The global traffic safety equipment market is undergoing significant expansion, driven by rising urbanization, increased road construction activities, and stringent government regulations aimed at improving traffic management. According to Grand View Research, the global traffic management systems market size was valued at USD 3.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 11.4% from 2023 to 2030. A key segment within this ecosystem—collapsible traffic cones—is gaining traction due to their portability, reusability, and space efficiency, especially in crowded urban environments and temporary traffic control zones. With demand surging across smart city initiatives and infrastructure projects worldwide, manufacturers specializing in innovative, durable, and compliant collapsible cone solutions are positioning themselves at the forefront of this growth. This report identifies the top 8 manufacturers leading in product development, scalability, and market reach, based on production capacity, material innovation, global distribution, and adherence to safety standards.

Top 8 Collapsible Traffic Cones Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 to JBC Safety Plastic

Domain Est. 2017

Website: jbcsafetyplastic.com

Key Highlights: JBC Safety Plastic, Inc. is a leading manufacturer of premium traffic control and highway safety products….

#2 Collapsible Traffic Cone

Domain Est. 2017

Website: roadskysafety.com

Key Highlights: RoadSky is a professional collapsible traffic cone manufacturer and supplier. We design and manufacture various types of cones, including parking cones, safety ……

#3 28″ Collapsible Cone Kit (5 Cones)

Domain Est. 2002

#4 JBC Safety Plastic Inc

Domain Est. 2010 | Founded: 1999

Website: trafficconesforless.com

Key Highlights: 6-day delivery · 30-day returnsJBC safety plastic Inc was founded in 1999. After 20 years in business, JBC is recognized as a leader in the traffic control and safety markets….

#5 Reflective Cones for Traffic Safety & Construction on Sale

Domain Est. 2010

Website: trafficsafetywarehouse.com

Key Highlights: 5–10 day deliveryTraffic safety cones at low wholesale prices. We carry a big selection of top quality cones for use in traffic control, construction, event and more….

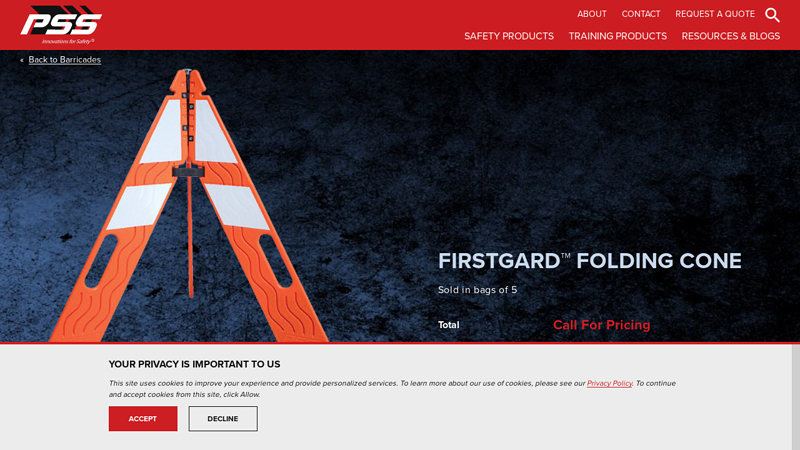

#6 FirstGard™ Folding Cone

Domain Est. 2015

Website: pss-innovations.com

Key Highlights: The Ultimate Foldable Traffic Cone for Enhanced Safety and Convenience. FirstGard is a patented, foldable cone that is ready at a moment’s notice….

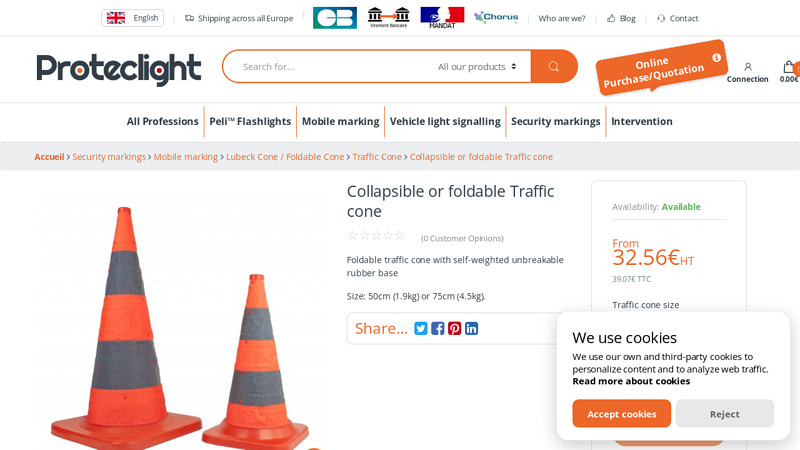

#7 Collapsible or foldable Traffic cone

Domain Est. 2019

Website: proteclight.com

Key Highlights: This foldable Lubeck cone is indispensable for optimum safety signage. Used by a large number of professionals such as the fire brigade, police forces and ……

#8 ArcMate Mfg. Corp.

Domain Est. 2024

Website: arcmate.shop

Key Highlights: In stock Free delivery18″ collapsible traffic cone with LED light on the top. Improve roadside safety for your Adopt-A-Highway group or when you have to change a tire….

Expert Sourcing Insights for Collapsible Traffic Cones

2026 Market Trends for Collapsible Traffic Cones

The market for collapsible traffic cones is poised for significant transformation by 2026, driven by technological advancements, sustainability demands, and evolving safety standards. These reusable, space-saving alternatives to traditional solid cones are gaining traction across construction, event management, and municipal sectors. Key trends shaping the 2026 landscape include:

Sustainability and Circular Economy Integration

Environmental responsibility will be a primary market driver. By 2026, collapsible cones made from recycled and recyclable materials—especially post-consumer plastics and biodegradable composites—will dominate. Regulatory pressures and corporate ESG (Environmental, Social, and Governance) goals will push manufacturers to offer take-back programs and closed-loop recycling systems. Demand will grow for cones with minimal carbon footprints, aligning with global sustainability targets and green procurement policies.

Smart Technology and IoT Integration

The rise of smart infrastructure will propel the adoption of intelligent collapsible cones. By 2026, expect widespread integration of embedded sensors, GPS tracking, and wireless communication (e.g., Bluetooth or LoRaWAN). These “smart cones” will enable real-time monitoring of cone placement, movement, and environmental conditions, improving worksite safety and operational efficiency. Municipalities and large contractors will use data from connected cones for traffic flow optimization, incident reporting, and asset management.

Material Innovation and Enhanced Durability

Advancements in polymer science will yield more resilient, weather-resistant, and UV-stable materials. Manufacturers will focus on lightweight yet impact-resistant thermoplastics and elastomers that maintain structural integrity under extreme temperatures and heavy use. Improved hinge and locking mechanisms will ensure longer product lifecycles, reducing replacement costs and supporting total cost of ownership arguments over traditional cones.

Expansion into New Applications and Geographies

Beyond traditional roadwork, collapsible cones will see increased use in temporary event zoning, airport ground operations, warehouse logistics, and disaster response. Emerging markets in Asia-Pacific, Latin America, and Africa—where urbanization and infrastructure investment are accelerating—will present high-growth opportunities. Localized production and distribution networks will emerge to meet regional demand and reduce shipping costs.

Regulatory Compliance and Standardization

As adoption spreads, regulatory bodies will likely introduce or update standards specific to collapsible cones—covering visibility, stability, and performance under load. Manufacturers will need to ensure compliance with international safety norms (e.g., MUTCD in the U.S., EN standards in Europe). Certification and third-party testing will become critical for market access and user trust.

Cost Efficiency and Total Ownership Value

While initial costs may be higher than conventional cones, the value proposition of collapsible models—through reduced storage, transportation, and labor expenses—will be a key selling point. By 2026, fleet managers and public agencies will increasingly justify purchases based on lifecycle cost analysis, driving broader adoption across both public and private sectors.

In summary, the 2026 collapsible traffic cone market will be defined by smarter, greener, and more versatile products. Success will depend on innovation in materials, connectivity, and sustainability, supported by evolving regulations and expanding global demand.

Common Pitfalls When Sourcing Collapsible Traffic Cones: Quality and Intellectual Property Risks

Poor Material Quality and Durability

One of the most frequent issues when sourcing collapsible traffic cones is substandard material quality. Many low-cost suppliers use inferior plastics that become brittle in cold weather or degrade quickly under UV exposure. This leads to cracking, fading, and structural failure, reducing the cone’s lifespan and compromising safety. Buyers should verify that materials meet industry standards (e.g., UV-resistant PVC or polyethylene) and request durability test reports.

Inconsistent Structural Integrity

Collapsible cones must reliably expand and collapse without breaking. Poorly designed hinges or weak connection points can cause the cone to fail under minimal pressure or repeated use. Sourcing from manufacturers without rigorous quality control often results in inconsistent product performance. Always request physical samples and conduct stress tests before bulk orders.

Non-Compliance with Safety Standards

Many collapsible cones fail to meet traffic safety regulations such as MUTCD (Manual on Uniform Traffic Control Devices) in the U.S. or EN ISO 9001 in Europe. Non-compliant products may lack required reflective strips, correct coloration (e.g., fluorescent orange), or proper height and visibility. This not only poses safety hazards but can also lead to legal liability.

Intellectual Property Infringement

A significant but often overlooked risk is sourcing cones that infringe on existing patents or designs. Some collapsible cone mechanisms are protected by utility or design patents. Suppliers, especially in regions with lax IP enforcement, may copy patented features without authorization. Buyers risk legal action, shipment seizures, or forced product recalls if they import infringing goods. Conduct patent searches and obtain IP indemnification from suppliers to mitigate this risk.

Lack of Traceability and Supplier Verification

Using unverified suppliers increases the risk of receiving counterfeit or misrepresented products. Without proper auditing, it’s difficult to confirm manufacturing processes, material origins, or compliance certifications. Always perform supplier due diligence, including factory audits and third-party inspections, to ensure authenticity and consistency.

Inadequate Packaging and Shipping Damage

Collapsible cones are often shipped flat, but poor packaging can lead to deformation or damage during transit. Insufficient protection may cause creasing or warping, making the cones unusable upon arrival. Confirm that the supplier uses robust, customized packaging suited for bulk shipping and long distances.

Hidden Costs from Quality Failures

While low initial pricing is attractive, poor quality leads to higher total costs due to replacements, returns, and downtime. Factoring in inspection, logistics, and potential compliance fines reveals that sourcing the cheapest option often backfires. Prioritize total cost of ownership over upfront savings.

Logistics & Compliance Guide for Collapsible Traffic Cones

Product Overview

Collapsible traffic cones are portable, reusable safety devices designed for temporary traffic control, crowd management, and hazard marking. Their collapsible design allows for compact storage and efficient transportation, making them ideal for municipal, construction, event management, and emergency response applications.

Packaging and Storage

- Packaging: Store cones in durable, stackable containers or mesh bags to prevent deformation and facilitate handling.

- Stacking: Ensure cones are fully collapsed before stacking. Limit stack height to avoid compression damage.

- Environment: Store in a cool, dry place away from direct sunlight and extreme temperatures to prevent UV degradation and material warping.

- Shelf Life: Inspect regularly for cracks, fading, or material fatigue. Replace if performance is compromised.

Transportation Guidelines

- Loading: Secure packaged cones with straps or dividers to prevent shifting during transit.

- Vehicle Type: Standard cargo vans, trucks, or flatbeds are suitable. Use weather-resistant covers if transporting uncovered.

- Weight Distribution: Distribute load evenly to maintain vehicle balance and comply with weight regulations.

- Hazard Classification: Non-hazardous materials. No special handling or placarding required under DOT or ADR.

Import/Export Compliance

- HS Code: Typically classified under 6914.90.00 (Ceramic traffic cones) or 3926.30.00 (Plastic safety cones) – verify based on material composition.

- Customs Documentation: Include commercial invoice, packing list, bill of lading, and certificate of origin.

- Country-Specific Regulations: Confirm compliance with destination country’s road safety standards (e.g., EN 13422 in EU, MUTCD in USA).

- Tariff & Duties: Check applicable tariffs using local customs databases; preferential rates may apply under trade agreements.

Safety and Regulatory Standards

- USA (MUTCD): Cones must meet Manual on Uniform Traffic Control Devices (MUTCD) specifications:

- Minimum height: 18 inches (Type I) to 36 inches (Type III)

- Retroreflective collars required for nighttime visibility

- Bright orange color (Pantone 151C)

- European Union (EN 13422):

- Cones must comply with EN 13422 for visibility, stability, and retroreflection

- CE marking required for sale in EU markets

- Canada (TCS): Must conform to Transportation of Dangerous Goods (TDG) and provincial traffic control standards.

- Australia (AS/NZS 1742.3): Compliance with Australian/New Zealand standards for road control devices.

Labeling and Marking Requirements

- Product Labels: Include manufacturer name, model number, material type, compliance marks (e.g., CE, MUTCD), and manufacturing date.

- Retroreflective Bands: Install approved reflective sheeting (e.g., ASTM D4956) at specified heights for nighttime visibility.

- Warning Labels: Attach safety instructions and usage limitations (e.g., “For Temporary Use Only”).

Environmental and Disposal Compliance

- Materials: Most collapsible cones are made from PVC or polyethylene—check local recyclability.

- Disposal: Do not incinerate PVC due to dioxin emissions. Dispose of in accordance with local waste regulations.

- RoHS/REACH: Ensure compliance with RoHS (EU) and REACH regulations for restricted substances if selling in Europe.

Quality Assurance and Inspection

- Pre-Shipment Inspection: Verify color, dimensions, reflectivity, and structural integrity.

- Batch Testing: Conduct periodic drop tests, UV resistance, and stability checks.

- Documentation: Maintain test reports, compliance certificates, and factory audit records.

Best Practices for End Users

- Deployment: Place cones at proper spacing (typically 10–20 feet apart) and secure in high-wind areas.

- Maintenance: Clean with mild soap and water; avoid harsh chemicals. Inspect before each use.

- Replacement: Replace cones that are cracked, faded, or no longer stand upright reliably.

Summary

Collapsible traffic cones must meet strict regulatory, safety, and logistical standards to ensure effectiveness and legal compliance. By adhering to packaging, transportation, import/export, and safety guidelines, suppliers and users can ensure reliable performance and avoid compliance risks across global markets.

Conclusion: Sourcing Collapsible Traffic Cones

Sourcing collapsible traffic cones presents a strategic opportunity to enhance operational efficiency, reduce transportation and storage costs, and support sustainability goals. These versatile alternatives to traditional solid cones offer significant space savings due to their foldable design, making them ideal for organizations requiring portability and frequent deployment—such as event management teams, construction companies, and municipal traffic control units.

When sourcing collapsible cones, key considerations include material durability (typically high-grade PVC or rubber), visibility (ensuring compliance with safety standards through reflective bands and bright colors), and resistance to environmental factors such as UV exposure and extreme temperatures. Evaluating suppliers based on product quality, certifications (e.g., MUTCD compliance), pricing, and reliability is crucial to ensuring long-term value.

Additionally, bulk purchasing and establishing relationships with reputable manufacturers—whether domestic or international—can lead to cost savings and consistent supply. While the initial investment in collapsible cones may be higher than traditional models, the long-term benefits in logistics, labor, and product lifespan justify the expense.

In conclusion, collapsible traffic cones are a smart, forward-thinking choice for modern traffic management needs. By carefully selecting high-quality, standards-compliant products from trustworthy suppliers, organizations can improve safety, streamline operations, and achieve greater cost-efficiency across their projects.