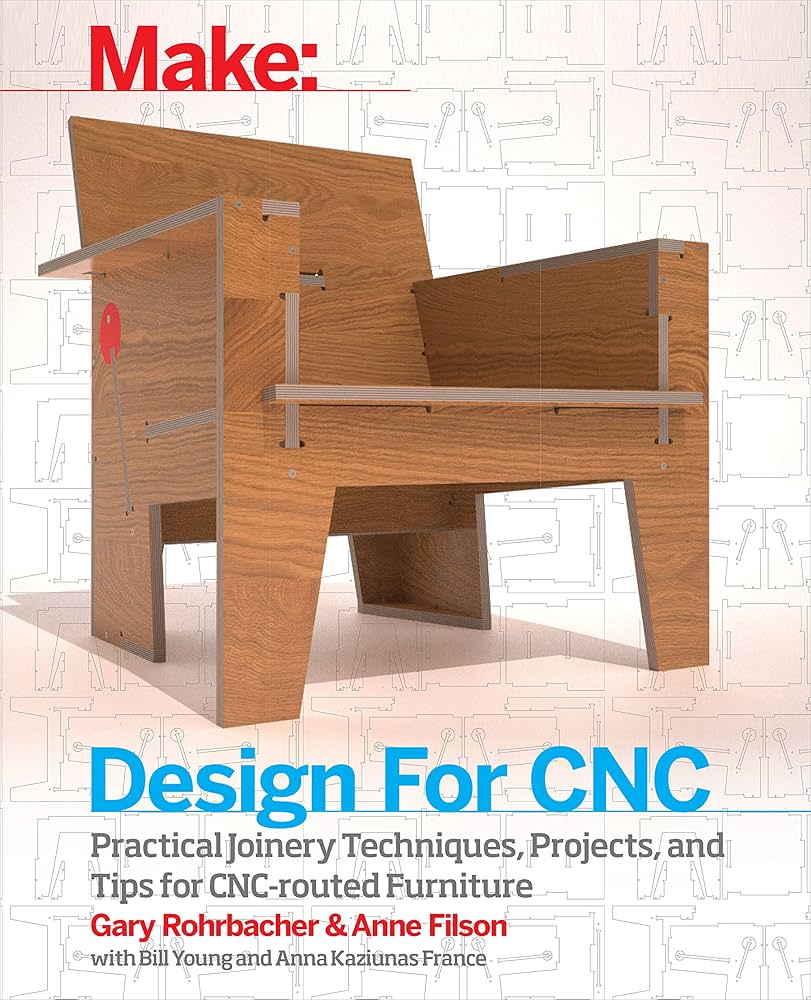

The global CNC furniture manufacturing industry has experienced substantial growth, driven by advancements in automation, precision engineering, and rising demand for customizable, high-quality wood products. According to Grand View Research, the global CNC router market—critical to automated furniture production—was valued at USD 1.42 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030. This growth is fueled by increasing adoption in the furniture sector, especially in regions like Asia-Pacific, where manufacturing hubs are leveraging CNC technology to enhance production efficiency and design complexity. Similarly, Mordor Intelligence forecasts sustained momentum in the CNC machinery market, citing rising investments in smart manufacturing and industrial automation as key drivers. As consumer preferences shift toward bespoke, dimensionally accurate furniture, manufacturers equipped with advanced CNC capabilities are gaining competitive advantage. In this evolving landscape, the following ten companies stand out for their technological innovation, production scale, and global reach in CNC-driven furniture manufacturing.

Top 10 Cnc Furniture Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Alpha CNC: CNC Machine Manufacturer

Domain Est. 2024

Website: alpha-cnc.net

Key Highlights: Alpha CNC is your trusted CNC machine manufacturer, offering tailored OEM and ODM services of the CNC router, furniture making machine, and laser machine….

#2 Furniture Making CNC Machines

Domain Est. 1996

Website: lagunatools.com

Key Highlights: Laguna Tools offers both Industrial and Automated CNC Machines to meet the demands of modern furniture makers….

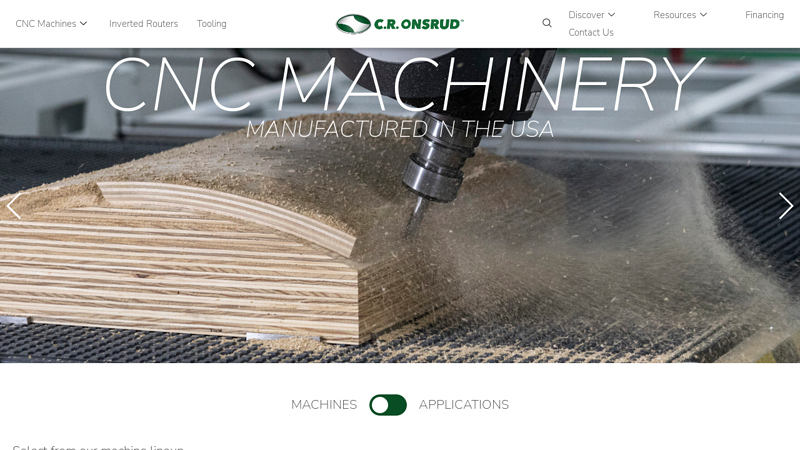

#3

Domain Est. 1997

Website: cronsrud.com

Key Highlights: Explore C.R. Onsrud’s CNC machinery, manufactured in the USA, designed to meet your business needs with customization options, quality, and reliability….

#4 CNC Router Furniture

Domain Est. 2001

Website: inventables.com

Key Highlights: One platform to scale your furniture business. From digital design to CNC machine manufacturing. An all-in-one, easy-to-use platform….

#5 American Made CNC Routers for Wood, Plastics, Aerospace and …

Domain Est. 1995

Website: thermwood.com

Key Highlights: Discover Thermwood’s high-performance, American-made CNC routers. Find the perfect 3 and 5-axis solutions for your woodworking, plastics, or aerospace ……

#6 SCM Wood USA

Domain Est. 1997 | Founded: 1952

Website: scmgroup.com

Key Highlights: Since 1952, SCM is leader in the field of secondary woodworking machinery and offers the widest range of technologies for both industry and craftsman, ……

#7 CNC Furniture Design

Domain Est. 2002

Website: technocnc.com

Key Highlights: CNC routers can be used to create furniture pieces. Our CNC Furniture design CNC routers are perfect for custom furniture design businesses….

#8 Diversified Machine Systems

Domain Est. 2006

Website: dmscncrouters.com

Key Highlights: Diversified Machine Systems builds U.S. CNC routers, specializing in 3 and 5 axis machines for composites, metals, wood, foam, and plastics….

#9 CNC machining centers and routers for woodworking and panels

Domain Est. 2010

Website: m.holzherusa.com

Key Highlights: CNC machines designed for efficient and accurate machining of solid wood, panels, windows and doors, composite material and aerospace….

#10 CNC machining centres for woodworking

Domain Est. 2020

Website: gredasrl.com

Key Highlights: Production of CNC machining centers for woodworking, plastic and alluminium. Special and custom production. Quality Made in Italy worlwide 100 partnerships….

Expert Sourcing Insights for Cnc Furniture

H2: Projected CNC Furniture Market Trends for 2026

By 2026, the CNC (Computer Numerical Control) furniture market is poised for significant transformation, driven by technological advancements, shifting consumer preferences, and evolving economic and environmental factors. Here’s an analysis of the key trends expected to shape the industry:

1. Surge in Mass Customization and Personalization:

A dominant trend will be the demand for bespoke furniture. Consumers increasingly seek unique, made-to-order pieces that reflect personal style and fit specific spatial requirements. CNC machining excels here, enabling cost-effective, small-batch production with intricate designs. By 2026, expect more brands to offer digital configurators allowing customers to customize dimensions, materials, and finishes online, with CNC systems seamlessly translating designs into physical products.

2. Integration of AI and Smart Manufacturing:

Artificial Intelligence (AI) will become deeply embedded in CNC furniture workflows. AI-driven design software will suggest optimized layouts, minimize material waste, and predict maintenance needs for CNC machinery. Smart factories will leverage IoT-connected CNC equipment, enabling real-time monitoring, predictive maintenance, and adaptive production scheduling—boosting efficiency and reducing downtime.

3. Sustainability as a Core Competitive Advantage:

Environmental concerns will heavily influence the market. CNC technology supports sustainability through precision cutting that reduces material waste by up to 30% compared to manual methods. By 2026, leading manufacturers will prioritize certified sustainable materials (like FSC wood, recycled composites) and highlight low-waste processes. Transparency in sourcing and carbon footprint will become key marketing differentiators.

4. Growth of On-Demand and Localized Production:

The rise of e-commerce and demand for faster delivery will fuel micro-factories and localized CNC hubs. Instead of mass-producing overseas, companies will use CNC technology to manufacture furniture closer to consumers, reducing shipping costs and emissions. This shift supports a circular economy and enables quicker response to market changes.

5. Expansion into Affordable Luxury and Mid-Market Segments:

While CNC furniture has often been associated with premium pricing, advancements in automation and scaling will drive costs down. By 2026, more mid-tier brands will adopt CNC technology to offer high-design, durable furniture at accessible price points, blurring the lines between mass production and craftsmanship.

6. Material Innovation and Hybrid Fabrication:

CNC machining will increasingly be combined with other technologies (e.g., 3D printing, robotic finishing) to work with advanced materials like engineered wood composites, bio-based plastics, and hybrid laminates. This allows for lighter, stronger, and more design-flexible furniture, opening new aesthetic and functional possibilities.

7. E-Commerce and Direct-to-Consumer (DTC) Dominance:

Digital-native brands leveraging CNC production will continue to grow. These companies use online platforms to showcase customizable options, streamline orders, and deliver directly to customers. By 2026, DTC will be a primary channel, supported by augmented reality (AR) tools that let users visualize CNC-fabricated furniture in their homes before purchase.

Conclusion:

The 2026 CNC furniture market will be defined by agility, sustainability, and personalization. Manufacturers who embrace AI integration, localized production, and eco-conscious practices will lead the industry. CNC technology will no longer be just a production tool but a strategic enabler of innovation, customization, and competitive differentiation in a rapidly evolving global market.

Common Pitfalls When Sourcing CNC Furniture: Quality and Intellectual Property Risks

Sourcing CNC (Computer Numerical Control) furniture from manufacturers—especially overseas—can offer cost efficiencies and design flexibility. However, several pitfalls related to quality control and intellectual property (IP) protection can undermine your business if not carefully managed.

Quality Control Challenges

One of the most significant risks in sourcing CNC furniture is maintaining consistent product quality. CNC machines rely heavily on precise programming and skilled operation, and minor deviations can lead to major defects.

Inconsistent Material Standards

Suppliers may use substandard or inconsistent wood, plywood, or engineered materials to cut costs. This affects durability, finish quality, and structural integrity. Always verify the type, grade, and sourcing of raw materials and request material certifications.

Poor Machining Precision

Even with CNC automation, poorly maintained machines or incorrect tool paths can result in inaccurate cuts, misaligned joints, or rough edges. Conduct factory audits and request sample batches before mass production to assess machining accuracy.

Lack of Finishing Consistency

Staining, sanding, and sealing processes are often manual steps that vary between batches. Inconsistent finishes can damage brand reputation. Define clear finish specifications and inspect multiple units from early production runs.

Inadequate Quality Assurance Processes

Some suppliers lack robust QA protocols. Implement third-party inspections during and post-production to catch defects early and avoid costly returns or customer complaints.

Intellectual Property (IP) Risks

CNC furniture often involves unique digital designs and CAD/CAM files, making IP protection a critical concern when sourcing.

Design Theft and Unauthorized Replication

Sharing design files with manufacturers exposes your creations to the risk of copying. Suppliers may reproduce your designs for other clients or sell them independently. Always sign comprehensive Non-Disclosure Agreements (NDAs) and use contracts that explicitly prohibit unauthorized use or replication.

Lack of IP Ownership Clarity

Ensure your contracts specify that you retain full ownership of design files and any modifications made during production. Ambiguity can lead to disputes or loss of exclusive rights.

Weak Legal Recourse in Some Regions

In certain manufacturing countries, IP enforcement is limited. Even with contracts, pursuing legal action may be difficult or impractical. Mitigate this by working with reputable suppliers, using escrow services for design file delivery, and limiting file access to essential staff.

Digital File Security

Unsecured transfer or storage of CNC design files increases the risk of leaks. Use encrypted channels and avoid sending full project files until necessary. Consider watermarking or segmenting files when possible.

By proactively addressing these quality and IP pitfalls, businesses can protect their investments, maintain brand integrity, and build sustainable relationships with CNC furniture suppliers.

Logistics & Compliance Guide for CNC Furniture

Understanding CNC Furniture Logistics

CNC (Computer Numerical Control) furniture involves precision-cut components manufactured using automated machinery. These pieces are often flat-packed or modular, requiring specialized handling during logistics. Efficient transportation, packaging, and inventory management are crucial due to the precision engineering and sometimes fragile nature of parts. Logistics planning must account for dimensional accuracy, material sensitivity (e.g., wood, MDF, or metal), and assembly requirements at the destination.

Packaging and Handling Standards

Proper packaging is essential to prevent damage during transit. CNC furniture components should be wrapped in protective materials such as bubble wrap, foam, or edge protectors. Use sturdy corrugated cardboard or wooden crates for external packaging, especially for international shipments. Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up”) and include assembly diagrams or part lists. Avoid overpacking, which can create pressure points, and ensure components are immobilized within the package to prevent shifting.

Transportation and Carrier Selection

Choose logistics partners experienced in handling flat-pack or oversized freight. For domestic shipments, standard parcel or LTL (Less Than Truckload) services may suffice. International shipments often require freight forwarding, with attention to container loading and customs documentation. Air freight is suitable for urgent, high-value orders; sea freight is cost-effective for bulk shipments. Ensure carriers provide tracking, insurance, and timely delivery confirmation to enhance supply chain visibility.

Import/Export Compliance

CNC furniture shipped across borders must comply with international trade regulations. Key considerations include:

- Harmonized System (HS) Codes: Accurately classify products (e.g., HS 9403.60 for wooden furniture) to determine tariffs and duties.

- Customs Documentation: Prepare commercial invoices, packing lists, and certificates of origin. Include itemized descriptions, values, weights, and dimensions.

- Phytosanitary Certificates: Required for wood products in many countries to prevent pest spread. Ensure wood is treated and certified per ISPM 15 standards.

- Product Safety Standards: Comply with destination country regulations such as U.S. CPSC, EU CE marking, or REACH for chemical content.

Environmental and Safety Regulations

CNC furniture materials must meet environmental and safety standards. Formaldehyde emissions from composite woods (e.g., MDF, plywood) are regulated under:

- CARB Phase 2 (U.S.): Limits formaldehyde in composite wood products.

- EPA TSCA Title VI: Federal regulation aligning with CARB standards.

- EU E1 or E0 Emission Standards: Apply to furniture sold in Europe.

Ensure compliance through third-party testing and certification. Use low-VOC adhesives and finishes to meet indoor air quality standards.

Labeling and Product Marking Requirements

Clearly label each product or package with required information:

- Manufacturer name and address

- Country of origin

- Material composition

- Safety and compliance marks (e.g., CE, FSC for sustainable wood)

- Assembly instructions and care guidelines

Labels must be durable and legible, adhering to regional consumer protection laws.

Return and Reverse Logistics

Implement a clear return policy for damaged, defective, or incorrect shipments. Establish a process for inspecting returned items, assessing repairability, and managing restocking or disposal. For flat-pack CNC furniture, include return packaging instructions and prepaid labels where applicable. Track return reasons to improve design, packaging, or logistics performance.

Recordkeeping and Audit Readiness

Maintain comprehensive records of shipments, compliance certifications, testing reports, and customs filings. Digital documentation systems improve traceability and audit preparedness. Regular internal audits help verify adherence to logistics protocols and regulatory requirements, reducing the risk of penalties or shipment delays.

Conclusion

Successfully managing logistics and compliance for CNC furniture requires attention to detail across the supply chain. From secure packaging and carrier coordination to strict adherence to international regulations, each step ensures customer satisfaction and legal compliance. Proactive planning and documentation minimize risks and support scalable growth in domestic and global markets.

Conclusion for Sourcing CNC Furniture:

Sourcing CNC (Computer Numerical Control) furniture offers a strategic advantage for businesses and designers seeking precision, customization, and scalability in modern furniture production. The integration of CNC technology enables consistent quality, intricate design capabilities, and efficient manufacturing processes, making it ideal for both small-batch bespoke pieces and large-scale production.

When sourcing CNC furniture, it is essential to partner with reliable manufacturers who utilize advanced CNC machinery, adhere to high-quality standards, and offer flexibility in materials and design. Evaluating factors such as production capacity, material sourcing, lead times, and post-production finishing ensures a successful supply chain. Additionally, leveraging digital design files (such as CAD/CAM) streamlines communication and enhances accuracy throughout the manufacturing process.

In a market increasingly driven by customization and sustainable practices, sourcing CNC furniture not only supports innovative design solutions but also promotes efficient material usage and reduced waste. Ultimately, investing in CNC-produced furniture combines craftsmanship with technological precision, delivering durable, high-quality products that meet contemporary demands for style, functionality, and scalability.