The global sous vide market is experiencing robust growth, driven by rising demand for precision cooking in commercial kitchens, expanding foodservice automation, and the increasing adoption of advanced culinary technologies. According to a 2023 report by Mordor Intelligence, the global vacuum cooking (sous vide) equipment market was valued at USD 1.25 billion and is projected to grow at a CAGR of 6.8% from 2023 to 2028. Similarly, Grand View Research reported a compound annual growth rate of approximately 7.1% for the commercial food preparation equipment market, citing sous vide technology as a key growth driver due to its consistency, efficiency, and scalability in high-volume operations. As restaurants, hotels, and central kitchens increasingly prioritize meal quality and operational repeatability, the demand for reliable, high-performance commercial sous vide machines has intensified. This growing market momentum has fostered innovation and competition among leading manufacturers worldwide. In this analysis, we identify the top seven commercial sous vide machine manufacturers shaping the industry through technological advancement, reliability, and market reach.

Top 7 Commercial Sous Vide Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Sous Vide Equipment for Food Manufacturers

Domain Est. 2010

Website: dcnorris.com

Key Highlights: Our industrial sous vide machines and smaller commercial models enable overnight, unattended cooking, maximising efficiency without compromising results….

#2 Steam Sous Vide

Domain Est. 2005

Website: unifiedbrands.net

Key Highlights: As the pioneer of sous vide commercial foodservice equipment technology, CapKold delivers convenience and innovation with our steam-based sous vide units….

#3 Wholesale Commercial Inquiries: – SousVide Supreme

Domain Est. 2009

Website: sousvidesupreme.com

Key Highlights: SousVide Supreme is the world’s finest water oven for home cooks and culinary professionals. The all-in-one, easy to use sous vide cooking appliance for …Missing: machine manufa…

#4 Sous Vide

Domain Est. 2015

Website: dcnorrisna.com

Key Highlights: DC Norris North America supplies a range of equipment designed to empower fully automated sous vide cooking at both commercial and industrial scales….

#5 About Sous Vide

Domain Est. 1997

Website: cuisinesolutions.com

Key Highlights: What is sous vide? French for “under vacuum,” sous vide is a cooking method in which food is sealed and cooked in water at precise times and temperatures….

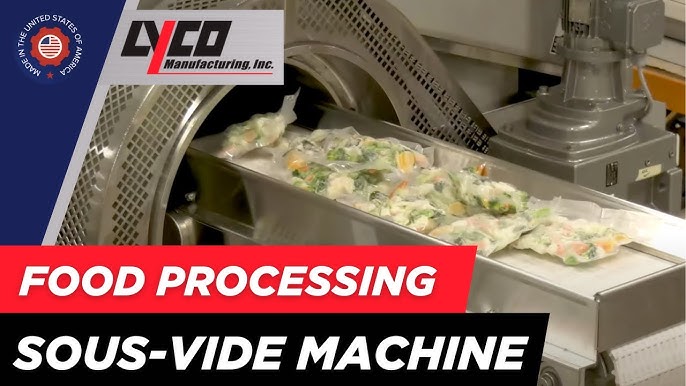

#6 Sous Vide Processing

Domain Est. 1998 | Founded: 1988

Website: lycomfg.com

Key Highlights: Lyco has been cooking and cooling with sous vide since 1988. Products include refried beans, soups, chowders, pizza sauce, condiments, mashed potatoes, ……

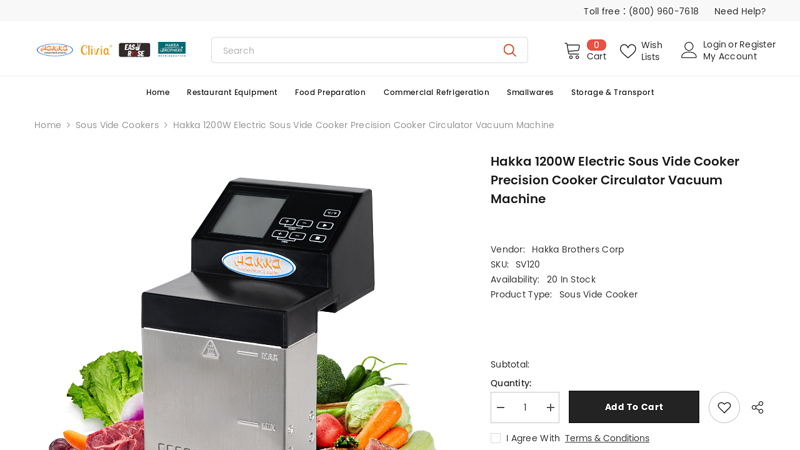

#7 Hakka 1200W Electric Sous Vide Cooker Precision Cooker …

Domain Est. 2021

Website: hakkabros.com

Key Highlights: In stock Free deliveryThe Hakka Sous Vide Cooker allows for precise temperature control from 5 to 99℃, ensuring the perfect cooking temperature for any recipe….

Expert Sourcing Insights for Commercial Sous Vide Machine

2026 Market Trends for Commercial Sous Vide Machines

Rising Demand in the Foodservice Industry

By 2026, the commercial sous vide machine market is expected to experience significant growth, driven by increasing demand in restaurants, hotels, and catering services. Chefs and culinary professionals continue to adopt sous vide cooking for its precision, consistency, and ability to enhance flavor and texture. High-end dining establishments and fast-casual chains alike are integrating sous vide into their kitchens to streamline operations and ensure food quality across multiple locations.

Technological Advancements and Smart Integration

A key trend shaping the 2026 landscape is the integration of smart technology into commercial sous vide equipment. Manufacturers are focusing on IoT-enabled devices with remote monitoring, programmable cooking profiles, and real-time temperature tracking via mobile apps. These features improve operational efficiency, reduce labor costs, and ensure compliance with food safety standards—making them especially appealing to large-scale foodservice providers.

Expansion in Non-Traditional Foodservice Sectors

Beyond traditional restaurants, sous vide machines are gaining traction in non-traditional sectors such as meal kit delivery services, ghost kitchens, and healthcare facilities. The rise of off-premise dining and convenience-focused food models aligns perfectly with the batch-cooking capabilities and shelf-life extension offered by sous vide. In healthcare and senior care, the method’s ability to preserve nutrients and ensure food safety is a major driver.

Focus on Energy Efficiency and Sustainability

With growing emphasis on sustainability, manufacturers are developing energy-efficient models that reduce water and power consumption. By 2026, eco-friendly commercial sous vide machines with advanced insulation, low-wattage heating elements, and recyclable materials are expected to dominate product innovation. Regulatory pressures and corporate sustainability goals are pushing foodservice operators to prioritize green kitchen equipment.

Regional Market Growth and Emerging Economies

While North America and Western Europe remain key markets due to established culinary innovation and high restaurant density, Asia-Pacific and Latin America are emerging as high-growth regions. Countries like China, India, and Brazil are witnessing rising disposable incomes, urbanization, and interest in Western culinary techniques—fueling demand for commercial sous vide solutions in both urban restaurants and hotel chains.

Competitive Landscape and Market Consolidation

The commercial sous vide machine market is becoming increasingly competitive, with established players such as Julabo, PolyScience, and Henny Penny expanding their product portfolios. At the same time, new entrants are introducing cost-effective, modular units tailored to small and mid-sized businesses. Strategic partnerships, mergers, and acquisitions are expected to increase by 2026 as companies aim to enhance distribution networks and technological capabilities.

Conclusion

The 2026 outlook for commercial sous vide machines is highly positive, characterized by technological innovation, expanding applications, and global market growth. As foodservice operators prioritize consistency, efficiency, and sustainability, sous vide technology is poised to become a standard in modern commercial kitchens worldwide.

Common Pitfalls When Sourcing Commercial Sous Vide Machines (Quality & Intellectual Property)

Sourcing commercial sous-vide machines for food service or production environments requires careful evaluation to ensure long-term reliability, food safety, and legal compliance. Overlooking key aspects related to quality and intellectual property (IP) can lead to operational failures, legal risks, and reputational damage. Below are common pitfalls to avoid:

Poor Build Quality and Material Selection

Many low-cost commercial sous-vide units use substandard materials such as thin-gauge stainless steel, non-food-grade plastics, or inadequate insulation. This compromises durability, temperature stability, and hygiene. Poorly constructed water baths may corrode, warp, or harbor bacteria over time. Always verify material specifications and prioritize machines built with commercial-grade 304 or 316 stainless steel and IP-rated components for wet environments.

Inaccurate or Inconsistent Temperature Control

Precision is critical in sous-vide cooking. Some machines, especially unbranded or budget models, suffer from poor temperature calibration or wide variance (±1°C or more), leading to undercooked or overcooked food. This increases food safety risks and impacts consistency. Ensure units include NIST-traceable calibration certificates and have undergone third-party performance testing.

Lack of IP Protection and Certification

Operating in commercial kitchens demands equipment that meets safety and environmental standards. Machines lacking proper Ingress Protection (IP) ratings—such as IPX4 or higher—are vulnerable to water damage and electrical hazards in high-moisture environments. Always confirm the unit’s IP rating aligns with kitchen conditions and complies with local electrical codes (e.g., UL, CE, ETL).

Absence of Intellectual Property Due Diligence

Sourcing from manufacturers that replicate patented designs or use counterfeit components exposes buyers to legal liability. Some suppliers may offer “branded look-alike” models infringing on patents held by established brands (e.g., immersion circulators with copied UI or mechanical designs). Conduct IP checks through patent databases and request proof of design or utility model ownership from the supplier to avoid infringement claims.

Inadequate After-Sales Support and Spare Parts Availability

Low-quality or IP-infringing machines often come from manufacturers with limited technical support or spare parts networks. When critical components fail, extended downtime can disrupt operations. Verify that the supplier offers comprehensive warranties, accessible service centers, and long-term parts availability—key indicators of legitimate, quality-focused production.

Hidden Software or Firmware Limitations

Some sous-vide units rely on proprietary software for temperature profiling or network connectivity. Machines without proper licensing or using pirated firmware may malfunction or breach software copyright laws. Ensure firmware is legally licensed and that updates are supported—especially important for IoT-enabled or cloud-connected models used in multi-location operations.

Avoiding these pitfalls requires due diligence in vetting suppliers, verifying certifications, and understanding both the physical and legal dimensions of the equipment. Prioritizing quality construction and IP compliance protects your investment and ensures safe, consistent culinary performance.

Logistics & Compliance Guide for Commercial Sous Vide Machine

Introduction

This guide outlines the essential logistics and compliance considerations for the procurement, installation, operation, and maintenance of a commercial sous vide machine in foodservice environments. Adhering to these guidelines ensures food safety, regulatory compliance, and efficient operational performance.

Regulatory Compliance

Commercial sous vide machines must comply with local, state, and federal food safety regulations. Key compliance areas include:

– FDA Food Code: Follow time and temperature requirements for cooking, chilling, and holding sous vide foods. Ensure proper recordkeeping of time/temperature logs.

– HACCP Plan Integration: Incorporate sous vide procedures into your Hazard Analysis and Critical Control Points (HACCP) plan, identifying critical control points such as cooking temperature, chilling rate, and storage duration.

– Local Health Department Approval: Verify that sous vide operations are permitted by your local health authority. Some jurisdictions require pre-approval or variance for sous vide cooking.

– Equipment Certification: Ensure the machine is NSF/ANSI Standard 4 or 8 certified, indicating it meets sanitation and construction standards for commercial food equipment.

Equipment Procurement & Logistics

- Vendor Selection: Source machines from reputable suppliers offering commercial-grade equipment with technical support and warranty coverage.

- Shipping & Delivery: Confirm delivery timelines, access requirements (elevator size, door clearance), and need for liftgate service. Inspect the unit upon arrival for damage.

- Installation Requirements:

- Ensure adequate space with proper ventilation.

- Verify electrical requirements (voltage, amperage, phase) match facility infrastructure.

- Connect to a dedicated circuit to prevent overloading.

- Level the unit and secure it to prevent movement during operation.

Operational Safety & Maintenance

- Staff Training: Train kitchen personnel on safe sous vide practices, including proper bag sealing, time/temperature settings, chilling procedures, and handling of vacuum-sealed foods.

- Cleaning & Sanitation: Clean and sanitize the water bath and exterior surfaces daily using non-abrasive cleaners. Follow manufacturer guidelines for descaling and deep cleaning.

- Preventative Maintenance: Schedule routine inspections for heating elements, water pumps, and control systems. Replace worn seals and filters as needed.

Food Safety Protocols

- Temperature Monitoring: Calibrate and verify accuracy of temperature probes regularly (at least monthly). Use a separate calibrated thermometer to validate water bath temperature.

- Chilling Procedures: Rapidly chill cooked sous vide products using an ice-water bath or blast chiller to reach 41°F (5°C) or below within 2 hours.

- Labeling & Dating: Clearly label all sous vide packages with product name, cook date, use-by date, and reheating instructions.

- Reheating Guidelines: Reheat refrigerated sous vide products to an internal temperature of 165°F (74°C) for at least 15 seconds before serving, unless previously cooked and served immediately.

Recordkeeping & Documentation

Maintain logs for:

– Daily time and temperature monitoring

– Equipment calibration and maintenance

– Staff training completion

– HACCP plan reviews and updates

These records support compliance audits and demonstrate due diligence in food safety practices.

Conclusion

Proper logistics planning and strict adherence to compliance standards are critical when operating a commercial sous vide machine. By following this guide, foodservice operators can ensure safe, legal, and efficient use of sous vide technology while minimizing risk and maximizing product quality.

Conclusion: Sourcing a Commercial Sous Vide Machine

After careful evaluation of market options, performance requirements, budget considerations, and operational needs, sourcing a commercial sous vide machine is a strategic investment that can significantly enhance kitchen efficiency, consistency, and food quality in a professional setting. The right machine should align with your volume demands, available kitchen space, ease of use, durability, and compliance with health and safety standards.

Key factors such as precise temperature control, scalability, brand reliability, warranty, and after-sales support must be prioritized during the selection process. Established brands like SousVide Supreme, Anova Commercial, PolyScience, and Julabo offer robust solutions tailored to commercial kitchens, each with distinct advantages depending on your use case—whether for high-volume restaurants, catering operations, or specialized culinary applications.

Ultimately, the ideal sous vide system will streamline preparation, reduce waste, improve food safety, and support culinary innovation. By investing in a high-quality, appropriately sized commercial sous vide machine, foodservice operators can achieve superior results while maximizing return on investment and maintaining a competitive edge in today’s demanding gastronomic landscape.