The global laser etching market is experiencing robust growth, driven by increasing demand for precision marking in industries such as automotive, electronics, medical devices, and consumer goods. According to Grand View Research, the global laser marking market size was valued at USD 1.86 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.7% from 2023 to 2030. A key contributor to this growth is the rising adoption of color laser etching technologies, which offer enhanced durability, design flexibility, and aesthetic appeal over traditional marking methods. Innovations in fiber and ultrafast laser systems have further enabled high-resolution, permanent color marking on metals, plastics, and coated materials—spurring adoption across high-value manufacturing sectors. As global industrial automation accelerates and customization demands rise, manufacturers are investing heavily in advanced laser solutions. This increasing momentum has led to a surge in specialized color laser etching equipment providers, setting the stage for significant market competition and technological differentiation.

Top 10 Color Laser Etching Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Rowmark

Domain Est. 1997

Website: rowmark.com

Key Highlights: With over 30 years experience Rowmark is the premier sign plastic manufacturer in the world. Manufactured with you in mind. Tough. Tested. Trusted….

#2 Laser Photonics

Domain Est. 2001

Website: laserphotonics.com

Key Highlights: Laser Photonics manufactures reliable, safe, and eco-friendly Laser Cleaning, Laser Cutting, Laser Engraving, Laser Marking, and Laser Welding solutions….

#3 Laser Marking for All Industries

Domain Est. 2006

Website: lasermarktech.com

Key Highlights: Discover innovative laser marking solutions tailored for various industries. Explore our cutting-edge technology as leaders in laser marking and engraving….

#4 Laser Etching

Domain Est. 1996

Website: keyence.com

Key Highlights: Laser etching is a process of using a laser to remove material from a surface. By running the laser beam along the desired path, the workpiece is etched in the ……

#5 Laser marking

Domain Est. 1996

Website: trumpf.com

Key Highlights: Laser marking is a collective term for several marking procedures: ablation, engraving, annealing, black marking, colour change and foaming….

#6 Laser engravers & laser cutters

Domain Est. 2007

Website: gravotech.us

Key Highlights: Our laser tables are designed to engrave, mark and cut on a wide variety of materials (plastic, wood, metal, leather, glass, paper, stone) and shapes….

#7 Laser Engraving, Laser Etching, Laser Marking, Laser Cutting …

Domain Est. 2010

Website: innotech-laser.com

Key Highlights: We offer product decorating, engraving, cutting, annealing, and etching, as well as cylindrical printing and full-color UV-cured prints….

#8 Full Spectrum Laser

Domain Est. 2010

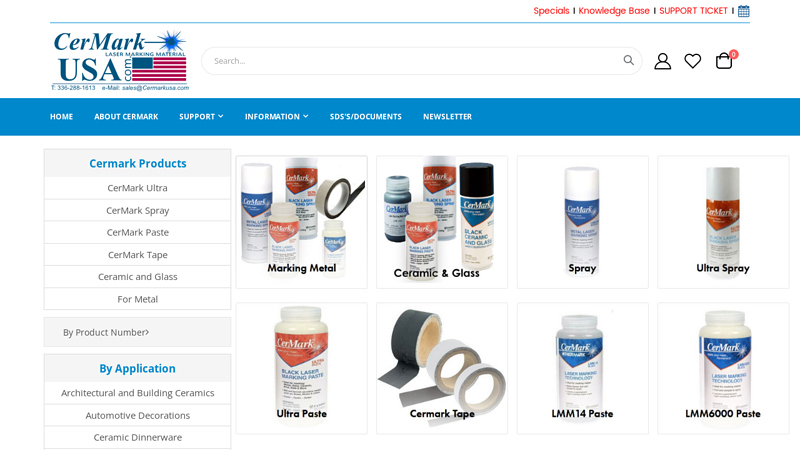

#9 Laser Marking

Domain Est. 2016

Website: cermarkusa.com

Key Highlights: Laser marking is a cost-effective and reliable way to mark parts and components with information such as serial numbers, barcodes, logos, and text….

#10 OMTech Laser

Domain Est. 2023

Website: omtech.com

Key Highlights: Turn your creative dreams into reality with our laser engraving and cutting machines, from desktop CO2 lasers to fiber lasers, which are perfect for ……

Expert Sourcing Insights for Color Laser Etching

H2: Projected 2026 Market Trends for Color Laser Etching

By 2026, the color laser etching market is anticipated to undergo significant transformation, driven by technological advancements, expanding applications, and evolving customer demands. Key trends shaping this dynamic landscape include:

1. Accelerated Technological Innovation & Performance Enhancement:

Expect substantial improvements in laser source technology (e.g., more powerful and stable fiber or ultrafast lasers), beam delivery systems, and control software. This will translate to higher resolution, faster processing speeds, and greater consistency in color marking. Expect wider adoption of AI-driven optimization for color calibration and process control, minimizing waste and ensuring brand-accurate color reproduction across diverse materials (metals, plastics, ceramics).

2. Expansion into High-Value, Regulated Industries:

Demand will surge in sectors requiring permanent, tamper-proof, and aesthetically pleasing markings. Medical device manufacturing will leverage color etching for clear device identification, logos, and instructional graphics on surgical tools and implants. The automotive and aerospace industries will adopt it for durable part serialization, branding on control panels, and traceability marks that withstand harsh environments. Consumer electronics will use it for premium branding on enclosures and buttons.

3. Increased Focus on Sustainability and Material Compatibility:

As environmental regulations tighten, color laser etching’s non-contact, chemical-free, and low-waste nature becomes a major competitive advantage over traditional printing and labeling. R&D will focus on expanding the range of recyclable and biocompatible materials that can be effectively and safely color-etched, further enhancing its green credentials.

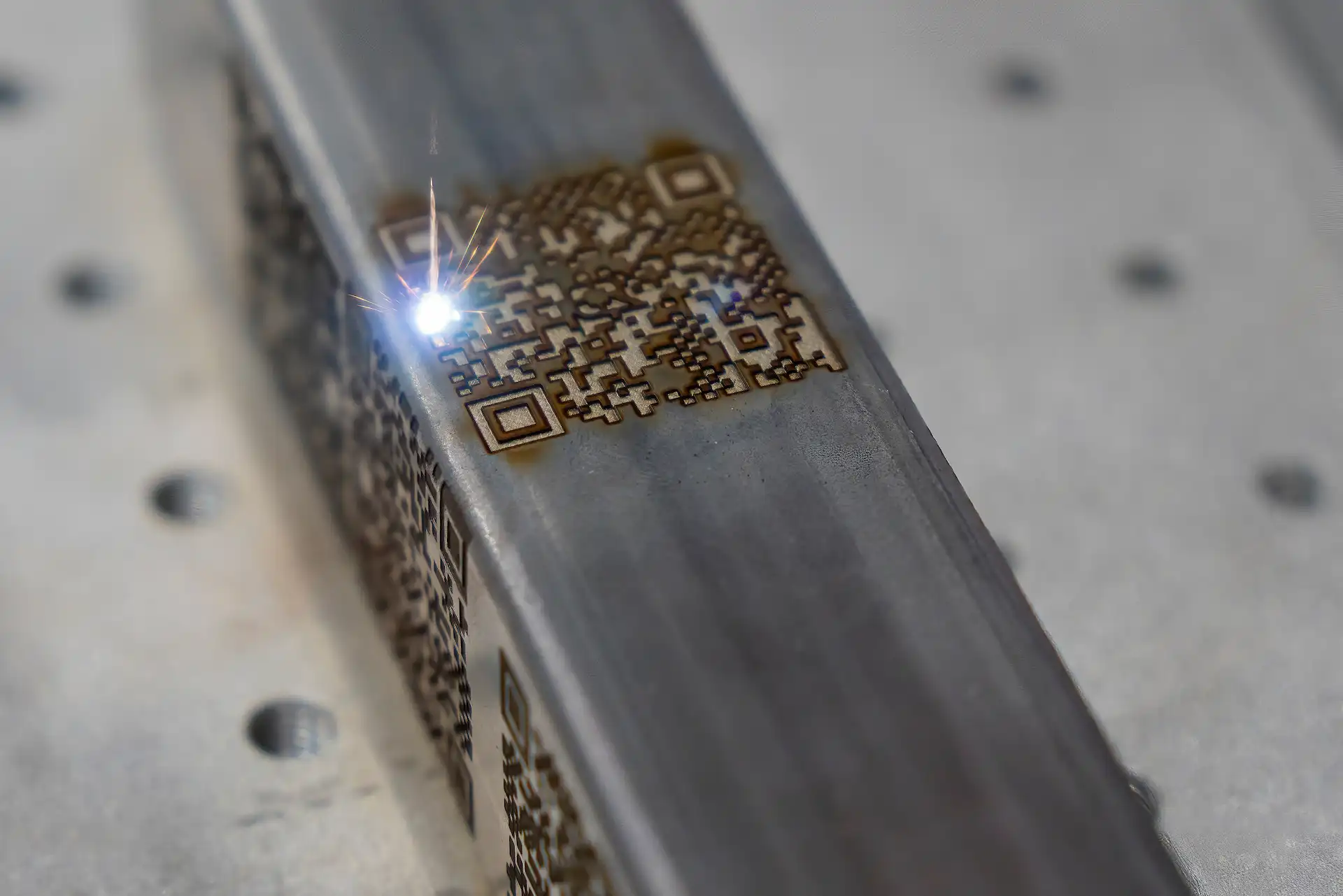

4. Integration with Smart Manufacturing (Industry 4.0):

Color laser etching systems will become seamlessly integrated into connected production lines. Real-time data exchange with MES/ERP systems will enable dynamic marking (e.g., unique QR codes, serial numbers, batch data) directly linked to production databases, supporting full traceability, anti-counterfeiting, and mass customization strategies.

5. Democratization through Cost Reduction & Accessibility:

While high-end systems will push performance boundaries, increased competition and technological maturity will drive down costs for mid-range systems. More compact, user-friendly, and affordable desktop or benchtop color laser etchers will become available, making the technology accessible to smaller manufacturers, research labs, and even prototyping workshops, expanding the overall market base.

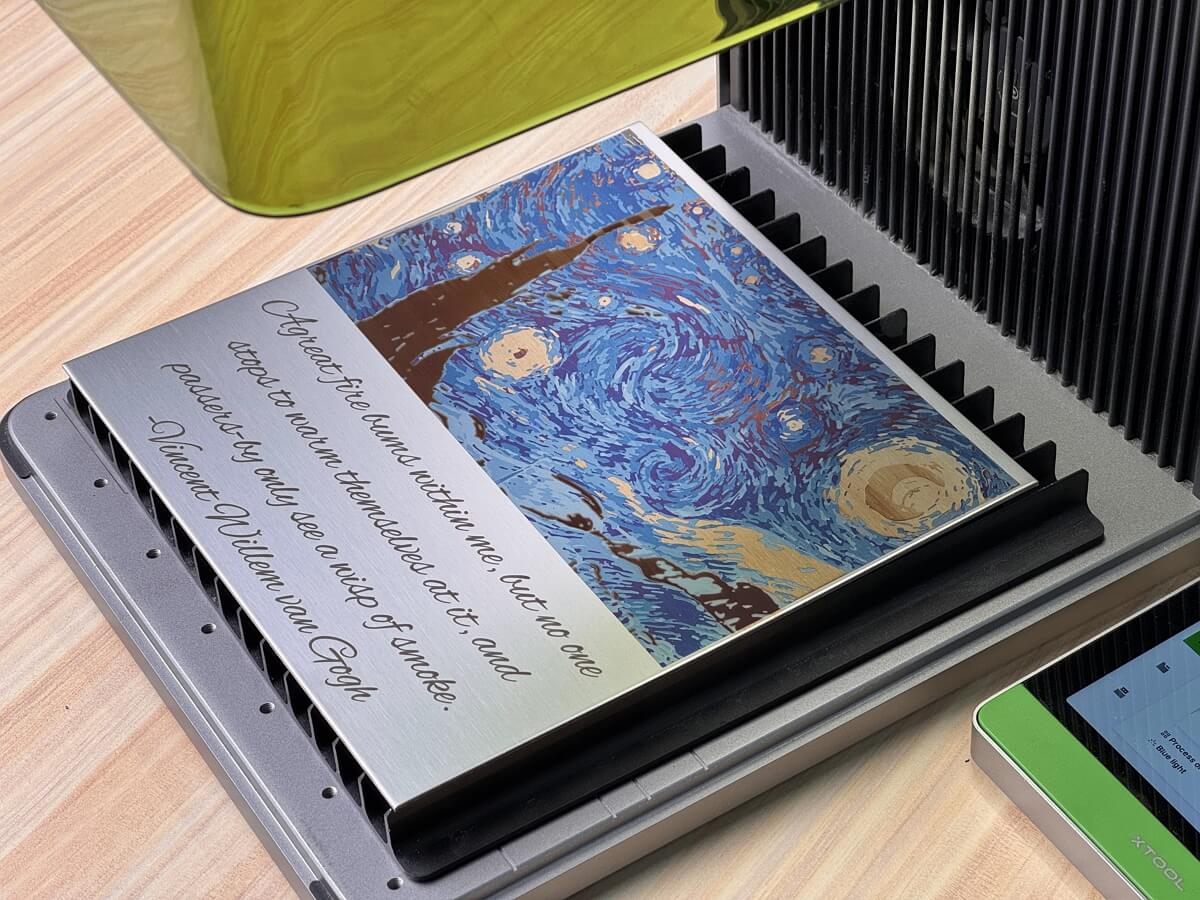

6. Emphasis on Aesthetics and Brand Differentiation:

Beyond functionality, color etching will be increasingly used as a premium branding and design tool. Companies will utilize vibrant, permanent colors to create distinctive product identities, enhance perceived value, and combat counterfeiting through unique, difficult-to-replicate visual signatures.

In conclusion, by 2026, the color laser etching market is poised for robust growth, moving beyond niche applications to become a mainstream solution valued for its precision, permanence, sustainability, and ability to deliver both functional traceability and high-impact aesthetics across diverse high-tech industries.

H2: Common Pitfalls in Sourcing Color Laser Etching – Quality and Intellectual Property Concerns

When sourcing color laser etching services, businesses often encounter critical challenges related to quality consistency and intellectual property (IP) protection. Failing to address these pitfalls can result in subpar products, legal disputes, and damage to brand reputation.

Quality-Related Pitfalls:

-

Inconsistent Color Reproduction:

Color laser etching relies on precise calibration of lasers and materials. Suppliers with outdated equipment or insufficient process controls may produce inconsistent hues, leading to mismatched branding or product finishes. This is particularly problematic for brands requiring color accuracy across large production runs. -

Material Compatibility Issues:

Not all materials respond the same way to laser etching. Sourcing from vendors without expertise in specific substrates (e.g., anodized aluminum, coated plastics) can result in poor adhesion, fading, or surface damage. Inadequate testing during prototyping increases the risk of field failures. -

Limited Resolution and Detail:

Lower-tier providers may lack high-resolution laser systems, resulting in blurry or pixelated etchings—especially problematic for intricate logos, barcodes, or fine text. This reduces professionalism and readability of the final product. -

Lack of Quality Control Processes:

Absence of standardized inspection protocols—such as batch testing, color matching under controlled lighting (e.g., D65 standard), and surface finish evaluation—can allow defective units to pass through undetected.

Intellectual Property (IP) Risks:

-

Unauthorized Use or Replication of Designs:

Sharing proprietary artwork or product designs with unvetted suppliers exposes companies to the risk of IP theft. Some manufacturers may replicate designs for third parties or sell them without consent, especially in regions with weak IP enforcement. -

Inadequate Legal Agreements:

Failure to establish robust non-disclosure agreements (NDAs) and IP ownership clauses in contracts leaves businesses vulnerable. Without clear terms, suppliers may claim partial rights to custom-developed etching processes or design files. -

Data Security Gaps:

Digital design files transmitted to suppliers can be intercepted or stored insecurely. Vendors without cybersecurity measures (e.g., encrypted file transfer, access controls) increase the likelihood of data breaches and IP leakage. -

Geopolitical and Jurisdictional Risks:

Sourcing from countries with ambiguous or poorly enforced IP laws complicates legal recourse in case of infringement. Enforcement becomes costly and time-consuming, especially without local legal representation.

Mitigation Strategies:

To avoid these pitfalls, businesses should conduct thorough due diligence on suppliers, including audits of technical capabilities, quality certifications (e.g., ISO 9001), and cybersecurity practices. Legal safeguards such as NDAs, clear IP assignment clauses, and secure digital workflows are essential. Pilot runs and third-party quality inspections can further ensure consistency and protect brand integrity.

Logistics & Compliance Guide for Color Laser Etching

Overview of Color Laser Etching

Color laser etching is a non-contact marking technology that uses laser beams to alter the surface properties of materials, creating vibrant, permanent color marks without inks or additives. This process is widely used in industries such as medical devices, automotive, electronics, and consumer goods for branding, traceability, and regulatory compliance. Due to its precision and durability, understanding the logistics and regulatory requirements is essential for safe and legal operation.

Equipment & Material Logistics

Selecting and managing the proper equipment and materials is foundational to a successful color laser etching operation. Lasers must be chosen based on material compatibility—common substrates include stainless steel, titanium, and select engineered plastics. Ensure the laser system meets relevant power and safety classifications (e.g., Class 1 or Class 4 with interlocks). Inventory management should include scheduled maintenance of optics, cooling systems, and exhaust filtration units. All materials must be stored in controlled environments to prevent contamination or degradation that could affect etching quality.

Regulatory Compliance Requirements

Color laser etching processes must comply with a range of international and local regulations. Key standards include:

– IEC 60825-1: Safety of laser products – establishes classification and labeling requirements.

– OSHA 29 CFR 1910.133: Eye and face protection standards for laser operations.

– REACH & RoHS (EU): Ensure materials processed do not release restricted substances during etching.

– FDA 21 CFR Part 820: Required for medical device marking in the U.S., covering process validation and traceability.

Operators must conduct risk assessments, maintain compliance documentation, and implement engineering controls such as interlocks and beam enclosures.

Workplace Safety & Training

Personnel involved in color laser etching must undergo comprehensive safety training covering laser hazards (optical, electrical, and fume-related), emergency shutdown procedures, and proper use of personal protective equipment (PPE), particularly laser safety goggles with appropriate optical density ratings. Work zones should be clearly marked with warning signs, and access restricted during operation. Regular safety audits and incident reporting systems help maintain a safe working environment.

Environmental & Waste Management

Laser etching may produce airborne particulates and volatile organic compounds (VOCs), especially when processing plastics or coated materials. Install certified fume extraction systems with HEPA and activated carbon filters to capture emissions. Collected waste (e.g., filter cartridges, swabs) must be handled as hazardous waste if contaminated with regulated substances. Maintain records of disposal in accordance with local environmental regulations such as the U.S. EPA or EU Waste Framework Directive.

Documentation & Traceability

Robust documentation is critical for compliance, especially in regulated industries. Maintain logs of laser parameters (wavelength, power, speed), material certifications, calibration records, and operator training. Etched identifiers (e.g., UDI codes, serial numbers) must meet readability and permanence standards (e.g., ISO/IEC 15415 for 2D codes). Audit trails should support full traceability from raw material to final marked product.

International Shipping & Import Considerations

When shipping laser-etched products or the equipment itself across borders, ensure compliance with:

– ITAR/EAR (U.S.): Controls on export of certain laser technologies.

– CE Marking (EU): Required for placing laser machinery on the European market.

– Customs Documentation: Accurate HS codes, product descriptions, and certificates of conformity.

Verify that etched markings do not inadvertently include restricted logos or data subject to intellectual property or security regulations.

Maintenance & Calibration Protocols

Regular maintenance ensures consistent etching quality and regulatory adherence. Follow manufacturer-recommended schedules for optical alignment, lens cleaning, and power calibration. Calibration records must be retained and traceable to national standards (e.g., NIST). Unexpected drift in color or contrast may indicate the need for servicing and should trigger a quality review.

Conclusion

A successful color laser etching operation relies on meticulous logistics planning and strict compliance with safety, environmental, and industry-specific regulations. By integrating proper equipment management, personnel training, and documentation practices, organizations can ensure high-quality, traceable, and legally compliant markings across global markets.

Conclusion on Sourcing Color Laser Etching

Sourcing color laser etching requires careful consideration of technology capabilities, material compatibility, supplier expertise, and cost-effectiveness. While true color laser etching is still an emerging and limited technology—often relying on specialized lasers (such as fiber or ultrafast lasers) interacting with specific coatings or substrates to produce color effects through surface oxidation or nanostructuring—it is not as widely available or standardized as traditional engraving or marking methods.

Key factors to consider when sourcing include:

- Technology Type: Confirm whether the supplier uses laser-induced coloration (e.g., through precise control of laser parameters on metals like titanium or stainless steel) or hybrid methods involving pre-coated materials or post-processing.

- Material Suitability: Not all materials support color laser etching. Metals such as titanium, steel, and certain anodized aluminum yield the best results, while plastics and other substrates may not.

- Supplier Experience: Work with vendors who have demonstrated expertise in color marking, including sample validation and quality control.

- Application Requirements: Evaluate durability, resolution, and aesthetic needs—color laser marks can be prone to fading or wear if not properly optimized.

- Cost and Scalability: Color laser etching can be more expensive and slower than standard engraving, so assess whether the value added justifies the investment.

In conclusion, while color laser etching offers unique aesthetic and functional benefits for branding, product identification, and decorative applications, sourcing should be approached strategically. Partnering with advanced, technically proficient suppliers and thoroughly testing prototypes ensures successful implementation. As the technology evolves, broader adoption and improved cost-efficiency are likely, making it a promising option for high-value, precision-oriented industries such as medical devices, luxury goods, and electronics.