The global CNC machining manufacturing market has experienced robust growth, driven by increasing demand for precision components across aerospace, automotive, medical, and defense industries. According to a 2023 report by Mordor Intelligence, the CNC machine market was valued at USD 74.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of over 7.5% from 2023 to 2028, reaching an estimated value of USD 115 billion. Similarly, Grand View Research reports that the global CNC machining market size was valued at USD 78.76 billion in 2022 and is expected to expand at a CAGR of 7.2% during the forecast period from 2023 to 2030. This expansion is fueled by advancements in automation, rising adoption of Industry 4.0 technologies, and the growing need for high repeatability and efficiency in production processes. Amid this dynamic landscape, leading CNC machined manufacturers are differentiating themselves through technological innovation, tight-tolerance capabilities, and scalable production capacity—making them key players in modern manufacturing ecosystems.

Top 10 Cnc Machined Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 CNC Factory

Domain Est. 2013

Website: cncfactory.com

Key Highlights: Welcome to 5th Generation CNC Technology. No thinking needed. No back- breaking work. Create beautiful products by just pressing a few buttons….

#2 Metalworking CNC Machine Tools Supplier & Equipment Distributor …

Domain Est. 1991

Website: productivity.com

Key Highlights: We are a single source machine tool distributor of metalworking machines, tooling and industrial supplies, robots and related manufacturing products and ……

#3 Haas Automation Inc.

Domain Est. 1996

Website: haascnc.com

Key Highlights: Haas Automation is the largest machine tool builder in the western world, manufacturing a complete line of CNC vertical machining centers, ……

#4 Makino

Domain Est. 1996

Website: makino.com

Key Highlights: Achieve superior results with Makino’s CNC machining. Makino machines and engineering services provide precision and reliability across applications….

#5 STYLE CNC Machines

Domain Est. 2012

Website: stylecncmachines.com

Key Highlights: STYLE is the manufacturer of CNC milling machines specialised in single pieces and small series. Discover our CNC milling machines….

#6 Okuma America

Domain Est. 1996

Website: okuma.com

Key Highlights: Okuma America Corporation helps users gain competitive advantage through the open possibilities of our CNC machine tools and advanced technologies….

#7 CNC Machines

Domain Est. 1997

Website: yamazen.com

Key Highlights: Yamazen is the complete machining solution. From Machine Tool products that slash production times by up to 40%, to innovative Tooling and Automation solutions….

#8 to Mazak Corporation

Domain Est. 1998

Website: mazak.com

Key Highlights: Mazak provides products and solutions that can support a wide range of parts machining processes, such as high-speed and high-accuracy machines, various ……

#9 Tormach

Domain Est. 2002

Website: tormach.com

Key Highlights: Tormach makes CNC machines and automation tools that are capable, affordable, and easy-to-use. Our full line runs on single-phase power….

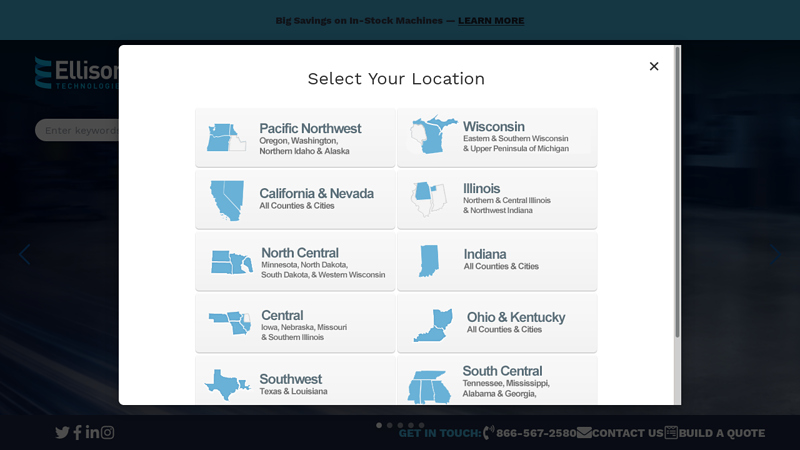

#10 Ellison Technologies: Advanced CNC Machining Solutions

Domain Est. 2005

Website: ellisontechnologies.com

Key Highlights: Discover advanced CNC machining solutions with Ellison Technologies—your trusted partner for metal-cutting innovations in North America.”…

Expert Sourcing Insights for Cnc Machined

H2: 2026 Market Trends for CNC Machined Components

The global market for CNC (Computer Numerical Control) machined components is poised for significant transformation by 2026, driven by technological advancements, evolving industry demands, and macroeconomic shifts. As industries increasingly prioritize precision, efficiency, and customization, CNC machining remains a cornerstone of modern manufacturing. Below are the key trends expected to shape the CNC machining landscape in 2026:

-

Increased Adoption of Automation and Smart Manufacturing

By 2026, the integration of automation, including robotic loading/unloading systems and AI-driven process optimization, will become standard in CNC facilities. The rise of Industry 4.0 technologies—such as IoT-enabled machines, predictive maintenance, and real-time monitoring—will enhance productivity and reduce downtime, especially in high-volume production environments. -

Growth in High-Precision and Complex Part Demand

Sectors such as aerospace, medical devices, and electric vehicles (EVs) will drive demand for highly complex, tight-tolerance components. CNC machining, with its ability to produce intricate geometries from advanced materials like titanium, Inconel, and high-performance composites, will remain irreplaceable in these applications. -

Expansion of Hybrid Manufacturing Systems

CNC machining centers are increasingly being combined with additive manufacturing (3D printing) in hybrid systems. By 2026, this trend will gain momentum, enabling manufacturers to build near-net-shape parts via additive methods and finish them with precision CNC machining—reducing material waste and lead times. -

Sustainability and Green Manufacturing Priorities

Environmental regulations and corporate sustainability goals will push CNC shops to adopt energy-efficient machines, optimize coolant usage, and implement closed-loop recycling of metal chips. The use of biodegradable coolants and low-emission machining processes will become more widespread. -

Rise of Nearshoring and Regional Supply Chains

Geopolitical uncertainties and supply chain disruptions will accelerate the trend of nearshoring, especially in North America and Europe. Localized CNC machining services will benefit from shorter lead times and reduced logistics costs, supporting rapid prototyping and on-demand production. -

Advancements in CNC Software and Simulation Tools

CAM (Computer-Aided Manufacturing) software will become more intuitive and integrated with AI, allowing for faster programming, error reduction, and optimized toolpaths. Cloud-based platforms will enable remote monitoring and collaborative design-to-manufacturing workflows. -

Growing Demand for Custom and Low-Volume Production

As mass customization gains traction across consumer electronics, healthcare, and industrial equipment, CNC machining will be favored for its flexibility in producing small batches with high repeatability—without the high tooling costs associated with molding or stamping. -

Workforce Upskilling and Talent Development

While automation reduces the need for manual operators, demand for skilled CNC programmers, machinists, and maintenance technicians with expertise in digital manufacturing will rise. Industry-academia partnerships and vocational training programs will play a crucial role in addressing the skills gap. -

Material Innovation and Machinability Challenges

The use of new alloys and engineered materials designed for lightweighting and performance will present both opportunities and challenges. CNC machine shops will need to adapt tooling, speeds, and feeds to handle these advanced materials efficiently. -

Digital Marketplaces and On-Demand Manufacturing Platforms

Online CNC manufacturing platforms (e.g., Xometry, Hubs) will continue to grow, enabling instant quoting, global capacity sharing, and faster turnaround. These digital ecosystems will democratize access to CNC services for startups and SMEs.

In conclusion, the 2026 CNC machined components market will be defined by smarter, faster, and more sustainable manufacturing practices. Companies that embrace digital transformation, invest in workforce development, and align with high-growth industries will be best positioned to thrive in this evolving landscape.

Common Pitfalls in Sourcing CNC Machined Parts: Quality and Intellectual Property Risks

Logistics & Compliance Guide for CNC Machined Parts

Understanding CNC Machined Components in Logistics

CNC (Computer Numerical Control) machined parts are high-precision components manufactured from metals, plastics, or composites using automated machining processes. These parts are widely used in aerospace, automotive, medical, and industrial equipment sectors. Due to their precision nature and material characteristics, special attention is required during logistics and compliance management to ensure quality, integrity, and regulatory adherence throughout the supply chain.

Packaging and Handling Requirements

Proper packaging is critical to prevent damage during transit. CNC machined parts should be individually wrapped or padded using anti-static or corrosion-inhibiting materials (e.g., VCI paper for metals). Use rigid containers or custom foam inserts to minimize movement. Clearly label packages with handling instructions such as “Fragile,” “Do Not Stack,” and orientation markers. Avoid exposure to moisture, dust, and extreme temperatures during storage and transport.

Transportation and Shipping Considerations

Select transportation modes based on part sensitivity, delivery timelines, and destination. For international shipments, consider air freight for high-value or time-sensitive components, and sea freight for bulk consignments. Use climate-controlled containers if parts are sensitive to humidity or temperature fluctuations. Partner with logistics providers experienced in handling precision-engineered goods and ensure real-time tracking capabilities are in place.

Import/Export Compliance and Documentation

CNC machined parts may be subject to export controls, especially if used in defense, aerospace, or dual-use applications. Verify if parts fall under export control regimes such as the U.S. Export Administration Regulations (EAR) or International Traffic in Arms Regulations (ITAR). Required documentation typically includes commercial invoices, packing lists, certificates of origin, and export declarations. Accurate HS (Harmonized System) codes must be assigned to determine tariffs and regulatory requirements.

Regulatory and Industry-Specific Standards

Ensure compliance with industry-specific standards such as ISO 9001 (quality management), AS9100 (aerospace), or ISO 13485 (medical devices). Some CNC parts may require material certifications (e.g., mill test reports, RoHS, or REACH compliance for EU markets). Maintain traceability through batch/lot numbers and documentation proving conformance to customer specifications and regulatory requirements.

Customs Clearance and Duty Optimization

Work with customs brokers to facilitate smooth clearance. Provide complete and accurate documentation to avoid delays. Leverage trade agreements or duty drawback programs where applicable. Classify parts correctly to benefit from reduced tariffs or exemptions, especially for components used in certified manufacturing or repair processes.

Risk Management and Insurance

Insure shipments against loss, damage, or theft. Assess risks related to transit routes, geopolitical factors, and handling vulnerabilities. Implement quality checkpoints at origin and destination to verify part integrity upon receipt. Maintain a non-conformance process to address discrepancies promptly.

Sustainability and Environmental Compliance

Follow environmental regulations related to packaging materials (e.g., recyclable or biodegradable options). Comply with waste disposal rules for machining byproducts (e.g., metal shavings, cutting fluids) if involved in reverse logistics or remanufacturing. Consider carbon footprint reduction strategies in transportation planning.

Supplier and Partner Coordination

Establish clear logistics and compliance protocols with suppliers, contract manufacturers, and freight forwarders. Conduct regular audits to ensure alignment with your compliance standards. Use digital platforms for document sharing, shipment tracking, and compliance recordkeeping to enhance transparency and efficiency.

Conclusion for Sourcing CNC Machined Parts:

Sourcing CNC machined parts requires a strategic approach that balances quality, cost, lead time, and supplier reliability. By clearly defining specifications, material requirements, tolerances, and volume needs, businesses can effectively identify suitable manufacturing partners. Evaluating suppliers based on technical capabilities, quality certifications (such as ISO 9001), machining technologies (e.g., 3-axis vs. 5-axis), and production capacity ensures long-term success. Additionally, considering factors like geographical location, communication efficiency, and scalability supports a resilient supply chain. Ultimately, successful sourcing of CNC machined components hinges on strong supplier relationships, thorough due diligence, and a focus on precision and consistency—enabling businesses to achieve high-quality results, reduce time-to-market, and maintain competitive advantage in their respective industries.