The global clay pavement market is experiencing steady growth, driven by increasing demand for durable, sustainable, and aesthetically pleasing construction materials in urban infrastructure and residential developments. According to a report by Mordor Intelligence, the global pavers market—encompassing clay, concrete, and natural stone—was valued at USD 105.6 billion in 2023 and is projected to grow at a CAGR of 5.8% through 2029, with clay pavers maintaining a strong share due to their thermal performance, longevity, and eco-friendly attributes. Similarly, Grand View Research highlights the rising preference for permeable paving solutions in smart city initiatives, further bolstering demand for high-quality clay pavements in both commercial and residential sectors. As sustainability and urban resilience become top priorities, manufacturers specializing in engineered clay solutions are scaling innovation in production efficiency, color retention, and load-bearing performance. In this evolving landscape, the following eight companies have emerged as leaders, combining market reach, technological advancement, and product reliability to shape the future of clay pavement systems worldwide.

Top 8 Clay Pavement Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Belgard Pavers & Hardscapes Manufacturer

Domain Est. 1997

Website: belgard.com

Key Highlights: Belgard has defined itself among brick and concrete paver manufacturers by offering distinct pavers for stone hardscapes, retaining walls, and more……

#2 Whitacre Greer Dry

Domain Est. 1998

Website: wgpaver.com

Key Highlights: Whitacre Greer is a small, boutique-type manufacturer of fired-clay paving brick and fire brick. The company utilizes the dry-pressed manufacturing process….

#3 ClayBricks

Domain Est. 1998

Website: claybricks.com

Key Highlights: Claybricks & Tiles Sdn. Bhd. (Claybricks) is presently one of the leading manufacturer and exporter of fine quality clay products in Malaysia….

#4 Endicott Clay Products Page

Domain Est. 1995

Website: endicott.com

Key Highlights: Discover why the top projects use Endicott Clay Products to build their legacy….

#5 The Belden Brick Company

Domain Est. 1995

Website: beldenbrick.com

Key Highlights: Delivering the highest-quality shales and clays that contribute to our customers’ and communities’ structural integrity and outstanding appearance….

#6 wienerberger

Domain Est. 1995

Website: wienerberger.com

Key Highlights: We are #1 in brick production worldwide and in clay roof tile production in Europe, with over 200 production sites in 28 countries. Additionally, we are the ……

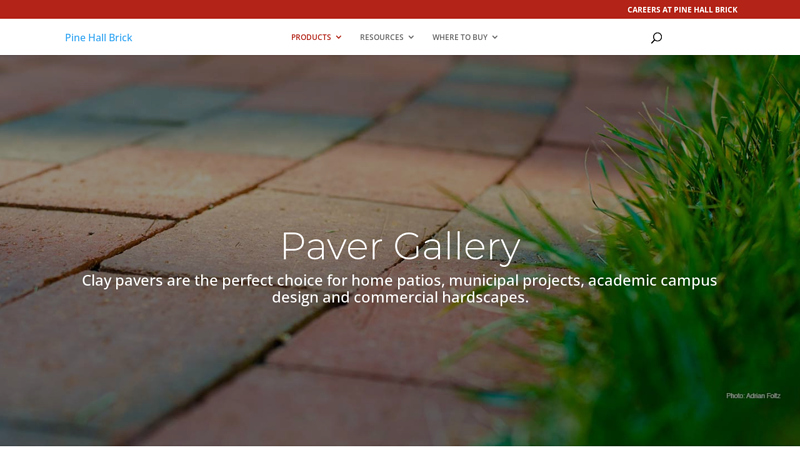

#7 Clay pavers from Pine Hall Brick in a range of colors and styles

Domain Est. 1996

Website: pinehallbrick.com

Key Highlights: Clay pavers are perfect for patios, walkways, driveways, city streets, plazas and more. They’re beautiful, functional and durable….

#8 Clay Brick Pavers

Domain Est. 1999

Website: glengery.com

Key Highlights: High-quality brick pavers built to last. Explore styles, colors, and textures available across the United States. Start your project with Glen-Gery today….

Expert Sourcing Insights for Clay Pavement

H2: 2026 Market Trends for Clay Pavement

The global clay pavement market is poised for steady growth and transformation by 2026, driven by increasing urbanization, sustainability demands, and advancements in manufacturing technologies. As cities prioritize resilient and eco-friendly infrastructure, clay pavers—renowned for their durability, aesthetic appeal, and permeability—are gaining renewed attention in both public and private construction sectors.

One key trend shaping the 2026 outlook is the rising demand for sustainable building materials. Clay pavers are manufactured from natural, abundant raw materials and are fully recyclable, aligning with green building certifications such as LEED and BREEAM. Governments and developers are increasingly adopting low-impact development (LID) practices, where permeable clay pavements help manage stormwater runoff and reduce urban flooding—making them a preferred choice in climate-resilient urban planning.

Another significant driver is urban redevelopment and the revitalization of pedestrian zones, city centers, and historic districts. Municipalities across Europe, North America, and parts of Asia-Pacific are investing in walkable cities and sustainable public spaces, where clay pavers offer both functional and aesthetic benefits. Their long lifespan (often exceeding 50 years) and minimal maintenance requirements enhance their cost-effectiveness over time, appealing to budget-conscious public authorities.

Technological innovation is also contributing to market growth. By 2026, manufacturers are expected to expand their product lines with precision-engineered clay pavers that offer improved interlocking, enhanced slip resistance, and greater thermal performance. Digital design tools and Building Information Modeling (BIM) are facilitating more efficient planning and installation, reducing labor costs and project timelines.

Regionally, Europe remains the largest market due to stringent environmental regulations and a strong tradition of using clay in construction. However, Asia-Pacific is projected to witness the highest growth rate, fueled by rapid urbanization in countries like India and China, where infrastructure development is a national priority. North America is also experiencing a resurgence in clay pavement use, particularly in municipal and residential landscaping projects emphasizing sustainability.

Despite these positive indicators, challenges remain. High initial installation costs compared to concrete or asphalt alternatives may limit adoption in price-sensitive markets. Additionally, supply chain constraints for high-quality clay and energy-intensive firing processes could impact production scalability and carbon footprint, prompting the industry to explore energy-efficient kilns and alternative fuels.

In conclusion, the 2026 market for clay pavement reflects a convergence of environmental responsibility, urban design innovation, and long-term value. As sustainability becomes a non-negotiable factor in infrastructure development, clay pavers are well-positioned to expand their footprint in global construction, particularly in applications where durability, permeability, and visual appeal are paramount.

Common Pitfalls Sourcing Clay Pavement (Quality, IP)

Sourcing clay pavement—whether for construction, restoration, or landscaping—requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these aspects can lead to structural failures, aesthetic mismatches, legal disputes, and project delays. Below are key pitfalls to avoid:

Overlooking Material Quality Variability

Clay pavers can vary significantly in composition, firing temperature, and durability. Sourcing without rigorous quality checks may result in pavers that crack, erode, or fade prematurely. Always verify compliance with relevant standards (e.g., ASTM C902 or EN 1344), and request test reports for compressive strength, water absorption, and frost resistance.

Ignoring Regional Clay Characteristics

Clay properties differ by geographic origin—color, texture, and performance can vary between regions. Sourcing pavers from a different region than specified may lead to mismatched aesthetics or inappropriate performance in local climate conditions. Ensure the clay source aligns with project requirements and environmental exposure.

Failing to Verify Supplier Credentials

Unreliable suppliers may offer substandard products or inconsistent batches. Avoid vendors without proven track records, certifications, or transparent manufacturing processes. Conduct site visits or third-party audits when possible to confirm production methods and quality control.

Neglecting Intellectual Property in Design and Branding

Many clay paver designs—especially for historic replication or premium architectural use—are protected by design patents, trademarks, or copyrights. Using a branded or patented pattern without authorization can lead to legal action. Always confirm whether the design is proprietary and obtain necessary licensing.

Assuming “Traditional” Means Non-Proprietary

Even designs that appear traditional or generic may be protected under IP law. Some manufacturers register subtle patterns, textures, or naming systems. Conduct due diligence on design origins and consult legal counsel when replicating specific styles.

Overlooking Licensing Agreements for Branded Products

When sourcing branded clay pavers (e.g., from well-known manufacturers), ensure your purchase includes rights for use in your project scope. Unauthorized resale or use outside permitted applications may violate licensing terms.

Inadequate Documentation for Quality and IP Compliance

Failure to maintain records of material certifications, supplier agreements, and design permissions can complicate dispute resolution or project audits. Keep detailed documentation on sourcing, testing, and IP clearances throughout the procurement process.

By proactively addressing these pitfalls, project stakeholders can ensure durable, compliant, and legally sound sourcing of clay pavement.

Logistics & Compliance Guide for Clay Pavement

This guide outlines the essential logistics considerations and compliance requirements for the handling, transportation, installation, and maintenance of clay pavement systems. Adhering to these guidelines ensures project efficiency, environmental responsibility, and regulatory adherence.

Transportation and Handling

- Material Packaging: Clay pavers are typically supplied on pallets secured with straps or wraps. Ensure packaging remains intact during transit to prevent chipping or breakage.

- Loading and Unloading: Use forklifts or pallet jacks with appropriate load capacity. Avoid dropping or dragging pallets. Store pavers on level, dry ground to prevent moisture absorption and damage.

- Stacking Guidelines: Do not stack pallets more than two high unless designed for it. Excessive stacking can lead to deformation or collapse.

- Weather Protection: Cover stored materials with waterproof tarps during transport and on-site storage. Prolonged exposure to rain can compromise clay integrity and lead to efflorescence.

Site Storage and Inventory Management

- Designated Storage Area: Establish a clean, accessible storage zone away from high-traffic construction areas.

- Inventory Tracking: Maintain a log of delivered quantities, batch numbers, and storage locations to ensure consistent color and texture in installation.

- First-In, First-Out (FIFO): Use older stock first to minimize weathering and ensure uniform appearance across the paved area.

Installation Logistics

- Subgrade Preparation: Confirm subgrade compaction and drainage alignment with engineering specifications before delivery.

- Delivery Scheduling: Coordinate deliveries to match installation pace, minimizing on-site storage duration and space requirements.

- Handling During Installation: Use proper tools (e.g., rubber mallets) to avoid damaging pavers. Do not walk on freshly laid clay pavers without protective boards.

Regulatory and Environmental Compliance

- Environmental Regulations: Follow local and national guidelines for stormwater management. Permeable clay pavement systems must comply with EPA or equivalent standards for runoff control.

- Material Sourcing: Ensure clay pavers are sourced from suppliers adhering to sustainable quarrying practices and environmental certifications (e.g., ISO 14001).

- Efflorescence Management: Address white salt deposits promptly using approved cleaning methods to meet aesthetic standards and prevent long-term degradation.

Safety and Worker Compliance

- Personal Protective Equipment (PPE): Require gloves, safety glasses, and steel-toed boots during handling and installation.

- Training: Provide workers with training on safe lifting techniques and equipment operation.

- OSHA or Local Safety Standards: Comply with all applicable occupational safety regulations during transport, storage, and installation phases.

Documentation and Certification

- Batch Certification: Retain manufacturer certifications for each batch, including compressive strength, water absorption, and freeze-thaw resistance data.

- Inspection Records: Document site inspections, subgrade approvals, and installation progress to support compliance audits.

- Warranty Compliance: Follow installation guidelines precisely to maintain product warranty validity.

Adherence to this logistics and compliance framework ensures the durability, performance, and regulatory acceptance of clay pavement installations. Always consult local authorities and project specifications for region-specific requirements.

Conclusion on Sourcing Clay Paving

In conclusion, sourcing clay pavement presents a sustainable, durable, and aesthetically pleasing solution for a variety of outdoor applications. Its natural composition, longevity, and low environmental impact make it an attractive choice for environmentally conscious projects. While initial costs may be higher compared to some alternatives, the long-term benefits—such as minimal maintenance, resistance to wear, and thermal regulation—justify the investment. Additionally, sourcing from reputable, local manufacturers can reduce transportation emissions and support regional economies. However, careful consideration must be given to sourcing practices to ensure responsible clay extraction and energy-efficient production methods. When properly planned and sourced, clay paving offers a resilient and timeless option that blends functionality with environmental responsibility.