The global commercial cereal dispenser market is experiencing steady growth, driven by rising demand for hygiene, efficiency, and portion control in foodservice environments. According to Grand View Research, the global foodservice equipment market—under which commercial dispensing solutions fall—was valued at USD 97.4 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. With increasing adoption of automated solutions in hotels, restaurants, and institutional cafeterias, cereal dispensers have become essential tools for minimizing contamination and waste while enhancing customer experience. Mordor Intelligence further projects a CAGR of approximately 4.8% for the foodservice equipment sector through 2028, highlighting the expanding need for innovative, durable dispensing systems. As operators prioritize food safety and operational efficiency, manufacturers of commercial cereal dispensers are responding with smart, sanitary, and user-friendly designs. In this context, the following five companies have emerged as leaders in the space, combining engineering excellence, global reach, and data-backed performance to meet the evolving demands of the foodservice industry.

Top 5 Commercial Cereal Dispenser Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

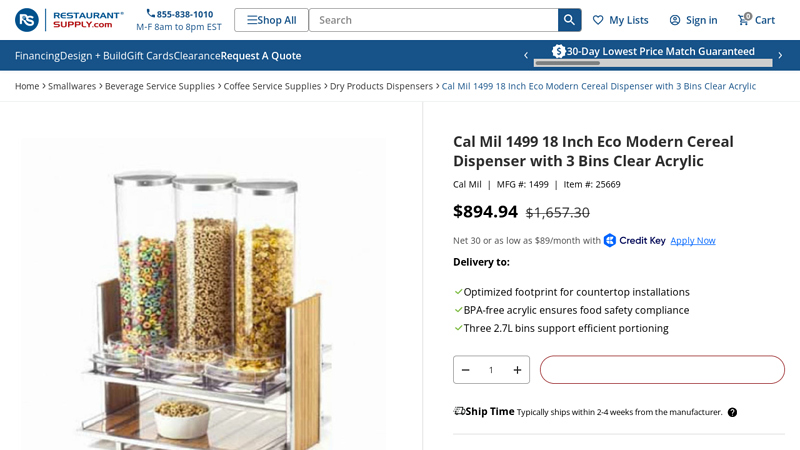

#1 Cal Mil 1499

Domain Est. 1998

Website: restaurantsupply.com

Key Highlights: In stock Rating 4.3 6 The Cal Mil 1499 Eco Modern Cereal Dispenser is a commercial countertop storage and dispensing unit designed for efficient organization of dry food products…

#2 Commercial cereal dispenser

Domain Est. 2005

Website: archiexpo.com

Key Highlights: ACD30-BL-FF is a Freestanding cereal dispenser, with a 4.5 Liter capacity and a set of 3 containers. Its patented “Free Flow” mechanism has 3 portion levels ……

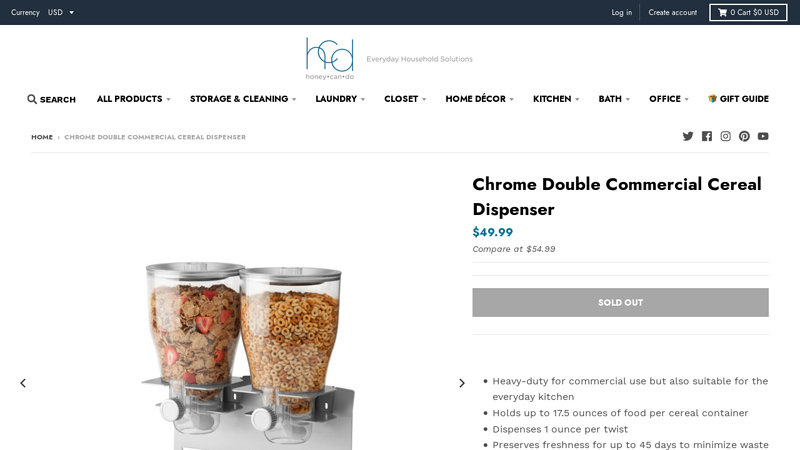

#3 Chrome Double Commercial Cereal Dispenser

Domain Est. 2007

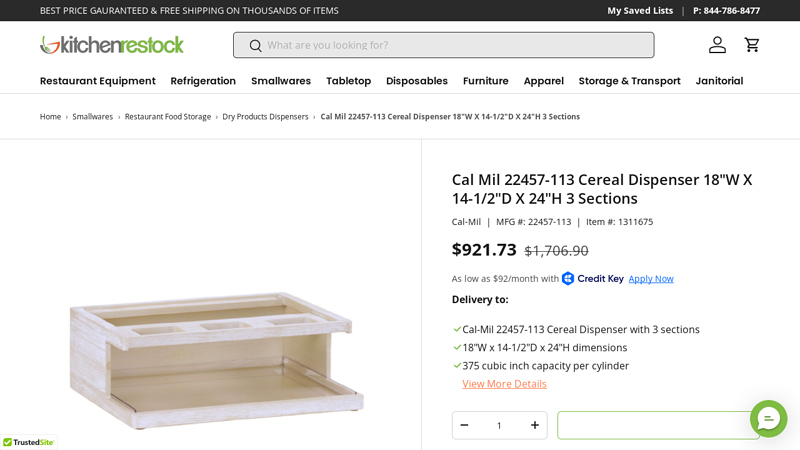

#4 Cal Mil 22457

Domain Est. 2014

Website: kitchenrestock.com

Key Highlights: In stock $88.47 deliveryThe Cal Mil 22457-113 Cereal Dispenser – 18″W x 14-1/2″D x 24″H is a sophisticated and functional solution designed for efficient cereal dispensing….

#5 Commercial Cereal Dispenser, Cereal Dispensers

Domain Est. 2024

Website: truercatering.com

Key Highlights: Crafted from food-grade PC and silicone, these grain dispensers boast a large capacity, ideal for accommodating high volumes of cereal. Their moisture-proof and ……

Expert Sourcing Insights for Commercial Cereal Dispenser

H2: Emerging Market Trends in Commercial Cereal Dispensers for 2026

As we approach 2026, the commercial cereal dispenser market is undergoing significant transformation driven by evolving consumer preferences, technological advancements, and heightened focus on hygiene and sustainability in foodservice environments. These trends are reshaping product design, distribution channels, and competitive dynamics across key sectors such as hotels, cafeterias, healthcare facilities, and quick-service restaurants.

-

Increased Demand for Hygiene and Contactless Solutions

In the wake of global health concerns, operators are prioritizing food safety and reduced physical contact. By 2026, commercial cereal dispensers with touchless interfaces, antimicrobial surfaces, and sealed dispensing mechanisms are expected to dominate the market. Infrared sensors and foot pedals are increasingly being integrated to minimize contamination risks, especially in high-traffic environments like corporate cafeterias and schools. -

Integration of Smart Technology and IoT

Smart dispensers equipped with IoT capabilities are gaining traction. These systems offer real-time inventory tracking, automatic refill alerts, and usage analytics, helping facility managers optimize stock levels and reduce food waste. By 2026, brands offering cloud-connected dispensers with predictive maintenance features are likely to capture a larger market share, particularly in large-scale operations. -

Sustainability and Waste Reduction Focus

Environmental concerns are pushing operators to adopt eco-friendly equipment. Manufacturers are responding with dispensers made from recyclable materials and designs that minimize product spillage and over-serving. Additionally, portion-control mechanisms are becoming standard, supporting sustainability goals and reducing operational costs. -

Customization and Flexible Design

There is growing demand for modular and customizable cereal dispensers that can accommodate a variety of grains, nuts, seeds, and branded cereals. In 2026, dispensers with interchangeable bins, adjustable portion sizes, and multi-compartment layouts will be increasingly popular, especially in premium hospitality and health-conscious venues. -

Expansion in Non-Traditional Markets

Beyond traditional breakfast settings, cereal dispensers are finding new applications in wellness centers, co-working spaces, and convenience retail. The trend toward grab-and-go nutrition supports the adoption of self-serve cereal stations, where convenience and perceived freshness drive consumer appeal. -

Regional Growth and Market Penetration

North America and Europe remain key markets due to established foodservice infrastructure and consumer familiarity with self-serve breakfast options. However, rapid growth is anticipated in Asia-Pacific and Latin America, fueled by urbanization, rising incomes, and the expansion of international hotel chains and franchise restaurants. -

Influence of Private Label and Health-Oriented Cereals

As consumers shift toward organic, gluten-free, and high-protein cereals, commercial dispensers are being adapted to support niche and private-label brands. Equipment that preserves freshness and segregates allergen-sensitive products will be critical to meeting regulatory and consumer demands.

In summary, by 2026, the commercial cereal dispenser market will be defined by innovation in hygiene, connectivity, and sustainability. Companies that invest in smart, modular, and eco-conscious designs will be best positioned to lead in this evolving landscape.

Common Pitfalls When Sourcing a Commercial Cereal Dispenser (Quality & Intellectual Property)

Sourcing a commercial cereal dispenser for foodservice operations involves more than just finding the lowest price. Overlooking critical factors related to quality and intellectual property (IP) can lead to operational disruptions, safety hazards, legal risks, and brand damage. Here are key pitfalls to avoid:

Poor Build Quality and Material Selection

Choosing a dispenser made from substandard materials (e.g., non-food-grade plastics, thin-gauge stainless steel) can result in rapid wear, contamination risks, and non-compliance with health codes. Low-quality components may crack, warp under temperature changes, or degrade when exposed to cleaning chemicals—compromising food safety and increasing long-term maintenance costs.

Lack of Third-Party Certifications

Failing to verify certifications such as NSF/ANSI 2, CE, or UL can expose buyers to regulatory non-compliance. Dispensers without proper certification may not meet hygiene, electrical safety, or structural requirements, leading to failed health inspections or liability in case of malfunction.

Inadequate Sealing and Moisture Protection

Many low-cost dispensers lack effective sealing mechanisms, allowing moisture and pests to enter. This compromises cereal freshness and safety. Poor gasket design or gaps in the housing can lead to mold growth and cross-contamination—particularly problematic in high-humidity environments.

Copycat Designs Infringing on IP

Sourcing from manufacturers that replicate patented designs (e.g., specific gravity-fed mechanisms, portion-control systems, or modular stacking features) poses serious IP risks. Using such products can result in cease-and-desist letters, import seizures, or lawsuits—especially when operating under a recognized brand.

Unclear or Absent IP Documentation

Suppliers may not provide proof of legitimate IP ownership or licensing for design and functionality. Without proper documentation (e.g., patent numbers, design registrations), buyers assume legal risk. This is especially critical when branding or customizing dispensers for private-label use.

Poor Ergonomics and User Safety

Low-quality dispensers often feature sharp edges, unstable bases, or difficult-to-clean crevices. These design flaws increase the risk of employee injury and violate occupational safety standards. Additionally, poorly designed dispensing mechanisms can lead to spills and waste, impacting operational efficiency.

Limited After-Sales Support and Spare Parts

Many budget suppliers offer little to no technical support or spare parts availability. When a critical component fails, the entire unit may become unusable—leading to downtime and lost revenue. Reliable access to service and replacements is essential for long-term operation.

Hidden Costs from Frequent Repairs or Replacement

While a low upfront price may seem attractive, poor quality often leads to higher total cost of ownership. Frequent breakdowns, part replacements, and labor for maintenance can far exceed the cost of investing in a durable, IP-compliant dispenser from the start.

By carefully evaluating both the physical quality and intellectual property legitimacy of commercial cereal dispensers, businesses can avoid costly mistakes and ensure safe, compliant, and efficient service.

Logistics & Compliance Guide for Commercial Cereal Dispenser

This guide outlines key considerations for the logistics and regulatory compliance associated with manufacturing, distributing, and operating commercial cereal dispensers in food service environments.

Product Classification and Intended Use

Commercial cereal dispensers are categorized as food contact equipment designed for portion-controlled dispensing of dry cereals and similar granular foods in settings such as hotels, cafeterias, and restaurants. Their classification impacts regulatory pathways and operational compliance requirements.

Regulatory Compliance Requirements

All commercial cereal dispensers must comply with food safety and equipment standards set by relevant authorities. Key regulations include:

- FDA Food Code: Equipment must be constructed and maintained to prevent contamination and allow for proper cleaning and sanitation.

- NSF/ANSI Standard 2: Dispensers must be certified to NSF/ANSI 2 (Food Equipment) or NSF/ANSI 51 (Non-Food Compounds) if applicable, ensuring materials are safe for food contact and design supports hygiene.

- Electrical Safety (if motorized): Units with electrical components (e.g., auger drives, sensors) must be certified to UL 197 (Commercial Cooking Appliances) or UL 499 (Heating Appliances) as appropriate, and bear marks from recognized testing laboratories (e.g., UL, ETL).

- RoHS and REACH Compliance: Electronic and plastic components must meet restrictions on hazardous substances in the EU (RoHS) and chemical safety (REACH), especially for international distribution.

Material Safety and Construction Standards

Dispenser components that contact food must be made from non-toxic, corrosion-resistant materials. Common compliant materials include:

- 304 or 316 stainless steel for hoppers, chutes, and dispensing mechanisms

- FDA-compliant food-grade plastics (e.g., polypropylene, polycarbonate) for transparent sections

- Seals and gaskets made from NSF-approved elastomers (e.g., silicone, EPDM)

All materials must be documented for food contact compliance, with supplier certificates of conformance (COC) maintained.

Cleaning and Sanitation Protocols

Dispensers must be designed to support effective cleaning:

- Smooth, crevice-free surfaces

- Removable parts for manual cleaning

- No horizontal ledges where debris can accumulate

- Drainage features to prevent moisture retention

Operators must follow manufacturer-recommended cleaning schedules using NSF-certified detergents and sanitizers compatible with dispenser materials.

Supply Chain and Distribution Logistics

- Packaging: Units should be shipped in protective packaging with clear handling instructions (e.g., “Fragile,” “This Side Up”) to prevent damage.

- Storage Conditions: Store in dry, temperature-controlled environments to prevent condensation and material degradation.

- Shipping Documentation: Include compliance certificates (NSF, UL), user manuals, and warranty information with each unit.

- Import/Export Compliance: For international shipments, ensure adherence to local electrical, labeling, and food equipment standards; provide necessary customs documentation (e.g., Certificate of Conformity, FDA registration for U.S. imports).

Installation and Operational Compliance

- Units must be installed on stable, level surfaces with adequate clearance for maintenance.

- Electrical connections (if applicable) must be made by qualified personnel in accordance with local codes (e.g., NEC in the U.S.).

- Operators must be trained on safe use, cleaning procedures, and allergen control (e.g., preventing cross-contact when dispensing multiple cereal types).

Maintenance and Recordkeeping

Maintain logs for:

– Routine cleaning and sanitation

– Preventive maintenance (e.g., lubrication, sensor calibration)

– Repairs and part replacements

Retain compliance documentation, test reports, and user manuals for the product lifecycle to support audits and inspections.

Environmental and End-of-Life Considerations

Design for recyclability where possible. Comply with WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions. Provide end-of-life disposal guidance to customers.

In conclusion, sourcing a commercial cereal dispenser requires careful consideration of several key factors including durability, hygiene, ease of use, capacity, and compliance with food safety regulations. Evaluating suppliers based on product quality, certifications, customer support, and cost-effectiveness ensures long-term reliability and value for money. Whether for use in schools, cafeterias, hotels, or retail environments, selecting the right dispenser enhances operational efficiency, minimizes waste, and improves the customer experience. By conducting thorough research and aligning the dispenser’s features with specific business needs, organizations can make a strategic investment that supports both convenience and food service excellence.