The global colored concrete hardener market is experiencing steady expansion, driven by rising infrastructure development, urbanization, and demand for durable, aesthetically enhanced flooring solutions in commercial and industrial sectors. According to Grand View Research, the global concrete admixtures market—of which color hardeners are a key segment—was valued at USD 33.01 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth trajectory is supported by increased construction activities in emerging economies and the growing preference for polished concrete finishes in architectural applications. With performance attributes such as abrasion resistance, dust reduction, and long-term visual appeal, colored surface hardeners have become essential in modern concrete finishing. As competition intensifies, a select group of manufacturers are leading innovation, quality, and geographic reach. Based on market presence, product range, and technical capabilities, the following seven companies stand out as top color hardener manufacturers shaping the industry.

Top 7 Color Hardener Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Super Stone, Inc.

Domain Est. 1997 | Founded: 1961

Website: superstone.com

Key Highlights: Manufacturing and Supplying contractors around the world with affordable and reliable products and tools for decorative concrete since 1961….

#2 Color Hardeners

Domain Est. 1995

Website: usa.sika.com

Key Highlights: SikaColor Color Hardeners create abrasion-resistant interior floors and freeze-thaw stable exterior hardscapes that stand up to both foot and vehicular traffic ……

#3 Increte Color Hardener

Domain Est. 1997

Website: euclidchemical.com

Key Highlights: Colored Dry Shake Surface Hardener. INCRETE COLOR HARDENER is a ready-to-use surface hardener for coloring and hardening freshly poured concrete….

#4 Solomon Colors

Domain Est. 1997

Website: solomoncolors.com

Key Highlights: Solomon Colors is your trusted source for colored concrete solutions. From leading pigments to precision color dispensers, all backed by expert support….

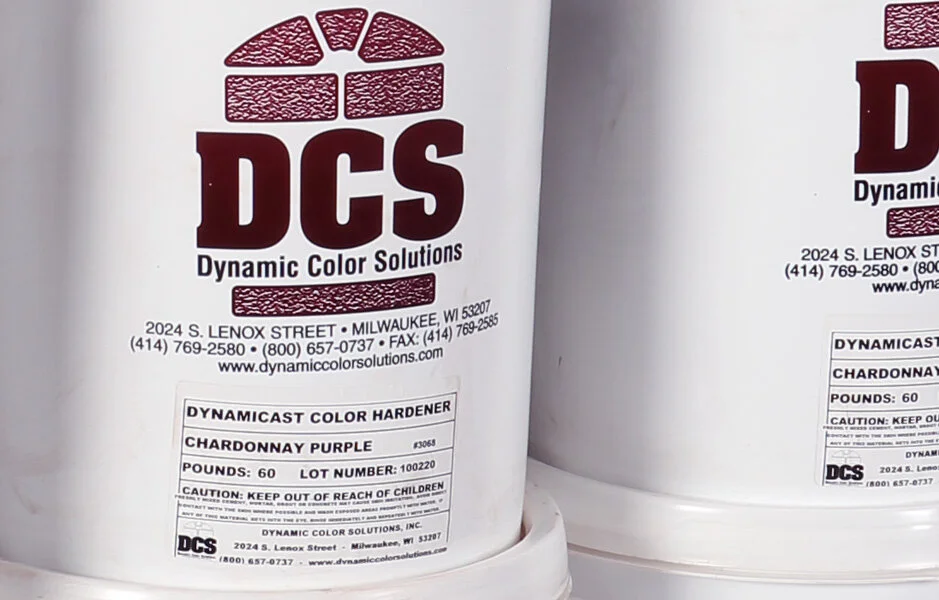

#5 Dry Pigment & Dynamicast Color Hardener

Domain Est. 1998

Website: dynamiccolorsolutions.com

Key Highlights: Dynamicast Color Hardener is a line of ready-to-use, surface-applied accent colors for manufactured stone veneer and other products. Dynamicast is a proprietary ……

#6 Dura Color Hardener (CH)

Domain Est. 1998

Website: prolinestamps.com

Key Highlights: Dura Color Hardener provides a uniform, streak-free color and strengthens the top layer of concrete to withstand high traffic and weathering….

#7 Color Hardener

Domain Est. 2009

Website: chemsystemsinc.com

Key Highlights: Helix Color Hardener is a specialty formulated, dry-shake, colored surface hardener. It is used for coloring, hardening and conditioning freshly placed concrete ……

Expert Sourcing Insights for Color Hardener

H2: 2026 Market Trends for Color Hardener

The global color hardener market is poised for steady growth and transformation by 2026, driven by evolving construction practices, aesthetic demands, and sustainability imperatives. Key trends shaping the market include:

1. Rising Demand in Non-Residential and Infrastructure Sectors:

Commercial, industrial, and public infrastructure projects (e.g., warehouses, retail spaces, airports, and transportation hubs) are increasingly specifying color-hardened concrete for its durability and visual appeal. As urbanization accelerates globally, especially in Asia-Pacific and Latin America, demand for high-performance flooring solutions will drive adoption of color hardeners in large-scale developments.

2. Aesthetic Customization and Architectural Integration:

Architects and designers are leveraging color hardeners to create visually striking, seamless surfaces that align with modern architectural aesthetics. The trend toward exposed concrete (architectural concrete) and decorative finishes will boost demand for custom color blends, integrally colored systems, and combination techniques (e.g., staining over color-hardened surfaces).

3. Focus on Sustainability and Low-Carbon Solutions:

Environmental regulations and green building certifications (e.g., LEED, BREEAM) are pushing manufacturers to develop eco-friendly formulations. By 2026, expect increased availability of color hardeners with recycled pigments, reduced-VOC (volatile organic compound) components, and compatibility with supplementary cementitious materials like fly ash or slag, lowering the carbon footprint of concrete installations.

4. Technological Advancements in Product Performance:

Innovation will center on improving wear resistance, UV stability, and color consistency. Next-generation products may incorporate nano-additives or advanced polymer modifiers to enhance surface density, reduce dusting, and extend service life—especially important for high-traffic areas and harsh environments.

5. Regional Market Expansion and Localization:

While North America and Europe remain mature markets with stable demand, fastest growth is anticipated in Asia-Pacific, driven by construction booms in India, Southeast Asia, and the Middle East. Localized production and distribution networks will emerge to meet regional preferences and reduce logistics costs.

6. Integration with Digital Design and BIM:

The construction industry’s shift toward Building Information Modeling (BIM) and digital planning tools will influence color hardener selection. Manufacturers offering digital color libraries, compatibility data, and technical support for BIM integration will gain competitive advantage.

In summary, the 2026 color hardener market will be characterized by a convergence of durability, design flexibility, and sustainability. Companies that innovate in eco-conscious formulations, support digital workflows, and cater to regional construction dynamics will be best positioned to capture growing demand.

Common Pitfalls When Sourcing Color Hardener (Quality, IP)

Sourcing color hardener—especially for architectural concrete applications—requires careful attention to both product quality and intellectual property (IP) considerations. Overlooking these aspects can lead to project delays, cost overruns, and legal complications. Below are key pitfalls to watch for:

Quality-Related Pitfalls

Inconsistent Color and Performance

One of the most frequent issues is variability in color shade, particle size, and chemical composition between production batches. Sourcing from suppliers without rigorous quality control (QC) processes can result in visible color mismatches or uneven wear resistance across a project.

Poor Material Compatibility

Not all color hardeners are suitable for every type of concrete mix or finishing technique. Using a product incompatible with local cement types, aggregates, or curing methods can lead to delamination, dusting, or inadequate abrasion resistance.

Insufficient Technical Support

Suppliers may provide the product but lack on-the-ground expertise to guide proper application. Without access to technical data sheets, installation training, or field support, contractors risk improper installation and substandard results.

Lack of Certifications and Testing Data

Reputable color hardeners should meet industry standards (e.g., ASTM C94, ISO 11803). Sourcing from vendors who cannot provide third-party test reports for compressive strength, colorfastness, or slip resistance increases the risk of poor performance.

Intellectual Property (IP) Pitfalls

Unauthorized Use of Proprietary Formulas

Some suppliers may offer “compatible” or “equivalent” color hardeners that mimic branded products but infringe on patented formulations or trademarks. Using such products—even unknowingly—can expose contractors and developers to legal liability.

Misrepresentation of Brand Affiliation

Vendors may falsely claim affiliation with well-known brands (e.g., “Bomanite-style” or “like Scofield”). This not only violates trademark laws but may also mislead buyers about the actual performance and support available.

Lack of Licensing for Branded Systems

Certain decorative concrete systems (e.g., integral color finishes in licensed networks) require authorized applicator status. Sourcing materials from unauthorized distributors may void warranties and prevent certification for specific design specifications.

Unclear IP Ownership in Custom Colors

When developing custom hues for a project, it’s critical to clarify who owns the formulation rights. Suppliers may retain IP over custom mixes, limiting reuse or requiring future purchases through them exclusively.

Avoiding these pitfalls requires due diligence: verify supplier credentials, request product certifications, confirm IP legitimacy, and ensure contractual clarity on material rights and performance guarantees.

Logistics & Compliance Guide for Color Hardener

Product Overview

Color hardener is a dry-shake, cementitious surface treatment used to enhance the durability, wear resistance, and aesthetics of concrete surfaces. It typically consists of cement, fine aggregates, pigments, and performance-enhancing additives. Proper logistics and compliance handling are essential to maintain product quality, ensure worker safety, and meet regulatory standards.

Storage Requirements

Store color hardener in a cool, dry, and well-ventilated area. Keep bags elevated on pallets to prevent moisture absorption from the floor. Protect from direct exposure to rain, snow, or high humidity. Ensure packaging remains sealed until use to prevent caking or degradation. Avoid prolonged exposure to temperatures above 40°C (104°F) or below freezing.

Transportation Guidelines

Transport color hardener in covered, dry vehicles to prevent exposure to moisture or contaminants. Secure bags to prevent shifting during transit, which may cause damage and spillage. Avoid mixing with hazardous materials or products sensitive to dust. Maintain a clean transport environment to prevent cross-contamination with other construction materials.

Handling & Worker Safety

Personnel should wear appropriate personal protective equipment (PPE), including NIOSH-approved dust masks, safety goggles, gloves, and long-sleeve clothing. Minimize dust generation during handling by avoiding aggressive pouring or dropping from height. Use mechanical aids for lifting heavy bags to prevent strain injuries. In case of skin or eye contact, rinse thoroughly with water; seek medical attention if irritation persists.

Regulatory Compliance

Ensure the product complies with relevant regional and international standards, such as ASTM C979 for colored concrete, and local building codes. Review Safety Data Sheet (SDS) in accordance with OSHA’s Hazard Communication Standard (29 CFR 1910.1200) or equivalent regulations (e.g., EU REACH/CLP). Confirm that pigments used are free from restricted heavy metals (e.g., lead, cadmium, hexavalent chromium) as per environmental and health regulations.

Environmental Considerations

Dispose of unused or contaminated material in accordance with local waste management regulations. Do not discharge into storm drains or waterways. Control dust emissions during application using water misting or vacuum systems where applicable. Implement spill containment procedures to minimize environmental impact.

Documentation & Traceability

Maintain records for each batch, including manufacturing date, lot number, SDS, and certificates of compliance. Ensure all documentation is readily available for audits or inspections. Distributors and contractors should verify product authenticity and shelf life prior to use—typically 6 to 12 months from manufacture when stored properly.

Emergency Procedures

In case of large spills, contain material using inert absorbents and collect for proper disposal. For respiratory irritation due to dust exposure, remove affected individuals to fresh air and seek medical evaluation. Keep SDS accessible on-site and train personnel on emergency response protocols.

Conclusion for Sourcing Color Hardener:

Sourcing the right color hardener is a critical step in ensuring the durability, aesthetics, and long-term performance of colored concrete surfaces. After evaluating suppliers, product quality, color consistency, and technical support, it is evident that selecting a reputable and reliable provider is essential. Factors such as pigment concentration, compatibility with concrete mix designs, UV resistance, and adherence to industry standards must be carefully considered. Additionally, establishing strong relationships with suppliers who offer consistent product availability, clear specifications, and responsive service can significantly reduce project risks and delays. In conclusion, a strategic and informed approach to sourcing color hardener not only enhances the visual appeal of concrete finishes but also contributes to the structural integrity and longevity of the installation, ultimately delivering greater value to clients and end-users.