frequency response, and diaphragm material—alongside supplier capabilities, lead times, quality certifications, and compliance standards, an informed sourcing decision can be made.

Prioritizing suppliers with a proven track record in audio component manufacturing, coupled with strong quality control and responsive customer support, ensures consistent product performance and minimizes production risks. Additionally, considering total cost of ownership—not just unit price—enables better value assessment, factoring in logistics, warranty, and potential downtime.

Ultimately, successful sourcing of compression drivers supports the development of high-performance audio systems while maintaining scalability, reliability, and cost-effectiveness across product lines. Ongoing supplier relationship management and market monitoring will further enhance sourcing agility and competitiveness in the evolving audio equipment landscape.

![[PDF] S & ERS CONE TRANSDUCERS & COMPRESSION DRIVERS](https://www.sohoinchina.com/wp-content/uploads/2026/01/pdf-s-ers-cone-transducers-compression-drivers-364.jpg)