The global demand for alternative and efficient solid fuels has surged in recent years, driven by rising energy costs and increased focus on cleaner-burning options. Coal bricks, also known as briquettes, have gained traction as a cost-effective and energy-dense fuel source, particularly in industrial heating, residential applications, and commercial cooking sectors. According to Mordor Intelligence, the global coal briquettes market was valued at approximately USD 5.8 billion in 2023 and is projected to grow at a CAGR of over 4.2% from 2024 to 2029. This expansion is fueled by growing industrialization in emerging economies, advancements in briquetting technology, and supportive government policies aimed at optimizing coal utilization. As demand climbs, a competitive landscape of manufacturers has emerged, with leading players investing in scalable production, quality control, and sustainable practices to capture market share. The following list highlights the top 10 coal bricks manufacturers driving innovation and volume in this evolving sector.

Top 10 Coal Bricks Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Royal Oak Charcoal

Domain Est. 1996

Website: royaloak.com

Key Highlights: Royal Oak is the largest US producer of natural lump charcoal and charcoal briquets that are 100% natural, so you get the best flavor without any unnatural ……

#2 Glen-Gery

Domain Est. 1999

Website: glengery.com

Key Highlights: Glen-Gery is the superior choice among architects, builders & homeowners who require high-quality building products that meet design challenges ……

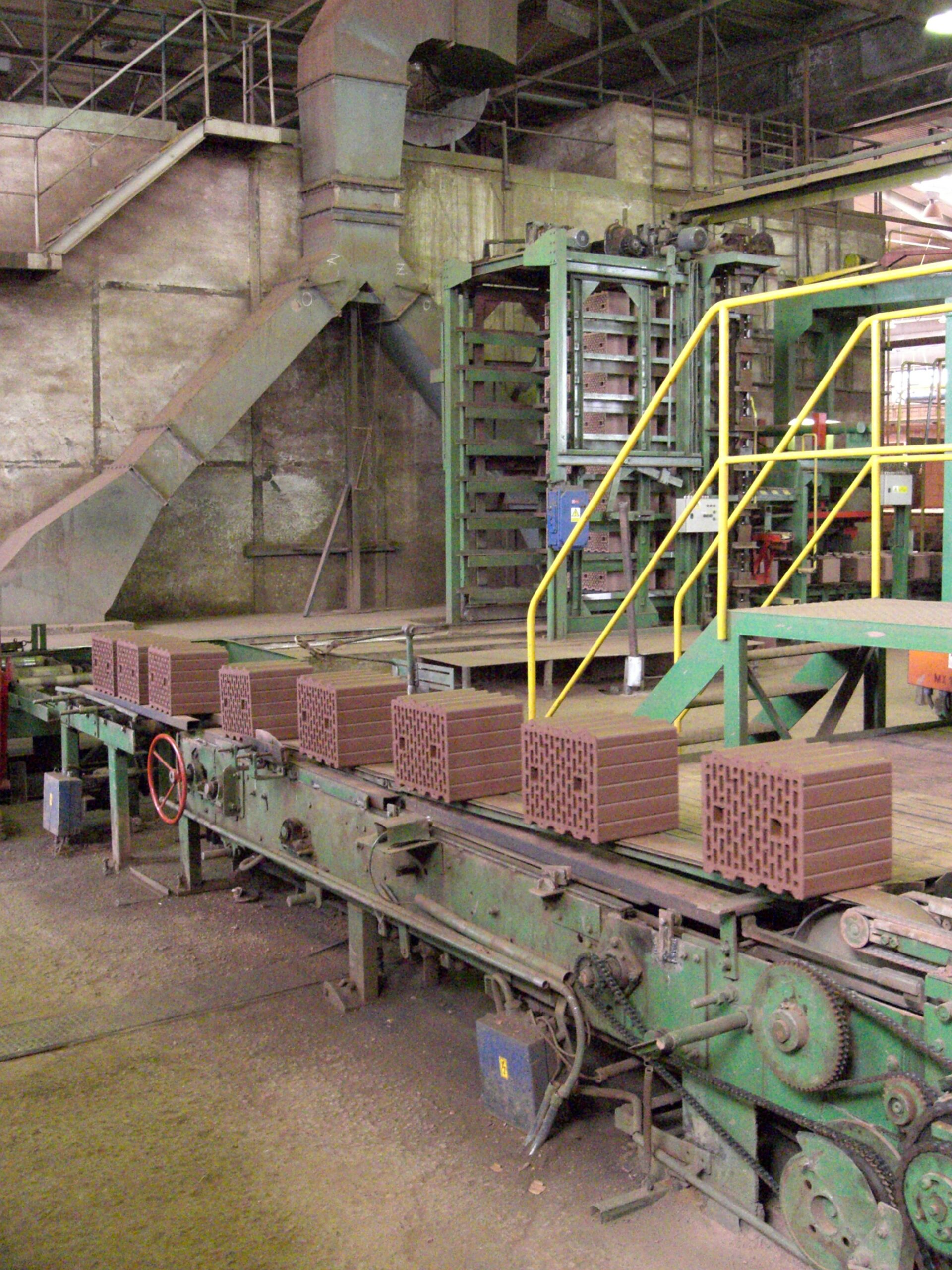

#3 Brikor

Domain Est. 2006

Website: brikor.net

Key Highlights: Brikor Group manufactures and supplies building and construction materials for projects ranging from low-cost housing to residential, commercial, industrial, ……

#4 The Belden Brick Company

Domain Est. 1995

Website: beldenbrick.com

Key Highlights: Delivering the highest-quality shales and clays that contribute to our customers’ and communities’ structural integrity and outstanding appearance….

#5 Endicott Clay Products Page

Domain Est. 1995

Website: endicott.com

Key Highlights: Discover why the top projects use Endicott Clay Products to build their legacy….

#6 Coal

Domain Est. 1998

Website: watsontownbrick.com

Key Highlights: Clay brick is the superior building material for residential and commercial projects. Stronger and more sustainable than other building materials….

#7 Competition Oak briquets

Domain Est. 1999

Website: bbcharcoal.com

Key Highlights: Rating 4.8 (48) Competition Oak briquets · Hardwood charcoal briquets made with real oak wood · No chemical additives or fillers · Burns long and hot · Available in 8.8 and 17.6 …

#8 Columbus Coal & Lime Company

Domain Est. 2000

Website: mcavoybrick.com

Key Highlights: Columbus Coal & Lime Company. Columbus Coal & Lime Company. Website: http://www.columbuscoal.com. Address: 1150 Sullivant Avenue. Columbus, OH 43223….

#9 Wood Bricks & Coal

Domain Est. 2005

Website: btpellet.com

Key Highlights: Fiber Fuel bricks are 2 pounds of compressed kiln dried wood waste. The wood waste is a by-product from the moulding manufacturing done by Lewis Mouldings (www….

#10

Domain Est. 2016

Website: jmsmining.com

Key Highlights: We manufacture support materials to maintain quality and in time availability of the same. We have owned three Commercial Coal Blocks in the auction organised ……

Expert Sourcing Insights for Coal Bricks

H2: 2026 Market Trends for Coal Bricks

The global market for coal bricks is expected to experience notable shifts by 2026, driven by evolving energy policies, environmental regulations, technological advancements, and regional demand dynamics. While coal bricks—compressed blocks of coal dust or pulverized coal used primarily for residential heating and small-scale industrial applications—have traditionally served as a low-cost fuel alternative, their future trajectory is increasingly influenced by sustainability concerns and the global transition toward cleaner energy sources.

-

Declining Demand in Developed Economies

By 2026, coal brick consumption is projected to continue decreasing in North America and Western Europe due to stringent emissions regulations and a strong policy push toward renewable energy and electrification of heating systems. Governments in these regions are enforcing bans or restrictions on solid fuel heating to combat air pollution, directly impacting coal brick usage in households. -

Stable or Moderate Demand in Developing Regions

In contrast, parts of Asia, particularly rural areas in China, India, and Southeast Asia, are expected to sustain coal brick demand through 2026. These regions rely on coal bricks as an affordable heating and cooking fuel where access to natural gas or electricity is limited. However, even in these markets, demand may plateau or slightly decline due to government-led clean energy initiatives and expanding LPG or biomass pellet programs. -

Environmental and Regulatory Pressures

Environmental concerns surrounding high sulfur content, particulate emissions, and carbon footprint will remain key challenges. By 2026, regulations such as China’s “Blue Sky” initiative and similar clean air programs in India are likely to restrict the use of low-quality coal bricks, favoring cleaner-burning or blended alternatives (e.g., coal-biomass briquettes). -

Technological Innovation and Product Evolution

The coal brick industry may respond to regulatory and environmental pressures by adopting cleaner production technologies. Manufacturers could shift toward producing upgraded coal bricks with lower emissions, improved combustion efficiency, or hybrid formulations that incorporate biomass or waste materials. These “clean coal” bricks may extend market relevance in transitional energy economies. -

Competition from Alternative Solid Fuels

The market for coal bricks will face intensified competition from biomass briquettes, charcoal, and other renewable solid fuels that offer lower emissions and sustainability benefits. By 2026, increasing availability and affordability of these alternatives are likely to erode coal brick market share, especially in urban and semi-urban settings. -

Price Volatility and Supply Chain Dynamics

Global coal prices will continue to influence coal brick economics. As thermal coal markets fluctuate due to geopolitical tensions, mining policy changes, and energy demand cycles, coal brick production costs may become less predictable. Countries with domestic coal reserves may maintain localized production, while import-dependent regions could see reduced viability. -

Long-Term Outlook and Market Contraction

By 2026, the coal brick market is expected to be in a structural decline globally, except in isolated regions with limited energy alternatives. The long-term outlook remains bearish as renewable energy access expands, electrification accelerates, and climate commitments prioritize decarbonization.

In summary, the 2026 market for coal bricks will be characterized by regional divergence, regulatory headwinds, and technological adaptation. While the product may persist in niche or transitional energy markets, its overall role is diminishing in the face of cleaner, more sustainable energy options.

Common Pitfalls Sourcing Coal Bricks (Quality, IP)

Sourcing coal bricks—compressed blocks of coal dust or fines used primarily for industrial fuel or domestic heating—can present significant challenges, especially concerning quality consistency and intellectual property (IP) risks. Failing to address these pitfalls can lead to operational inefficiencies, financial losses, and legal complications.

Quality Inconsistencies and Misrepresentation

One of the most prevalent issues when sourcing coal bricks is inconsistency in quality. Suppliers may offer samples that do not accurately represent bulk shipments, leading to performance problems such as low calorific value, high ash content, or poor combustion efficiency. Variability in moisture content, binder composition, and density can impact burn time and emissions. Buyers often lack adequate testing protocols, making it difficult to verify specifications upon delivery. Additionally, some suppliers may mislabel or blend lower-grade coal into bricks without disclosure, undermining reliability and increasing maintenance costs for end-users.

Intellectual Property and Brand Infringement Risks

While coal bricks themselves are typically commodity products, certain formulations, production methods, or branded briquetting technologies may be protected by patents or trademarks. Sourcing from manufacturers using proprietary processes without proper licensing can expose buyers to IP infringement claims—especially when importing across borders. For example, a supplier might use a patented binding agent or compression technique covered under international patents. Buyers assuming coal bricks are generic may inadvertently support or distribute products that violate IP rights, leading to shipment seizures, legal liability, or reputational damage. Conducting due diligence on manufacturing processes and supplier IP compliance is essential but often overlooked.

Logistics & Compliance Guide for Coal Bricks

Overview

Coal bricks, also known as coal briquettes, are compacted blocks made from coal dust and other combustible materials, used primarily for heating and industrial fuel applications. Transporting and trading coal bricks involves navigating a complex web of logistics considerations and regulatory compliance requirements. This guide outlines the key aspects of managing the logistics and ensuring compliance for domestic and international shipments of coal bricks.

Classification & Regulatory Framework

Coal bricks are typically classified under the Harmonized System (HS) Code 2701.12 or 2701.19, depending on composition and origin. They may also fall under national tariff codes based on regional classifications. Regulatory oversight includes:

– International: IMO (International Maritime Organization) regulations under the IMDG Code (for sea transport), particularly if coal is classified as hazardous due to self-heating or methane emission risks.

– National/Regional: EPA (Environmental Protection Agency) in the U.S., EU Emissions Trading System (EU ETS), and other regional environmental regulations restricting sulfur content and emissions.

– Customs Requirements: Import/export permits, phytosanitary or fumigation certificates (if packaging involves wood), and proof of origin may be required.

Hazard Classification & Safety

- IMDG Code: Coal bricks may be classified as UN 1361, Briquettes, carbonaceous, Class 4.2 (Substances liable to spontaneous combustion), particularly if they contain fine coal particles prone to oxidation.

- Testing Requirements: Shippers must conduct or obtain test reports confirming whether the coal bricks are exempt from hazardous classification (e.g., through low heat evolution tests).

- Packaging & Labeling: If classified as hazardous, packages must display proper Class 4.2 labels, handling instructions, and shipping names. Non-hazardous shipments require standard labeling with product description, weight, and handling warnings.

Packaging & Handling

- Standard Packaging: Coal bricks are commonly packed in polypropylene (PP) bags (25–50 kg), jumbo bags (1,000 kg), or wooden crates.

- Moisture Protection: Use moisture-resistant packaging to prevent degradation and dust formation.

- Stacking & Palletization: Secure on pallets using shrink wrap or straps; avoid overloading containers. Maximum stacking height should consider bag strength and warehouse safety.

- Dust Control: Minimize dust generation during loading/unloading using enclosed conveyors or dust suppression systems.

Transportation Modes

- Maritime: The most common method for international trade. Requires compliance with IMDG Code, proper stowage away from heat sources, and ventilation if classified as hazardous. Vessels must carry a Dangerous Goods Declaration if applicable.

- Rail & Road: Subject to ADR (Europe), DOT (U.S.), or national hazardous materials regulations if classified. Use covered wagons or tarpaulin-covered trucks to prevent loss and environmental contamination.

- Air Freight: Generally not recommended due to self-heating risks; prohibited if classified as Class 4.2 under IATA DGR.

Storage Requirements

- Ventilation: Store in dry, well-ventilated areas to prevent heat buildup and methane accumulation.

- Segregation: Keep away from oxidizers, flammable materials, and foodstuffs.

- Fire Prevention: Install smoke detectors, fire suppression systems, and prohibit smoking in storage zones. Regular inspections for spontaneous heating are recommended.

Environmental & Emissions Compliance

- Sulfur Content Limits: Many jurisdictions (e.g., EU, China, U.S.) limit sulfur content in solid fuels. Verify coal brick composition meets local standards (e.g., <1% sulfur in residential use areas).

- Carbon Reporting: In regions with carbon pricing, importers may need to report CO₂ emissions from coal combustion. Maintain documentation on calorific value and emission factors.

- Waste & Spill Management: Develop spill response plans. Recycle or safely dispose of damaged packaging and fines (coal dust).

Documentation Requirements

Essential documents for legal shipment include:

– Commercial Invoice

– Packing List

– Bill of Lading / Air Waybill

– Certificate of Origin

– Material Safety Data Sheet (MSDS/SDS)

– Test Reports (e.g., calorific value, sulfur content, spontaneous combustion screening)

– Dangerous Goods Declaration (if applicable)

– Import/Export Licenses (as required by destination country)

Import/Export Restrictions

- Prohibited Destinations: Some countries ban or restrict coal imports due to environmental policies (e.g., EU Green Deal initiatives, urban clean air zones).

- Tariffs & Duties: Apply based on HS code and trade agreements. Verify preferential rates under FTAs.

- Local Standards: Comply with destination-specific requirements such as size, ash content, or ignition time.

Best Practices

- Partner with experienced freight forwarders familiar with bulk solid fuels.

- Conduct pre-shipment inspections to ensure quality and regulatory compliance.

- Maintain a compliance audit trail, including test reports and shipping records.

- Monitor regulatory changes in target markets, especially environmental legislation.

Conclusion

Successful logistics and compliance for coal bricks require careful classification, adherence to safety standards, and thorough documentation. As global regulations on fossil fuels tighten, shippers must stay informed and adapt to evolving environmental and trade requirements. Proactive planning ensures safe, legal, and efficient transportation of coal bricks across supply chains.

In conclusion, sourcing coal bricks requires careful consideration of several key factors including quality, cost, supply chain reliability, environmental regulations, and sustainability practices. It is essential to establish relationships with reputable suppliers who can consistently provide high-quality coal bricks with verified specifications such as calorific value, ash content, and moisture levels. Additionally, logistical efficiency, transportation costs, and compliance with local and international environmental standards play a significant role in the overall viability of the sourcing strategy. As the global energy landscape shifts toward cleaner alternatives, organizations should also evaluate the long-term sustainability of coal brick usage and consider transitioning to more environmentally friendly options where feasible. A well-structured sourcing plan balances operational needs with economic and environmental responsibilities, ensuring both efficiency and compliance in the supply of coal bricks.