The global cleanroom apparel market is experiencing robust expansion, driven by escalating demand for contamination control across industries such as pharmaceuticals, biotechnology, semiconductor manufacturing, and healthcare. According to a 2023 report by Mordor Intelligence, the market was valued at USD 6.1 billion in 2022 and is projected to grow at a CAGR of 6.8% from 2023 to 2028. Similarly, Grand View Research estimates that the market could reach USD 9.3 billion by 2030, fueled by stringent regulatory standards and rising investments in cleanroom infrastructure, particularly in Asia-Pacific and North America. This growth underscores the critical need for high-performance, reliable cleanroom garments, positioning manufacturers at the forefront of technological innovation and quality assurance. As competition intensifies and industry standards become more rigorous, identifying top-tier cleanroom apparel suppliers is essential for organizations committed to operational integrity and compliance.

Top 10 Cleanroom Apparel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Isofield

Domain Est. 2018

Website: isofield.com

Key Highlights: We are a specialist manufacturer of Clean and Sterile PPE (Personal Protective Equipment) designed for Pharmaceutical, Biotech and life-science customers….

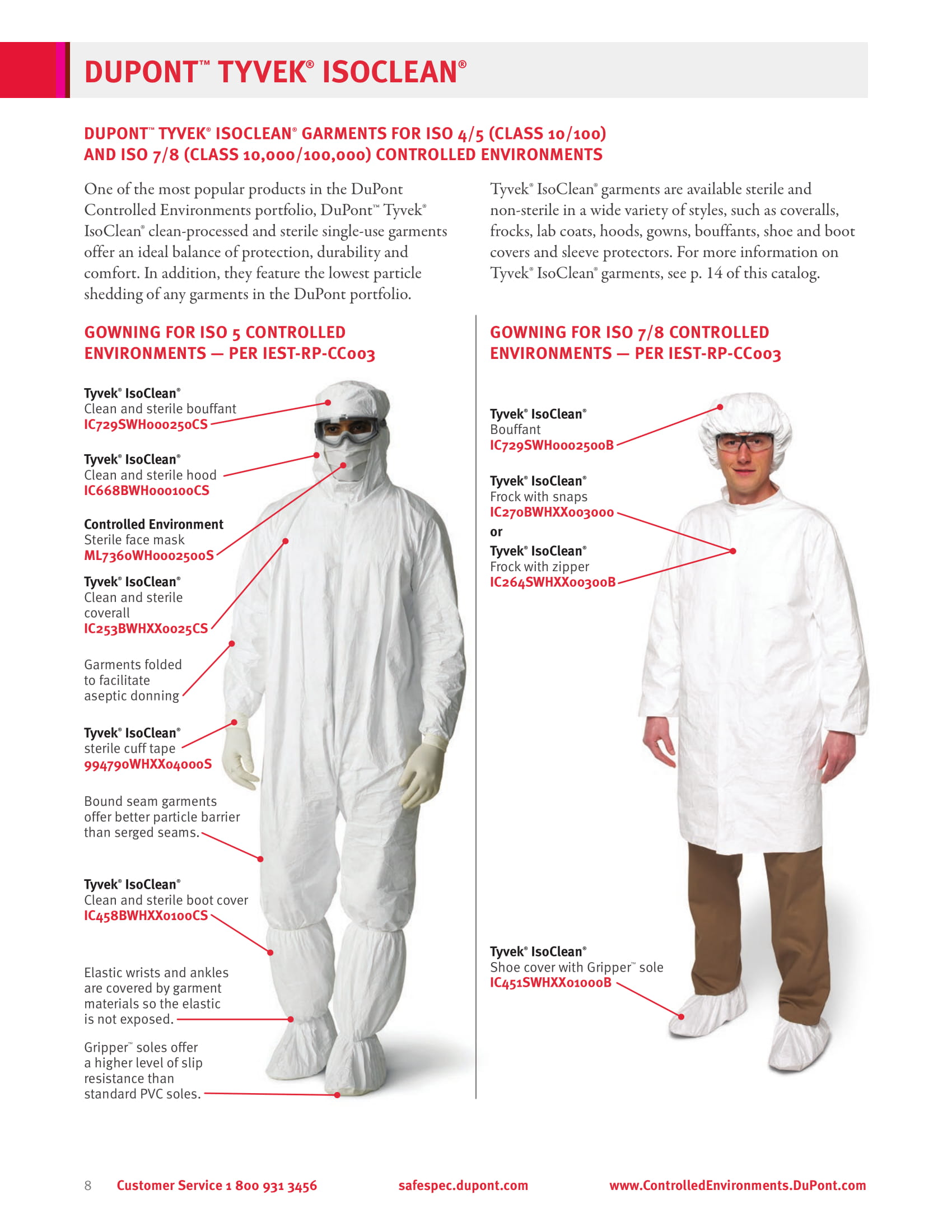

#2 Tyvek® IsoClean® Cleanroom Apparel

Domain Est. 1987

Website: dupont.com

Key Highlights: The DuPont cleanroom clothing portfolio offers a comprehensive selection of single-use cleanroom garments and accessories designed for use in pharmaceutical, ……

#3 Cleanroom Apparel & Solutions

Domain Est. 1995

Website: cintas.com

Key Highlights: Cleanroom Suits & Gowning Solutions Your cleanroom deserves more than just garments – it deserves a true partner in contamination control….

#4 Cleanroom Textiles

Domain Est. 1995

Website: cws.com

Key Highlights: We prepare your cleanroom textiles and accessories to the highest standards to ensure that stocks of cleanroom garments are available in sufficient quantities ……

#5 Berkshire Corporation

Domain Est. 1997

Website: berkshire.com

Key Highlights: We provide the highest-quality cleanroom supplies from Berkshire’s trusted brand. Let us help you streamline your cleanroom consumables supply chain….

#6 Cleanroom Cleaning Services, Biosafety Garments & Contamination …

Domain Est. 1999

Website: uniclean.com

Key Highlights: UniClean offers cleanroom services and products to the medical device, biotech, pharmaceutical, electronics, semiconductor and other industries….

#7 Cleanroom garments

Domain Est. 1999

Website: dastex.com

Key Highlights: Our cleanroom garments are made of fabrics with different technical properties. In addition to cleanroom relevant properties such as filtration efficiency ……

#8 Prudential Overall Supply

Domain Est. 2001

Website: prudentialuniforms.com

Key Highlights: Prudential Overall Supply provides professional work uniform rental services, laundry and cleaning programs, cleanroom services and facility supplies….

#9 Cleanroom Apparel and Tools

Domain Est. 2010

Website: sterislifesciences.com

Key Highlights: Our cleanroom apparel packs and customizable items protect personnel and simplify compliance with gowning standard operating procedures (SOPs). Our range of ……

#10 Cleanroom Garments & Apparel

Website: cleanroomproducts.com

Key Highlights: Order cleanroom garments at the internet’s best prices on booties, lab coats, scrubs, frocks, facemasks, & more. CleanPro® offers end-to-end lines of ……

Expert Sourcing Insights for Cleanroom Apparel

H2: 2026 Market Trends for Cleanroom Apparel

The global cleanroom apparel market is projected to experience robust growth by 2026, driven by rising demand across critical industries such as pharmaceuticals, biotechnology, semiconductors, and healthcare. As regulatory standards become more stringent and technological advancements enhance material performance, several key trends are expected to shape the market landscape.

-

Increased Demand from Life Sciences and Healthcare Sectors

The expansion of biopharmaceutical manufacturing, vaccine development, and personalized medicine is fueling the need for high-performance cleanroom garments. With continued investments in R&D and the globalization of pharmaceutical production, especially in emerging markets, the demand for contamination-controlled environments—and by extension, cleanroom apparel—is rising steadily. -

Growth in the Semiconductor and Electronics Industry

The rapid development of advanced electronics, 5G technology, and artificial intelligence is boosting semiconductor fabrication, which requires ultra-clean manufacturing environments. Cleanroom apparel with low particle shedding, anti-static properties, and high durability is becoming essential, particularly in Asia-Pacific countries like China, South Korea, and Taiwan—key hubs for chip manufacturing. -

Shift Toward Reusable and Sustainable Apparel

Environmental concerns and rising operational costs are driving a shift from single-use disposable garments to reusable cleanroom apparel. By 2026, manufacturers are expected to focus on recyclable materials, improved laundering technologies, and lifecycle assessments to reduce environmental impact while maintaining compliance with cleanliness standards. -

Advancements in Smart and Functional Fabrics

Integration of smart textiles—featuring embedded sensors for monitoring temperature, humidity, or contamination exposure—is anticipated to gain traction. These innovations will enhance worker safety, improve compliance tracking, and support digital transformation in cleanroom operations, particularly in GMP (Good Manufacturing Practice) environments. -

Regional Market Expansion

While North America and Europe remain dominant due to established regulatory frameworks and mature pharmaceutical sectors, the Asia-Pacific region is expected to witness the highest growth rate. Government initiatives, increasing foreign investments, and the localization of high-tech manufacturing are accelerating cleanroom infrastructure development in countries such as India, Vietnam, and Malaysia. -

Stringent Regulatory Compliance and Standardization

Regulatory bodies such as the FDA, EU GMP, and ISO are continuously updating contamination control guidelines. Cleanroom apparel manufacturers must comply with ISO 14644 and ISO 13485 standards, driving innovation in garment design, testing protocols, and quality assurance processes. -

Supply Chain Resilience and Localization

Post-pandemic lessons have prompted companies to diversify supply chains and reduce reliance on single-source suppliers. By 2026, regional production of cleanroom apparel is expected to increase, supported by local manufacturing incentives and the need for faster delivery times and greater supply stability.

In conclusion, the 2026 cleanroom apparel market will be defined by innovation, sustainability, and expansion across high-tech industries. Companies that invest in advanced materials, digital integration, and environmentally responsible practices will be best positioned to capitalize on this evolving landscape.

Common Pitfalls Sourcing Cleanroom Apparel (Quality, IP)

Sourcing cleanroom apparel involves critical considerations beyond simple procurement, particularly regarding quality consistency and intellectual property (IP) protection. Overlooking these aspects can lead to contamination risks, operational disruptions, and legal vulnerabilities.

Inconsistent Quality and Non-Compliance

One of the most significant pitfalls is receiving cleanroom garments that fail to meet required quality standards or regulatory specifications. Variability in fabric integrity, seam construction, or particle shedding can compromise cleanroom environments. Suppliers may provide samples that meet standards but deliver bulk orders with subpar materials or workmanship. Additionally, garments might not comply with industry standards such as ISO 14644 or IEST-RP-CC003, leading to audit failures or product contamination.

Lack of Traceability and Documentation

Reliable sourcing requires full traceability of materials and manufacturing processes. Poor documentation—such as missing or falsified certificates of conformance, test reports, or lot tracking—makes it difficult to verify quality claims or investigate contamination events. Without proper traceability, organizations risk using apparel that introduces contaminants or fails under critical conditions.

Intellectual Property (IP) Risks and Design Copying

Cleanroom apparel designs, especially those with specialized features like unique closure systems, anti-static properties, or ergonomic enhancements, may be protected by patents, trademarks, or trade secrets. Sourcing from unverified suppliers, particularly in regions with weak IP enforcement, increases the risk of inadvertently procuring counterfeit or infringing products. This exposes the buyer to legal liability and reputational damage. Furthermore, sharing custom designs with suppliers without proper legal agreements can result in IP theft or unauthorized reproduction.

Supplier Reliability and Hidden Costs

Relying on suppliers without thorough vetting can lead to disruptions in supply chain continuity, inconsistent lead times, or hidden costs related to rework, rejection, or contamination incidents. Some suppliers may cut corners to offer lower prices, compromising long-term performance and safety. Additionally, lack of transparency in pricing or contractual terms may result in unexpected expenses or dependency on a single source.

Inadequate Testing and Validation Support

A major oversight is partnering with suppliers who do not support rigorous testing and qualification processes. Buyers need suppliers who provide data from particle emission tests, microbial barrier assessments, and electrostatic discharge (ESD) evaluations. Without access to this data, organizations cannot validate that apparel meets their specific cleanroom classification requirements.

Avoiding these pitfalls requires due diligence in supplier selection, robust quality agreements, IP protection clauses in contracts, and ongoing performance monitoring to ensure compliance, consistency, and legal safety.

Logistics & Compliance Guide for Cleanroom Apparel

Overview

Cleanroom apparel is essential for maintaining contamination control in regulated environments such as pharmaceuticals, biotechnology, semiconductor manufacturing, and medical device production. Proper logistics and compliance practices ensure that garments remain effective in protecting sensitive processes and meet industry standards. This guide outlines key considerations in the transportation, storage, handling, and regulatory compliance of cleanroom apparel.

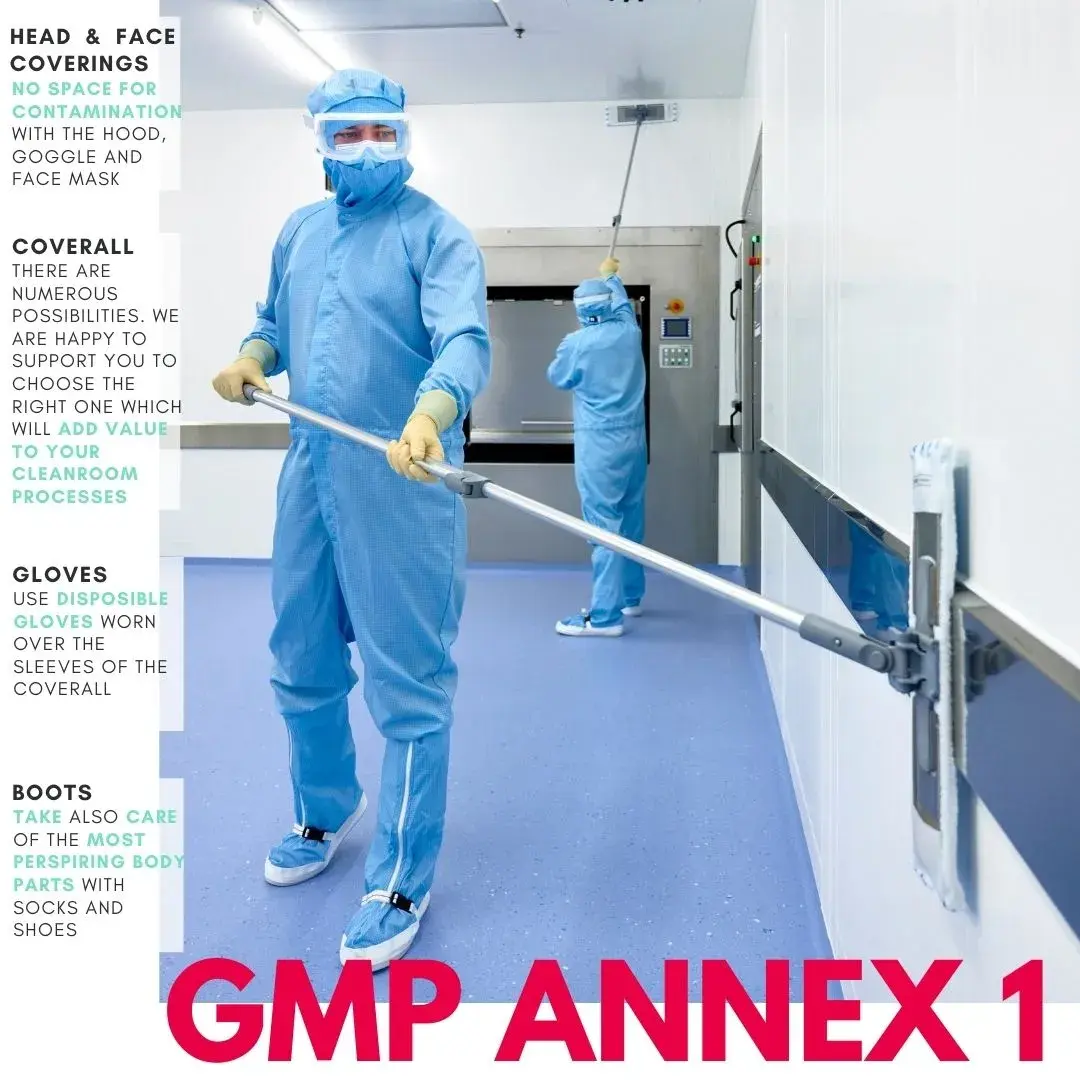

Regulatory Standards and Industry Guidelines

Cleanroom apparel must comply with a range of international and industry-specific standards. Key regulations include:

– ISO 14644-1: Classifies cleanroom air cleanliness; apparel must support the required classification.

– ISO 13485: Quality management for medical devices; impacts apparel used in production environments.

– GMP (Good Manufacturing Practices): Mandated by regulatory bodies like the FDA and EMA; requires contamination controls including proper garment use.

– ANSI/ESD S20.20: For electrostatic discharge (ESD) protection in electronics manufacturing.

– USP <797> and <800>: Relevant for compounding pharmacies; specify gowning requirements.

Organizations must ensure apparel selection, use, and maintenance align with applicable standards.

Apparel Types and Classification

Cleanroom garments vary by material, design, and level of protection:

– Disposable garments: Typically made from spunbond-meltblown-spunbond (SMS) polypropylene; used in lower-class cleanrooms or single-use applications.

– Reusable garments: Made from polyester or polyester-cotton blends with anti-static properties; laundered in certified facilities.

– Garment classification: Based on particle shedding, filtration efficiency, and ESD performance. Must match the cleanroom ISO class (e.g., ISO 5 vs. ISO 8).

Selection should be based on risk assessment and cleanroom classification.

Logistics: Transportation and Storage

Proper logistics prevent contamination prior to use:

– Packaging: Apparel must be double-bagged in low-lint, static-dissipative packaging. Inner packaging should be sealed and cleanroom-compatible.

– Transportation: Use enclosed, climate-controlled vehicles. Avoid exposure to dust, moisture, extreme temperatures, and pollutants.

– Storage: Store in a clean, dry, temperature-controlled environment (typically 18–24°C, 30–60% RH). Keep away from direct sunlight and chemicals. Garments should remain sealed until point of use.

– Inventory Management: Implement FIFO (First In, First Out) rotation. Track lot numbers and expiration dates (for disposable items).

Handling and Donning Procedures

To maintain integrity:

– Handling: Always handle garments with clean gloves in a controlled environment. Avoid touching the interior surface.

– Donning: Follow a defined gowning procedure in the gowning room. Sequence typically includes: head cover, beard cover (if applicable), bodysuit, boots, gloves, and face mask. Training and audits are essential.

– Contamination Control: Never remove garments in the cleanroom. Damaged or contaminated garments must be immediately replaced and disposed of or sent for reprocessing.

Laundering and Reuse (Reusable Apparel)

For reusable garments:

– Laundering: Must be done in a certified cleanroom laundry facility compliant with ISO 14698 and IEST-RP-CC003.

– Process Controls: Use purified water (WFI or purified water), validated detergents, and controlled drying and folding processes.

– Packaging Post-Laundering: Garments must be packaged in clean, sealed bags and labeled with lot number, date, and sterility status if applicable.

– Tracking and Validation: Maintain logs of laundering cycles. Garments have a finite lifespan; track wear and retire per manufacturer or internal SOPs.

Supplier Qualification and Documentation

- Supplier Audits: Qualify suppliers based on compliance with ISO, GMP, and cleanroom-specific standards.

- Certificates of Conformance (CoC): Require CoCs for every batch, certifying compliance with particle shedding, ESD, and sterility (if needed).

- Traceability: Maintain full traceability from raw material to end-user, including batch numbers and sterilization records.

Training and Compliance Monitoring

- Personnel Training: Regular training on gowning procedures, contamination control, and apparel handling is mandatory.

- Audits and Inspections: Conduct routine audits of storage, handling, and usage. Include garment integrity checks.

- Deviation Management: Document and investigate any non-conformances (e.g., damaged packaging, incorrect apparel use).

Disposal and Environmental Considerations

- Disposable Apparel: Dispose of as regulated waste if contaminated with hazardous materials. Otherwise, follow local waste disposal regulations.

- Sustainability: Evaluate reusable vs. disposable options based on environmental impact, cost, and risk. Some facilities use hybrid models.

Conclusion

Effective logistics and compliance for cleanroom apparel are critical to maintaining contamination control and regulatory adherence. By implementing standardized procedures for sourcing, handling, storage, and use, organizations can ensure product integrity, personnel safety, and audit readiness. Regular review of practices against evolving standards is recommended to maintain compliance and operational excellence.

Conclusion:

Sourcing cleanroom apparel is a critical component in maintaining contamination control and ensuring operational integrity in sensitive environments such as pharmaceuticals, biotechnology, semiconductor manufacturing, and healthcare. A well-structured sourcing strategy must prioritize quality, compliance, and consistency, while considering factors such as fabric material, garment design, sizing, sterility, and industry-specific regulatory standards (e.g., ISO classifications, FDA, or EU GMP guidelines).

Partnering with reputable suppliers who demonstrate proven track records in cleanroom apparel manufacturing, offer thorough documentation, and adhere to stringent quality control processes is essential. Additionally, evaluating total cost of ownership—factoring in durability, laundering compatibility, and service life—can lead to long-term operational efficiencies and cost savings.

Ultimately, effective sourcing of cleanroom apparel not only supports compliance and product integrity but also enhances personnel safety and process reliability. Continuous supplier evaluation, staying abreast of technological advancements, and aligning procurement practices with evolving industry standards will ensure that organizations maintain the highest levels of cleanliness and performance in their controlled environments.