The global ceramic blades market, including those used in hair clippers, is experiencing steady growth driven by increasing consumer demand for durable, heat-resistant, and hypoallergenic grooming tools. According to Grand View Research, the global razor and blade market was valued at USD 3.7 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030, with rising adoption of high-performance materials like zirconium dioxide fueling innovation in personal care devices. Similarly, Mordor Intelligence projects consistent expansion in the grooming products sector, citing technological advancements and heightened interest in professional-grade at-home grooming as key drivers. As demand for precision and long-lasting clipper blades rises, manufacturers specializing in ceramic solutions are positioned at the forefront of this evolution. Below are the top seven ceramic blade manufacturers leading innovation, quality, and market share in the clipper industry.

Top 7 Clipper Ceramic Blades Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 The Edge Pro

Domain Est. 2001

Website: theedgepro.com

Key Highlights: The Edge Pro is a factory authorized distributor for most major brands of Barber and Stylist Products, from clippers to blades to neck strips and so much more.Missing: ceramic man…

#2 Andis

Domain Est. 1996

Website: andis.com

Key Highlights: Free delivery over $100 30-day returnsAndis makes the best hair clippers, trimmers, shavers and pet grooming tools for the professional barber or stylist, pet groomer, cattle fitte…

#3 LaubeShop Pet & Grooming Supplies – Free Shipping!

Domain Est. 2006

Website: laubeshop.com

Key Highlights: 1-day delivery 30-day returnsProviding groomers, veterinarians, and barbers with durable, built-to-order grooming equipment that ships to you for free directly from the US….

#4 5pcs Ceramic Blades for Most Andis Oster Wahl AG A5 Hair …

Domain Est. 2013

Website: margaretvillebarn.com

Key Highlights: In stock Rating 4.1 (122) 1 day ago · 18 Teeth Ceramic Edge Carbon Coated Steel Pet Clipper Blade Dog Grooming Blade Electric Accessories for Andis Wahl · Material: Ceramic; Made…

#5 Ceramic Clipper Blade Company

Domain Est. 2020

Website: ceramicclipperblades.com

Key Highlights: The largest range of ceramic clipper blades in the world. Find your perfect blade with our huge range of standard and custom premium Zirconia ceramic clipper ……

#6 Taper Blade For Pro Clipper

Domain Est. 2020

Website: supremetrimmer.com

Key Highlights: In stock Free deliveryThe Ceramic Taper Blade provides smooth, precise cuts with exceptional durability, outlasting steel blades. Designed to glide effortlessly through hair….

#7 CERAMIC CLIPPER BLADE COMPANY LIMITED overview

Website: find-and-update.company-information.service.gov.uk

Key Highlights: CERAMIC CLIPPER BLADE COMPANY LIMITED – Free company information from Companies House including registered office address, filing history, accounts, ……

Expert Sourcing Insights for Clipper Ceramic Blades

H2: Market Trends for Clipper Ceramic Blades in 2026

By 2026, the market for clipper ceramic blades is expected to experience significant growth and transformation, driven by technological advancements, increasing consumer demand for precision grooming tools, and a rising focus on hygiene and durability in personal care equipment. Key trends shaping the industry include:

-

Growing Preference for Ceramic Over Steel Blades

Ceramic blades are gaining popularity due to their superior heat resistance, corrosion resistance, and longer lifespan compared to traditional steel blades. Consumers in both professional grooming (barbershops, salons) and personal use segments are increasingly opting for ceramic blades to ensure cooler, smoother cuts and reduced skin irritation. -

Expansion in the Pet Grooming Sector

The pet care industry is witnessing robust growth, and with it, demand for high-performance grooming tools. Ceramic blades are becoming the preferred choice for pet clippers due to their ability to stay cool during prolonged use—critical for sensitive animal skin. By 2026, this segment is expected to contribute significantly to overall market expansion. -

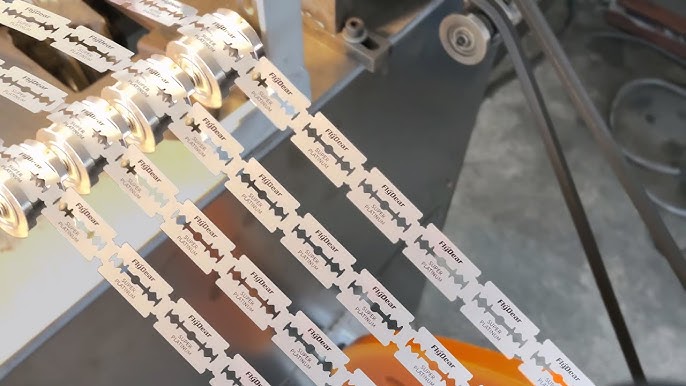

Innovation in Blade Design and Coatings

Manufacturers are investing in nano-coating technologies and enhanced blade geometries to improve edge retention and reduce friction. Brands offering zirconia-based ceramic blades with anti-microbial properties are gaining a competitive edge, particularly in professional markets where hygiene is paramount. -

Sustainability and Eco-Conscious Consumerism

As environmental concerns influence purchasing behavior, ceramic blades are positioned favorably due to their longer lifespan and reduced need for replacement—lowering waste. Brands emphasizing recyclable packaging and energy-efficient manufacturing processes are expected to resonate more with eco-conscious consumers in 2026. -

E-Commerce and Direct-to-Consumer Sales Growth

Online retail channels are becoming the primary sales avenue for clipper blades. Enhanced digital marketing, customer reviews, and subscription models for blade replacements are driving convenience and brand loyalty. By 2026, a strong digital presence will be critical for market competitiveness. -

Geographic Market Shifts

While North America and Europe remain dominant markets due to high grooming standards and disposable income, Asia-Pacific is expected to witness the fastest growth. Rising urbanization, grooming awareness, and expanding middle-class populations in countries like India and China are fueling demand.

In conclusion, the 2026 market for clipper ceramic blades will be characterized by innovation, sustainability, and expanding applications across human and pet grooming. Companies that prioritize performance, hygiene, and consumer education are likely to lead the evolving landscape.

Common Pitfalls When Sourcing Clipper Ceramic Blades (Quality, IP)

Sourcing Clipper ceramic blades presents several risks, particularly concerning quality consistency and intellectual property (IP) protection. Being aware of these pitfalls is crucial for maintaining product performance, brand reputation, and legal compliance.

Poor Material Quality and Inconsistent Hardness

One of the most frequent issues is receiving blades made from substandard ceramic materials. Low-quality zirconia or alumina may lack the necessary hardness and durability, leading to rapid dulling, chipping, or cracking during use. Inconsistent sintering processes can result in variable blade hardness across batches, affecting cutting performance and user safety.

Inadequate Precision in Manufacturing Tolerances

Ceramic blades require extremely tight tolerances to ensure smooth, precise cutting. Poorly sourced blades often suffer from dimensional inaccuracies—such as uneven blade edges or misaligned teeth—which can cause snagging, uneven cuts, or discomfort for users. This lack of precision undermines the core value proposition of high-performance clippers.

Insufficient Coating or Surface Treatment

Many ceramic blades feature specialized coatings (e.g., non-stick or anti-microbial treatments) to enhance performance and hygiene. Suppliers may omit these coatings or apply them inconsistently to cut costs. This not only reduces blade efficiency but can also increase friction and heat buildup, shortening blade life and potentially damaging clipper motors.

Lack of IP Due Diligence and Risk of Infringement

Sourcing from manufacturers without proper IP safeguards can expose buyers to legal risks. Some suppliers may replicate patented blade geometries, edge profiles, or proprietary designs without authorization. Purchasing such infringing products—even unknowingly—can lead to cease-and-desist orders, customs seizures, or litigation, especially in markets with strong IP enforcement like the EU or U.S.

Misrepresentation of OEM Compatibility

Suppliers may falsely claim compatibility with leading clipper brands (e.g., Andis, Wahl). Poorly engineered ceramic blades might not fit correctly or could interfere with the clipper’s mechanics, resulting in subpar performance or damage to the host device. This misrepresentation damages brand trust and increases return rates.

Inadequate Quality Control and Testing

Reputable suppliers implement rigorous QC protocols, including edge strength tests, durability cycles, and dimensional inspections. Many low-cost manufacturers skip or minimize these steps, leading to high defect rates and field failures. Without access to test reports or batch certifications, buyers have little assurance of product reliability.

Failure to Secure IP Ownership or Licensing

When developing custom ceramic blade designs, businesses often neglect to formalize IP ownership in supplier contracts. This can result in disputes over design rights or prevent the buyer from manufacturing the same blade elsewhere. Always ensure contracts explicitly assign IP rights or grant exclusive, royalty-free licenses.

Avoiding these pitfalls requires thorough vetting of suppliers, clear technical specifications, third-party quality audits, and legal review of IP terms. Due diligence at the sourcing stage protects both product integrity and long-term business interests.

Logistics & Compliance Guide for Clipper Ceramic Blades

This guide outlines the essential logistics and compliance considerations for the safe, efficient, and legally compliant handling, transportation, and distribution of Clipper Ceramic Blades. Adherence to these guidelines ensures product integrity and regulatory alignment across the supply chain.

Product Classification and Handling

Clipper Ceramic Blades are precision cutting tools made from advanced ceramic materials. They are non-magnetic, chemically inert, and resistant to corrosion, but are brittle and sensitive to impact. Proper handling is required to prevent chipping or breakage.

- Fragility: Treat as fragile goods. Avoid dropping or exposing to excessive vibration.

- Packaging: Store and transport in original protective packaging to prevent contact damage.

- Environmental Conditions: Store in a dry, temperature-controlled environment (15–25°C; 59–77°F). Avoid exposure to moisture and direct sunlight.

Shipping and Transportation

All shipments of Clipper Ceramic Blades must comply with international transport regulations and carrier requirements.

- Domestic Shipments (e.g., U.S., EU, UK):

- Use UN-certified packaging if required by volume or configuration.

- Label packages with “Fragile” and “This Side Up” indicators.

-

Ensure secure stacking to prevent crushing.

-

International Shipments:

- Comply with IATA (air), IMDG (sea), or ADR (road) regulations as applicable.

- Ceramic blades do not classify as dangerous goods under current regulations; however, proper documentation is required.

-

Include commercial invoices, packing lists, and certificates of origin where necessary.

-

Customs Documentation:

- Harmonized System (HS) Code: 8213.00 (Articles of cutlery with cutting edges, including blades).

- Declare accurate product description, quantity, weight, and value.

- Confirm tariff classifications with local customs authorities to avoid delays.

Regulatory Compliance

Ensure full compliance with regional and international standards governing product safety and market access.

- REACH (EU): Confirm no restricted substances are present in packaging or blade components.

- RoHS (EU/UK): Ceramic blades are typically exempt, but verify compliance for any metallic components (e.g., mounting hardware).

- FDA (U.S.): Not applicable for blades used in non-medical applications. If used in food processing, ensure compliance with FDA 21 CFR for food-contact surfaces.

- Proposition 65 (California, USA): No known chemicals requiring warning labels are present in ceramic blade composition.

Import/Export Controls

- Export Licenses: Generally not required for ceramic blades, as they are not listed under dual-use or strategic trade controls (e.g., Wassenaar Arrangement).

- Restricted Destinations: Verify compliance with sanctions lists (e.g., OFAC, EU Consolidated List). Do not ship to embargoed countries without authorization.

Storage and Inventory Management

- Warehouse Conditions:

- Maintain clean, dry storage areas.

- Use shelving to avoid floor contact and moisture exposure.

-

Rotate stock using FIFO (First In, First Out) method.

-

Inventory Security:

- Implement access controls to prevent theft or tampering.

- Monitor inventory levels to avoid overstocking and prolonged storage.

Returns and Reverse Logistics

- Return Authorization: All returns require prior authorization and a valid RMA (Return Merchandise Authorization) number.

- Packaging: Returned items must be in original packaging with protective inserts.

- Inspection: Inspect returned blades for damage before restocking or disposal.

- Disposal: Damaged or non-salvageable blades should be disposed of in accordance with local waste regulations. Ceramic materials may be recyclable through specialized facilities.

Compliance Contacts and Documentation

Maintain up-to-date records and designate compliance officers for audit readiness.

- Required Documents:

- Safety Data Sheets (SDS) – Not typically required; confirm based on formulation.

- Certificates of Conformance (CoC)

- Packing declarations

-

Export control classifications

-

Compliance Officer: Designate a responsible party to manage regulatory updates and respond to audits.

Adhering to this Logistics & Compliance Guide ensures the safe, legal, and efficient distribution of Clipper Ceramic Blades worldwide. Regular review and staff training are recommended to maintain compliance with evolving regulations.

In conclusion, sourcing ceramic clipper blades requires careful consideration of several key factors, including blade quality, compatibility with clipper models, durability, and cost-effectiveness. Ceramic blades offer advantages such as heat resistance, reduced friction, and longer sharpness compared to traditional steel blades, making them ideal for high-demand grooming environments. When selecting suppliers, it is essential to prioritize reputable manufacturers or distributors that provide consistent quality, certifications, and reliable customer support. Conducting thorough research, comparing samples, and evaluating long-term value over upfront cost will ensure optimal performance and client satisfaction. Ultimately, investing in high-quality ceramic blades from trusted sources not only enhances grooming efficiency but also contributes to the longevity of clipper tools and the overall professionalism of the service provided.