The global clamp meter market has experienced steady growth, driven by rising demand for electrical safety, increasing industrial automation, and widespread adoption in HVAC and power distribution systems. According to Mordor Intelligence, the clamp meter market was valued at approximately USD 671.3 million in 2023 and is projected to grow at a CAGR of over 6.8% from 2024 to 2029. This expansion is fueled by heightened investments in infrastructure development and the need for non-invasive current measurement solutions across commercial and industrial applications. As demand for precision, durability, and digital integration climbs, leading manufacturers are innovating with features like Bluetooth connectivity, improved accuracy, and ruggedized designs. In this competitive landscape, nine key players stand out for their technological advancements, global reach, and comprehensive product portfolios—shaping the future of clamp-on multimeter solutions worldwide.

Top 9 Clamp On Multimeter Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

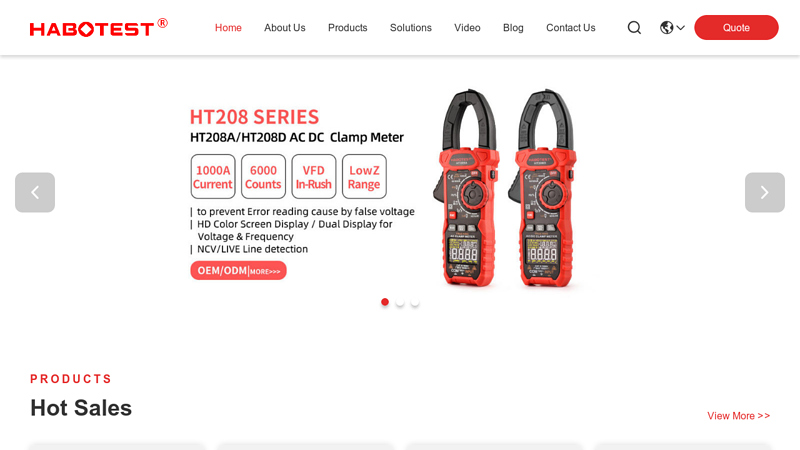

#1 Quality Handheld Digital Multimeter & Digital Clamp Meters factory …

Domain Est. 2019

Website: habotest.com

Key Highlights: China leading provider of Handheld Digital Multimeter and Digital Clamp Meters, Dongguan Habotest Instrument Technology Co.,Ltd is Digital Clamp Meters ……

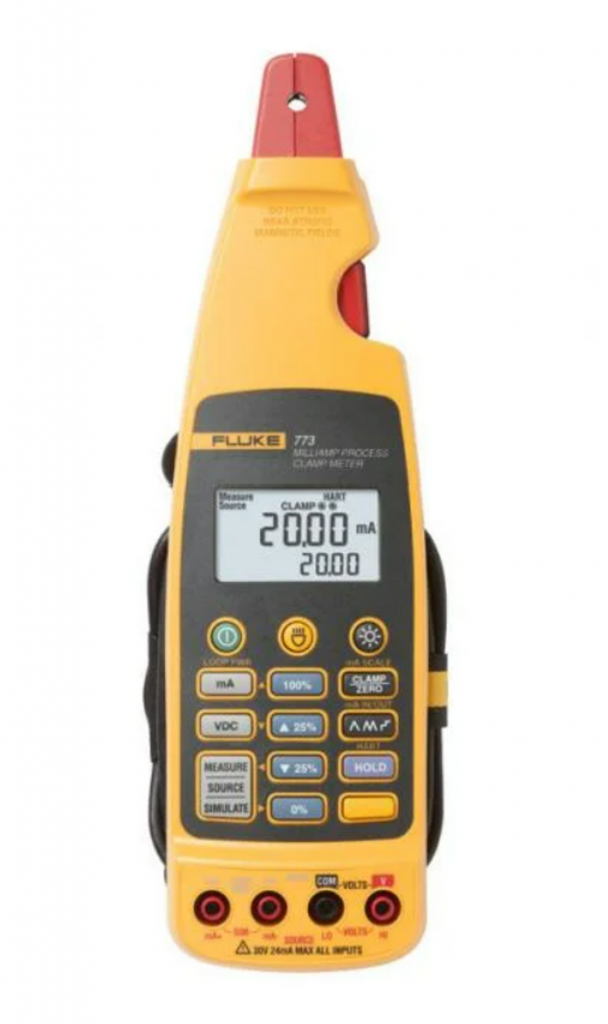

#2 Clamp Meters – Professional Amp and Voltage Meters

Domain Est. 1986

Website: fluke.com

Key Highlights: Browse Fluke clamp meters for accurate current and voltage measurement. Find professional amp clamp meters and clamp voltage meters for precise testing….

#3 Clamp Meters

Domain Est. 1997

Website: meters.uni-trend.com

Key Highlights: Clamp meters are handheld devices with multimeter functions and able to measure AC/DC current directly without breaking the electrical conductor….

#4 Clamp Meters

Domain Est. 1998

Website: kleintools.com

Key Highlights: Klein Tools’ line of clamp meters is designed to give professionals increased accuracy and easy to read results regardless of what the job requires….

#5 Milliamp Clamp Meter

Domain Est. 2002

Website: kinginnovation.com

Key Highlights: This high precision clamp meter was developed to safely identify and measure even the smallest current fluctuations in both conventional and 2-wire….

#6 Clamp Meters

Domain Est. 2005

Website: sperryinstruments.com

Key Highlights: The DSA540A Sperry Instruments Clamp Meter is a 10 function, 26 range auto-ranging unit with non-contact voltage detection engineered to measure AC/DC Current ( ……

#7 Clamp Meters, Clamp Multimeters

Domain Est. 2006

Website: hioki.com

Key Highlights: Hioki provides a wide range of models for AC, DC, and leakage current measurement. The lineup also includes DC high-voltage probes for measuring the open- ……

#8 TightSight™ Clamp Meter 400A AC/DC

Domain Est. 2012

Website: idealind.com

Key Highlights: This CAT III 600 V rated, auto-ranging TRMS digital clamp meter can measure up to 400 Amps AC and DC current through its clamp head….

#9 China VICTOR Digital Multimeter & Digital Clamp Multimeter factories

Domain Est. 2021

Website: m.victormultimeter.com

Key Highlights: XI’AN BEICHENG ELECTRONICS CO.,LTD specializes in products of digital instruments and instrumentation in China under the brand of VICTOR and YITENSEN….

Expert Sourcing Insights for Clamp On Multimeter

2026 Market Trends for Clamp-On Multimeters

The global clamp-on multimeter market is poised for significant evolution by 2026, driven by technological advancements, shifting industrial demands, and a growing emphasis on safety and efficiency. Here are the key trends expected to shape the market:

1. Increased Demand for Smart and Connected Devices

By 2026, the integration of IoT and wireless connectivity (Bluetooth, Wi-Fi) in clamp-on multimeters will be a dominant trend. Technicians will increasingly rely on models that can transmit real-time data to smartphones or cloud platforms for remote monitoring, data logging, and team collaboration. This shift supports predictive maintenance and enhances workflow efficiency in industrial and utility environments.

2. Focus on Safety and Compliance

As electrical systems become more complex and higher voltage, safety standards will tighten. Clamp-on multimeters with higher safety ratings (e.g., CAT IV 600V or CAT III 1000V) will gain market preference. Manufacturers will emphasize arc-flash protection, rugged designs, and compliance with international standards like IEC 61010, catering to electricians and utility workers in high-risk environments.

3. Growth in Renewable Energy and EV Sectors

The expansion of solar, wind, and electric vehicle (EV) infrastructure will fuel demand for specialized clamp-on multimeters. Models capable of measuring DC current with high accuracy, handling high-frequency signals, and diagnosing EV charging systems will see rising adoption. This trend will open new application areas beyond traditional electrical maintenance.

4. Advancements in Measurement Accuracy and Functionality

Consumers will expect higher precision, wider measurement ranges, and enhanced features such as True RMS, inrush current measurement, and harmonic analysis. Dual-display and clamp meters with built-in thermal cameras or voltage detectors will become more common, offering multifunctional capabilities in a single tool.

5. Rise of Battery-Powered and Eco-Friendly Designs

As sustainability becomes a priority, manufacturers will focus on energy-efficient designs and long-lasting rechargeable batteries. Solar-assisted charging and reduced packaging waste are expected to become selling points, especially in European and North American markets with strong environmental regulations.

6. Expansion in Emerging Markets

Rapid urbanization and industrialization in Asia-Pacific, Latin America, and Africa will drive demand for affordable yet reliable clamp-on multimeters. Localized distribution networks and value-priced product lines will be key strategies for market penetration by global players.

7. Integration with Augmented Reality (AR) and Mobile Apps

By 2026, leading clamp-on multimeter brands may offer AR-enabled diagnostics through companion apps, allowing technicians to visualize electrical data overlaid on equipment. This trend will enhance training, troubleshooting accuracy, and reduce downtime.

In conclusion, the 2026 clamp-on multimeter market will be defined by smarter, safer, and more specialized tools that meet the evolving needs of modern electrical and industrial applications. Innovation, connectivity, and sustainability will be central to competitive advantage.

Common Pitfalls When Sourcing Clamp-On Multimeters (Quality & IP)

Sourcing clamp-on multimeters requires careful consideration to ensure safety, accuracy, and durability—especially regarding quality and Ingress Protection (IP) ratings. Falling into common traps can lead to equipment failure, inaccurate readings, or even safety hazards. Below are key pitfalls to avoid:

Poor Build Quality and Component Selection

Many low-cost clamp meters use substandard materials and low-grade internal components to cut costs. This often results in fragile housings, unreliable jaws, and inaccurate sensors. Over time, these units degrade quickly under regular use, leading to measurement drift or outright failure. Always verify the manufacturer’s reputation, look for certifications (e.g., IEC 61010), and inspect build quality through samples or user reviews before bulk procurement.

Misleading or Unverified IP Ratings

Ingress Protection (IP) ratings indicate a device’s resistance to dust and moisture. A common pitfall is sourcing meters with inflated or unverified IP claims—such as advertising “IP67” without third-party testing. Without genuine IP certification, the meter may fail in harsh environments (e.g., outdoor use or industrial settings), risking internal damage or electrical hazards. Always request certified test reports and ensure the IP rating is independently verified.

Inadequate Safety Ratings for Intended Use

Some clamp meters lack appropriate safety categories (CAT III, CAT IV) for high-voltage environments. Using a meter rated below the required safety standard can lead to arc flashes or electric shock. Ensure the clamp meter matches the electrical system’s voltage and category requirements—especially for industrial or utility applications.

Overlooking True RMS Capability

Non-True RMS meters provide inaccurate readings when measuring non-linear loads (e.g., variable speed drives, computers). Sourcing basic averaging meters for modern electrical systems leads to faulty diagnostics. Confirm the meter specifies “True RMS” for accurate measurements across complex waveforms.

Insufficient Calibration and Support

Low-quality suppliers may not offer proper calibration certificates or post-purchase support. Without traceable calibration, measurement reliability is compromised. Also, lack of spare parts or firmware updates can shorten the tool’s lifespan. Choose suppliers offering calibration documentation and technical support.

Ignoring Environmental and Mechanical Durability

Beyond IP ratings, consider drop resistance, operating temperature range, and display visibility in bright light. Clamp meters used in the field must withstand physical stress. Devices without ruggedized designs or protective holsters may fail prematurely under real-world conditions.

Avoiding these pitfalls ensures reliable performance, operator safety, and long-term cost savings when sourcing clamp-on multimeters. Prioritize verified quality, genuine IP ratings, and compliance with safety standards to make informed procurement decisions.

Logistics & Compliance Guide for Clamp On Multimeter

Product Classification and HS Code

Clamp on multimeters are typically classified under Harmonized System (HS) code 9030.33, which covers electrical measuring or checking instruments for voltage, current, resistance, or power. Accurate HS code classification is essential for determining import duties, taxes, and trade regulations in target markets. Confirm the classification with local customs authorities or a licensed customs broker, as variations may exist by country.

Import Regulations and Documentation

Importers must provide standard documentation, including a commercial invoice, packing list, bill of lading or airway bill, and certificate of origin. Some countries may require additional documents such as a conformity assessment, test reports, or an import license. Ensure all documentation clearly describes the product as a “clamp on multimeter” and includes technical specifications to avoid customs delays.

Safety and Electromagnetic Compliance

Clamp on multimeters must comply with relevant electrical safety and electromagnetic compatibility (EMC) standards. Key certifications include:

– CE Marking (EU): Complies with Low Voltage Directive (LVD) 2014/35/EU and Electromagnetic Compatibility Directive 2014/30/EU.

– FCC Certification (USA): Required under Part 15 for unintentional radiators to limit electromagnetic interference.

– PSE Mark (Japan): Mandatory for electrical safety under the Electrical Appliance and Material Safety Law.

– RCM Mark (Australia/New Zealand): Indicates compliance with electrical safety and EMC requirements.

Environmental and Chemical Compliance

Ensure compliance with substance restrictions such as:

– RoHS (EU): Restricts hazardous substances like lead, mercury, and cadmium.

– REACH (EU): Requires declaration of Substances of Very High Concern (SVHC).

– Proposition 65 (California, USA): Requires warning labels if the product contains listed chemicals.

Verify that all components, including test leads and battery, meet applicable environmental standards.

Packaging and Labeling Requirements

Packaging must be durable for international shipping and include:

– Product name and model number

– Manufacturer/importer details

– Safety warnings and usage instructions

– Required certification marks (e.g., CE, FCC)

– Language-specific labels as required by the destination country (e.g., bilingual labeling in Canada)

Battery Shipping Considerations

If the multimeter includes a lithium battery, it must comply with IATA Dangerous Goods Regulations for air transport. Package batteries per UN 38.3 testing requirements and mark shipments accordingly. Ground shipping may have less stringent rules, but compliance with local transport regulations is still required.

Warranty and After-Sales Support

Establish clear logistics for warranty claims and repairs. Provide localized user manuals and customer support contacts. Consider setting up regional service centers or partnering with local distributors to handle returns and technical support efficiently.

Record Keeping and Audit Preparedness

Maintain records of compliance certifications, test reports, import documentation, and supply chain traceability for a minimum of 5–10 years, depending on jurisdiction. These records may be required during regulatory audits or customs inspections.

In conclusion, sourcing a clamp-on multimeter requires careful consideration of key factors such as accuracy, measurement range, safety ratings, and functionality to match the specific needs of the user—whether for industrial maintenance, HVAC work, or general electrical troubleshooting. Features like auto-ranging, data logging, backlight displays, and compatibility with both AC and DC current measurements enhance usability and efficiency. Additionally, selecting a reputable brand that adheres to international safety standards (such as CAT ratings) ensures reliable performance and operator protection. By evaluating application requirements, budget, and desired features, one can effectively choose a clamp-on multimeter that offers durability, precision, and long-term value. Proper sourcing ultimately leads to improved diagnostic capabilities, increased productivity, and enhanced electrical safety in the field.