The global acrylic sheet market, including colored plexiglass, is experiencing steady expansion driven by rising demand across construction, automotive, signage, and consumer goods industries. According to a report by Mordor Intelligence, the acrylic sheet market was valued at USD 9.87 billion in 2023 and is projected to grow at a CAGR of 5.2% from 2024 to 2029, reaching an estimated USD 13.4 billion by the end of the forecast period. This growth is fueled by acrylic’s superior properties—such as light transmission, weather resistance, and design flexibility—making it a preferred alternative to glass in a variety of applications. With innovation in coloring techniques and increased customization options, the demand for high-quality colored acrylic plexiglass continues to climb, especially in architectural and retail environments. In this competitive landscape, a select group of manufacturers are leading the way through technological excellence, sustainable production practices, and global supply chain capabilities. Below, we profile the top 8 colored acrylic plexiglass manufacturers shaping the industry’s future.

Top 8 Colored Acrylic Plexiglass Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Premium Acrylic Sheets

Domain Est. 1998

Website: e-tplastics.com

Key Highlights: E & T Plastics Mfg. Co., Inc. offers durable, colorfast acrylic sheets ideal for diverse applications. Customize to meet your specifications….

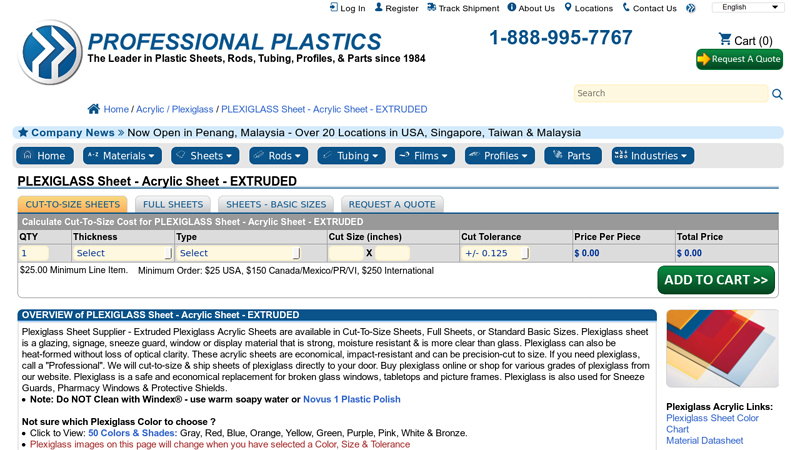

#2 Plexiglass Sheet

Domain Est. 1997

Website: professionalplastics.com

Key Highlights: 3-day returnsWe will cut-to-size & ship sheets of plexiglass directly to your door. Buy plexiglass online or shop for various grades of plexiglass from our website….

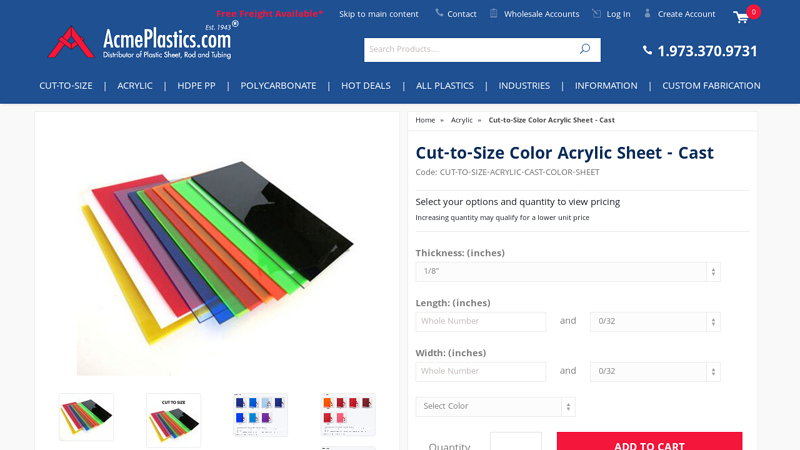

#3 Cut

Domain Est. 1997

Website: acmeplastics.com

Key Highlights: Free delivery 15-day returnsAcme Plastics has colored acrylic sheets available in custom sizes and hues. Select from 27 vibrant shades to suit your needs. Order online today!…

#4 Plastic, Acrylic & Polycarbonate Sheet Supplier

Domain Est. 1997

Website: acplasticsinc.com

Key Highlights: Our offering includes acrylic sheeting, plexiglass sheeting, polycarbonate sheeting, multiwall sheeting, abs plastic sheeting, HDPE and much more….

#5 Delvie’s Plastics

Domain Est. 2002

Website: delviesplastics.com

Key Highlights: 4-day delivery 30-day returnsAcrylic plexiglass sheet, cut to size, in hundreds of colors and thicknesses. With an emphasis on customer service, low prices, and the highest quality…

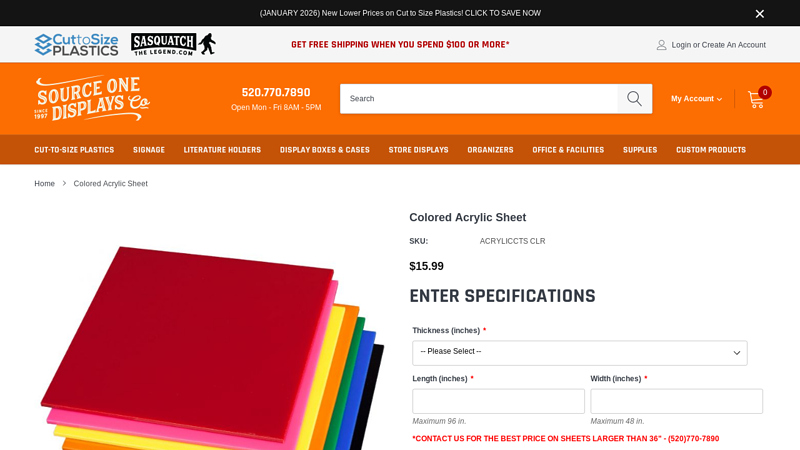

#6 Colored Acrylic Sheet

Domain Est. 2003

Website: sourceone.org

Key Highlights: $14.99 deliveryThis colored acrylic and Plexiglass sheet is commonly used for general fabrication, POP displays, signage, and many other applications….

#7 Acrylic Sheets (Plexiglass)

Domain Est. 2004

Website: canalplastic.com

Key Highlights: 4-day delivery 14-day returnsShop premium cast acrylic sheets at Canal Plastics. Clear, colored & frosted plexiglass. Custom cut-to-size. Mirror & iridescent are extruded….

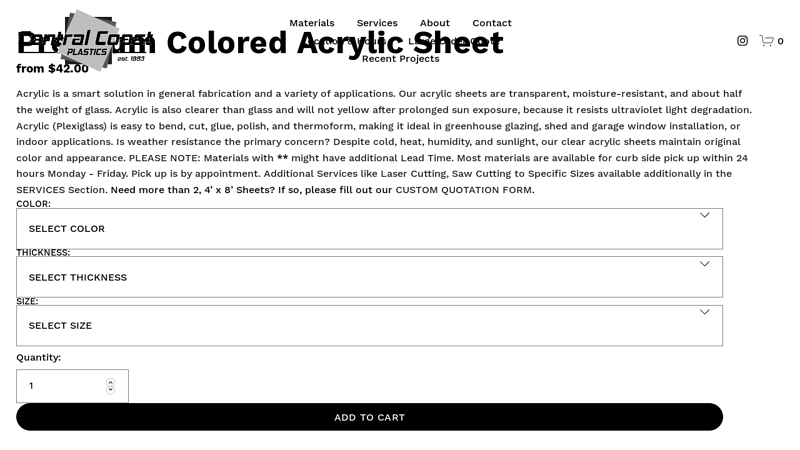

#8 Premium Colored Acrylic Sheet

Domain Est. 2010

Expert Sourcing Insights for Colored Acrylic Plexiglass

H2: Projected 2026 Market Trends for Colored Acrylic Plexiglass

The global market for colored acrylic plexiglass (polymethyl methacrylate or PMMA) is expected to experience steady growth leading into 2026, driven by advancements in material science, rising demand across key industries, and a shift toward sustainable and aesthetically versatile materials. Several macroeconomic, technological, and consumer-driven trends are shaping the trajectory of this niche yet critical segment of the plastics industry.

-

Increased Demand in Architectural and Interior Design

By 2026, the construction and design sectors are projected to be primary drivers of colored acrylic plexiglass consumption. Architects and interior designers are increasingly favoring colored acrylics for their light transmission, durability, and design flexibility. Applications such as decorative panels, illuminated signage, skylights, and feature walls in commercial and residential buildings are expanding, especially in urban redevelopment projects and smart city initiatives across Asia-Pacific and North America. -

Growth in Retail and Display Applications

The retail industry’s emphasis on visual merchandising and eye-catching point-of-purchase displays continues to boost demand. Colored acrylic plexiglass offers vibrant hues, UV resistance, and ease of fabrication, making it ideal for custom display units, shelving, and branding elements. The rise of experiential retail and pop-up stores is expected to further stimulate market demand by 2026. -

Sustainability and Recyclability Trends

Environmental concerns are influencing material choices across industries. By 2026, manufacturers of colored acrylic plexiglass are anticipated to focus more on developing recyclable and bio-based PMMA variants. Regulatory pressures in Europe and North America, such as the EU’s Circular Economy Action Plan, will likely accelerate innovation in eco-friendly formulations and closed-loop recycling processes, enhancing the market appeal of sustainable colored acrylics. -

Technological Advancements in Coloring and Coating

Innovations in pigment dispersion, UV stabilization, and surface coatings are improving the performance and longevity of colored acrylic sheets. By 2026, expect wider adoption of nano-pigmented and gradient-colored acrylics, enabling more complex visual effects for high-end applications in automotive interiors, consumer electronics, and art installations. -

Expansion in Automotive and Transportation Sectors

The automotive industry is increasingly using colored acrylics for interior ambient lighting, trim components, and lightweight glazing solutions. Electric vehicle (EV) manufacturers, in particular, are exploring colored transparent materials for futuristic design aesthetics. This trend is expected to gain momentum by 2026 as EV production scales globally. -

Regional Market Shifts

Asia-Pacific, led by China, India, and Southeast Asia, is projected to be the fastest-growing regional market due to rapid urbanization, infrastructure development, and expanding manufacturing capabilities. Meanwhile, North America and Europe will maintain strong demand, supported by renovation activities and stringent building codes favoring energy-efficient and durable materials. -

Supply Chain and Raw Material Dynamics

Fluctuations in the prices of raw materials like methyl methacrylate (MMA) may impact production costs. However, by 2026, increased regional production capacity and strategic partnerships between chemical suppliers and acrylic sheet manufacturers are expected to stabilize supply chains and reduce dependency on imports.

In conclusion, the 2026 market for colored acrylic plexiglass will be characterized by innovation, sustainability, and diversified applications. Companies that invest in R&D, eco-conscious manufacturing, and customized solutions are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Colored Acrylic Plexiglass (Quality & IP)

Sourcing colored acrylic plexiglass—often used interchangeably with PMMA (polymethyl methacrylate)—requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these aspects can lead to production delays, legal exposure, and subpar end products. Below are key pitfalls to avoid:

Poor Material Quality and Inconsistent Color

One of the most frequent issues is receiving acrylic sheets that fail to meet expected standards. Common quality concerns include:

- Color Inconsistency: Variations in hue, saturation, or transparency between batches or even within a single sheet can ruin design integrity, especially in high-visibility applications like signage or displays.

- Surface Defects: Scratches, bubbles, or haze during manufacturing compromise clarity and visual appeal.

- Thickness Tolerance Variance: Non-uniform thickness affects fit in precision applications and can cause assembly problems.

- UV and Weather Resistance: Some colored acrylics degrade under sunlight unless specifically formulated for outdoor use—leading to fading or brittleness.

Tip: Always request physical samples and batch certifications (e.g., ASTM or ISO compliance), and work with reputable suppliers who adhere to consistent manufacturing standards.

Misrepresentation of Material Type (Acrylic vs. Polycarbonate)

Suppliers may mislabel or confuse acrylic (PMMA) with polycarbonate (PC), especially in regions where terminology is used loosely. While both are transparent thermoplastics, they differ significantly:

- Acrylic offers superior clarity and UV resistance but is more brittle.

- Polycarbonate is impact-resistant but scratches easily and yellows faster in sunlight.

Using the wrong material can lead to product failure. Always verify material specifications and request test reports if performance is critical.

Lack of IP Compliance and Trademark Infringement

Colored acrylic sheets—especially proprietary shades like “Pantone-matched” or branded colors (e.g., “Acrylite®” or “Perspex®”)—often involve intellectual property protections:

- Trademark Violations: Suppliers may falsely claim their product is equivalent to a branded acrylic (e.g., “as good as Plexiglas®”), which can expose the buyer to trademark infringement if used in marketing or resale.

- Patented Color Formulations: Certain dyes or dispersion processes are patented. Unauthorized replication or distribution may breach IP rights.

- Design Rights: Custom-colored sheets developed for specific clients may be protected under design patents or trade secrets.

Tip: Ensure suppliers provide documentation proving legal rights to produce and sell the material. Avoid using trademarked names without authorization.

Inadequate Supply Chain Transparency

Many suppliers source acrylic from third-party manufacturers, especially in regions with less stringent quality control. This lack of traceability can lead to:

- Unknown additives or recycled content affecting performance.

- Difficulty in auditing for compliance with environmental or safety standards (e.g., REACH, RoHS).

- Risk of counterfeit materials.

Recommendation: Choose suppliers who offer full chain-of-custody documentation and perform third-party quality audits.

Overlooking Long-Term Availability and Discontinuation Risk

Custom or niche colors may be discontinued without notice, especially if they are low-volume productions. This can jeopardize product continuity for long-term projects.

Best Practice: For mission-critical colors, negotiate supply agreements or secure minimum stock commitments from the supplier.

By addressing these quality and IP-related pitfalls proactively, businesses can ensure reliable sourcing of colored acrylic plexiglass that meets both performance and legal standards.

Logistics & Compliance Guide for Colored Acrylic Plexiglass

Product Overview and Classification

Colored acrylic plexiglass, also known as polymethyl methacrylate (PMMA), is a transparent thermoplastic commonly used as a lightweight, shatter-resistant alternative to glass. It is available in sheets, rods, and custom-fabricated forms with various pigments and finishes. For logistics and compliance purposes, proper classification under international and domestic regulations is essential due to its material properties and potential hazards during transport.

Regulatory Classification and Hazard Identification

Colored acrylic plexiglass is generally classified as a non-hazardous solid material under most transportation regulations when in finished form (e.g., sheets or blocks). However, it may be subject to specific rules depending on form, additives, or manufacturing residues.

- UN Number: Typically not assigned for solid, non-processed acrylic sheets.

- IMO/IMDG Code: Not regulated as dangerous goods under maritime transport when in solid form.

- IATA/ICAO: Not classified as hazardous for air transport under Packing Instruction 902 if non-combustible and non-reactive.

- 49 CFR (U.S. DOT): Not regulated as hazardous material when shipped as a solid article.

Note: Dust generated during cutting or machining may pose inhalation risks and could be regulated under occupational safety standards (e.g., OSHA).

Packaging and Handling Requirements

Proper packaging ensures product integrity and compliance with carrier standards.

- Protective Wrapping: Use plastic film, kraft paper, or foam to prevent surface scratches.

- Edge Protection: Apply edge guards or corner protectors to prevent chipping.

- Palletization: Secure sheets on wooden or plastic pallets using stretch wrap or strapping. Overhang should not exceed 3 inches (7.6 cm).

- Weight Limits: Ensure pallet loads comply with carrier weight restrictions (e.g., ≤ 1,500 lbs for standard freight).

- Labeling: Include product identification, handling instructions (e.g., “Fragile,” “This Side Up”), and shipper/consignee details.

International Shipping and Documentation

Global shipments require accurate documentation to clear customs and comply with trade regulations.

- Commercial Invoice: Must detail product description, quantity, value, HTS code, country of origin, and Incoterms®.

- Packing List: Include dimensions, weight per package, and total shipment volume.

- Certificate of Origin: May be required for tariff determination under trade agreements.

- Customs Tariff Classification:

- HTS Code (U.S.): 3920.51.00 (sheets, plates, film, foil, and strip of polymethyl methacrylate).

- HS Code (International): 3920.51 — Plastics plates, sheets, film, foil, and strip, non-cellular and not reinforced, of polymethyl methacrylate.

- REACH and RoHS Compliance: Confirm that colorants and additives comply with EU regulations on restricted substances, particularly for shipments into Europe.

Environmental and Safety Compliance

Manufacturers and shippers must adhere to environmental, health, and safety standards.

- REACH (EU): Ensure no SVHCs (Substances of Very High Concern) are present above threshold levels.

- RoHS (EU): Applicable if used in electrical/electronic equipment; verify lead, cadmium, and other restricted substance limits.

- Proposition 65 (California): Check if any components require warning labels due to potential carcinogens or reproductive toxins.

- TSCA (U.S.): Confirm compliance with the Toxic Substances Control Act for chemical substances.

Storage and Handling Precautions

To maintain material quality and ensure workplace safety:

- Storage Environment: Store in a cool, dry area away from direct sunlight to prevent warping or discoloration.

- Stacking: Limit stack height to prevent deformation; use separators between sheets.

- Fire Safety: Acrylic is combustible; store away from ignition sources. NFPA Class 2 flammability rating applies.

- Personal Protective Equipment (PPE): Use gloves and eye protection when handling cut edges.

End-of-Life and Recycling Considerations

Colored acrylic plexiglass is recyclable but requires specialized processing.

- Recycling Code: #7 (Other Plastics) — Not universally accepted in curbside programs.

- Disposal: Follow local regulations; landfill disposal may be permitted but is discouraged.

- Sustainability Claims: Avoid unsubstantiated “biodegradable” or “eco-friendly” labels unless certified.

Summary of Key Compliance Actions

- Verify non-hazardous classification for transport.

- Use appropriate packaging to prevent damage.

- Provide accurate customs documentation with correct HTS/HS codes.

- Confirm regulatory compliance (REACH, RoHS, TSCA) based on destination.

- Implement safe handling and storage procedures.

- Support responsible end-of-life management through recycling programs.

This guide ensures safe, legal, and efficient logistics for colored acrylic plexiglass across global supply chains. Always consult local regulations and carriers for updated requirements.

In conclusion, sourcing colored acrylic (plexiglass) requires careful consideration of several key factors to ensure quality, cost-effectiveness, and suitability for the intended application. It is essential to evaluate suppliers based on material quality, color consistency, sheet dimensions, thickness options, and certifications (such as UV resistance or food safety, if applicable). Comparing pricing, lead times, and minimum order quantities will help identify a reliable and efficient supplier that meets project requirements.

Additionally, verifying whether the acrylic is extruded or cast is crucial, as this impacts clarity, durability, and machinability. Sourcing locally can reduce shipping costs and delivery times, while international suppliers may offer cost advantages but come with longer lead times and potential customs considerations.

Ultimately, establishing long-term relationships with reputable suppliers, requesting samples before bulk orders, and staying informed about market trends will contribute to a successful sourcing strategy. By balancing quality, cost, and reliability, businesses and individuals can secure high-performing colored acrylic plexiglass that meets both technical and aesthetic needs.