The global CNC laser cutting market has experienced robust growth, driven by increasing demand for precision manufacturing across industries such as automotive, aerospace, and electronics. According to a report by Mordor Intelligence, the CNC laser cutting machine market was valued at USD 4.85 billion in 2023 and is projected to reach USD 6.98 billion by 2029, growing at a CAGR of approximately 6.3% during the forecast period. This expansion is fueled by advancements in automation, rising adoption of fiber laser technology, and the need for high-speed, accurate metal fabrication. As competition intensifies, a select group of manufacturers has emerged as leaders, leveraging innovation, scalability, and global supply chain integration to dominate market share. Below is a data-driven ranking of the top 10 CNC laser cutting manufacturers shaping the future of industrial manufacturing.

Top 10 Cnc Laserschneiden Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 BCAMCNC – CNC & Laser Machine Manufacturer

Website: bcamcnc.com

Key Highlights: Jinan Bcamcnc Machinery Co., Ltd.,is a professional manufacturer of CNC machines with an 12000㎡ factory, 20+ patents, and a global presence in 90+ countries ……

#2 MECANUMERIC

Website: mecanumeric.com

Key Highlights: MECANUMERIC, a French manufacturer of machine tools, is committed to providing a CNC solution to every industrial problem, thanks to its areas of expertise in ……

#3 Wattsan

Website: wattsan.com

Key Highlights: Wattsan is a manufacturer of laser and cnc milling machines of European quality at affordable prices with worldwide delivery….

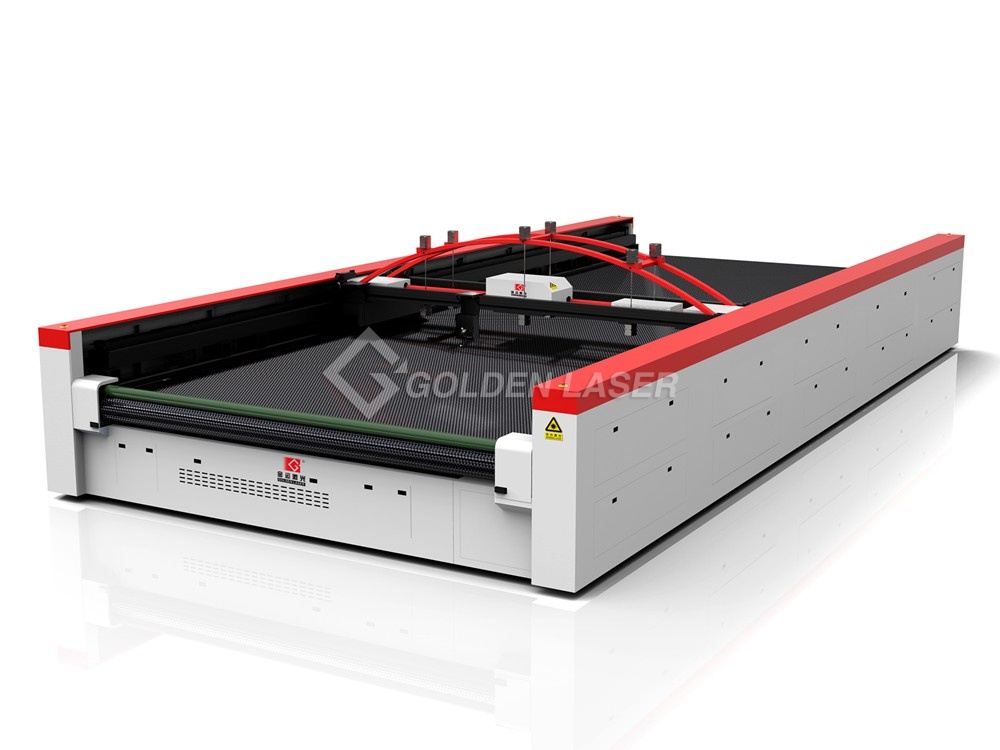

#4 Fiber Laser Cutting Machine and CO2 Laser Cutter Manufacturer …

Website: gwklaser.com

Key Highlights: Leading manufacturer of laser cutting machine, CO2 laser cutter, laser welding machine, laser bending machine and laser cleaning machine, etc….

#5 Large Format Laser Cutting Systems and Laser Engravers

Website: kernlasers.com

Key Highlights: USA manufacturer of large format laser cutting systems and laser engraver equipment. Specializing in metal and acrylic cutting machines….

#6 ACCURL

Website: accurl.com

Key Highlights: ACCURL CNC machinery executes rapid and precise cuts, angle cuts, undercuts, and finishes, eliminating the necessity for multi-part molds and manual labor….

#7 Bodor

Website: bodor.com

Key Highlights: Bodor laser is a fiber laser cutting machine manufacturer specialized in cnc fiber laser cutting machine equipment with integrating development, production, ……

#8 Universal Laser Systems

Website: ulsinc.com

Key Highlights: Solve Material Processing Challenges. Overcome your most demanding and complex applications. ULS helps companies evaluate the feasibility of laser technology….

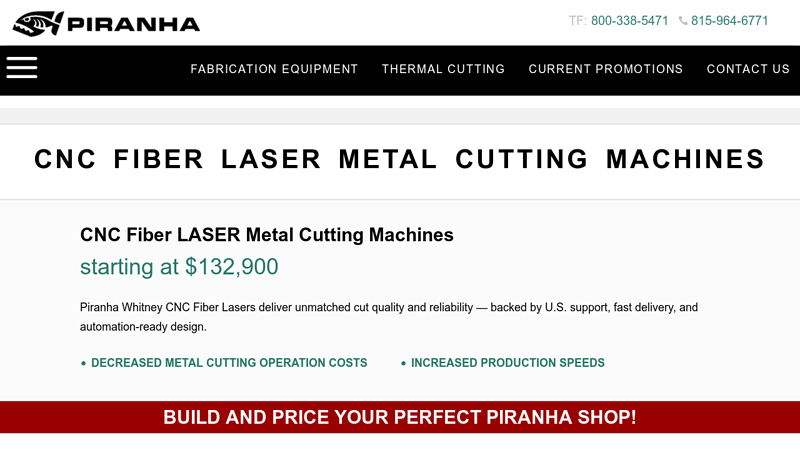

#9 CNC Fiber LASER Metal Cutting Machines

Website: piranhafab.com

Key Highlights: CNC Fiber LASER Metal Cutting Machines. starting at $132,900. Piranha Whitney CNC Fiber Lasers deliver unmatched cut quality and reliability — backed by U.S. ……

#10 Best Fiber Laser Cutter for Sale

Website: oreelaser.com

Key Highlights: Products mainly include Flatbed fiber laser cutting machine, Tube fiber laser cutting machine, Sheet&Tube dual-use fiber laser cutting machine, 3D fiber laser ……

Expert Sourcing Insights for Cnc Laserschneiden

H2: Market Trends for CNC Laser Cutting in 2026

By 2026, the CNC laser cutting market is poised for significant transformation driven by technological innovation, growing industrial automation, and expanding applications across key sectors. Several macro and microeconomic trends are shaping the industry landscape, positioning CNC laser cutting as a cornerstone technology in advanced manufacturing.

-

Increased Adoption of High-Power Fiber Lasers

In 2026, high-power fiber lasers (ranging from 6 kW to over 20 kW) are expected to dominate the CNC laser cutting market. These systems offer faster cutting speeds, improved energy efficiency, and enhanced cut quality—especially for thick metals. Their reliability and lower maintenance compared to CO₂ lasers are driving demand in automotive, aerospace, and heavy machinery sectors. -

Integration with Industry 4.0 and Smart Manufacturing

Smart factories are leveraging CNC laser systems equipped with IoT connectivity, real-time monitoring, and predictive maintenance capabilities. By 2026, most new CNC laser cutting machines will feature digital twins, AI-driven optimization, and seamless integration with MES (Manufacturing Execution Systems), boosting productivity and reducing downtime. -

Rise in Demand from Electric Vehicles (EVs) and Renewable Energy

The global push toward electrification is fueling demand for precision metal components used in EV battery enclosures, motor parts, and power electronics. Similarly, the renewable energy sector—particularly solar and wind—requires large volumes of precisely cut structural and electrical components, further boosting CNC laser adoption. -

Expansion in Emerging Markets

Asia-Pacific, especially China, India, and Southeast Asia, will continue to lead growth in CNC laser cutting due to rapid industrialization, government initiatives (e.g., “Make in India,” “China Manufacturing 2025”), and the establishment of advanced manufacturing hubs. Latin America and Eastern Europe are also emerging as key growth regions. -

Focus on Sustainability and Energy Efficiency

Manufacturers are prioritizing eco-friendly production methods. CNC laser cutting systems in 2026 will increasingly emphasize energy-efficient designs, recyclable material compatibility, and reduced waste through nesting software and precision cutting. Regulatory pressures and ESG (Environmental, Social, and Governance) goals are accelerating this shift. -

Advancements in Automation and Robotics

Integration with robotic arms and automated material handling systems (e.g., auto-loading/unloading, pallet changers) is becoming standard. This enables lights-out manufacturing, reducing labor costs and improving throughput—especially in high-volume production environments. -

Customization and Small-Batch Production Growth

With the rise of mass customization and agile manufacturing, CNC laser cutting is increasingly favored for its flexibility in handling low-volume, high-mix production. This trend is particularly strong in architecture, consumer goods, and medical device manufacturing. -

Competitive Pricing and Market Consolidation

As technology matures and more players enter the market, especially from China and South Korea, price competition is intensifying. This drives innovation but also leads to market consolidation, with larger manufacturers acquiring niche technology providers to expand their portfolios.

Conclusion:

By 2026, the CNC laser cutting market will be characterized by smarter, faster, and more sustainable systems, deeply integrated into digital manufacturing ecosystems. Companies that embrace automation, high-power fiber technology, and Industry 4.0 principles will gain a competitive edge, while regional expansion and sector-specific applications will continue to drive global market growth.

H2: Common Pitfalls When Sourcing CNC Laserschneiden Services (Quality and Intellectual Property Concerns)

Sourcing CNC laserschneiden (laser cutting) services, especially from international suppliers, can present several challenges, particularly in the areas of quality control and intellectual property (IP) protection. Being aware of these common pitfalls helps businesses mitigate risks and ensure reliable, secure production.

1. Inconsistent Quality Standards

One of the most frequent issues is variability in cut quality. Differences in laser machine calibration, operator skill, and material handling can lead to inaccuracies in dimensions, rough edges, or warping. Suppliers may claim compliance with ISO standards but lack proper certification or consistent quality management systems.

2. Lack of Material Traceability and Certification

Some vendors fail to provide documentation verifying the origin and grade of raw materials. This is critical in industries like aerospace or medical devices, where material specifications directly impact safety and regulatory compliance.

3. Inadequate Communication and Technical Misunderstanding

Language barriers or unclear technical communication can result in misinterpretation of drawings, tolerances, or finishing requirements. Misaligned expectations often lead to rework, delays, or rejected parts.

4. Insufficient Prototyping and First Article Inspection (FAI)

Skipping or rushing prototype validation increases the risk of mass production errors. Without a thorough FAI process, dimensional inaccuracies or design flaws may go unnoticed until large batches are produced.

5. Weak Intellectual Property Protection

Sharing detailed CAD files and technical drawings with third-party manufacturers poses a significant IP risk. In some regions, legal enforcement of IP rights is limited, increasing the chance of unauthorized replication or resale of your designs.

6. No Non-Disclosure Agreements (NDAs) or Weak Contracts

Many suppliers, especially smaller workshops, may not sign NDAs or include IP clauses in contracts. Even when agreements are in place, jurisdictional limitations can make enforcement difficult.

7. Hidden Costs and Scope Creep

Initial quotes may exclude costs for setup, tooling, or post-processing. Unforeseen charges often emerge after production begins, impacting overall project budgets.

8. Long Lead Times and Poor Responsiveness

Delays in communication, production scheduling, or shipping can disrupt supply chains. Limited transparency into production status makes proactive planning challenging.

9. Counterfeit or Substandard Equipment Usage

Some suppliers use lower-tier or poorly maintained laser systems to cut costs, resulting in inferior edge quality and dimensional inaccuracy. This is especially common with fiber or CO₂ lasers that are not regularly serviced.

10. Lack of Audit and On-Site Verification

Remote sourcing often prevents physical audits of facilities. Without on-site visits or third-party inspections, it’s difficult to verify claims about equipment, workforce training, or quality processes.

Mitigation Strategies:

To avoid these pitfalls, establish clear technical specifications, require material certifications, conduct supplier audits, use legally binding NDAs, and perform regular quality inspections—preferably through third-party services. Engaging suppliers with proven track records and transparent operations significantly reduces both quality and IP risks.

Logistics & Compliance Guide for CNC Laserschneiden

Overview

CNC Laserschneiden (CNC laser cutting) is a precision manufacturing process widely used in industries such as automotive, aerospace, electronics, and architecture. Efficient logistics and strict compliance with regulatory standards are essential to ensure product quality, worker safety, and legal conformity across national and international markets.

Logistics Considerations

Material Procurement and Handling

- Source raw materials (e.g., steel, aluminum, acrylic) from certified suppliers to guarantee consistent quality.

- Implement inventory management systems (e.g., ERP or WMS) to track material stock levels, batch numbers, and shelf life.

- Store materials in climate-controlled, dust-free environments to prevent warping or contamination, especially for sensitive substrates like plastics.

Production Workflow Integration

- Schedule CNC laser cutting operations using production planning software to minimize downtime and optimize tool usage.

- Ensure seamless transfer of digital design files (DXF, DWG) from CAD systems to CNC machines using standardized formats and version control.

- Integrate cutting operations with downstream processes such as bending, welding, or surface finishing through automated material handling systems (e.g., robotic arms).

Shipping and Distribution

- Package laser-cut parts with protective materials (e.g., foam, bubble wrap) to prevent scratches or deformation during transit.

- Label shipments with part numbers, batch codes, and handling instructions (e.g., “Fragile,” “This Side Up”).

- Utilize reliable logistics partners with experience in handling precision metal and plastic components, particularly for just-in-time (JIT) deliveries.

Compliance Requirements

Safety Regulations

- Comply with local occupational health and safety standards (e.g., OSHA in the U.S., DGUV in Germany).

- Install protective enclosures, emergency stop systems, and interlocks on laser cutting machines.

- Provide personnel with appropriate personal protective equipment (PPE), including laser safety goggles, gloves, and flame-resistant apparel.

Environmental and Emissions Standards

- Equip laser cutting systems with fume extraction and filtration units to capture hazardous particulates and volatile organic compounds (VOCs).

- Adhere to emissions regulations such as the EU Industrial Emissions Directive (IED) or U.S. EPA standards.

- Properly dispose of cutting waste (e.g., metal slag, filter residues) in accordance with hazardous waste disposal laws.

Quality and Certification Standards

- Follow ISO 9001 for quality management systems to ensure consistent product quality.

- Comply with industry-specific standards such as ISO 3887 for metal cutting or DIN 2310 for surface finishes.

- Maintain documentation for material certifications (e.g., EN 10204 3.1) and process validation records.

International Trade and Customs

- Ensure product conformity with destination market regulations (e.g., CE marking in Europe, FCC in the U.S.).

- Prepare accurate export documentation, including commercial invoices, packing lists, and certificates of origin.

- Classify goods correctly using Harmonized System (HS) codes (e.g., 8456.20 for laser cutting machines) to avoid customs delays.

Conclusion

Effective logistics management and strict compliance with safety, environmental, and quality standards are critical for successful CNC Laserschneiden operations. By adopting standardized procedures, investing in certified equipment, and maintaining thorough documentation, manufacturers can ensure operational efficiency, legal compliance, and customer satisfaction in both domestic and global markets.

Conclusion for Sourcing CNC Laser Cutting Services

Sourcing CNC laser cutting services requires a strategic approach that balances precision, cost-efficiency, lead times, and quality standards. CNC laser cutting offers exceptional accuracy, repeatability, and versatility for manufacturing complex metal and non-metal components across industries such as automotive, aerospace, electronics, and medical devices.

When sourcing this service, it is essential to evaluate suppliers based on their technical capabilities—including laser power, material thickness capacity, and cutting tolerances—as well as their certifications (e.g., ISO 9001), experience in your specific industry, and track record for on-time delivery. Proximity to your operations, scalability, and communication responsiveness also play a critical role in ensuring smooth collaboration.

Additionally, digital manufacturing platforms and online quoting tools have simplified the comparison of service providers, enabling faster prototyping and production scaling. However, direct engagement with suppliers remains valuable for complex projects requiring customization or strict quality control.

In conclusion, effective sourcing of CNC laser cutting services hinges on a thorough supplier qualification process, clear technical specifications, and strong supply chain integration. By selecting the right partner, companies can achieve high-quality fabrication, reduced waste, and faster time-to-market—ultimately driving operational efficiency and competitive advantage.