The global CNC (Computer Numerical Control) machine tools market has experienced strong growth, driven by rising demand for precision manufacturing across industries such as automotive, aerospace, and electronics. According to Mordor Intelligence, the CNC machine market was valued at USD 74.5 billion in 2023 and is projected to reach USD 105.6 billion by 2029, growing at a CAGR of approximately 6.1% during the forecast period. This expansion underscores the critical role of standardized programming languages—specifically G-code and M-code—in enabling automated, high-accuracy machining processes. As industry leaders continue to innovate in CNC control systems, the manufacturers behind the foundational G and M code platforms are becoming increasingly influential. These companies not only shape machine interoperability and programming efficiency but also drive advancements in smart manufacturing and Industry 4.0 integration. Below is a data-informed overview of the top 10 manufacturers leading innovation in CNC G and M code development and control system solutions.

Top 10 Cnc G And M Code Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 G

Domain Est. 1996

Website: haascnc.com

Key Highlights: Find the full list of G-codes that you can use to program your Haas CNC Mill….

#2 Mazak CNC Machine Code Reference

Domain Est. 1996

Website: premierequipment.com

Key Highlights: Complete Mazak CNC machine code reference with G-codes, M-codes & MAZATROL programming tables. Expert guide for CNC programmers….

#3 CNC G Code & M Code Programming for CNC Machining

Domain Est. 1998

Website: carlsonmfg.com

Key Highlights: Carlson Manufacturing, Inc. has decades of experience in cnc machining. We offer the following as an intro to cnc machining and CNC G code programming….

#4 What is CNC Programming?

Domain Est. 1989

Website: autodesk.com

Key Highlights: CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines….

#5 Milltronics

Domain Est. 1995

Website: milltronics.com

Key Highlights: Milltronics offers 50 different models of CNC milling and CNC turning machines for toolroom and production environments….

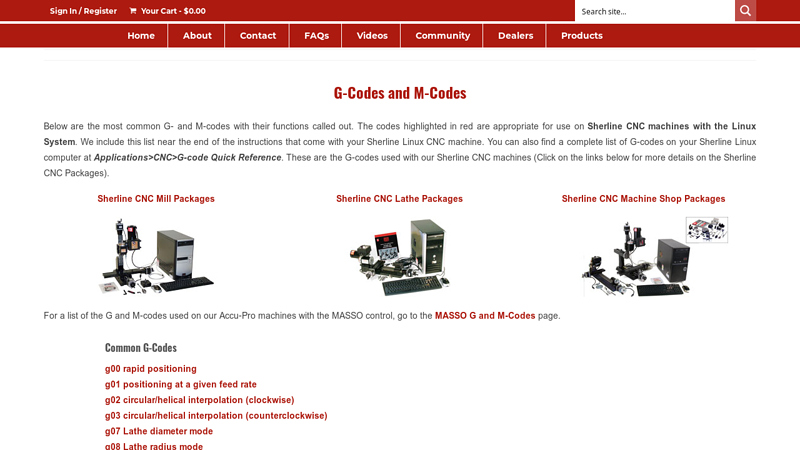

#6 G

Domain Est. 1995

Website: sherline.com

Key Highlights: Below are the most common G- and M-codes with their functions called out. The codes highlighted in red are appropriate for use on Sherline CNC machines with ……

#7 An Introduction to CNC G

Domain Est. 1996

Website: summitmt.com

Key Highlights: G-code is one of the languages used to operate Computer Numerical Control (CNC) machines. CNC machines rely on a computer to direct operations, rather than a ……

#8 to Mazak Corporation

Domain Est. 1998

Website: mazak.com

Key Highlights: Mazak provides products and solutions that can support a wide range of parts machining processes, such as high-speed and high-accuracy machines, various ……

#9 Jyoti CNC Automation Limited

Domain Est. 2005

Website: jyoti.co.in

Key Highlights: Jyoti CNC is the largest CNC machine tool manufacturing company of India and having a subsidiary “Huron” based at Strasbourg, France….

#10 G

Domain Est. 2007

Website: cnccookbook.com

Key Highlights: Explore our comprehensive G-Code and M-Code list, featuring easy examples and tutorials for Fanuc, LinuxCNC, GRBL, and Haas CNC machines….

Expert Sourcing Insights for Cnc G And M Code

2026 Market Trends for CNC G and M Code

As manufacturing evolves with advancements in automation, digitalization, and artificial intelligence, the role and application of CNC G and M code—the foundational programming language for computer numerical control (CNC) machines—are undergoing significant transformation. While G and M codes remain essential for machine tool operation, the market landscape surrounding their use is shifting rapidly. Here are the key trends expected to shape the CNC G and M code market in 2026.

Growing Integration with Advanced CAM Software

By 2026, Computer-Aided Manufacturing (CAM) software will be more tightly integrated with CNC programming workflows, reducing the need for manual G and M code writing. Leading CAM platforms will offer intuitive graphical interfaces, AI-driven toolpath optimization, and seamless post-processing capabilities that automatically generate machine-specific G and M code. This trend will enhance programming efficiency and reduce human error, particularly in complex multi-axis machining environments.

Rise of AI and Machine Learning in Code Optimization

Artificial Intelligence (AI) and machine learning are set to revolutionize CNC programming by intelligently optimizing G and M code in real time. In 2026, predictive algorithms will analyze machining parameters, tool wear, material properties, and historical performance data to dynamically adjust feed rates, spindle speeds, and toolpaths—often translating these adjustments into optimized G/M code sequences. This will improve machining precision, extend tool life, and reduce cycle times across industries.

Increased Demand for Hybrid Skills: Programming and Digital Literacy

While manual coding may decline in routine applications, skilled technicians and engineers fluent in G and M code will remain in high demand. Employers in 2026 will seek professionals who combine traditional CNC programming knowledge with expertise in digital twins, simulation tools, and data analytics. Understanding G and M code will be critical for troubleshooting, custom automation, and integrating legacy systems with modern Industry 4.0 frameworks.

Expansion in Education and Upskilling Programs

As CNC technology becomes more sophisticated, educational institutions and technical training providers will expand curricula focused on G and M code fundamentals alongside modern manufacturing technologies. Micro-credentials, online certifications, and virtual labs will make CNC programming knowledge more accessible, supporting workforce development in advanced manufacturing sectors, especially in emerging economies.

Standardization and Interoperability Challenges

Despite technological advances, the lack of universal standards in G and M code dialects across machine tool brands will persist into 2026. This fragmentation will drive demand for smarter post-processors and unified programming platforms capable of translating standardized inputs into vendor-specific code. Industry consortia and software developers will likely collaborate to improve interoperability, promoting more efficient data exchange across CNC ecosystems.

Growth in Automated Code Generation for Smart Factories

In fully integrated smart factories, G and M code will increasingly be generated automatically through Manufacturing Execution Systems (MES) and IoT-enabled workflows. Real-time data from sensors and adaptive control systems will feed into code generation engines, allowing for on-the-fly adjustments without human intervention. This shift will support lights-out manufacturing and scalable production models, particularly in aerospace, automotive, and medical device manufacturing.

Continued Relevance in Maintenance and Legacy Systems

Even as automation grows, many facilities will continue operating legacy CNC machines well into 2026. These machines rely directly on G and M code, ensuring ongoing demand for technicians who can read, write, and modify programs. Maintenance, retrofitting, and machine modernization projects will sustain the need for deep G/M code expertise, especially in small and medium enterprises (SMEs) with constrained capital budgets.

Conclusion

By 2026, CNC G and M code will remain a cornerstone of precision manufacturing, though its role will evolve from manual programming to a component of intelligent, automated systems. While direct coding may become less common in everyday operations, understanding G and M code will be more important than ever for optimizing performance, ensuring compatibility, and enabling innovation in next-generation manufacturing environments. The market will reward those who blend foundational knowledge with digital fluency, positioning G and M code not as a legacy artifact, but as a vital link in the future of smart production.

Common Pitfalls Sourcing CNC G and M Code (Quality, IP)

When acquiring CNC G and M code from external sources—such as freelancers, code libraries, or third-party vendors—manufacturers and machinists face several risks related to code quality and intellectual property (IP). Being aware of these pitfalls is essential to ensure production efficiency, part accuracy, and legal compliance.

Poor Code Quality and Inefficiency

Sourced G and M code may suffer from suboptimal programming practices, including inefficient toolpaths, incorrect feed rates, or improper spindle speeds. These flaws can lead to longer cycle times, increased tool wear, poor surface finishes, or even machine damage. Code that isn’t optimized for specific machines or materials may require extensive rework before it’s usable.

Lack of Standardization and Documentation

Externally sourced code often lacks proper documentation, comments, or adherence to internal shop standards. Without clear annotations or structure, modifying or troubleshooting the program becomes time-consuming and error-prone. Inconsistent formatting across different sources can also hinder integration into existing workflows.

Machine-Specific Compatibility Issues

G and M codes are not universally standardized across all CNC controllers (e.g., Fanuc, Siemens, Haas, Heidenhain). Code written for one control system may not run correctly—or at all—on another. Sourcing code without verifying compatibility can result in crashes, incorrect movements, or scrapped parts.

Hidden Errors and Safety Risks

Poorly tested or hastily written code may contain undetected errors such as incorrect coordinate systems, missing tool change commands, or improper use of modal codes. These can pose serious safety risks, including tool collisions, workpiece damage, or injury to operators.

Intellectual Property (IP) Infringement

Using sourced code without proper licensing or verification of ownership can lead to IP violations. Many code repositories or freelance platforms may distribute code derived from proprietary programs or protected designs. Unknowingly using such code can expose your company to legal action, especially in competitive industries.

Unclear Licensing and Usage Rights

Even if code is legally obtained, the licensing terms may restrict how it can be used—such as limitations on commercial use, modification, or redistribution. Failing to review these terms can result in non-compliance, particularly if the code is integrated into proprietary manufacturing processes.

Dependency on External Sources

Relying heavily on outsourced code reduces in-house expertise and creates dependency. If the original coder is unavailable or the source is discontinued, maintaining, updating, or troubleshooting the code becomes challenging, potentially disrupting production.

Mitigation Strategies

To avoid these pitfalls, always:

– Review and test all sourced code thoroughly on a simulator or in a controlled environment.

– Verify compatibility with your CNC control and machine setup.

– Ensure proper documentation and standardization before integration.

– Confirm the legal origin and licensing of the code.

– Invest in training in-house programmers to reduce long-term reliance on external sources.

By proactively addressing these quality and IP concerns, businesses can safely leverage external CNC programming resources while protecting their operations and intellectual assets.

Logistics & Compliance Guide for CNC G and M Code

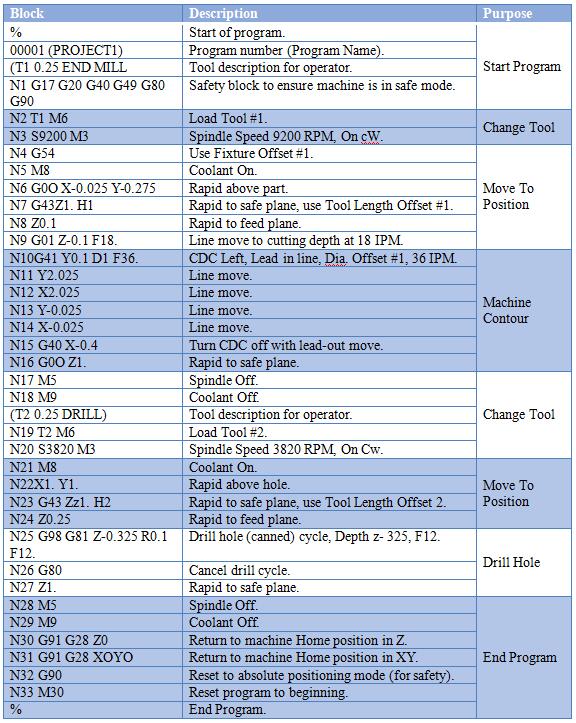

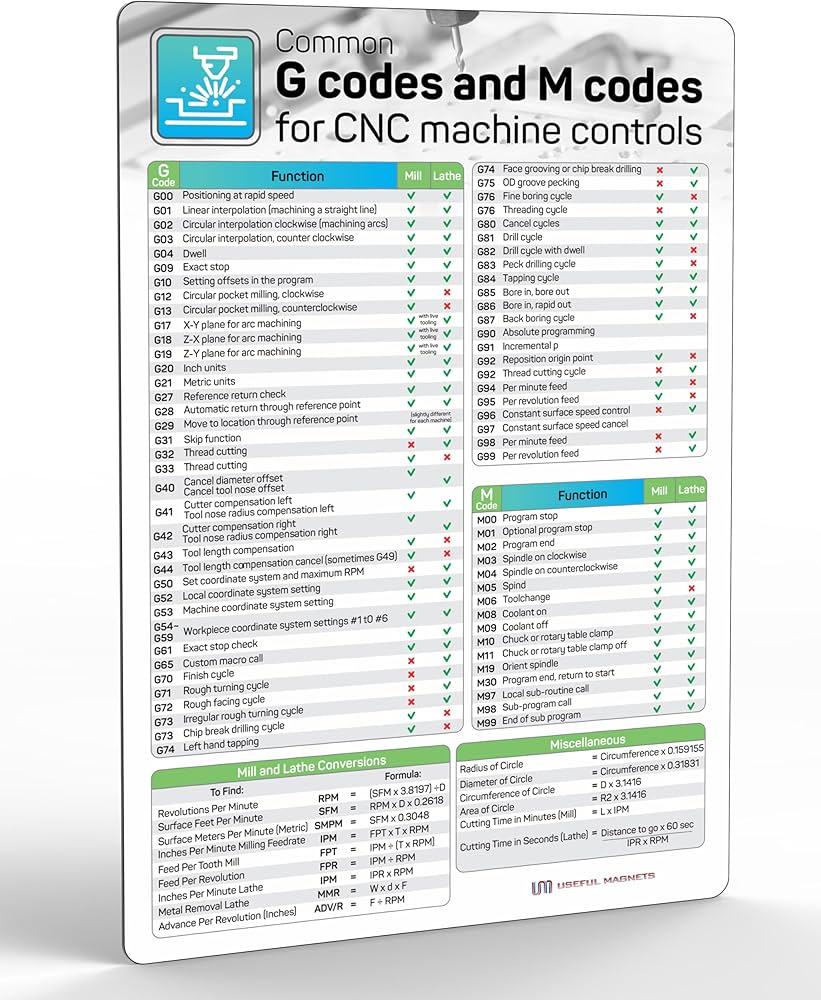

Understanding G and M Codes in CNC Systems

G and M codes are standard programming languages used in Computer Numerical Control (CNC) machines to control motion, tool behavior, and machine functions. G codes govern geometric movements (e.g., G00 for rapid positioning, G01 for linear interpolation), while M codes manage machine operations (e.g., M03 to start the spindle, M06 for tool change). Proper use ensures precision, safety, and repeatability in manufacturing processes.

Regulatory and Industry Standards

CNC programming must comply with international and industry-specific standards. Key standards include:

– ISO 6983: The international standard for CNC programming syntax and code structure.

– ANSI B63.1: U.S. standard defining safety and operational guidelines for numerical control equipment.

– OSHA Regulations: Workplace safety standards requiring safe machine operation, lockout/tagout procedures, and operator training.

– ISO 9001: Quality management systems that may require documented CNC programming practices and version control.

Adherence ensures regulatory compliance and facilitates global interoperability.

Safe Programming and Operational Practices

To maintain compliance and safety:

– Always simulate G and M code programs using CAM software or machine simulation before execution.

– Implement program validation procedures, including dry runs without material.

– Use standardized code formats to minimize human error.

– Ensure all operators are trained in both CNC programming and emergency response.

– Include safety blocks (e.g., spindle off, coolant off) at program end (e.g., M05, M09).

Documentation and Version Control

Proper documentation is critical for compliance and traceability:

– Maintain a centralized library of G and M code programs with version tracking.

– Label files clearly with part number, revision, date, and author.

– Use change logs to record modifications and approvals.

– Store backups securely with disaster recovery protocols.

This supports audit readiness and quality assurance.

Tool and Machine Compliance

Ensure CNC machines and tools meet operational requirements:

– Regularly calibrate machines and verify coordinate systems (e.g., G54–G59 work offsets).

– Validate tool length and diameter compensation (e.g., G43, G41/G42).

– Confirm that M code commands (e.g., M08 for coolant on) align with machine capabilities.

– Follow manufacturer guidelines for machine-specific code variants.

Data Security and Intellectual Property

Protect CNC programs as intellectual property:

– Restrict access to programming files using role-based permissions.

– Encrypt sensitive code when transmitting or storing offsite.

– Apply watermarking or metadata to deter unauthorized use.

– Comply with data protection regulations such as GDPR if handling data across regions.

Environmental and Waste Compliance

CNC operations must align with environmental regulations:

– Manage coolant and cutting fluid disposal per EPA or local environmental codes.

– Control metal shavings and particulate emissions using proper filtration systems.

– Optimize G code paths to reduce energy consumption and material waste.

Efficient programming contributes to sustainability compliance.

Training and Operator Certification

Ensure all personnel are properly trained:

– Provide certification programs covering G and M code logic, machine operation, and safety.

– Maintain training records for audits and compliance verification.

– Conduct regular refresher courses to address updates in code standards or machine technology.

Audit and Continuous Improvement

Perform periodic reviews of CNC programming practices:

– Audit code libraries for standardization and efficiency.

– Evaluate compliance with internal policies and external regulations.

– Use feedback from operators and quality control to refine programming procedures.

– Implement corrective actions for non-conformances promptly.

This ensures ongoing operational excellence and regulatory alignment.

Conclusion: Sourcing CNC G-Code and M-Code

Sourcing accurate and reliable G-code and M-code for CNC machining is a critical step in ensuring precision, efficiency, and safety in manufacturing operations. These standardized programming languages serve as the foundation for controlling CNC machines, directing movements (G-code) and managing auxiliary functions such as tool changes and coolant control (M-code).

The most effective approach to sourcing these codes involves a combination of in-house programming, proven software tools (such as CAM software), and adherence to machine-specific documentation. Leveraging libraries of pre-tested subroutines, industry best practices, and collaboration with experienced machinists further enhances code reliability. Additionally, simulation tools help verify code accuracy before execution, minimizing the risk of errors, scrapped parts, or machine damage.

Ultimately, successful sourcing of G-code and M-code hinges on a balance between automation, technical knowledge, and rigorous quality control. Investing time in proper code development and validation not only improves machining accuracy but also increases productivity and reduces operational downtime in modern CNC environments.