The global commercial stair railing market is experiencing steady growth, driven by increasing construction activities, stringent safety regulations, and rising demand for aesthetically pleasing architectural finishes in commercial buildings. According to a report by Mordor Intelligence, the global architectural railing systems market was valued at USD 8.7 billion in 2022 and is projected to grow at a CAGR of 5.8% from 2023 to 2028. This growth is further supported by urbanization trends, infrastructure modernization, and the expansion of commercial real estate—particularly in sectors such as retail, hospitality, and healthcare. As building codes increasingly emphasize occupant safety and accessibility, the role of reliable, code-compliant stair railing systems has become more critical than ever. In this competitive landscape, a select group of manufacturers stand out for their innovation, product durability, design versatility, and adherence to international safety standards. Below are the top 10 commercial stair railing manufacturers shaping the industry with proven performance and scalable solutions.

Top 10 Commercial Stair Railing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

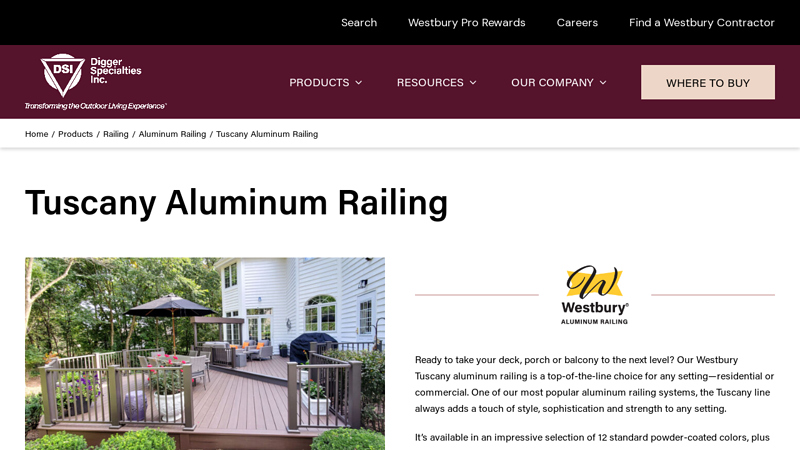

#1 Westbury Tuscany Aluminum Railing

Domain Est. 1998

Website: diggerspecialties.com

Key Highlights: Rating 5.0 · Review by Cody VanceDSI Westbury Tuscany aluminum railing sets the standard for premium quality aluminum deck railing that enhances the beauty of decks, porches a…

#2 Vista Railings: Aluminum Railing Manufacturers

Domain Est. 1999

Website: vistarailings.com

Key Highlights: Vista Railings provides premium aluminum railing and glass railing solutions that meet or exceed the quality standards and safety demands of today’s family ……

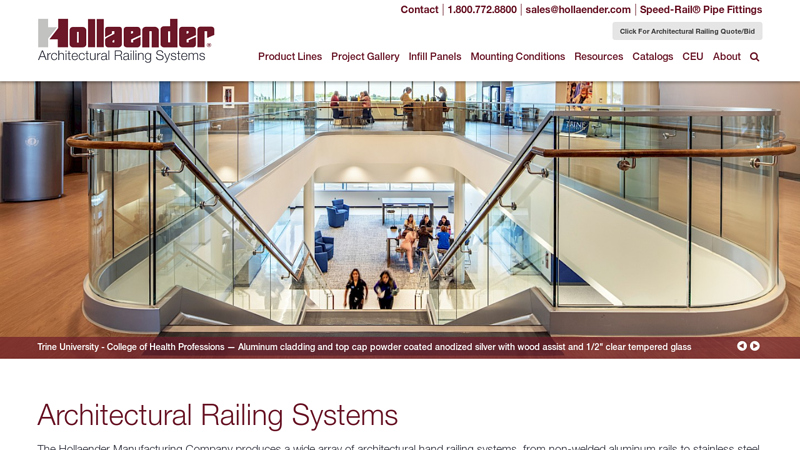

#3

Domain Est. 1996

Website: architecturalhandrail.hollaender.com

Key Highlights: The Hollaender Manufacturing Company produces a wide array of architectural hand railing systems, from non-welded aluminum rails to stainless steel ……

#4 Commercial Railing Systems

Domain Est. 1999

Website: liversbronze.com

Key Highlights: Livers Bronze creates commercial railing systems made from stainless steel, bronze, glass, perforated metal, and more….

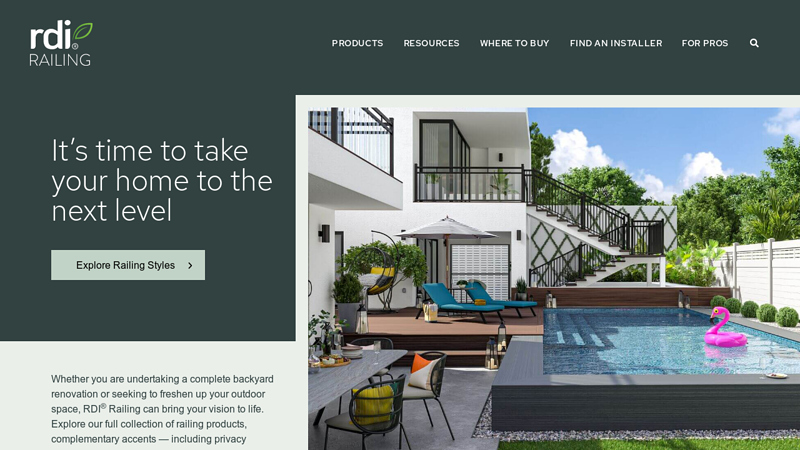

#5 RDI Railing

Domain Est. 2003

Website: rdirail.com

Key Highlights: Shop RDI’s versatile product offerings in commercial and residential railings, lighting and more. Find LED lights, decorative accents and ADA-compliant ……

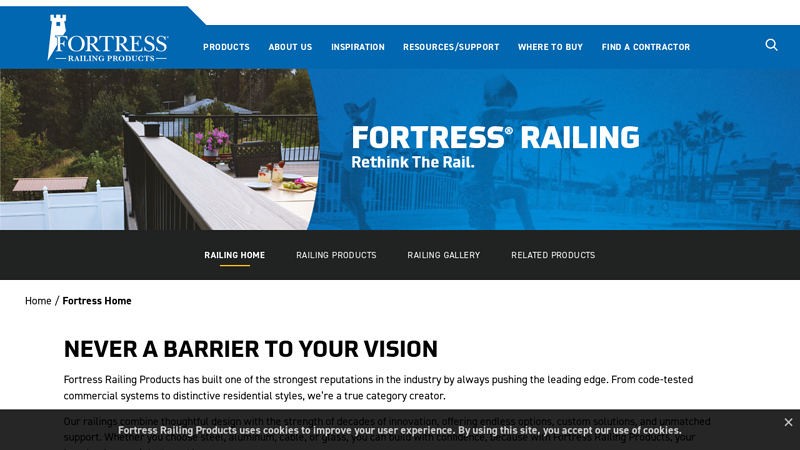

#6 Fortress Railing

Domain Est. 2006

Website: fortressrailing.com

Key Highlights: From commercial code-tested stair systems to stylish residential deck railing designs, Fortress Railing delivers strength, safety, and style….

#7 Feeney

Domain Est. 2008

Website: feeneyinc.com

Key Highlights: Discover the combination of beauty, functionality and durability of Feeney luxury cable and aluminum railings, awnings, architectural rods and more….

#8 Promenaid

Domain Est. 2009

Website: promenaid.com

Key Highlights: Our commitment to style and simplicity sets us apart from all other handrails. From start to finish, we make the process easy, quick and hassle-free….

#9 Century Aluminum Railings

Domain Est. 2012

Website: centuryrailings.com

Key Highlights: Make your deck or patio project a reality with Century glass & aluminum railings. Scenic, Picket, Glass & Pipe Railing systems manufactured in Canada….

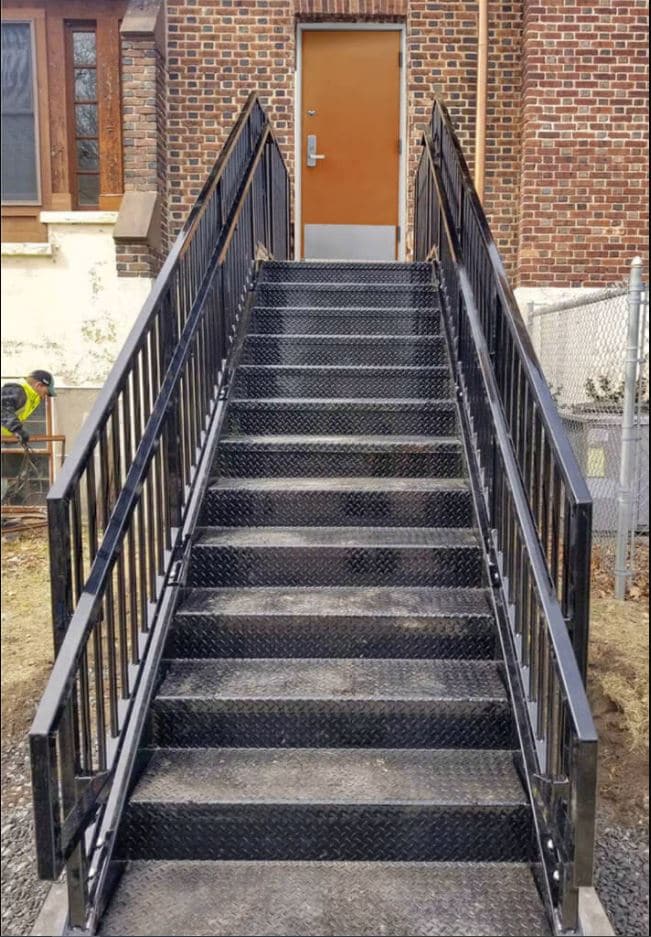

#10 Metal Handrails & Stair Railings Made in the USA

Domain Est. 2021

Website: optimumrails.com

Key Highlights: Free delivery 30-day returnsBuy customizable handrails and stair railings online. Our hand railings are made in the USA with the highest quality materials & craftsmanship….

Expert Sourcing Insights for Commercial Stair Railing

2026 Market Trends for Commercial Stair Railing

The commercial stair railing market is poised for significant evolution by 2026, driven by shifting priorities in architecture, sustainability, safety regulations, and material innovation. As construction rebounds and urbanization continues, key trends will reshape demand, design preferences, and technological integration in this essential building component.

Sustainability and Eco-Friendly Materials Driving Demand

Environmental responsibility is becoming a cornerstone of commercial construction, directly influencing stair railing choices. Architects and developers are increasingly specifying materials with low embodied carbon, high recyclability, and sustainable sourcing. Recycled aluminum and steel are gaining favor over virgin metals due to their durability and reduced environmental impact. Additionally, bio-based composites and sustainably harvested hardwoods with certifications like FSC are entering premium market segments. By 2026, green building standards such as LEED and BREEAM will likely mandate or strongly incentivize the use of sustainable railing systems, pushing manufacturers to innovate with closed-loop production and low-VOC finishes.

Integration of Smart Technologies and IoT

The Internet of Things (IoT) is beginning to permeate building infrastructure, and commercial stair railings are no exception. By 2026, expect to see growth in “smart railings” equipped with embedded sensors for occupancy monitoring, safety alerts, and energy-efficient lighting integration. For example, motion-activated LED strips within railings can enhance wayfinding in low-light conditions while reducing energy consumption. In high-traffic or healthcare environments, railings may incorporate touchless hand sanitizing dispensers or air quality sensors. While still in early adoption, these intelligent features will appeal to smart building developers aiming for operational efficiency and enhanced user experience.

Emphasis on Universal Design and Accessibility

Accessibility standards are expanding beyond compliance to embrace inclusive, universal design principles. The 2026 market will favor stair railing systems that accommodate diverse users, including the elderly, disabled, and children. This includes consistent handrail heights, improved grip ergonomics, enhanced contrast for visibility, and continuity at landings and turns. Designers will increasingly integrate railings seamlessly with other accessibility features, such as tactile indicators and audible signals, especially in public and civic buildings. Regulatory frameworks like the ADA and international equivalents will continue to tighten, pushing innovation in inclusive railing solutions.

Minimalist Aesthetics and Architectural Integration

Contemporary commercial architecture favors clean lines, transparency, and open spaces—trends that are reshaping stair railing design. Frameless glass railings with discreet clamping systems and slender metal profiles (particularly in black steel, brushed nickel, or matte finishes) are becoming dominant in offices, retail spaces, and hospitality venues. The focus is on creating visual continuity and maximizing natural light. By 2026, customization and seamless integration with the overall building aesthetic will be key differentiators, with manufacturers offering modular systems that allow for rapid installation and design flexibility.

Rise in Prefabrication and Modular Systems

To meet tight construction schedules and reduce on-site labor costs, the industry is shifting toward prefabricated and modular stair railing solutions. Off-site manufacturing ensures higher quality control, consistency, and faster project completion. By 2026, modular systems—especially those compatible with mass timber and modular construction methods—will be in high demand. These systems allow for easy customization, scalability, and retrofitting, making them ideal for adaptive reuse projects and rapidly constructed commercial developments.

In conclusion, the 2026 commercial stair railing market will be defined by sustainability, technological integration, inclusivity, aesthetic refinement, and construction efficiency. Stakeholders who embrace these trends—manufacturers, architects, and contractors—will be best positioned to lead in an increasingly competitive and design-conscious industry.

Common Pitfalls When Sourcing Commercial Stair Railing: Quality and Intellectual Property Concerns

When sourcing commercial stair railing systems, businesses often encounter critical challenges related to both product quality and intellectual property (IP) compliance. Overlooking these areas can result in safety hazards, regulatory violations, costly delays, and legal liabilities. Below are key pitfalls to avoid.

Compromised Material Quality and Workmanship

One of the most frequent issues is receiving stair railings made from substandard materials or with poor craftsmanship. Suppliers may use thinner gauge metals, inferior finishes, or non-compliant alloys to cut costs. This can lead to premature corrosion, structural weakness, and failure to meet building codes such as the International Building Code (IBC) or OSHA standards. Always verify material certifications (e.g., ASTM standards) and conduct third-party inspections when possible.

Inadequate Compliance with Safety and Accessibility Codes

Commercial stair railings must adhere to strict safety regulations, including height requirements, load capacity, and graspability. Sourcing from vendors unfamiliar with local or international codes (e.g., ADA, IBC, or ISO standards) can result in installations that fail inspections or pose liability risks. Ensure suppliers provide code-compliant design documentation and testing reports.

Lack of Traceability and Certification

Reputable stair railing systems should come with full traceability—mill test reports, fabrication records, and installation guidelines. Sourcing without proper documentation makes it difficult to verify quality or assign responsibility in case of failure. Avoid suppliers who cannot provide a clear chain of custody or product certifications.

Intellectual Property Infringement Risks

Using or sourcing stair railing designs that replicate patented or copyrighted products—such as unique baluster patterns, connection systems, or branded modular components—can lead to IP litigation. Some suppliers may offer “look-alike” products that infringe on protected designs. Conduct due diligence by verifying design rights and requiring suppliers to warrant IP compliance in contracts.

Unauthorized Use of Brand Names or Specifications

A common IP-related pitfall is specifying or purchasing products labeled as conforming to a particular brand (e.g., “meets ABC Railings specs”) without authorization. Even if the product is functionally equivalent, this practice may constitute trademark or false advertising violations. Use performance-based specifications instead of brand-specific language unless licensing agreements are in place.

Counterfeit or Gray Market Products

Purchasing from unauthorized distributors or overseas suppliers can result in counterfeit railings that mimic high-end brands but lack quality control and IP legitimacy. These products may bypass safety testing and lack warranty support. Always source through authorized channels and verify supplier credentials.

Failure to Protect Custom Designs

If your project involves a proprietary railing design, failing to secure IP protections (e.g., design patents or copyrights) or include confidentiality agreements with suppliers can expose your innovation to copying. Ensure contracts include clauses prohibiting reverse engineering and unauthorized reproduction.

Avoiding these pitfalls requires thorough supplier vetting, clear contractual terms, and proactive legal and technical oversight. Prioritizing quality assurance and IP compliance safeguards both the integrity of the built environment and your organization’s reputation.

Logistics & Compliance Guide for Commercial Stair Railing

Proper logistics and compliance are critical when sourcing, transporting, installing, and maintaining commercial stair railings. This guide outlines best practices and regulatory requirements to ensure safety, efficiency, and adherence to standards.

Regulatory Standards and Building Codes

Commercial stair railings must comply with national and local building codes to ensure occupant safety. Key standards include:

- International Building Code (IBC): Specifies requirements for height (typically 34–38 inches), graspability, structural strength, and continuity of handrails.

- Americans with Disabilities Act (ADA) Standards: Mandates accessible design, including handrail height (34–38 inches), smooth surfaces, and extensions at top and bottom of stairs.

- OSHA Regulations (for workplaces): Requires guardrails and handrails in industrial and commercial environments to prevent falls.

- Local Jurisdiction Amendments: Always verify with local authorities, as municipal codes may impose additional or stricter requirements.

Failure to comply can result in fines, project delays, or safety hazards.

Material Selection and Certification

Choose materials that meet fire safety, durability, and environmental standards:

- Metal Railings (Stainless Steel, Aluminum, Powder-Coated Steel): Must meet ASTM or EN standards for structural integrity and corrosion resistance.

- Glass Railings: Tempered or laminated safety glass compliant with CPSC 16 CFR 1201 or ANSI Z97.1.

- Wood Railings: Should use treated lumber complying with AWPA standards and fire-retardant treatments where required.

- Certifications: Ensure materials come with mill certificates, fire ratings, and test reports (e.g., ASTM E84 for flame spread).

Packaging and Transportation Logistics

To prevent damage during shipping:

- Protective Packaging: Use corner guards, foam wraps, and custom crates for fragile components like glass panels or polished metals.

- Labeling: Clearly mark packages with handling instructions (e.g., “Fragile,” “This Side Up”) and project identifiers.

- Shipping Method: Use flatbed trucks for long sections or crated loads; consider just-in-time delivery to reduce on-site storage.

- Insurance: Confirm freight insurance covers damage or loss, especially for custom or high-value railings.

Site Handling and Storage

On-site procedures should preserve product integrity:

- Unloading: Use appropriate equipment (e.g., forklifts, cranes) to avoid bending or scratching.

- Storage: Store materials indoors or under cover; elevate from ground to prevent moisture damage.

- Inventory Management: Track components to ensure all parts are accounted for before installation.

Installation and Quality Assurance

Installation must follow approved shop drawings and manufacturer specifications:

- Pre-Installation Inspection: Verify dimensions, anchoring points, and substrate conditions.

- Qualified Installers: Use certified or trained personnel familiar with code requirements.

- Inspection and Testing: Conduct post-installation load tests (per IBC 1607.8) and visual inspections for alignment and finish quality.

- Documentation: Maintain records of inspections, test results, and as-built drawings for compliance audits.

Maintenance and Ongoing Compliance

After installation, ensure long-term safety and code adherence:

- Routine Inspections: Schedule periodic checks for loose fasteners, corrosion, or wear.

- Maintenance Logs: Document repairs and cleaning activities.

- Updates: Stay informed about code changes and retrofit railings if necessary to meet new standards.

Documentation and Compliance Records

Retain the following for audits and certifications:

- Approved engineering drawings and permits

- Material test reports and certifications

- Installation inspection reports

- As-built documentation

- Maintenance records

Proper documentation supports compliance and simplifies future renovations or inspections.

By following this logistics and compliance guide, stakeholders can ensure commercial stair railings are safely delivered, correctly installed, and fully compliant with all applicable regulations.

Conclusion for Sourcing Commercial Stair Railing

Sourcing commercial stair railing requires a strategic balance between safety compliance, durability, aesthetics, and cost-effectiveness. After thorough evaluation of materials, design standards, and supplier capabilities, it is evident that selecting the right railing system is critical not only for meeting building codes and accessibility requirements (such as OSHA, IBC, and ADA) but also for enhancing the overall functionality and visual appeal of the space.

Stainless steel, aluminum, and tempered glass are among the most reliable material options, each offering unique advantages in terms of strength, corrosion resistance, and modern design integration. Partnering with reputable manufacturers and suppliers ensures product quality, timely delivery, and adherence to project specifications. Additionally, considering long-term maintenance and lifecycle costs contributes to a more sustainable and economical investment.

In conclusion, effective sourcing of commercial stair railing involves comprehensive planning, attention to regulatory standards, and collaboration with trusted vendors. By prioritizing safety, quality, and design alignment, stakeholders can deliver a solution that enhances both the safety and aesthetic value of commercial environments for years to come.