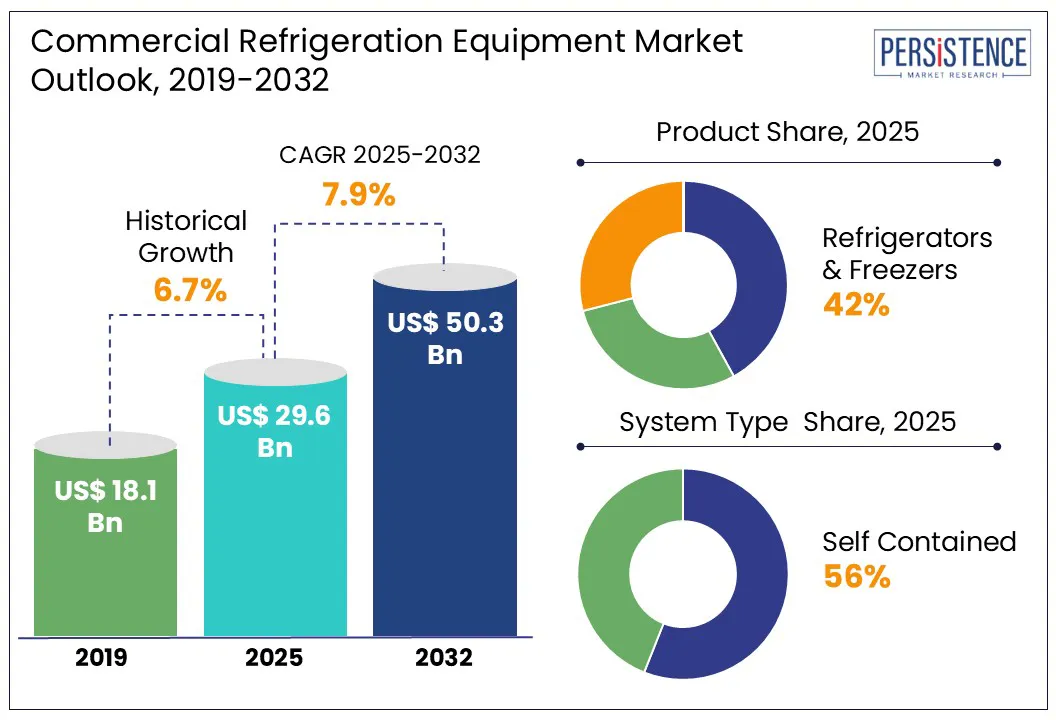

The global commercial refrigeration market is experiencing robust expansion, driven by rising demand from the foodservice, retail, and healthcare sectors. According to Grand View Research, the market was valued at USD 85.6 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by increasing urbanization, stricter food safety regulations, and the proliferation of convenience stores and cold chain logistics. Additionally, Mordor Intelligence forecasts sustained momentum, with energy-efficient and smart refrigeration solutions gaining prominence amid sustainability initiatives and digital transformation in retail environments. As demand escalates, manufacturers are innovating to deliver reliable, eco-friendly units that meet diverse commercial needs. In this evolving landscape, a select group of industry leaders stands out for their technological advancements, global reach, and market share—shaping the future of commercial refrigeration.

Top 10 Commercial Fridge Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Beverage

Domain Est. 1996

Website: beverage-air.com

Key Highlights: Your complete refrigeration source. Beverage-Air is a leading domestic manufacturer committed to producing American made equipment for the foodservice market….

#2 True Manufacturing

Domain Est. 1997

Website: truemfg.com

Key Highlights: True® Refrigeration is the first and only commercial refrigeration manufacturer to offer a 7-year labor, 7-Year Parts, 7-Year Compressor Warranty on all ……

#3 The market leader in Commercial Refrigeration

Domain Est. 1997

Website: heatcraftrpd.com

Key Highlights: Heatcraft Refrigeration Products provides solutions for commercial and industrial refrigeration applications. We manufacture unit coolers, condensers, ……

#4 Master

Domain Est. 1997 | Founded: 1938

Website: master-bilt.com

Key Highlights: Your trusted partner for quality commercial refrigeration, freezers, and display merchandisers since 1938….

#5 Norlake

Domain Est. 1997 | Founded: 1947

Website: norlake.com

Key Highlights: Trusted since 1947, Norlake delivers custom walk-in coolers, freezers, and refrigeration systems built for performance and reliability….

#6 Commercial Refrigeration Products

Domain Est. 2001

Website: continentalrefrigerator.com

Key Highlights: Explore our wide range of high-quality commercial refrigeration products, including refrigerators, freezers, and more. Find the perfect solution for your ……

#7 Steelheart ® Reach

Domain Est. 2003

Website: hoshizakiamerica.com

Key Highlights: Our rugged, stainless steel construction inside and out provides the highest quality and durability in commercial refrigeration equipment….

#8 Kelvinator Commercial

Domain Est. 2009

Website: kelvinatorcommercial.com

Key Highlights: The Kelvinator Commercial refrigeration line includes stainless steel door refrigerators and upright freezers, high-performance chest freezers, and glass top ……

#9 Habco Manufacturing

Domain Est. 2015

Website: habcomfg.com

Key Highlights: HABCO’s top-of-the-line commercial refrigerators and refrigeration equipment are made with four key elements: value, innovation, quality, and sustainability….

#10 The Best Commercial Refrigerators & Commercial Equipment …

Domain Est. 1998

Website: turboairinc.com

Key Highlights: PRO Series. Proudly made in the USA. Masterfully crafted, aesthetically designed ; Eco-Friendly. Turbo Air. All Turbo Air refrigerators. use natural refrigerant!…

Expert Sourcing Insights for Commercial Fridge

H2: 2026 Market Trends for Commercial Refrigeration

The commercial fridge market is poised for significant transformation by 2026, driven by technological innovation, regulatory changes, and shifting consumer demands. As industries from foodservice to healthcare prioritize efficiency, sustainability, and smart operations, several key trends are shaping the trajectory of the commercial refrigeration sector.

1. Growth in Demand from Foodservice and Retail Sectors

The expansion of quick-service restaurants (QSRs), convenience stores, and e-grocery fulfillment centers is fueling demand for commercial refrigeration units. With the rise of food delivery platforms and 24/7 retail models, businesses require reliable, high-capacity refrigeration solutions. Urbanization and changing consumer eating habits further underscore the need for advanced cooling systems in commercial environments.

2. Sustainability and Energy Efficiency Regulations

By 2026, stricter environmental regulations—especially those targeting greenhouse gas emissions—are expected to accelerate the adoption of eco-friendly refrigerants such as R290 (propane), CO₂ (R744), and other natural refrigerants. Countries across the EU, North America, and parts of Asia are enforcing policies under the Kigali Amendment and F-Gas regulations, pushing manufacturers to phase out high-GWP (Global Warming Potential) refrigerants. Energy efficiency standards will also drive innovation in compressor technology, insulation materials, and smart energy management systems.

3. Technological Advancements: Smart and Connected Fridges

IoT integration is transforming commercial fridges into intelligent assets. By 2026, a growing number of units will come equipped with sensors, remote monitoring, predictive maintenance alerts, and real-time temperature tracking. These features enhance food safety compliance, reduce energy waste, and minimize operational downtime. Cloud-based platforms will allow centralized management of refrigeration fleets across multiple locations, particularly beneficial for large restaurant chains and supermarkets.

4. Modular and Customizable Designs

There is an increasing demand for modular, space-optimized refrigeration units that can be tailored to specific operational needs. Compact undercounter units, glass-door merchandisers, and multi-temperature cabinets are gaining popularity in urban retail and hospitality settings where floor space is limited. Customization supports branding and improves customer experience, especially in premium retail and specialty food stores.

5. Expansion in Emerging Markets

While North America and Europe remain major markets, regions such as Southeast Asia, Latin America, and Africa are expected to witness robust growth by 2026. Rising disposable incomes, urbanization, and the expansion of modern grocery retail formats are creating new opportunities for commercial fridge suppliers. Localized manufacturing and partnerships with regional distributors will be key strategies for market penetration.

6. Resilience and Supply Chain Optimization

Post-pandemic supply chain disruptions have led businesses to prioritize equipment reliability and serviceability. Manufacturers are responding by improving component durability, offering extended warranties, and enhancing after-sales service networks. Additionally, the integration of refrigeration systems with broader supply chain management tools ensures better inventory control and reduces spoilage.

7. Focus on Hygiene and Food Safety

Heightened awareness of food safety—driven by regulatory scrutiny and consumer expectations—is influencing fridge design. Features such as antimicrobial surfaces, improved air filtration, and precise humidity control will become standard in high-end models. Compliance with HACCP and FDA standards will remain a key selling point.

In conclusion, the 2026 commercial fridge market will be defined by sustainability, digitalization, and adaptability. Companies that invest in energy-efficient, smart, and flexible refrigeration solutions will be best positioned to capitalize on evolving industry demands and regulatory landscapes.

Common Pitfalls When Sourcing Commercial Fridges (Quality and IP)

Logistics & Compliance Guide for Commercial Fridges

Commercial fridges are essential for food safety and operational efficiency in restaurants, hotels, healthcare facilities, and retail environments. Ensuring compliant and efficient logistics—from procurement to installation and ongoing operation—is critical. This guide outlines key logistics considerations and compliance requirements to help businesses manage commercial fridge deployment effectively.

Procurement & Sourcing

When sourcing commercial fridges, evaluate suppliers based on product specifications, energy efficiency, and regulatory compliance. Prioritize vendors who provide full documentation, including CE or UKCA marking (in Europe/UK), ENERGY STAR certification (in the U.S.), and compliance with local electrical and safety standards. Ensure units are suitable for the intended environment (e.g., high-humidity kitchens or outdoor use).

Transportation & Handling

Commercial fridges are heavy and often fragile. Use appropriate handling equipment (e.g., pallet jacks, dollies, or forklifts) during loading, transit, and unloading. Units should remain upright during transport to prevent compressor oil migration. Secure appliances to prevent shifting and damage. Climate-controlled transport may be needed in extreme weather to protect components.

Import & Customs Compliance (International Shipments)

For cross-border shipments, ensure compliance with import regulations. Required documentation typically includes:

– Commercial invoice

– Packing list

– Certificate of origin

– Product compliance certificates (e.g., CE, ETL, UL)

– Energy efficiency labels (e.g., EU Energy Label or U.S. FTC Appliance Label)

Check tariff classifications (e.g., HS Code 8418.40 for refrigerators) and any import duties or VAT obligations. Some countries may require third-party testing or registration with national standards bodies.

Installation & Site Preparation

Verify that the installation site meets electrical, ventilation, and structural requirements. Commercial fridges require:

– Proper voltage and dedicated circuits

– Adequate clearance around the unit for airflow (typically 2–4 inches)

– Level, stable flooring capable of supporting the unit’s weight

– Compliance with local plumbing and electrical codes

Ensure installation is performed by qualified technicians and documented for warranty and audit purposes.

Regulatory & Safety Compliance

Commercial fridges must comply with multiple regulations, including:

– Electrical Safety Standards: UL 471 (U.S.), IEC 60335-2-24 (international)

– Energy Efficiency Regulations: DOE (U.S.), Ecodesign Directive (EU)

– Refrigerant Regulations: EPA Section 608 (U.S.), F-Gas Regulation (EU) – particularly for units using HFCs

– Food Safety Standards: FDA Food Code (U.S.), HACCP requirements – units must maintain safe food storage temperatures (typically 0°C to 5°C / 32°F to 41°F)

Maintain records of compliance certifications and service logs.

Maintenance & Operational Compliance

Schedule regular maintenance to ensure efficiency and compliance:

– Clean condenser coils monthly

– Check door seals and gaskets for integrity

– Monitor internal temperatures daily and log results

– Perform professional servicing annually

Proper maintenance extends equipment life and supports food safety audits.

End-of-Life & Disposal

Dispose of commercial fridges in accordance with environmental regulations. Refrigerants must be recovered by certified technicians before disposal. Appliances may contain hazardous materials (e.g., PCBs in older units) and must be recycled through approved e-waste channels. Comply with:

– EPA Responsible Appliance Disposal (RAD) Program (U.S.)

– WEEE Directive (EU)

– Local municipal hazardous waste regulations

Recordkeeping & Audits

Maintain comprehensive records for:

– Purchase and delivery documentation

– Installation reports

– Compliance certifications

– Maintenance and repair logs

– Refrigerant handling records (including technician certification)

These records support regulatory audits and warranty claims.

By following this logistics and compliance guide, businesses can ensure that commercial fridges are safely transported, properly installed, and operated in full compliance with industry standards and legal requirements.

In conclusion, sourcing commercial fridge suppliers requires a strategic approach that balances quality, reliability, cost-efficiency, and long-term support. By clearly defining your business requirements—such as cooling capacity, energy efficiency, dimensions, and compliance with food safety regulations—you can narrow down potential suppliers effectively. Conducting thorough due diligence, including evaluating supplier reputation, certifications, warranty offerings, and customer service, ensures the selection of a trustworthy partner.

Additionally, considering both local and international suppliers can open opportunities for competitive pricing and innovative technology, though logistics and after-sales service must be carefully assessed. Building strong, transparent relationships with suppliers and establishing service level agreements (SLAs) helps mitigate risks and supports scalability. Ultimately, a well-informed sourcing decision not only meets current operational needs but also contributes to long-term sustainability, energy savings, and customer satisfaction in the foodservice or retail environment.