The global coal chute door market is experiencing steady growth, driven by rising demand for efficient material handling solutions in power generation, mining, and industrial sectors. According to Mordor Intelligence, the global coal handling systems market—which includes critical components like chute doors—is projected to grow at a CAGR of over 4.2% from 2023 to 2028. This expansion is fueled by increasing investments in thermal power plants, particularly in emerging economies across Asia-Pacific such as India and China, where coal remains a dominant energy source. Additionally, the need for dust suppression, improved safety standards, and operational efficiency is pushing industries to adopt advanced, durable coal chute door systems. As infrastructure modernization continues and aging coal handling facilities are upgraded, manufacturers that offer high-performance, wear-resistant, and customizable chute door solutions are gaining a competitive edge. Based on market presence, technological capabilities, and customer feedback, the following seven manufacturers have emerged as key players in the coal chute door industry.

Top 7 Coal Chute Door Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Coal Chute Door

Domain Est. 2023

Website: wellbrockinternational.com

Key Highlights: We are one of the leading manufacturers and exporters from India, specializing in Scaffolding and Formwork, Chain Link Fences and Fittings, Tractor Linkage ……

#2 Safe

Domain Est. 1996

Website: asgco.com

Key Highlights: Safe-Guard Conveyor Chute Inspection and Access Doors are necessary part of any material handling system. Add an Inspection Door to your existing head chute….

#3 Stainless Steel Trash Chute Doors for Sale

Domain Est. 2000

Website: oswaldsupply.com

Key Highlights: 4-day delivery 30-day returnsMany of our stainless steel trash chute doors are sold with an ADA compliant closer. T handle and L handle style are both available at no extra cost….

#4 Coal Chute Design and Transfer Point Replacement

Domain Est. 2004

Website: acensium.com

Key Highlights: Successful coal chute design, or other bulk material transfer-point replacement, requires adherence to a key set of criteria….

#5 Brochure

Domain Est. 2009

Website: chutesenterprises.com

Key Highlights: Chutes Enterprises Designs manufactures and installs complete waste and soiled linen chute systems. Our manufacturing plant is located in lower New York Statr….

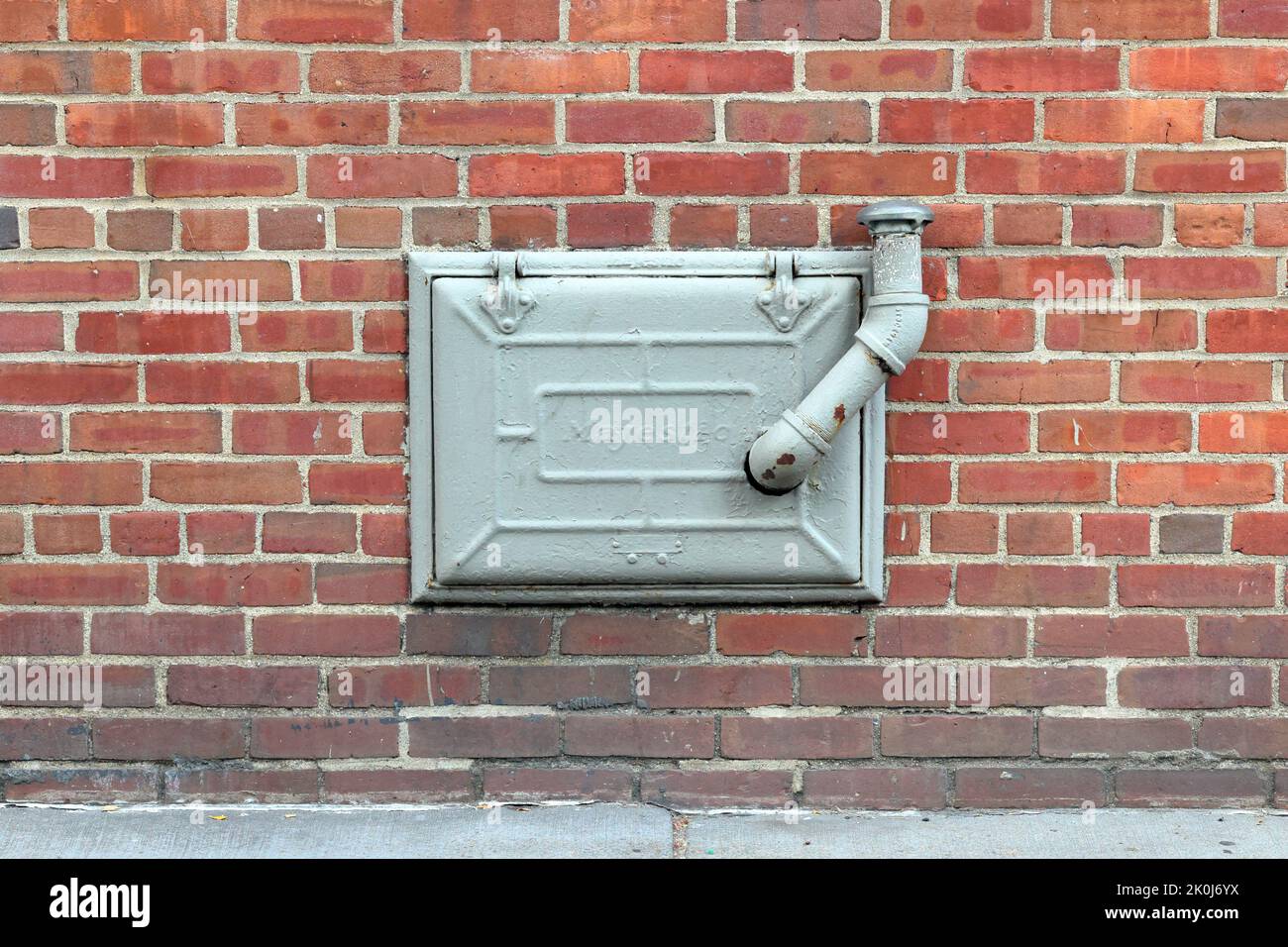

#6 Coal Chutes

Domain Est. 2011

Website: roll-offparts.com

Key Highlights: Our Coal Chutes, otherwise known as inspection doors, are made with carbon steel construction with a paintable zinc chromate primer finish. Opening is12.5″ high ……

#7 A Guide to Coal Chute Replacement

Domain Est. 1995

Website: power-eng.com

Key Highlights: If coal dust collects under transfer chutes or in the transfer area, it’s cleaned up. When line components wear out or fail, they’re replaced….

Expert Sourcing Insights for Coal Chute Door

H2: 2026 Market Trends for Coal Chute Doors

The global market for coal chute doors is expected to undergo notable shifts by 2026, influenced by evolving energy policies, technological advancements, and regional industrial dynamics. Despite the long-term decline in coal usage in many developed economies, coal chute doors remain essential components in mining, power generation, and bulk material handling sectors—particularly in emerging markets.

-

Declining Demand in Developed Economies: In North America and Western Europe, the coal chute door market is projected to experience stagnation or decline by 2026. This trend is driven by the ongoing phase-out of coal-fired power plants, stringent environmental regulations, and a shift toward renewable energy sources. As a result, replacement and maintenance demand for coal chute doors will likely shrink, with most activity limited to retrofitting or decommissioning projects.

-

Steady Demand in Asia-Pacific: The Asia-Pacific region, especially countries like India, Indonesia, and Vietnam, will remain key growth areas for coal chute doors. These nations continue to rely on coal for baseload power generation due to energy security concerns and infrastructure development needs. As new coal-fired power plants are commissioned or existing facilities upgraded, demand for durable, high-performance coal chute doors is expected to remain stable or grow moderately.

-

Increased Focus on Efficiency and Safety: By 2026, manufacturers are expected to prioritize innovation in material durability, sealing mechanisms, and automation. Smart coal chute doors equipped with sensors for monitoring wear, blockages, and operational efficiency will gain traction, particularly in automated mining and material handling systems. These advancements aim to reduce downtime and improve safety in industrial environments.

-

Impact of Alternative Energy Transitions: Global decarbonization efforts may accelerate the retirement of coal infrastructure beyond 2026, casting uncertainty on long-term market prospects. However, transitional reliance on coal in certain developing economies will sustain demand for coal chute doors through mid-decade, especially in regions where clean energy infrastructure is still under development.

-

Regional Supply Chain Shifts: Geopolitical factors and efforts to localize manufacturing may reshape supply chains for coal chute doors. Proximity to coal mining regions and industrial hubs will become increasingly important, with local fabrication and customization gaining preference to reduce lead times and logistics costs.

In summary, the 2026 market for coal chute doors will be characterized by regional divergence: contraction in mature markets and sustained demand in developing economies. Innovation in design and materials, coupled with integration into smart industrial systems, will define competitive advantage. However, long-term market viability will depend on broader energy transition trends and policy developments beyond 2026.

Common Pitfalls When Sourcing Coal Chute Doors (Quality and Intellectual Property)

Sourcing Coal Chute Doors—used in bulk material handling systems, especially in coal-fired power plants and industrial facilities—requires careful evaluation to avoid issues related to product quality and intellectual property (IP). Here are common pitfalls to watch for:

Poor Material Quality and Durability

Many suppliers cut costs by using substandard steel, inferior coatings, or inadequate sealing mechanisms. This leads to premature wear, corrosion, and failure under harsh operating conditions. Always verify material specifications (e.g., ASTM standards), request mill test reports, and ensure the door is designed for abrasive coal handling environments.

Inadequate Ingress Protection (IP) Rating Compliance

Coal chute doors must often meet specific IP ratings (e.g., IP54 or higher) to prevent dust ingress and ensure operational safety. Some suppliers falsely claim compliance or provide doors that don’t undergo proper testing. Demand third-party certification or test reports to confirm the actual IP rating.

Lack of Customization for Specific Applications

Off-the-shelf doors may not fit unique chute geometries or operational needs (e.g., high-pressure environments or automated actuation). Sourcing generic products without customization leads to poor fit, leakage, and operational inefficiencies. Work with suppliers who offer engineered-to-order solutions.

Ignoring Intellectual Property (IP) Rights

Some manufacturers reverse-engineer proprietary coal chute door designs from major OEMs (Original Equipment Manufacturers), infringing on patents or design rights. Purchasing such products exposes your organization to legal risks and potential liability. Always verify that the supplier owns or licenses the design and avoid vendors offering “OEM equivalents” without proper authorization.

Insufficient Warranty and After-Sales Support

Low-cost suppliers may offer limited or no warranty, leaving buyers responsible for repairs or replacements. Additionally, lack of technical support complicates installation and maintenance. Prioritize suppliers with clear warranty terms and responsive customer service.

Failure to Conduct Factory Acceptance Testing (FAT)

Skipping FAT increases the risk of receiving non-conforming products. Always require performance testing, dimensional verification, and IP validation before shipment.

By addressing these pitfalls proactively—focusing on material quality, verified IP compliance, and supplier credibility—organizations can ensure reliable, legal, and cost-effective sourcing of coal chute doors.

Logistics & Compliance Guide for Coal Chute Door

This guide outlines essential logistics considerations and compliance requirements related to the transportation, handling, installation, and regulatory adherence of coal chute doors used in industrial and commercial applications.

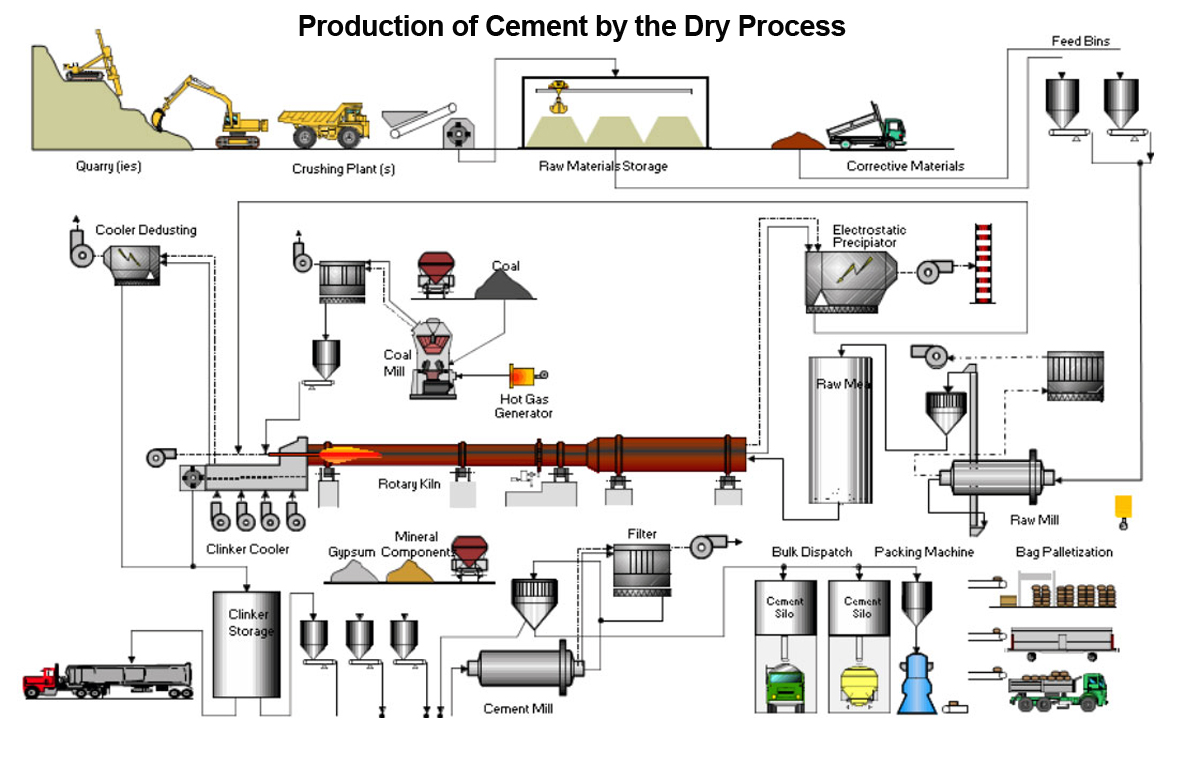

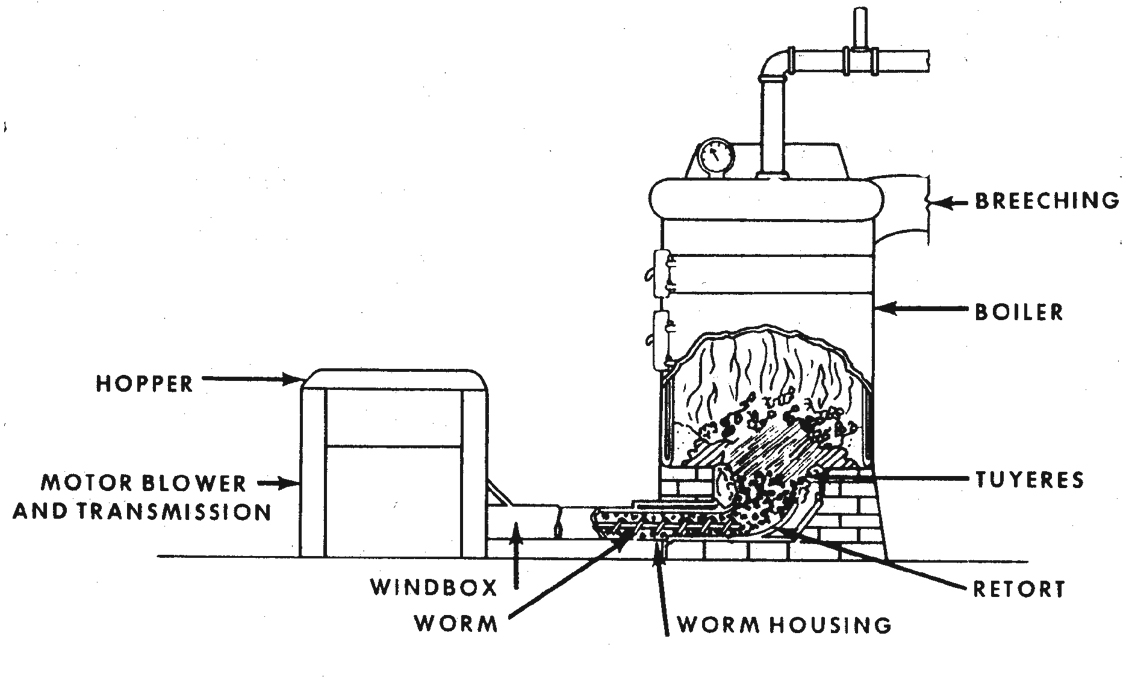

Overview of Coal Chute Door Applications

Coal chute doors are critical components in bulk material handling systems, primarily used in coal-fired power plants, industrial boilers, and material transfer stations. These doors control the flow of coal from storage silos or hoppers into conveyors, feeders, or processing units. Their design ensures dust containment, operational safety, and efficient flow control during coal transfer operations.

Design and Material Specifications

Coal chute doors are typically constructed from durable materials such as carbon steel or abrasion-resistant (AR) steel to withstand the harsh conditions associated with coal handling. Key design features include:

– Heavy-duty hinges and latches for secure closure

– Sealing mechanisms to minimize dust emissions

– Manual, pneumatic, or electric actuation options

– Customizable dimensions to match existing chute configurations

Compliance with engineering standards such as ASME B31.3 (Process Piping) and ASTM A36 (structural steel) is essential during manufacturing.

Transportation and Handling Logistics

Due to their weight and size, coal chute doors require careful planning during transportation:

– Use flatbed trucks or specialized freight carriers capable of handling heavy industrial equipment

– Secure doors with straps and corner protectors to prevent deformation

– Ensure proper lifting points are used during loading/unloading; slings or forklifts must engage designated lifting lugs

– Protect coatings and sealing surfaces during transit using protective wrappings

Documentation, including packing lists and material certifications, must accompany shipments.

Import/Export Regulations and Documentation

When shipping coal chute doors internationally, compliance with trade regulations is mandatory:

– Obtain Harmonized System (HS) code classification (typically under 7308.90 for structural steel components)

– Prepare commercial invoice, packing list, bill of lading, and certificate of origin

– Verify destination country’s import duties, anti-dumping regulations, and steel product restrictions

– Comply with U.S. Commerce Department regulations if exporting from the United States, particularly under Section 232 (steel tariffs) if applicable

Engage a licensed customs broker to ensure smooth clearance.

Environmental and Safety Compliance

Coal chute doors contribute to environmental and workplace safety by containing coal dust, a known respiratory hazard and explosion risk. Compliance includes:

– Adherence to OSHA 29 CFR 1910.1000 (air contaminants) and 1910.272 (grain handling facilities, applicable by analogy)

– Conformance with NFPA 654 (Standard for Preventing Fire and Dust Explosions) for combustible particulate solids

– Meeting local air quality regulations such as EPA’s National Emission Standards for Hazardous Air Pollutants (NESHAP) if applicable

Regular inspection and maintenance are required to ensure door seals remain effective.

Installation and Operational Compliance

Installation must follow manufacturer guidelines and site-specific engineering plans:

– Verify alignment with existing chute structures to prevent material bridging or leakage

– Conduct functional testing of actuation systems and door closure integrity

– Integrate with plant control systems if using automated actuation

– Document installation per ISO 9001 quality management standards

Personnel must be trained in lockout/tagout (LOTO) procedures per OSHA 1910.147 before performing maintenance.

Maintenance and Inspection Requirements

Routine maintenance ensures continued compliance and operational reliability:

– Inspect door seals, hinges, and latches monthly for wear or damage

– Lubricate moving parts according to manufacturer specifications

– Replace worn components promptly to prevent fugitive emissions

– Maintain logs of inspections and repairs for regulatory audits

Adhering to a preventive maintenance schedule supports compliance with environmental and safety standards.

Disposal and End-of-Life Considerations

At end-of-life, coal chute doors are typically recycled as scrap metal:

– Follow EPA and local regulations for handling industrial scrap

– Remove non-metallic components (e.g., gaskets, actuators) for proper disposal

– Use certified recycling facilities compliant with RCRA (Resource Conservation and Recovery Act) if hazardous materials are present

Documentation of recycling activities may be required for sustainability reporting.

Conclusion

Proper logistics planning and adherence to regulatory standards are vital for the safe and compliant lifecycle management of coal chute doors. From manufacturing and transport to installation and disposal, stakeholders must ensure alignment with environmental, safety, and trade regulations to minimize risk and maintain operational efficiency.

Conclusion for Sourcing Coal Chute Door:

Sourcing a suitable coal chute door requires careful consideration of material durability, proper dimensions, sealing efficiency, and compatibility with existing coal handling systems. It is essential to select a door made from robust materials such as cast iron or steel to withstand wear, corrosion, and frequent usage in harsh industrial environments. A well-designed coal chute door should provide effective dust containment, prevent material leakage, and allow for easy operation and maintenance. Engaging with reputable suppliers who offer quality assurance, compliance with industry standards, and technical support ensures long-term reliability and operational efficiency. Ultimately, investing in a high-quality coal chute door contributes to improved safety, reduced downtime, and optimized performance in coal handling operations.