The global circular knife manufacturing market is experiencing steady growth, driven by rising demand for precision cutting solutions across industries such as food processing, textiles, paper, and recycling. According to Grand View Research, the global industrial knives market was valued at USD 4.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This growth is fueled by increasing automation in manufacturing and the need for high-performance, durable cutting tools that minimize downtime and maximize efficiency. Circular knives, known for their consistent performance in high-speed applications, are a critical component in this ecosystem. With industries prioritizing sustainability and operational efficiency, manufacturers are focusing on advanced materials, such as high-grade stainless steel and tungsten carbide, as well as innovative heat treatment processes to enhance blade longevity. As competition intensifies and global demand rises, the following list highlights the top 10 circular knife manufacturers leading the market through innovation, quality, and strategic global reach.

Top 10 Circular Knife Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Dienes USA

Domain Est. 2001

Website: dienesusa.com

Key Highlights: DIENES is the world’s leading manufacturer of circular knives, knife holders, slitting systems, shafts, brakes, & chucks….

#2 Simonds International

Domain Est. 2003

Website: simondsint.com

Key Highlights: As the oldest cutting tool manufacturer in North America, Simonds International offers one of the broadest and most trusted lines of cutting tools….

#3 Industrial Knife Manufacturer

Domain Est. 2022

Website: maxwellslitters.com

Key Highlights: MaxwellSlitters is a leading manufacturer and supplier of HSS quality industrial blades, industrial knives, Slitting tools, and saws globally….

#4 KANEFUSA CORPORATION

Domain Est. 2006

Website: kanefusa.net

Key Highlights: Circular saw blades, knives and other tools for industries with excellent quality since 1896. Technology & Innovation…

#5 Star Knives

Domain Est. 2008

Website: starknives.net

Key Highlights: Star Knives & Saws is a leading manufacturer and supplier of high-quality Star Knives and Saws. A privately owned Indian company, Star Knives provides ……

#6 Circular Knives

Domain Est. 2009

Website: carolinaknife.com

Key Highlights: Carolina Knife & Manufacturing manufactures these circular knives from several materials OEM and for all industries. Contact Us Today!…

#7 Brous Blades

Domain Est. 2010

Website: brousblades.com

Key Highlights: All Limited Custom Knives are personally hand-made by Jason Brous using high-grade and exotic steels. We spend countless hours perfecting these blades….

#8 Circular Knife Blades for Industrial Cutting

Domain Est. 2013

Website: sundicuttingtools.com

Key Highlights: Sundi Tools offers premium circular knives and cutting blades suitable for a variety of applications, from industrial to commercial to heavy-duty projects….

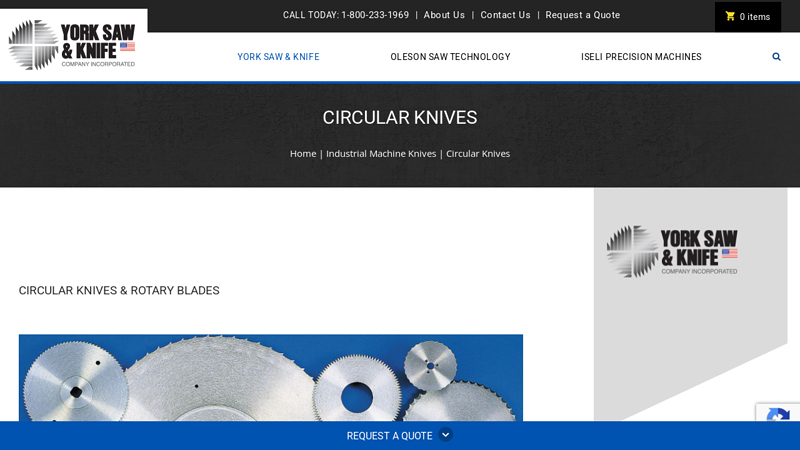

#9 Circular Knives & Round Slitters

Domain Est. 1996

Website: yorksaw.com

Key Highlights: York Saw & Knife circular machine knives are an excellent choice for a number of cutting, slitting & scoring applications….

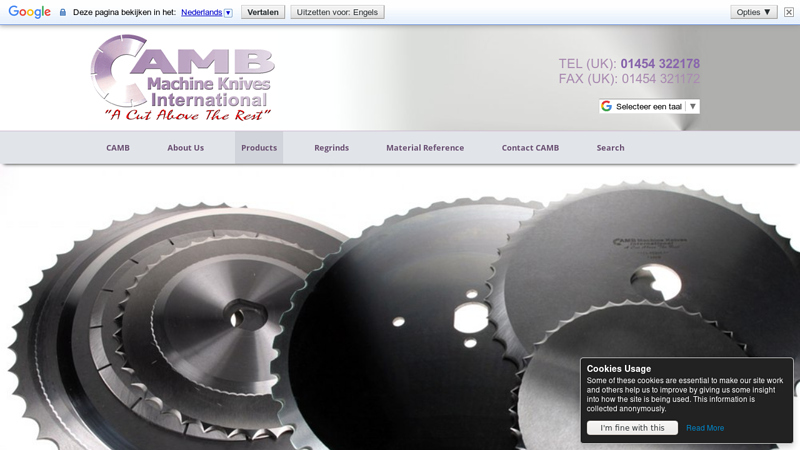

#10 Circular Knives

Domain Est. 1998

Website: camb-knives.co.uk

Key Highlights: We supply a wide range of circular knives for a variety of uses. We hold a large stock of Stainless Steel circular knives for use in the poultry processing ……

Expert Sourcing Insights for Circular Knife

H2: Emerging Market Trends for Circular Knives in 2026

As we approach 2026, the circular knife market is undergoing significant transformation driven by technological innovation, sustainability imperatives, and evolving industrial demands. This analysis explores key trends shaping the circular knife industry during the second half (H2) of 2026, highlighting shifts in manufacturing, material science, automation integration, and regional market dynamics.

1. Surge in Demand from Packaging and Recycling Sectors

The global push for sustainable packaging and enhanced recycling processes continues to drive demand for high-performance circular knives. In H2 2026, industries such as paper recycling, plastic film processing, and corrugated board manufacturing are investing heavily in precision cutting equipment. Circular knives are essential in shredding, slitting, and trimming operations, and their demand is rising in tandem with increased recycling targets set by governments and corporations.

2. Advancements in Blade Material and Coating Technologies

Material innovation is a key trend in H2 2026. Manufacturers are increasingly adopting advanced alloys, tungsten carbide, and ceramic composites to improve blade longevity and cutting efficiency. Nano-coatings such as diamond-like carbon (DLC) and titanium aluminum nitride (TiAlN) are being widely applied to reduce friction, resist wear, and maintain sharpness under high-throughput conditions. These enhancements lower total cost of ownership by reducing downtime and replacement frequency.

3. Integration with Smart Manufacturing and Industry 4.0

Circular knife systems are becoming integral components of smart factories. In H2 2026, more industrial cutting machines feature real-time monitoring, predictive maintenance, and IoT connectivity. Sensors embedded in knife holders and spindles track blade wear, temperature, and vibration, enabling proactive maintenance. This trend is particularly strong in Europe and North America, where manufacturers prioritize operational efficiency and minimal unplanned downtime.

4. Growth in Automation and Robotics

Automation in material handling and cutting processes is accelerating. Robotic arms equipped with circular knives are being deployed in food processing, textiles, and automotive recycling. In the food industry, for example, automated circular knives ensure precise slicing of meat, cheese, and baked goods, improving consistency and hygiene. The trend is supported by advancements in machine vision and adaptive control systems.

5. Regional Market Shifts and Supply Chain Localization

Asia-Pacific remains the fastest-growing market for circular knives in H2 2026, led by China, India, and Southeast Asia. Rapid industrialization, expansion of e-commerce (driving packaging needs), and government initiatives in waste management are key drivers. Meanwhile, in response to geopolitical risks and supply chain disruptions, North American and European manufacturers are localizing production, boosting regional demand for high-quality circular knife systems.

6. Focus on Sustainability and Circular Economy

The circular knife industry is aligning with broader circular economy principles. Companies are designing blades for regrinding and reuse, reducing waste. Additionally, circular knives used in recycling facilities are being optimized to handle mixed waste streams more efficiently, supporting higher recovery rates of plastics and paper. This sustainability focus is increasingly influencing procurement decisions.

7. Consolidation and Strategic Partnerships

Market consolidation is evident in H2 2026, with larger tooling manufacturers acquiring niche players specializing in high-precision or application-specific circular knives. Strategic partnerships between knife manufacturers and OEMs of cutting machinery are also increasing, enabling co-development of integrated solutions tailored to specific industrial applications.

Conclusion

By H2 2026, the circular knife market is characterized by innovation, digitization, and sustainability. Driven by demand from recycling, packaging, and automated production lines, the sector is evolving rapidly. Companies that invest in advanced materials, smart technologies, and sustainable practices are best positioned to capitalize on these trends and lead in the increasingly competitive global marketplace.

Common Pitfalls Sourcing Circular Knives (Quality, IP)

Sourcing circular knives—used in industries like paper converting, packaging, textiles, and food processing—can be fraught with challenges, particularly concerning quality consistency and intellectual property (IP) protection. Falling into these common pitfalls can lead to production downtime, legal risks, and compromised product performance.

1. Overlooking Material Quality and Hardness Specifications

One of the most frequent issues is assuming all circular knives are equivalent, regardless of material. Sourcing knives made from inferior-grade steel or with inconsistent heat treatment leads to premature wear, chipping, or failure. Buyers may not verify hardness (e.g., HRC 58–62) or material type (e.g., high-carbon steel, tool steel, or carbide), resulting in knives that dull quickly or fail under operational stress.

2. Inadequate Dimensional and Tolerance Control

Circular knives require precise tolerances for diameter, thickness, concentricity, and surface finish. Sourcing from suppliers without rigorous quality control can result in out-of-spec components that cause vibration, poor cutting performance, or machine damage. Buyers often fail to specify critical tolerances or audit supplier metrology capabilities.

3. Poor Surface Finish and Edge Preparation

A substandard grind or improper edge geometry (bevel angle, edge relief) affects cutting precision and lifespan. Suppliers may cut corners on finishing processes, leading to burrs or inconsistent edges. Without clear specifications and inspection protocols, these defects may go undetected until they impact production.

4. Lack of Traceability and Certification

Reputable suppliers provide material certifications (e.g., mill test reports) and process documentation. Sourcing from vendors that lack traceability increases the risk of receiving counterfeit or recycled materials, undermining performance and safety. This is especially critical in regulated industries like food or medical packaging.

5. Intellectual Property (IP) Infringement Risks

Circular knife designs—especially custom geometries or patented blade profiles—may be protected by IP rights. Sourcing knock-offs or unlicensed copies exposes buyers to legal liability, including infringement lawsuits or customs seizures. Buyers often underestimate the risk when sourcing from low-cost regions where IP enforcement is weak.

6. Unverified Supplier Credentials and Experience

Engaging suppliers without proven expertise in precision knife manufacturing can lead to inconsistent quality. Red flags include lack of industry references, minimal technical support, or unwillingness to sign non-disclosure agreements (NDAs). Some suppliers may subcontract production without buyer knowledge, further diluting quality control.

7. Inadequate Testing and Validation Protocols

Assuming sample knives represent production batch quality is risky. Without requiring performance testing (e.g., edge retention, runout testing) or on-site audits, buyers may receive batches that deviate significantly from approved samples. This is especially problematic with offshore suppliers.

8. Failure to Secure IP Ownership in Custom Designs

When commissioning custom circular knives, businesses must ensure contracts clearly assign IP rights. Without proper agreements, suppliers may retain rights to the design, reuse it for competitors, or charge ongoing licensing fees. This undermines competitive advantage and creates long-term dependency.

9. Ignoring After-Sales Support and Re-Sharpening Services

The total cost of ownership includes re-sharpening and maintenance. Sourcing from suppliers that lack technical support or reconditioning services leads to extended downtime and higher lifecycle costs. Buyers should evaluate service networks and turnaround times before committing.

10. Supply Chain and Lead Time Volatility

Relying on a single or distant supplier can expose operations to delays, especially if quality issues require rework or replacement. Lack of contingency planning increases the risk of production stoppages due to knife shortages or non-conformance.

Best Practices to Mitigate Risks

- Define clear technical specifications and quality standards upfront

- Conduct supplier audits and request sample validation under real conditions

- Use legally binding contracts that protect IP and ensure compliance

- Prioritize suppliers with certifications (e.g., ISO 9001) and industry experience

- Establish a dual-sourcing strategy where feasible

Avoiding these pitfalls ensures reliable performance, protects intellectual assets, and supports long-term operational efficiency when sourcing circular knives.

Logistics & Compliance Guide for Circular Knives

Circular knives, due to their sharpness and function, may be subject to specific regulations during logistics and transport, especially across international borders or in regulated environments (e.g., aviation, public facilities). This guide outlines key logistics and compliance considerations to ensure safe, legal handling and shipment.

Regulatory Classification and Legal Status

Circular knives are often classified based on blade length, intended use (industrial vs. consumer), and design. In many jurisdictions:

- Industrial circular knives used in manufacturing, textiles, or recycling may be treated as tools rather than weapons, but still require proper packaging and documentation.

- Consumer-grade circular knives (e.g., utility knives) may fall under restrictions similar to other bladed tools.

- Check local, national, and international regulations (e.g., U.S. TSA, EU customs, IATA Dangerous Goods Regulations) to determine whether the item is restricted, prohibited, or requires declaration.

Packaging and Handling Requirements

Proper packaging is essential to prevent injury and comply with safety standards:

- Secure Sheathing: All circular knives must be enclosed in rigid, non-puncturable sheaths or guards that fully cover the blade.

- Immobilization: Knives should be immobilized within the packaging to prevent movement during transit.

- Outer Packaging: Use strong, durable outer packaging (e.g., corrugated fiberboard or wooden crates) clearly marked with “Sharp Object – Handle with Care” warnings.

- Segregation: Keep circular knives separate from fragile or sensitive goods to avoid damage.

Transport and Shipping Compliance

Different modes of transport impose specific requirements:

- Air Freight: Under IATA guidelines, sharp objects like circular knives are generally permitted in cargo shipments if properly packed. However, they are typically prohibited in passenger cabin baggage and restricted in checked luggage depending on blade length.

- Ground and Sea Freight: Generally allowed with proper packaging, but must comply with national hazardous materials or dangerous goods codes if applicable (e.g., if blades are made of restricted alloys or coated with hazardous substances).

- Documentation: Include accurate commodity descriptions, HS codes (e.g., 8208.10 for circular knives for machines), and safety data sheets (SDS) if required.

Import/Export Controls

International shipments require attention to:

- Customs Declarations: Declare circular knives accurately, specifying intended use (industrial cutting tool, spare part, etc.).

- Licensing: Some countries require import/export licenses for tools that could be used as weapons.

- Trade Restrictions: Be aware of embargoes or sanctions that may affect shipment to certain countries.

Workplace and Facility Compliance

When receiving or using circular knives on-site:

- Adhere to OSHA (or equivalent) safety standards for handling sharp objects.

- Provide employee training on safe handling, storage, and disposal.

- Store knives in locked, designated areas when not in use, especially in public-access facilities.

Environmental and Disposal Regulations

End-of-life circular knives (especially those made of tungsten carbide or coated materials) may be subject to environmental regulations:

- Follow local e-waste or industrial waste disposal protocols.

- Do not discard in general waste streams if blades contain regulated materials.

- Consider manufacturer take-back or recycling programs.

Summary of Best Practices

- Always classify the knife correctly based on use and design.

- Package securely with full blade protection and hazard warnings.

- Verify compliance with transport mode and route-specific rules.

- Maintain accurate documentation for customs and safety audits.

- Train staff in safe handling and regulatory requirements.

By adhering to this guide, businesses can ensure the safe, compliant logistics of circular knives across global supply chains.

Conclusion for Sourcing a Circular Knife:

Sourcing a circular knife requires a strategic approach that balances quality, cost, durability, and supplier reliability. After evaluating various suppliers, materials, and technical specifications, it is clear that selecting the right circular knife involves more than just competitive pricing—it demands attention to precision engineering, material composition (such as high-grade steel or tungsten carbide), and compatibility with specific cutting applications. Partnering with reputable manufacturers or suppliers who offer certifications, consistent quality control, and after-sales support ensures long-term performance and reduces machine downtime. Additionally, considering factors like customization options, lead times, and sustainability practices can further enhance operational efficiency. Ultimately, a well-informed sourcing decision leads to improved cutting accuracy, extended blade life, and reduced total cost of ownership, making it a critical component in optimizing production processes across industries such as textiles, paper, food processing, and metalworking.