The U.S. apparel manufacturing industry is experiencing a resurgence driven by rising consumer demand for sustainable, fast-turnaround, and domestically produced clothing. According to Grand View Research, the U.S. apparel market size was valued at USD 118.4 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by shifting supply chain strategies, increased adoption of onshore manufacturing, and heightened interest in ethical production practices. Meanwhile, Mordor Intelligence projects a CAGR of over 5.5% for the U.S. textile and apparel market through 2028, citing nearshoring initiatives and digital transformation in production as key drivers. As brands prioritize supply chain resilience and transparency, domestic manufacturers are stepping up with advanced technologies and agile operations. In this evolving landscape, the following ten clothing manufacturers have emerged as leaders in innovation, quality, and scalability across the United States.

Top 10 Clothing Usa Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Apparel Production Inc.

Domain Est. 2006

Website: apparelproductionny.com

Key Highlights: Apparel Production is New York City’s leading fashion design house, clothing factory, and garment manufacturer for Men’s, Women’s, and Children’s clothing….

#2 InStyle USA

Domain Est. 2005

Website: instyleusa.net

Key Highlights: InStyle USA is an established private label manufacturer and contractor. We offer dependable full-service garment production of the highest quality. Our team of ……

#3 Mega Apparel

Domain Est. 2012

Website: megaapparel.com

Key Highlights: We provide immediate solutions to all custom apparel requirements, including screen printing, embroidery, private labeling, cutting, sewing, and much more….

#4 Los Angeles based Clothing Manufacture

Domain Est. 2012

Website: euphoriccolors.com

Key Highlights: Euphoric Colors is a pioneering, vertically integrated fashion apparel manufacturer based in the USA. We are revolutionizing how clothing is designed, made, and ……

#5 ARGYLE Haus of Apparel

Domain Est. 2014

Website: argylehaus.com

Key Highlights: American Made Clothing Manufacturer. ARGYLE is a Los Angeles–based fashion design house and manufacturing partner. built for startups ……

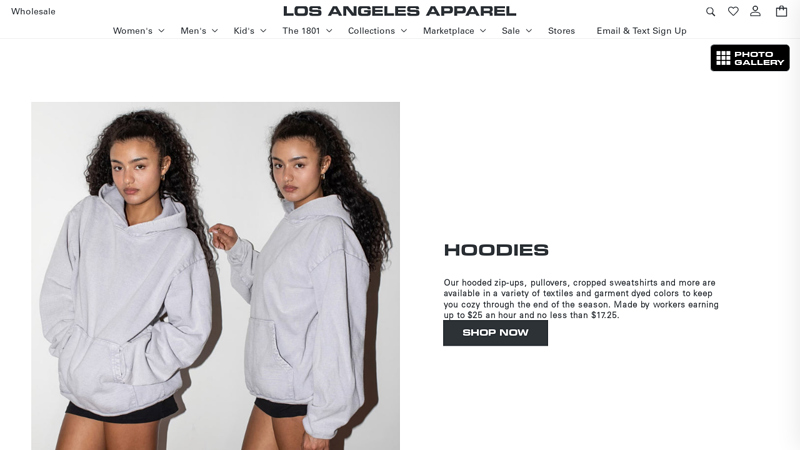

#6 Los Angeles Apparel

Domain Est. 2016

Website: losangelesapparel.net

Key Highlights: Free delivery over $125Los Angeles Apparel is a basics apparel manufacturer and distributor founded by Dov Charney, a long-standing leader in American garment manufacturing….

#7 Quality Fashion Clothing for Your Brand

Domain Est. 2021

Website: bmc.fashion

Key Highlights: Discover premium fashion clothing from BMC Fashion, your trusted custom clothing manufacturers. Elevate your brand with our expert apparel manufacturing….

#8 Custom Clothing Manufacturers USA for Growing Brands

Domain Est. 2021

Website: seamapparel.com

Key Highlights: Leading custom clothing manufacturers and apparel manufacturers in the USA, providing high-quality private label apparel manufacturing for brands and ……

#9 Lefty Production Co.: One

Domain Est. 2012

Website: leftyproductionco.com

Key Highlights: Lefty Production Co. offers garment and accessories production in Los Angeles. From fabric sourcing to packing, we handle all aspects of your brand….

#10 Zega Apparel

Domain Est. 2013

Website: zegaapparel.com

Key Highlights: Zega Apparel offers leading services including custom clothing manufacturers USA along with cut & sew clothing services to private labels across the globe….

Expert Sourcing Insights for Clothing Usa

2026 Market Trends for Clothing in the USA

The U.S. apparel market in 2026 is poised for continued evolution, shaped by shifting consumer behaviors, technological advancements, and heightened focus on sustainability and inclusivity. Key trends are expected to redefine how clothing is designed, marketed, and consumed.

Sustainability and Circular Fashion Take Center Stage

By 2026, sustainability will no longer be a niche concern but a core expectation. Consumers—especially Gen Z and Millennials—will demand transparency in sourcing, ethical labor practices, and reduced environmental impact. Brands are anticipated to expand circular fashion initiatives, including resale programs, rental services, and take-back schemes. Investment in eco-friendly materials like recycled fibers, biodegradable fabrics, and innovative alternatives (e.g., mushroom leather) will grow. Regulatory pressure and ESG (Environmental, Social, and Governance) reporting requirements may further accelerate these changes.

Technology Integration and Digital Innovation

Technology will play a pivotal role in enhancing customer experience and supply chain efficiency. Virtual try-ons powered by augmented reality (AR), AI-driven personal styling, and 3D garment prototyping will become standard offerings. Direct-to-consumer (DTC) brands will leverage data analytics to offer hyper-personalized product recommendations and limited-edition drops. Additionally, blockchain technology is expected to gain traction for verifying product authenticity and tracking garment lifecycles.

Inclusivity and Body Positivity Drive Design

The push for inclusivity will extend beyond size ranges to encompass adaptive clothing, gender-neutral collections, and culturally sensitive fashion. Brands that embrace diverse body types, gender expressions, and abilities will gain stronger customer loyalty. Retailers will increasingly adopt inclusive marketing campaigns and expand size offerings to meet the demands of a more diverse consumer base.

Resilience of Athleisure and Casual Wear

The casualization of American dress will persist, with athleisure remaining a dominant category. Comfort-driven apparel—such as leggings, hoodies, and performance fabrics—will continue to bridge the gap between work-from-home wear and social outings. As hybrid lifestyles endure, versatile, functional clothing that transitions seamlessly between settings will be in high demand.

Rise of Localism and Supply Chain Resilience

In response to global disruptions and consumer preference for authenticity, many U.S. brands will prioritize nearshoring and domestic manufacturing. “Made in USA” labels will carry greater weight, signaling quality and reduced carbon footprint. Shorter supply chains will enable faster production cycles and greater responsiveness to market trends.

E-Commerce Maturity and Omnichannel Optimization

While online shopping remains dominant, the line between digital and physical retail will blur. Brick-and-mortar stores will transform into experiential hubs featuring seamless click-and-collect services, in-store customization, and community events. Social commerce—particularly via platforms like TikTok and Instagram—will grow, with shoppable content and influencer collaborations driving impulse purchases.

In summary, the U.S. clothing market in 2026 will be defined by purpose-driven brands that blend sustainability, technology, and inclusivity while meeting evolving consumer expectations for convenience and authenticity.

Common Pitfalls When Sourcing Clothing in the USA: Quality and Intellectual Property Issues

Sourcing clothing domestically in the USA offers advantages like shorter lead times, better communication, and support for local manufacturing. However, brands and retailers often encounter specific challenges related to quality control and intellectual property (IP) protection. Understanding these pitfalls is critical to ensuring product integrity and legal compliance.

Quality Inconsistencies Despite Domestic Sourcing

One common misconception is that sourcing from the USA guarantees superior quality. While U.S. manufacturers often adhere to higher labor and safety standards, quality can still vary significantly.

- Inconsistent Fabric Sourcing: Many U.S. manufacturers source fabrics globally. If not properly vetted, these materials may not meet expected durability, shrinkage, or color-fastness standards, leading to inconsistent final products.

- Small Batch Variability: Domestic producers often specialize in small runs or custom orders. While flexible, this can result in batch-to-batch inconsistencies in stitching, fit, or finishing if processes aren’t tightly controlled.

- Lack of Standardized QC Protocols: Smaller manufacturers may not have formal quality assurance systems. Without clear inspection checkpoints, defects can go unnoticed until shipment.

- Over-Reliance on Craftsmanship Over Systems: While skilled labor is a U.S. strength, craftsmanship alone isn’t a substitute for documented quality processes. Without standard operating procedures, scaling production can expose quality gaps.

To mitigate these risks, brands should conduct factory audits, implement third-party QC inspections, and establish detailed product specifications—including fabric certifications, seam strength, and tolerances.

Intellectual Property Risks and Enforcement Challenges

Sourcing in the U.S. does not automatically protect your designs or brand assets. Intellectual property infringement can still occur, both within the supply chain and in the broader market.

- Design Theft by Manufacturers or Subcontractors: Even with U.S.-based partners, unauthorized copying or replication of designs can happen—especially if contracts lack strong IP clauses. Some factories may use your patterns or samples to produce for competitors.

- Weak Contractual Protections: Verbal agreements or informal contracts are common among small manufacturers but leave brands vulnerable. Without clear terms on ownership of designs, molds, and samples, disputes can arise over IP rights.

- Unintentional Infringement: Brands risk infringing on existing trademarks, copyrights, or patented garments if they fail to conduct due diligence. Unique prints, embellishments, or functional design elements may be protected by others.

- Difficulty Enforcing IP Rights: While U.S. IP laws are strong, enforcement requires time and legal resources. Monitoring for infringement and pursuing legal action can be costly, especially for small businesses.

To safeguard IP, always use comprehensive contracts that assign ownership of designs to your brand, require confidentiality (NDAs), and prohibit unauthorized production. Additionally, consider registering original designs, logos, and innovative garment features with the U.S. Copyright Office or USPTO.

By proactively addressing quality and IP concerns, brands can leverage the benefits of U.S. clothing manufacturing while minimizing risks to their reputation and legal standing.

Logistics & Compliance Guide for Clothing in the USA

Import Regulations and Customs Clearance

Importing clothing into the United States requires compliance with U.S. Customs and Border Protection (CBP) regulations. All shipments must be declared using the Automated Commercial Environment (ACE) system. Importers need a U.S. Importer Number (usually an Employer Identification Number, or EIN) and must classify their garments using the Harmonized Tariff Schedule (HTS) codes. Most clothing items fall under Chapter 61 (knit apparel) or Chapter 62 (woven apparel) of the HTS. Accurate classification determines duty rates, which vary based on fabric type, origin, and garment style.

Importers must also comply with rules of origin under applicable trade agreements (e.g., USMCA, CAFTA-DR) to qualify for duty-free or reduced-rate treatment. Country of origin labeling is mandatory and must be permanently affixed to each garment. CBP may conduct audits or inspections, so maintaining detailed records for at least five years is required.

Textile and Labeling Requirements

The Federal Trade Commission (FTC) enforces labeling regulations for textiles under the Textile Fiber Products Identification Act and the Care Labeling Rule. All clothing must have a permanent label listing:

– Fiber content (by percentage, in descending order)

– Country of origin

– Manufacturer or dealer identification (name or registered number)

– Care instructions (washing, drying, ironing, etc.)

Labels must be durable, legible, and attached in a way that they remain with the garment through normal use. Mislabeling can result in penalties, product recalls, or seizure by CBP. Additionally, the FTC requires that claims such as “Made in USA” meet strict standards—only products entirely manufactured and sourced in the U.S. qualify.

Safety and Flammability Standards

Clothing intended for children (size 0–14) must comply with flammability standards set by the Consumer Product Safety Commission (CPSC) under 16 CFR Part 1610 (Standard for the Flammability of Clothing Textiles). Children’s sleepwear (sizes 0–14) has stricter requirements under 16 CFR Part 1615 and Part 1616, mandating flame-resistant fabrics and snug-fitting designs to reduce fire risk.

Apparel must also comply with general product safety regulations. This includes restrictions on harmful substances such as lead, phthalates (under the Consumer Product Safety Improvement Act), and certain dyes or chemicals regulated by the Environmental Protection Agency (EPA) or state laws like California’s Proposition 65.

Documentation and Recordkeeping

Accurate documentation is critical for smooth logistics and compliance. Required documents for importing clothing include:

– Commercial invoice

– Packing list

– Bill of lading or air waybill

– Entry summary (CBP Form 7501)

– Textile visa (if required, though rare under current U.S. policy)

Importers should retain all records—including purchase orders, test reports, and correspondence—for a minimum of five years. Third-party logistics (3PL) providers and customs brokers can assist with documentation, but the legal responsibility lies with the importer of record.

Distribution and Supply Chain Logistics

Once cleared through customs, clothing enters the U.S. supply chain via distribution centers, fulfillment warehouses, or direct retail delivery. Efficient logistics involve choosing between air freight (faster, more expensive) and ocean freight (slower, cost-effective for bulk). Proper inventory management, warehousing, and transportation coordination are essential to meet retail or e-commerce demand.

Many brands use drop-shipping or just-in-time models to reduce inventory costs. Compliance with state-level sales tax regulations (via the Streamlined Sales Tax Governing Board or economic nexus rules) is required when selling directly to consumers. Additionally, sustainable packaging and shipping practices are increasingly important for brand reputation and regulatory trends.

Compliance Monitoring and Audits

Regular internal audits help ensure ongoing compliance with federal and state regulations. Importers should verify supplier compliance through factory audits, third-party testing (e.g., for flammability or chemical content), and documentation reviews. Staying informed about updates from CBP, FTC, CPSC, and U.S. Department of Commerce is crucial to adapt to regulatory changes.

Engaging a licensed customs broker and legal counsel specializing in international trade can mitigate risks and ensure adherence to all logistics and compliance requirements for clothing in the U.S. market.

In conclusion, sourcing clothing manufacturers in the USA offers numerous advantages, including superior quality control, faster turnaround times, reduced shipping costs, and greater transparency throughout the production process. Domestic manufacturing supports ethical labor practices, promotes sustainability through shorter supply chains, and allows for stronger collaboration and communication between designers and producers. While production costs may be higher compared to offshore options, the benefits of agility, reliability, and alignment with “Made in the USA” branding often outweigh the expenses—especially for small to mid-sized brands, startups, and those prioritizing speed-to-market and social responsibility. When selecting a U.S. clothing manufacturer, it’s essential to assess capabilities, minimum order quantities, specialization, and compliance standards to ensure a strong partnership. Ultimately, sourcing domestically empowers brands to maintain greater control over their products and build a trustworthy, resilient, and values-driven apparel business.