The global cobalt laser market is experiencing steady growth, driven by rising demand in industrial, medical, and scientific applications. According to Grand View Research, the global solid-state laser market—which includes cobalt-doped lasers—was valued at USD 2.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.8% from 2023 to 2030. Cobalt lasers, specifically those utilizing cobalt-doped magnesium fluoride (Co:MgF₂), are gaining traction for their tunability in the mid-infrared spectrum, making them critical for spectroscopy, environmental sensing, and defense technologies. This surge in demand is fueling innovation and competition among key manufacturers. Based on market presence, technological capability, and application reach, the following five companies stand out as leading cobalt laser manufacturers shaping the industry landscape.

Top 5 Cobolt Laser Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

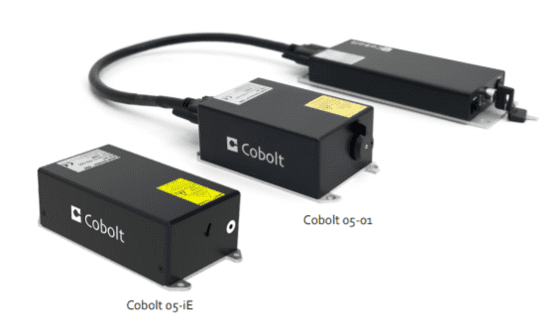

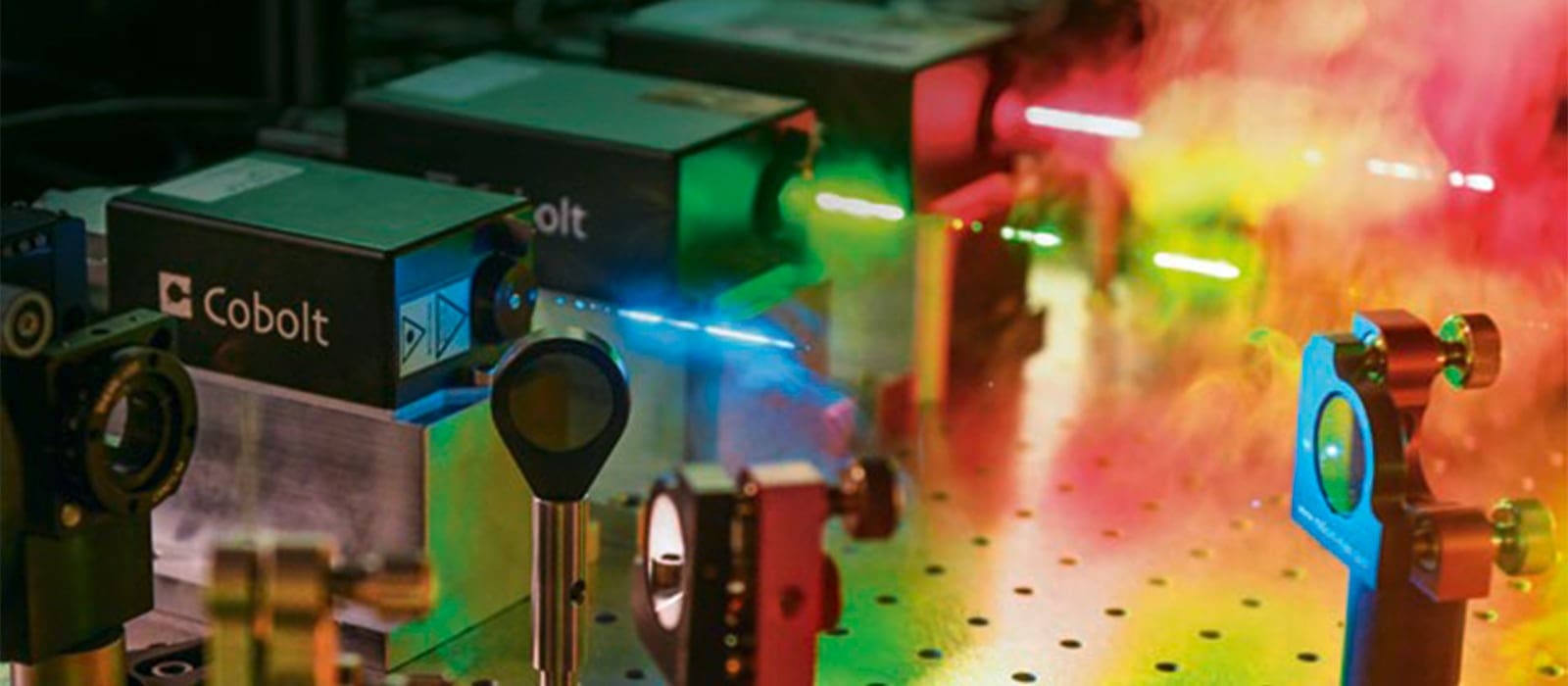

#1 Cobolt Lasers

Website: hubner-photonics.com

Key Highlights: Cobolt lasers are renowned for their exceptional reliability and long operational lifetimes, a trusted choice across demanding applications….

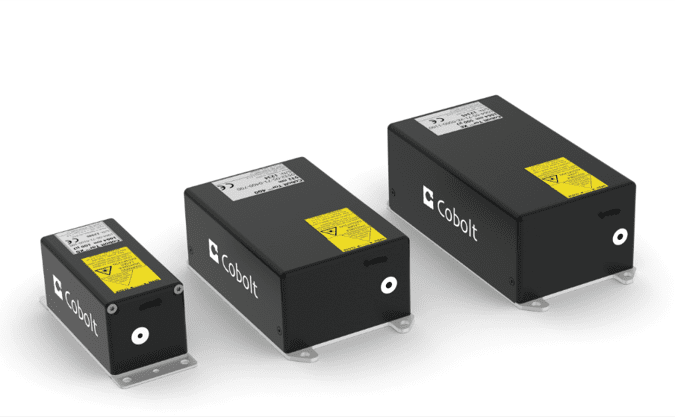

#2 Cobolt lasers

Website: hubner-group.com

Key Highlights: Cobolt Lasers. Customized to your requirements. The HÜBNER Group company Cobolt is a proven Swedish supplier of high-performance lasers for more than 15 years….

#3 Cobolt AB, a part of HÜBNER Photonics

Website: data-surfer.com

Key Highlights: Cobolt AB is a leading supplier of high-performance lasers, known for its commitment to quality and innovation. The company supports cutting-edge applications ……

#4 Cobolt Lasers

Website: github.com

Key Highlights: Cobolt Lasers has 6 repositories available. Follow their code on GitHub….

#5 Hübner Photonics Laser combiners and CW OPOs

Website: laser2000.eu

Key Highlights: Hübner’s Cobolt lasers form the largest range of high-performance diode-pumped solid-state lasers (DPSSLs) available on the market. Hübner refers to these as ……

Expert Sourcing Insights for Cobolt Laser

H2: 2026 Market Trends Analysis for Cobolt Lasers

The global laser technology market is poised for significant evolution by 2026, driven by advancements in photonics, increased demand across biomedical, industrial, and quantum technology sectors, and the growing need for compact, stable, and high-performance laser sources. Cobolt lasers—known for their high coherence, narrow linewidth, and reliability in scientific and industrial applications—will likely experience strategic growth and transformation influenced by several key trends.

-

Expansion in Biophotonics and Life Sciences

By 2026, the biophotonics market is projected to grow at a CAGR of over 9%, fueled by innovations in flow cytometry, confocal microscopy, and super-resolution imaging. Cobolt lasers, particularly single-frequency DPSS and fiber-coupled models, are well-positioned to benefit due to their spectral purity and stability. Demand for 532 nm and 561 nm wavelengths will remain strong in fluorescence-based applications, with increasing adoption in point-of-care diagnostics and in vivo imaging. -

Growth in Quantum Technologies

The quantum computing and quantum sensing sectors are expected to see accelerated investment by 2026, with governments and private enterprises expanding R&D efforts. Cobolt lasers, especially those operating at specific wavelengths (e.g., 375 nm for ion trapping), will play a critical role in atomic cooling, manipulation, and readout. Their low noise and high beam quality make them ideal for integration into quantum hardware, positioning Cobolt as a key supplier in this high-value niche. -

Industrial Automation and Precision Manufacturing

As industries adopt more advanced laser-based solutions for micromachining, lidar, and 3D sensing, there will be growing demand for compact and robust laser modules. Cobolt’s expertise in turnkey laser systems with excellent thermal stability supports integration into automated production lines. Trends toward miniaturization and increased throughput will favor Cobolt’s OEM-focused product lines, especially in semiconductor inspection and photovoltaics. -

Consolidation and Competition in the Laser Market

The laser industry is expected to see further consolidation by 2026, with larger photonics companies acquiring niche players to broaden their portfolios. Cobolt, currently part of HÜBNER Photonics, may leverage its brand reputation to expand market share, but will face intensified competition from emerging Chinese laser manufacturers offering lower-cost alternatives. Differentiation through superior performance, reliability, and technical support will be critical. -

Sustainability and Energy Efficiency

Environmental regulations and corporate sustainability goals will increasingly influence laser design and manufacturing. Cobolt lasers, known for high electrical-to-optical efficiency and long lifetimes, align well with green technology trends. By 2026, energy-efficient and RoHS-compliant laser systems will be preferred in both academic and industrial settings, offering Cobolt a competitive advantage. -

Advancements in Integration and Smart Lasers

The trend toward “smart” photonic systems—lasers with built-in monitoring, feedback control, and digital interfaces—will accelerate. Cobolt is likely to enhance its offerings with IoT-enabled features, remote diagnostics, and compatibility with AI-driven instrumentation platforms. This shift supports integration into next-generation lab-on-a-chip devices and autonomous research systems.

Conclusion

By 2026, Cobolt lasers are expected to maintain a strong foothold in high-precision markets, particularly in life sciences and quantum technologies. Strategic focus on reliability, wavelength specificity, and OEM integration will be crucial for sustained growth. However, success will depend on continuous innovation, adaptation to competitive pressures, and alignment with emerging application domains where performance outweighs cost sensitivity.

Common Pitfalls When Sourcing Cobalt Lasers: Quality and Intellectual Property Risks

When sourcing cobalt lasers—particularly high-performance diode-pumped solid-state (DPSS) lasers used in scientific, medical, and industrial applications—organizations must navigate several critical pitfalls related to quality assurance and intellectual property (IP) protection. Failing to address these can result in operational inefficiencies, legal exposure, and compromised product integrity.

Quality Inconsistencies and Reliability Concerns

One of the most prevalent risks in sourcing cobalt lasers is variability in product quality. Many suppliers, especially those in less-regulated markets, may offer lasers that appear similar on paper but underperform in real-world applications. Key quality pitfalls include:

- Lack of Standardized Testing: Some manufacturers do not adhere to rigorous performance testing for parameters like beam stability, wavelength accuracy, and power output consistency.

- Component Substitution: Unverified suppliers might use lower-grade optical components or substitute critical materials, leading to premature failure or reduced laser lifetime.

- Inadequate Thermal Management: Poor thermal design can cause mode instability and reduced coherence, affecting application precision—especially in sensitive uses like flow cytometry or confocal microscopy.

- Insufficient Certification: Absence of international quality certifications (e.g., ISO 9001, IEC standards) may signal unreliable manufacturing processes.

To mitigate these risks, buyers should require third-party validation, request sample testing under application-specific conditions, and verify supplier track records in delivering reliable laser systems.

Intellectual Property Infringement and Counterfeiting

Cobalt lasers often incorporate proprietary technologies protected by patents and trade secrets. Sourcing from unauthorized or unverified vendors increases the risk of IP violations:

- Patented Technology Use Without Licensing: Many laser designs—such as specific cavity configurations or frequency-doubling techniques—are protected. Suppliers may replicate these without proper licensing, exposing end users to legal liability.

- Counterfeit or Clone Products: Some suppliers offer “compatible” or “replacement” lasers that mimic original equipment manufacturer (OEM) designs. These may infringe on design patents or trademarks and lack performance guarantees.

- Unclear IP Ownership: Contracts with suppliers may fail to clarify who owns modifications or custom designs, leading to disputes over rights and usage rights.

To protect against IP risks, organizations should conduct due diligence on supplier legitimacy, verify patent clearance for key technologies, and include strong IP indemnification clauses in procurement agreements. Partnering with authorized distributors or OEMs directly reduces exposure to counterfeit or infringing products.

By proactively addressing quality and IP concerns, businesses can ensure reliable performance and legal compliance when integrating cobalt lasers into their systems.

Logistics & Compliance Guide for Cobolt Lasers

This guide provides essential information for the safe, efficient, and legally compliant handling, transportation, and use of Cobolt lasers. Adherence to these guidelines ensures product integrity, user safety, and regulatory compliance.

Product Classification & Regulatory Status

Cobolt lasers are classified as Class 3B or Class 4 laser products under international laser safety standards (IEC 60825-1). Each unit is labeled accordingly and must be used in compliance with applicable national and international regulations, including but not limited to:

– IEC 60825 (Laser Safety)

– FDA 21 CFR Part 1040.10 (U.S. Radiation Emitting Products)

– EU Directive 2014/35/EU (Low Voltage Directive) and 2014/53/EU (EMC Directive), where applicable

– RoHS and REACH compliance for hazardous substances

Documentation including the Declaration of Conformity (DoC), technical files, and safety instructions are available upon request or via the manufacturer’s website.

Packaging & Handling Instructions

Cobolt lasers must be shipped in the original protective packaging, which includes:

– Custom-molded foam inserts

– Anti-static protection

– Secure outer corrugated box with handling labels

Always handle units with care. Avoid:

– Dropping or subjecting to mechanical shock

– Exposure to extreme temperatures or humidity

– Touching optical surfaces or electrical contacts

Inspect packaging upon receipt. Report any signs of damage immediately to the carrier and supplier.

Shipping & Transportation

Cobolt lasers are non-hazardous for transport under IATA, IMDG, and ADR regulations when properly packaged. However, due to sensitive optics and electronics:

– Use only approved couriers experienced in handling precision instruments

– Include shock and temperature indicators for high-value or long-distance shipments when required

– Ensure packages are clearly labeled with “Fragile,” “This Side Up,” and “Protect from Moisture”

– Maintain shipment records for traceability

International shipments require:

– Commercial invoice detailing product description, value, and country of origin

– Proper Harmonized System (HS) code (typically 9013.20 for laser generators)

– Export control screening (no ITAR or EAR restrictions apply to standard Cobolt lasers, but verify per configuration)

Import & Customs Clearance

Importers are responsible for ensuring compliance with local regulations. Key considerations include:

– Payment of applicable duties and taxes

– Verification of CE, UKCA, or other regional conformity markings

– Compliance with local laser safety regulations (e.g., FDA registration for U.S. imports)

– Retention of supporting documentation (DoC, invoice, packing list) for audit purposes

Work with a licensed customs broker to expedite clearance and avoid delays.

Installation & Operational Compliance

Installation must be performed by qualified personnel in accordance with:

– Manufacturer’s installation manual

– Local electrical codes (e.g., NEC, IEC 60364)

– Laser safety standards (e.g., ANSI Z136.1 in the U.S.)

Required safety measures include:

– Controlled access to laser operation area

– Use of appropriate laser safety eyewear

– Installation of interlocks and warning signs (laser radiation symbol)

– Beam path enclosure where applicable

Maintenance & Service

Scheduled maintenance must be performed by authorized service personnel only. Unauthorized modifications void compliance certifications and warranties. Keep records of all service activities. Replace defective components only with manufacturer-approved parts.

End-of-Life & Disposal

Dispose of Cobolt lasers in accordance with local electronic waste (WEEE) and hazardous material regulations. Do not dispose of in regular trash. Contact certified e-waste recyclers for proper handling. Remove batteries (if applicable) and recycle separately.

Support & Documentation

For compliance documentation, safety data sheets, or regulatory inquiries, contact:

Cobolt Support

[email protected]

+46 8 XXX XX XX

Always refer to the latest product-specific manuals and regulatory updates available at www.coboltlasers.com/compliance.

Conclusion for Sourcing Cobalt Lasers

After a thorough evaluation of the market, technical requirements, supplier capabilities, and cost considerations, sourcing Cobalt lasers—specifically those manufactured by Coherent (formerly Cobalt/OSI) —remains a strategic decision based on reliability, performance, and integration suitability for high-precision applications such as flow cytometry, biomedical imaging, and industrial inspection.

Cobalt lasers (e.g., the Sapphire series) are recognized for their single-mode output, high beam quality, long operational life, and excellent power stability, making them a preferred choice in mission-critical and OEM environments. While alternative laser sources from other manufacturers may offer competitive pricing, the proven track record, technical support, and consistency of Cobalt-branded lasers justify their premium positioning.

Key considerations in the sourcing decision include:

- Supply Chain Stability: Coherent maintains global manufacturing and distribution channels, though lead times can vary. Establishing long-term agreements or safety stock is advisable.

- Technical Compatibility: Cobalt lasers are well-documented and widely supported in existing systems, reducing integration risk.

- Total Cost of Ownership: Despite higher upfront costs, the durability and service life of Cobalt lasers often result in lower lifetime costs compared to less reliable alternatives.

- Future-Proofing: As Coherent continues to innovate under its laser portfolio, sourcing Cobalt lasers ensures access to firmware updates, replacements, and technical upgrades.

In conclusion, sourcing Cobalt lasers is recommended for applications requiring high reliability, precision, and long-term serviceability. A dual-sourcing strategy may be explored for risk mitigation, but transitioning away from Cobalt lasers should be carefully evaluated due to potential integration challenges and performance trade-offs.