The global CNC PCB manufacturing industry is experiencing robust growth, driven by rising demand for precision electronics across aerospace, automotive, medical, and telecommunications sectors. According to a 2023 report by Mordor Intelligence, the global printed circuit board (PCB) market was valued at approximately USD 81.3 billion in 2022 and is projected to grow at a CAGR of over 5.2% from 2023 to 2028, with CNC machining playing a critical role in high-accuracy prototyping and production. This surge is attributed to advancements in HDI (High-Density Interconnect) technologies, increasing automation, and the proliferation of IoT devices requiring compact, reliable circuitry. As quality, turnaround time, and technical capability become key differentiators, selecting the right CNC PCB manufacturer is more crucial than ever. Based on production capacity, technological expertise, global reach, and customer reviews, here are the top 9 CNC PCB manufacturers shaping the future of electronic manufacturing.

Top 9 Cnc Pcb Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 China PCBA Manufacturer

Domain Est. 2002

Website: pcbasic.com

Key Highlights: Established in Shenzhen, China, in 2011, PCBasic boasts more than 15 years of hard work and innovation in the field of PCB & PCBA manufacturing….

#2 LPKF PCB Prototype Technology & Laser Material Processing

Domain Est. 1995

Website: lpkf.com

Key Highlights: As a leading provider of laser manufacturing solutions, LPKF Laser & Electronics helps to create more powerful electronic systems and increase functionality ……

#3 China PCB Prototype & Fabrication Manufacturer

Domain Est. 2012

Website: pcbway.com

Key Highlights: $29 deliveryWhy Buy Printed Circuit Boards From us? · 3-, 4- & full 5-axis, post-processing CNC machining · FDM, SLA, SLM, MJF 3D printing · Laser cutting, bending Sheet metal….

#4 High

Domain Est. 2008

Website: seeedstudio.com

Key Highlights: 3–7 day delivery 30-day returnsSeeed Fusion offers comprehensive PCB manufacturing and prototype PCB assembly services with guaranteed quality, quick turnaround, and competitive pr…

#5 ALLPCB

Domain Est. 2011

Website: allpcb.com

Key Highlights: Explore the ALLPCB approach to PCB manufacturing and assembly: From prototype to production, we’ve got you covered….

#6 PCB Manufacturing & Assembly Capabilities

Domain Est. 2011

Website: jlcpcb.com

Key Highlights: Printed Circuit Board manufacturing and assembly capabilities, PCB technologies or design rules for guide of PCB design and production….

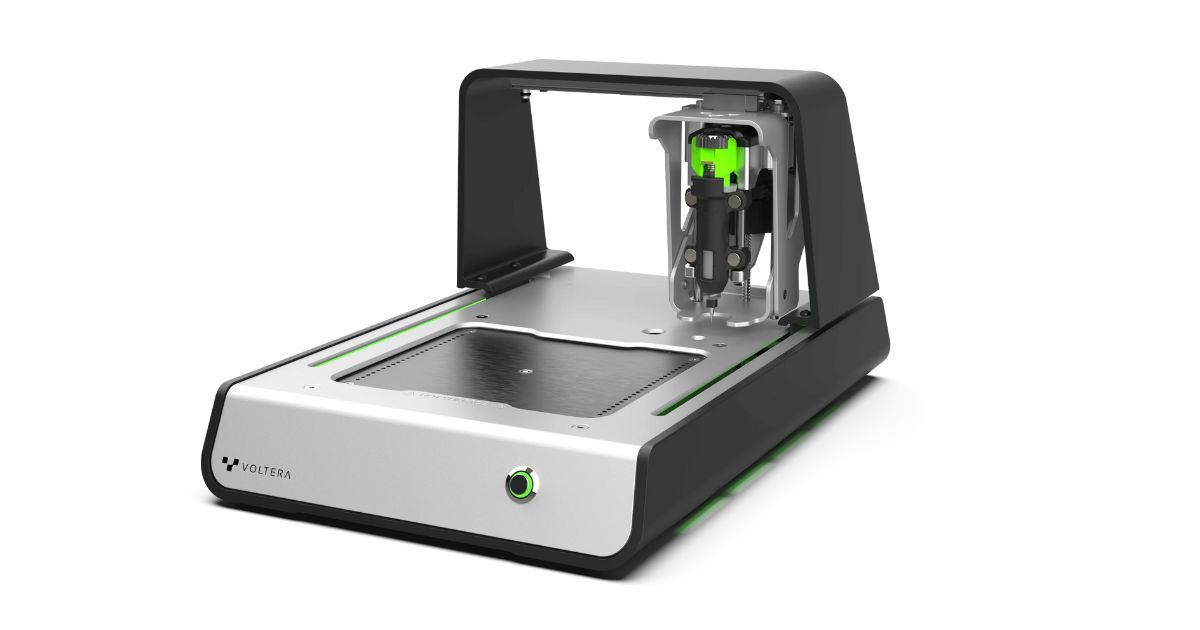

#7 Voltera

Domain Est. 2014

Website: voltera.io

Key Highlights: Voltera puts additive prototyping in your hands. Build traditional circuit boards or flexible, stretchable, and conformable electronics quickly and easily….

#8 WellPCB

Domain Est. 2016

Website: wellpcb.com

Key Highlights: WellPCB provides complete PCB solutions including in-house fabrication, assembly, component sourcing, and testing. Achieve superior quality and quick ……

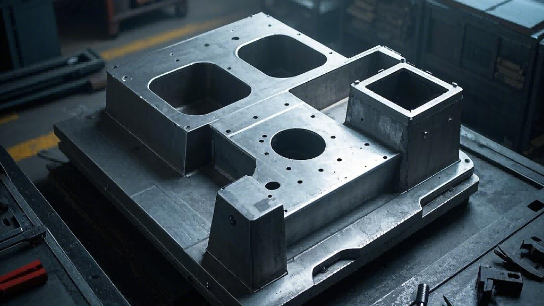

#9 JLCCNC

Domain Est. 2021

Website: jlccnc.com

Key Highlights: Get precision CNC machined parts online! Fast turnaround (3-5 days), custom milling &acrylic services. Upload your design for an instant quote &real-time ……

Expert Sourcing Insights for Cnc Pcb

H2: Projected 2026 Market Trends for CNC PCB Manufacturing

The CNC (Computer Numerical Control) PCB (Printed Circuit Board) manufacturing sector is poised for significant transformation by 2026, driven by advancements in automation, rising demand for high-precision electronics, and the integration of Industry 4.0 technologies. Below are the key market trends expected to shape the CNC PCB landscape in 2026:

-

Increased Adoption of Smart Manufacturing

By 2026, CNC PCB production is expected to be heavily influenced by smart factory solutions. Integration of IoT-enabled CNC machines allows real-time monitoring, predictive maintenance, and adaptive control, improving production efficiency and reducing downtime. Manufacturers are investing in digital twins and AI-driven analytics to optimize routing paths, tool selection, and drilling precision. -

Miniaturization and High-Density Interconnect (HDI) Demand

The growing need for compact, high-performance electronics in smartphones, wearables, and medical devices is pushing CNC systems to achieve finer tolerances. CNC machines will evolve to support micro-milling capabilities, enabling precise fabrication of HDI PCBs with smaller vias and tighter trace spacing. This trend favors CNC over traditional chemical etching in prototyping and low-volume production. -

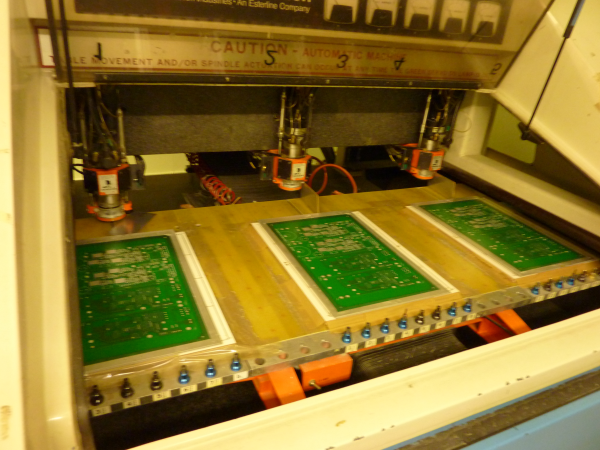

Rise of Automation and Robotics Integration

Fully automated CNC PCB lines, including robotic loading/unloading and in-process inspection systems, are expected to become standard in mid-to-large scale operations. This shift reduces human error, increases throughput, and supports 24/7 operations—critical for meeting the just-in-time demands of consumer electronics and automotive sectors. -

Sustainability and Waste Reduction Focus

Environmental regulations and corporate ESG (Environmental, Social, Governance) goals are driving the adoption of CNC over wet-chemical processes, which generate hazardous waste. CNC machining is a dry process, producing minimal chemical byproducts. By 2026, eco-conscious manufacturers will increasingly favor CNC for its sustainability advantages, especially in Europe and North America. -

Growth in Rapid Prototyping and On-Demand Manufacturing

The demand for fast-turnaround PCB development, particularly in R&D and startups, is boosting the use of desktop and benchtop CNC mills. These systems enable same-day prototyping without outsourcing, reducing dependency on offshore fabrication. Cloud-based design and CNC toolpath generation platforms will further democratize access to CNC PCB production. -

Expansion in Automotive and Industrial Electronics

As electric vehicles (EVs), advanced driver-assistance systems (ADAS), and industrial automation grow, so does the need for durable, high-reliability PCBs. CNC machining offers better control over multilayer board structuring and rigid-flex PCB fabrication, making it ideal for mission-critical applications where consistency and material integrity are paramount. -

Technological Convergence with Additive Manufacturing

Hybrid manufacturing systems combining CNC milling with additive techniques (like conductive ink deposition) are expected to emerge by 2026. These hybrid platforms will allow for selective material removal and addition in a single workflow, enabling complex 3D electronics and embedded components. -

Regional Market Shifts and Supply Chain Resilience

Geopolitical factors and supply chain disruptions are prompting reshoring and nearshoring of PCB production. CNC-based fabrication, being less reliant on large-scale chemical infrastructure, is well-suited for localized manufacturing hubs. North America and Europe are expected to see increased investment in domestic CNC PCB capabilities for defense, aerospace, and medical applications.

Conclusion:

By 2026, the CNC PCB market will be defined by smarter, faster, and more sustainable manufacturing processes. Driven by innovation in automation, precision engineering, and environmental responsibility, CNC technology will solidify its role as a critical enabler of next-generation electronics production—especially in high-mix, low-volume, and rapid development environments.

Common Pitfalls When Sourcing CNC-Machined PCBs: Quality and Intellectual Property Risks

Sourcing CNC-machined printed circuit boards (PCBs) can offer rapid prototyping and low-volume production benefits. However, businesses often encounter significant challenges related to quality control and intellectual property (IP) protection. Being aware of these pitfalls is essential to ensure reliable performance and safeguard sensitive designs.

Quality Inconsistencies

One of the primary risks when sourcing CNC-machined PCBs—especially from less reputable or offshore manufacturers—is inconsistent quality. Unlike standardized photolithographic PCB fabrication, CNC routing involves mechanical cutting that can introduce variability due to tool wear, misalignment, or operator error. This can result in inconsistent trace widths, inaccurate hole placement, or uneven board edges, potentially leading to electrical failures or assembly issues.

Moreover, material selection and handling can affect final quality. Poor-grade substrates or improper handling during machining may cause delamination, burring, or surface defects. Without rigorous quality assurance processes and clear specifications, these issues may go undetected until late in the development cycle, increasing time-to-market and costs.

Lack of Design for Manufacturability (DFM) Feedback

Many CNC PCB suppliers, particularly those focused on quick-turn services, may not provide comprehensive Design for Manufacturability (DFM) reviews. This can result in designs that are technically feasible but difficult or impossible to machine reliably. For example, exceedingly thin traces or small isolation gaps may exceed the practical limits of the CNC tooling, leading to short circuits or open traces. Without early feedback, these flaws are only discovered post-production, causing delays and rework.

Intellectual Property Exposure

Sourcing CNC-machined PCBs often involves sharing detailed Gerber files, CAD data, or even native design files—valuable intellectual property that can be copied, reverse-engineered, or misused. Many contract manufacturers, especially in regions with weaker IP enforcement, may not have stringent data protection policies. There is a risk that your designs could be replicated without authorization or shared with third parties.

Even with non-disclosure agreements (NDAs), enforcement can be difficult and costly, particularly across international jurisdictions. Additionally, some suppliers may retain design data for “efficiency” purposes, increasing the window of vulnerability long after your order is fulfilled.

Inadequate Traceability and Documentation

CNC-machined PCBs from certain suppliers may lack proper documentation or traceability. Without clear records of materials used, tooling parameters, or inspection results, it becomes difficult to reproduce boards consistently or troubleshoot field failures. This lack of transparency is particularly problematic when scaling up or seeking regulatory compliance.

Mitigation Strategies

To avoid these pitfalls, consider the following:

– Choose suppliers with certified quality management systems (e.g., ISO 9001).

– Require detailed DFM feedback and prototyping iterations.

– Use secure file-sharing methods and enforce strong NDAs with clear data retention clauses.

– Specify data deletion policies post-project completion.

– Work with suppliers in jurisdictions known for stronger IP protection when possible.

By proactively addressing these quality and IP risks, businesses can leverage CNC machining for PCBs safely and effectively.

Logistics & Compliance Guide for CNC PCB

Overview

CNC (Computer Numerical Control) machining is a precise manufacturing method used to produce printed circuit boards (PCBs) by milling away substrate material to create conductive traces and isolate components. Unlike traditional etching, CNC-machined PCBs are ideal for rapid prototyping and low-volume production. This guide outlines key logistics and compliance considerations when sourcing or manufacturing CNC PCBs.

Regulatory Compliance Requirements

RoHS Compliance

All PCBs, including CNC-machined versions, must comply with the Restriction of Hazardous Substances (RoHS) Directive (EU). This limits the use of lead, mercury, cadmium, and other hazardous materials. Ensure your design and materials—especially solder mask, silkscreen, and substrate—meet RoHS standards. Request a RoHS compliance certificate from your manufacturer.

REACH Compliance

REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) applies to chemicals used in PCB manufacturing. Confirm that all materials used in your CNC PCB (e.g., resins, coatings) are registered and comply with REACH regulations, especially if shipping to the European Union.

IPC Standards

Adherence to IPC (Association Connecting Electronics Industries) standards ensures quality and reliability. For CNC PCBs, relevant standards include:

– IPC-6012: Qualification and performance specification for rigid PCBs

– IPC-2221: Generic standard on PCB design

Ensure your manufacturer follows these standards for dimensional accuracy, trace width, and insulation requirements.

Environmental & Safety Considerations

Waste Management

CNC machining generates waste in the form of milled substrate (e.g., FR-4, polyimide). Proper disposal or recycling of non-metallic and metallic debris is required under local environmental regulations. Work with manufacturers that have documented waste management procedures.

Dust and Fume Control

Machining PCB substrates produces fine particulate matter and potentially hazardous fumes. Facilities must comply with OSHA (Occupational Safety and Health Administration) or equivalent local regulations by using dust extraction systems and proper ventilation.

Logistics & Supply Chain Management

Material Sourcing

Common substrates like FR-4 are widely available, but specialty materials (e.g., Rogers, aluminum-backed) may have longer lead times. Verify material availability and certification (e.g., UL recognition) before finalizing designs. Ensure traceability of raw materials for compliance audits.

Shipping & Packaging

PCBs are sensitive to electrostatic discharge (ESD), moisture, and physical damage. Use ESD-safe packaging (e.g., shielded bags, conductive foam) and include desiccants if shipping to humid environments. Label packages with ESD and fragile warnings. For international shipments, comply with IATA/IMDG regulations if batteries or conductive materials are present.

Import/Export Regulations

When shipping CNC PCBs across borders:

– Classify products under the correct HS (Harmonized System) code (e.g., 8534.00 for PCBs)

– Prepare commercial invoices, packing lists, and certificates of origin

– Comply with export controls (e.g., EAR in the U.S.) if PCBs incorporate controlled technologies

Quality Assurance & Documentation

Testing and Inspection

Although CNC PCBs are often used for prototypes, basic electrical testing (continuity, isolation) should be performed. Request test reports and inspection records (e.g., optical inspection for trace integrity) from the manufacturer.

Documentation Requirements

Maintain a comprehensive compliance dossier, including:

– RoHS and REACH compliance declarations

– Material declarations (IMDS if applicable)

– IPC compliance reports

– Certificates of conformance (CoC)

– Safety data sheets (SDS) for materials used

Conclusion

Successfully managing the logistics and compliance of CNC PCBs requires attention to environmental regulations, material standards, and international shipping requirements. Partner with reputable manufacturers who provide full documentation and adhere to industry best practices. Proactive compliance reduces delays, avoids penalties, and ensures product reliability.

Conclusion for Sourcing CNC PCBs

Sourcing CNC-machined PCBs offers a reliable and precise solution for prototyping and low-volume production, especially when tight tolerances, complex geometries, or rigid material requirements are involved. While CNC milling does not replace traditional PCB fabrication for large-scale manufacturing due to its slower speed and higher per-unit cost, it provides significant advantages in rapid turnaround, design flexibility, and the ability to produce functional boards without the need for chemical etching or external fabrication houses.

When sourcing CNC PCBs, it is essential to evaluate factors such as material selection, tooling limitations, design complexity, and required accuracy. Choosing the right service provider—whether in-house, local, or online—can greatly impact the quality and efficiency of the final product. Additionally, integrating Design for Manufacturability (DFM) principles early in the design phase helps avoid unnecessary revisions and ensures smoother production.

In summary, CNC machining is a valuable method for quickly iterating and validating PCB designs, particularly in R&D and small-batch applications. As a result, sourcing CNC PCBs is a strategic choice for engineers and designers prioritizing speed, control, and precision in their electronics development workflow.