The global fasteners market, driven by robust demand from automotive, construction, and industrial machinery sectors, is projected to grow at a CAGR of 5.8% from 2023 to 2030, according to Grand View Research. Within this expanding landscape, coil bolts—renowned for their superior load distribution and vibration resistance—have become critical components in structural and mechanical applications. As infrastructure development accelerates and manufacturing processes demand higher precision, the need for high-quality coil bolt manufacturers has intensified. Based on production capacity, global reach, product innovation, and industry certifications, the following eight manufacturers have emerged as leaders, shaping the standards of performance and reliability in the coil bolt segment.

Top 8 Coil Bolt Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Coil Bolts

Domain Est. 1994

Website: grainger.com

Key Highlights: Coil bolts, sometimes called form bolts, screw into coil ties and provide clamping force to hold concrete forms together….

#2 Coil Thread Products

Domain Est. 2002

Website: ocm-inc.com

Key Highlights: Explore OCM’s full line of coil thread products—engineered for strength, durability, and ease of use on concrete forming projects. From coil rods and ……

#3 Global Leader in Fastening Technology

Domain Est. 2012

Website: stanleyengineeredfastening.com

Key Highlights: Lightweight, durable, and cost-effective, our plastic fasteners are designed for modern applications across automotive, electronics, and consumer goods….

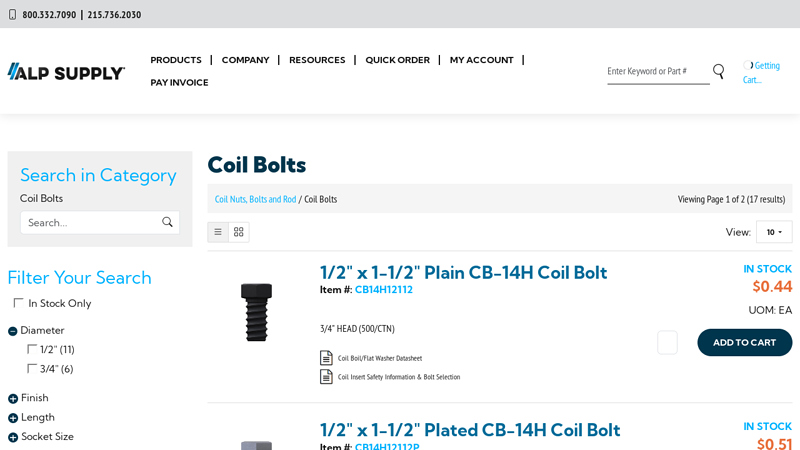

#4 Coil Bolts

Domain Est. 1996

Website: tengco.com

Key Highlights: Tengco’s coil bolts are made using cold heading or hot forging to ensure durability and ease of use, and can be custom-designed to meet your needs….

#5 B14A – Adjustable Coil Bolt

Domain Est. 1996

Website: daytonsuperior.com

Key Highlights: The B14A allows formwork adjustments to be made with the free-running nut and can accommodate various form thickness as with one size adjustable bolt….

#6 Coil Thread Security Bolts

Domain Est. 2001

Website: brycefastener.com

Key Highlights: Coil Thread security bolts work well in precast concrete forms that contain the corresponding female coil insert. The concrete grit does not affect coil threads ……

#7 Coil Bolts

Domain Est. 2008

Website: aftfasteners.com

Key Highlights: Free delivery over $200 · 30-day returns…

#8 Coil Bolts for Coil Inserts

Domain Est. 2016

Expert Sourcing Insights for Coil Bolt

H2: 2026 Market Trends for Coil Bolts

The global coil bolt market is poised for steady growth and transformation through 2026, driven by evolving construction practices, infrastructure development, and industrial automation. As we assess the second half (H2) of the year 2026, several key market trends are shaping the demand, supply, and technological advancement in the coil bolt sector.

1. Increased Demand from Construction and Infrastructure Sectors

In H2 2026, the coil bolt market continues to benefit from robust public and private investments in infrastructure projects, particularly in emerging economies across Asia-Pacific, the Middle East, and Africa. Governments are accelerating smart city initiatives, transportation networks, and renewable energy installations—all of which require high-quality fasteners like coil bolts. Urbanization and the need for earthquake-resistant and modular construction further boost demand for durable and reliable fastening solutions.

2. Shift Toward High-Strength and Corrosion-Resistant Materials

Manufacturers are increasingly adopting advanced materials such as stainless steel, alloy steel, and coated carbon steel to meet growing performance and longevity requirements. In H2 2026, environmental regulations and the need for sustainable building practices are pushing the industry toward corrosion-resistant coil bolts, especially for use in coastal, industrial, and high-humidity environments. Innovations in surface treatments—such as zinc-nickel plating and duplex coating—are gaining traction.

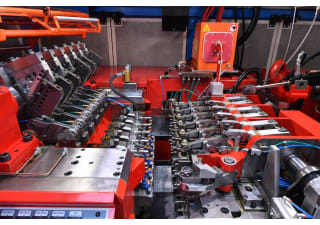

3. Automation and Smart Manufacturing Integration

The coil bolt production landscape is being transformed by Industry 4.0 technologies. In H2 2026, automated forging, precision threading, and real-time quality control systems are becoming standard among leading manufacturers. IoT-enabled machinery allows for predictive maintenance and reduced downtime, improving output efficiency. Additionally, digital twins and AI-driven supply chain optimization are helping companies respond faster to fluctuating demand.

4. Regional Market Dynamics

Asia-Pacific remains the dominant market for coil bolts in H2 2026, led by China, India, and Southeast Asian nations undergoing rapid industrialization. North America shows steady demand, supported by infrastructure revitalization programs under national investment plans. Europe maintains a mature but stable market, with growth driven by green building standards and the renovation wave. Meanwhile, Latin America and Africa are emerging as high-potential regions due to increased foreign direct investment in construction and energy projects.

5. Sustainability and Circular Economy Pressures

Environmental, Social, and Governance (ESG) criteria are influencing procurement decisions. In H2 2026, coil bolt manufacturers are under pressure to reduce carbon emissions, minimize waste, and improve energy efficiency across production cycles. Recyclable materials and closed-loop manufacturing systems are being adopted. Some suppliers are introducing take-back programs or offering carbon footprint labeling on products.

6. Supply Chain Resilience and Localization

Geopolitical tensions and past disruptions have prompted companies to reevaluate global supply chains. In H2 2026, there is a continued shift toward regionalized production and inventory strategies. Nearshoring and onshoring of fastener manufacturing are on the rise, particularly in North America and Europe, reducing dependency on single-source suppliers and enhancing delivery reliability.

7. Price Volatility and Raw Material Challenges

Fluctuations in steel prices and energy costs remain a concern in H2 2026. While demand is strong, manufacturers face margin pressures due to elevated input costs. Some companies are mitigating risks through long-term contracts with raw material suppliers and hedging strategies. Alternatives such as recycled steel are being explored to balance cost and sustainability.

Conclusion

By H2 2026, the coil bolt market reflects a convergence of traditional industrial demand and modern technological innovation. Growth is sustained by infrastructure expansion and construction activity, while advancements in materials, automation, and sustainability are redefining competitiveness. Companies that invest in R&D, supply chain agility, and eco-friendly practices are best positioned to capture market share in this evolving landscape.

Common Pitfalls Sourcing Coil Bolts (Quality, IP)

Sourcing coil bolts—long, coiled steel rods used in construction and manufacturing—requires careful attention to quality and IP (Ingress Protection) ratings, especially when used in electrical enclosures or harsh environments. Overlooking key factors can lead to performance failures, safety risks, and increased lifecycle costs. Below are common pitfalls to avoid:

Poor Material Quality and Inconsistent Tolerances

Low-grade steel or substandard manufacturing processes can result in coil bolts with inconsistent diameters, poor thread integrity, or reduced tensile strength. This increases the risk of breakage during installation or under load. Always verify material certifications (e.g., ASTM, ISO) and insist on mill test reports to ensure compliance with required mechanical properties.

Misunderstanding or Ignoring IP Requirements

Coil bolts used in electrical or outdoor applications often contribute to the overall IP rating of an assembly. A common mistake is selecting bolts that compromise enclosure integrity—such as using non-sealing fasteners in IP65/IP66-rated housings. Ensure the bolt design (e.g., shoulder bolts, sealed heads) and配套 components (gaskets, washers) support the target IP rating.

Inadequate Corrosion Resistance

Standard zinc-plated or uncoated coil bolts may corrode quickly in humid, saline, or chemically aggressive environments. This not only degrades appearance but also weakens structural integrity. Choose appropriate coatings like hot-dip galvanizing, Dacromet, or stainless steel variants (e.g., A2/A4) based on the operating environment.

Incorrect Thread Type or Pitch

Using mismatched thread types (e.g., metric vs. imperial) or pitches can lead to cross-threading, galling, or incomplete engagement. This is particularly critical in automated assembly processes. Confirm thread specifications with engineering drawings and ensure supplier consistency across batches.

Lack of Traceability and Certification

Reputable applications—especially in construction, energy, or rail—require full traceability. Sourcing coil bolts without proper batch traceability, heat numbers, or third-party inspection reports can lead to non-compliance during audits or project sign-off.

Overlooking Total Cost of Ownership

Focusing solely on unit price may lead to selecting cheaper, lower-quality bolts that fail prematurely, increasing maintenance, safety incidents, and downtime. Evaluate suppliers based on lifecycle performance, warranty, and technical support, not just upfront cost.

Avoiding these pitfalls requires clear specifications, supplier vetting, and quality assurance protocols throughout the procurement process.

Logistics & Compliance Guide for Coil Bolt

Overview

Coil bolts, also known as continuous rod fasteners or coil screws, are threaded fasteners typically supplied in coiled form for automated feeding and high-speed assembly applications. Due to their specialized use in manufacturing, construction, and industrial settings, proper logistics handling and regulatory compliance are critical to ensure safety, performance, and adherence to international standards.

Packaging & Storage

Coil bolts must be packaged to prevent tangling, corrosion, and mechanical damage during transit and storage. Standard practices include:

– Coiled Spools or Reels: Supplied on plastic or metal spools with protective end caps.

– Moisture Protection: Use of vapor corrosion inhibitors (VCI) or sealed plastic wraps in humid environments.

– Labeling: Each coil must be clearly labeled with product specifications, material grade, batch/lot number, and manufacturer details.

– Storage Conditions: Store in a dry, temperature-controlled environment away from direct sunlight and corrosive agents.

Transportation Requirements

- Handling: Use appropriate lifting equipment (e.g., forklifts with drum clamps) to move large coils; avoid dropping or rolling spools.

- Securing Loads: Coil bolts must be securely fastened within shipping containers or trucks to prevent movement during transit.

- Stacking Limits: Follow manufacturer guidelines to prevent deformation or damage due to excessive stacking weight.

- Hazard Classification: Coil bolts are generally non-hazardous; however, sharp edges may require protective packaging to meet carrier safety standards.

Customs & Import/Export Compliance

- HS Code Classification: Use appropriate Harmonized System (HS) codes (e.g., 7318.15 for threaded steel rods) to ensure correct tariff application.

- Country-Specific Regulations: Verify import requirements for destination countries, including conformity assessment procedures and documentation (e.g., Certificate of Origin, Commercial Invoice, Packing List).

- ITAR/EAR Considerations: Most coil bolts are not controlled under U.S. export regulations (ITAR/EAR), but high-strength or specially alloyed variants may require export licenses.

- RoHS & REACH Compliance: Ensure coil bolts (especially those used in EU markets) comply with Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulations, particularly for surface coatings.

Quality & Certification Standards

- Material Standards: Confirm compliance with ASTM A307, ASTM A193, ISO 898-1, or other relevant specifications based on application.

- Traceability: Maintain full traceability from raw material to final product, including heat numbers and test reports.

- Certifications: Provide Mill Test Certificates (e.g., EN 10204 3.1 or 3.2) upon request.

- Inspection Protocols: Implement incoming and outgoing quality checks for thread accuracy, tensile strength, and surface finish.

Environmental & Safety Compliance

- Waste Disposal: Discarded packaging and unusable coils should be disposed of in accordance with local environmental regulations; metal coils may be recyclable.

- Workplace Safety: Follow OSHA (or equivalent) guidelines when handling coils to prevent injury from sharp edges or uncontrolled unraveling.

- Chemical Treatments: Disclose any surface treatments (e.g., zinc plating, oil coatings) and ensure they meet environmental safety standards.

Documentation & Recordkeeping

Maintain accurate records for:

– Batch production and testing data

– Shipping manifests and delivery confirmations

– Compliance certifications and test reports

– Customer-specific requirements and audit trails

Conclusion

Effective logistics and compliance management for coil bolts ensure product integrity, regulatory adherence, and customer satisfaction. By following standardized procedures in packaging, transportation, documentation, and quality assurance, suppliers and distributors can minimize risks and support seamless industrial operations globally.

Conclusion for Sourcing Coil Bolts

In conclusion, the successful sourcing of coil bolts requires a strategic approach that balances quality, cost, reliability, and supply chain efficiency. By carefully evaluating suppliers based on certifications, material standards, production capabilities, and delivery performance, organizations can ensure the consistent supply of high-quality coil bolts that meet technical specifications and industry requirements. Establishing long-term partnerships with reputable suppliers, leveraging volume purchasing, and implementing robust quality control processes further enhance sourcing effectiveness. Additionally, monitoring market trends and material costs allows for proactive adjustments to mitigate risks related to price volatility and supply disruptions. Ultimately, a well-structured coil bolt sourcing strategy contributes to improved operational efficiency, reduced downtime, and sustained competitiveness in manufacturing and construction applications.