The global cleated belt conveyor market is experiencing robust growth, driven by increasing automation across industries such as food processing, pharmaceuticals, and material handling. According to a report by Mordor Intelligence, the global conveyor belt market is projected to grow at a CAGR of over 5.2% from 2023 to 2028, with cleated belts representing a critical segment due to their ability to transport bulk, loose, or inclined materials efficiently. Grand View Research further supports this trajectory, estimating the overall conveyor systems market to expand at a CAGR of 5.7% from 2024 to 2030, fueled by rising demand for improved logistics efficiency and factory automation. As industries seek durable, customizable, and high-performance conveying solutions, cleated belt conveyor manufacturers are at the forefront of innovation—developing products that enhance throughput, reduce downtime, and support sustainable operations. In this evolving landscape, identifying the top manufacturers becomes essential for businesses aiming to optimize material handling performance.

Top 10 Cleated Belt Conveyor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

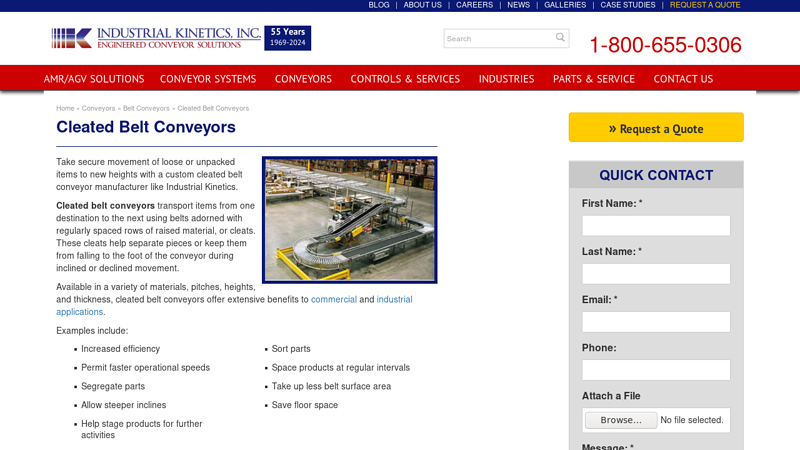

#1 Cleated Belt Conveyors

Domain Est. 1996

Website: iki.com

Key Highlights: Our custom cleated belt conveyors are constructed from carbon steel, galvanized carbon steel, stainless steel, and aluminum….

#2 Cleated Conveyor Belt

Domain Est. 1996

Website: karlschmidt.com

Key Highlights: A cleated conveyor belt is a standard conveyor belt enhanced with cleats. These cleats, or raised barriers, come in various shapes such as rectangles, ……

#3 Cleated Belt

Domain Est. 1997

Website: titanconveyors.com

Key Highlights: Customizable cleated belt conveyors and parts conveyors handle various parts up an incline with different walls, cleat heights, and spacing to suit your ……

#4 Inclined Cleated Belt Conveyors

Domain Est. 1997

Website: cambelt.com

Key Highlights: We offer high-incline cleated belt conveyors, tailored to your specific requirements. Our experts can engineer, design and construct conveyors at any angle of ……

#5 Configure Your Cleated Belt Conveyor

Domain Est. 1999

Website: elcom.fr

Key Highlights: Need a cleated belt conveyor? Customize it online: length, width, cleat type, motor and more. Instantly get CAD files and a quote….

#6 Customized Cleated Belts

Domain Est. 2000

Website: smileymonroe.com

Key Highlights: At Smiley Monroe we work closely with our customers to design customized conveyor belts for a wide range of machines and applications including magnet belts….

#7 Cleated Belt Conveyor Solutions

Domain Est. 2007

Website: dornerconveyors.com

Key Highlights: With a cleated conveyor belt from Dorner, you can enhance the efficiency, security, and productivity of your product manufacturing and packaging endeavors….

#8 Cleated Belt Conveyor Systems

Domain Est. 2009

Website: mknorthamerica.com

Key Highlights: mk’s cleated belt conveyor systems come in five standard platforms to move, stage, and space products on an assembly line….

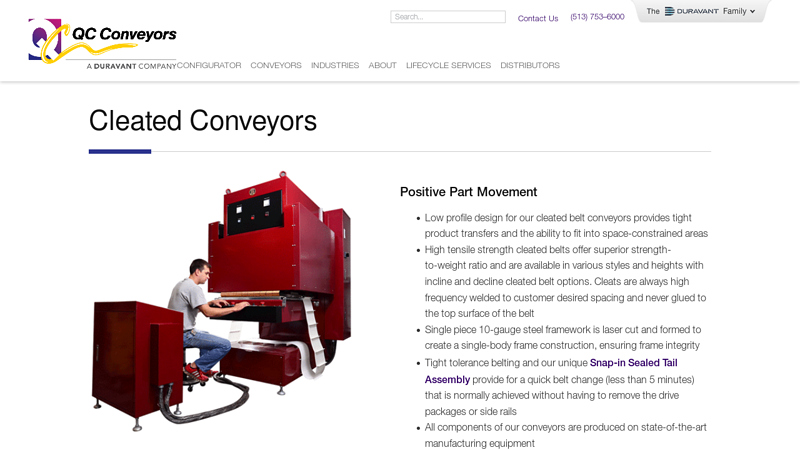

#9 Cleated Conveyors

Domain Est. 2013

Website: qcconveyors.com

Key Highlights: Low profile design for our cleated belt conveyors provides tight product transfers and the ability to fit into space-constrained areas ……

#10 Cleated Conveyor Belts Americas

Domain Est. 2018

Website: continental-industry.com

Key Highlights: Continental cleated belts are ideal for conveying materials such as stone, sand, gravel, various wood products and a multitude of recycling products by taking ……

Expert Sourcing Insights for Cleated Belt Conveyor

2026 Market Trends for Cleated Belt Conveyors

The cleated belt conveyor market is poised for notable evolution by 2026, driven by industrial automation, e-commerce growth, and a heightened focus on efficiency and sustainability. Key trends shaping the landscape include:

Rising Demand from E-Commerce and Logistics

The explosive expansion of online retail continues to fuel demand for automated material handling solutions. Cleated belt conveyors are essential in sorting centers and distribution hubs for reliably transporting packages of varying sizes and weights on inclines and declines. By 2026, increased investment in warehouse automation, particularly in emerging markets, will drive adoption of robust and customizable cleated systems to manage high-volume throughput.

Growth in Food and Beverage Processing

Stringent hygiene standards and the need for efficient handling of bulk or delicate items (like fresh produce, baked goods, and packaged foods) are propelling demand in the food and beverage sector. Cleated belts prevent product slippage during elevation changes and are increasingly fabricated from FDA-compliant, easy-to-clean materials like stainless steel and food-grade polymers. The trend toward sustainable packaging and traceability will further boost demand for conveyors that integrate with smart sensors and track-and-trace systems.

Technological Advancements and Smart Integration

By 2026, cleated belt conveyors are expected to incorporate more smart technologies. Integration with IoT sensors for predictive maintenance, real-time monitoring of belt tension, cleat wear, and load distribution will enhance operational efficiency and reduce downtime. Modular designs and digital twins will enable faster customization and system optimization, meeting the needs of diverse industrial applications.

Focus on Sustainability and Energy Efficiency

Environmental regulations and corporate sustainability goals are pushing manufacturers toward energy-efficient conveyor systems. Lightweight belt materials, low-friction rollers, and variable frequency drives (VFDs) will be increasingly incorporated into cleated conveyor designs. Additionally, recyclable belt materials and longer product lifecycles will become key differentiators in the market.

Regional Expansion and Customization

While North America and Europe remain strong markets due to advanced automation, Asia-Pacific—especially India and Southeast Asia—is expected to witness the highest growth. Rapid industrialization, rising labor costs, and government initiatives supporting manufacturing (e.g., “Make in India”) will drive demand. This growth will necessitate highly customized cleated belt solutions tailored to local industry needs, from electronics assembly to agricultural processing.

In summary, by 2026, the cleated belt conveyor market will be defined by smarter, cleaner, and more adaptable systems, serving as critical components in increasingly automated and sustainable industrial ecosystems.

Common Pitfalls When Sourcing Cleated Belt Conveyors: Quality and Intellectual Property (IP) Concerns

When sourcing cleated belt conveyors, businesses often focus on cost and delivery timelines, potentially overlooking critical aspects related to quality and intellectual property (IP). These oversights can lead to operational inefficiencies, legal risks, and long-term financial losses. Below are the most common pitfalls related to quality and IP that buyers should be aware of.

Overlooking Material and Construction Quality

One of the most frequent mistakes is selecting a cleated belt conveyor based solely on upfront cost without evaluating the quality of materials and construction. Low-quality belts may use substandard rubber, PVC, or polyurethane, leading to premature wear, belt slippage, or cleat detachment. Inferior welds or fastening methods for cleats reduce durability, especially in high-load or abrasive environments. Buyers should verify material certifications, tensile strength, and resistance to environmental factors such as moisture, temperature, and chemicals.

Ignoring Industry-Specific Standards and Certifications

Failing to ensure compliance with industry standards—such as FDA, USDA, or CE marks—can lead to regulatory issues, especially in food processing, pharmaceuticals, or hazardous environments. Some suppliers may claim compliance without proper documentation. Always request test reports and third-party certifications to validate claims and ensure the conveyor meets required safety and hygiene standards.

Underestimating Design and Engineering Validation

Many suppliers offer “off-the-shelf” cleated belt conveyors that may not be optimized for a specific application. Using an unvalidated design can result in poor performance, increased maintenance, and downtime. Buyers should confirm whether the supplier conducts engineering analysis (e.g., load testing, belt tracking simulations) and offers customized solutions backed by proven design principles.

Falling for Counterfeit or Copycat Designs

A significant IP-related risk is sourcing from manufacturers who replicate patented conveyor designs without authorization. These copycat products may appear identical but lack the performance, reliability, or safety features of the original. Purchasing such products can expose the buyer to legal liability, especially if the original IP holder takes enforcement action. Always verify the supplier’s ownership of designs or their licensing agreements with patent holders.

Lack of Transparency in Manufacturing Origins

Some suppliers outsource production to third-party factories with poor quality control or questionable IP practices. Without transparency about where and how the conveyor is made, buyers risk receiving inconsistent products or inadvertently supporting IP infringement. Conduct supplier audits or request documentation on manufacturing processes and IP rights to mitigate this risk.

Failure to Secure IP Rights in Custom Solutions

When working with suppliers on custom-designed cleated belt conveyors, businesses often assume they own the design. However, unless explicitly stated in the contract, IP rights may remain with the manufacturer. This can prevent future replication, modifications, or sourcing from alternative vendors. Always include IP ownership clauses in procurement agreements for custom projects.

Neglecting After-Sales Support and Documentation

Low-cost suppliers may not provide comprehensive technical documentation, maintenance guides, or spare parts support. This lack of after-sales service can hinder troubleshooting and increase downtime. Additionally, missing documentation may complicate IP validation or regulatory compliance efforts. Ensure suppliers offer full technical support and detailed product records.

By recognizing and addressing these quality and IP-related pitfalls, businesses can make more informed sourcing decisions, reduce operational risks, and protect their long-term interests when procuring cleated belt conveyors.

Logistics & Compliance Guide for Cleated Belt Conveyor

Overview

Cleated belt conveyors are specialized material handling systems designed to transport products on inclines or declines, using raised cleats on the belt to prevent material slippage. Proper logistics planning and compliance adherence are essential for safe, efficient, and legal operation during transport, installation, and use.

Transportation & Handling

Ensure cleated belt conveyors are securely packaged and protected during transit. Use wooden crates or skids to prevent damage to belt surfaces and cleats. For long-distance shipping, secure the conveyor frame with straps and block wheels or rollers to prevent shifting. Avoid exposure to moisture or extreme temperatures during transport, which may degrade belt materials (e.g., rubber, PVC).

Installation Requirements

Install the conveyor on a level, stable surface with adequate structural support. Follow manufacturer specifications for anchoring and alignment. Ensure all safety guards, emergency stops, and drive components are correctly assembled. Verify electrical wiring complies with local codes (e.g., NEC in the U.S., IEC in Europe). Test the system incrementally before full operation.

Safety Compliance

Cleated belt conveyors must comply with relevant safety standards such as:

– OSHA 29 CFR 1910.219 (U.S. – Mechanical Power-Transmission Apparatus)

– ANSI/ASME B20.1 (Safety Standard for Conveyors)

– EU Machinery Directive 2006/42/EC (for CE-marked equipment)

Install appropriate guarding around moving parts, pinch points, and drive systems. Provide clearly labeled emergency stop buttons within easy reach. Train personnel on lockout/tagout (LOTO) procedures and safe operation.

Material Handling Regulations

Ensure the conveyor is suitable for the intended load type and weight. Do not exceed rated capacity. For food, pharmaceutical, or sanitary applications, use FDA-compliant or EU 1935/2004-approved belt materials (e.g., food-grade rubber or urethane). Clean and maintain the conveyor regularly to prevent contamination.

Environmental & Operational Compliance

Operate the conveyor within specified temperature, humidity, and load conditions. Noise levels should comply with local regulations (e.g., OSHA permissible exposure limits). In explosive or hazardous environments (e.g., ATEX zones), use conveyors with certified explosion-proof components.

Maintenance & Inspection

Conduct routine inspections for wear on cleats, belt tracking, and motor performance. Lubricate moving parts as recommended. Replace damaged or worn components promptly. Maintain logs of inspections and repairs to demonstrate regulatory compliance and support warranty claims.

Documentation & Certification

Retain all manuals, compliance certificates (e.g., CE, UL), and installation records. Provide operators with training documentation. Update compliance records when modifications are made to the system.

Disposal & Recycling

At end-of-life, dispose of conveyor components according to local environmental regulations. Recycle metal frames and segregate non-recyclable belt materials (e.g., rubber composites) through approved waste handlers.

Conclusion for Sourcing Cleated Belt Conveyors

Sourcing cleated belt conveyors requires a strategic approach that balances performance, durability, and cost-effectiveness. These specialized conveyors are essential for transporting bulk materials, irregularly shaped items, or products requiring elevation, making them vital in industries such as food processing, packaging, agriculture, and recycling.

When sourcing cleated belt conveyors, key considerations include material compatibility, cleat profile and spacing, belt width and length, drive system, and environmental conditions (e.g., washdown, temperature, or corrosion resistance). It is crucial to partner with reputable suppliers who offer customizable solutions, high-quality materials (such as FDA-compliant or abrasion-resistant belts), and reliable after-sales support.

Furthermore, evaluating total cost of ownership—factoring in maintenance, energy efficiency, and lifespan—ensures long-term operational efficiency. By conducting thorough supplier assessments, verifying industry certifications, and reviewing customer feedback, organizations can make informed procurement decisions.

In conclusion, investing time in proper sourcing of cleated belt conveyors leads to improved throughput, reduced downtime, and enhanced safety, ultimately supporting sustainable and efficient material handling operations.