The global electric motor market is experiencing robust growth, driven by increasing demand for energy-efficient solutions across industrial, automotive, and consumer sectors. According to Grand View Research, the global electric motor market size was valued at USD 135.6 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2024 to 2030. This surge is fueled by the rising adoption of electric vehicles (EVs), automation in manufacturing, and stringent energy efficiency regulations—factors that have significantly elevated the importance of high-performance motors like those produced by leading CIM (Computer-Integrated Manufacturing) motor manufacturers. As industries pivot toward smart manufacturing and precision-driven automation, the role of advanced CIM motors in enhancing operational efficiency and reducing energy consumption has become pivotal. In this evolving landscape, a select group of manufacturers has emerged at the forefront, combining innovation, scalability, and reliability to meet the demands of next-generation applications. Here’s a data-driven look at the top eight CIM motor manufacturers shaping the future of motion control and industrial automation.

Top 8 Cim Motor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Grundfos USA

Domain Est. 1995

Website: grundfos.com

Key Highlights: Find the right dosing pump for your application. CIM/CIU Integration and Selection tool. Select CIM/CIU technology….

#2 Blizzard Entertainment

Domain Est. 1994

Website: blizzard.com

Key Highlights: Creators of the Warcraft, Diablo, StarCraft, and Overwatch series, Blizzard Entertainment is an industry-leading developer responsible for the most epic ……

#3 Collins Aerospace

Domain Est. 1996

Website: rtx.com

Key Highlights: At Collins Aerospace, we’re working side-by-side with our customers and partners to dream, design and deliver solutions that redefine the future of our ……

#4 Motors

Domain Est. 1999

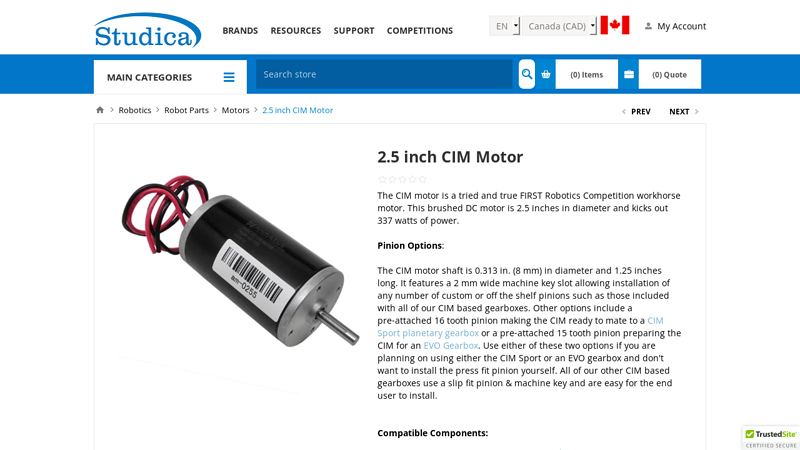

#5 2.5 inch CIM Motor

Domain Est. 2002

Website: studica.ca

Key Highlights: The CIM motor is a tried and true FIRST Robotics Competition workhorse motor. This brushed DC motor is 2.5 inches in diameter and kicks out 337 watts of power….

#6 CIM

Domain Est. 2004

Website: cim-tech.com

Key Highlights: A complete CNC machine programming package. This versatile product combines Computer Aided Manufacturing (CAM) features with the power of AutoCAD….

#7 Compact Induction Motor (CIM)

Domain Est. 2022

Website: gevernova.com

Key Highlights: Our medium power induction motors’ frame and stator have been specially developed to offer a highly efficient cooling, then allowing higher power ratings with ……

#8 Global Composite Material News

Website: composites.media

Key Highlights: Composites in Manufacturing delivers the latest news, product developments, topical features, application stories and event previews from across the UK ……

Expert Sourcing Insights for Cim Motor

H2: Market Trends Analysis for Cim Motor in 2026

As we approach 2026, the global electric motor and motion control market is undergoing a transformation driven by technological innovation, regulatory pressure, and shifting industrial demands. For Cim Motor, a company specializing in high-efficiency electric motors, servo systems, and motion solutions, understanding and adapting to these trends is critical for maintaining competitiveness and capturing market share. Below is an analysis of key market trends shaping Cim Motor’s landscape in 2026, focusing on the second half (H2) of the year and forward-looking implications.

1. Accelerated Adoption of Energy-Efficient and IE4/IE5 Motors

Regulatory mandates across the EU, North America, and parts of Asia are enforcing stricter energy efficiency standards. By H2 2026, the transition from IE3 to IE4 (Super Premium Efficiency) and IE5 (Ultra Premium Efficiency) motors is becoming mainstream. Cim Motor’s strategic focus on high-efficiency induction and permanent magnet motors positions it well to capitalize on this trend, especially in HVAC, pumps, and industrial automation sectors.

Implication: Cim Motor should continue investing in R&D to enhance motor efficiency while optimizing cost structures to remain competitive against global players like ABB, Siemens, and WEG.

2. Growth in Electric Vehicle (EV) and E-Mobility Supply Chains

Although Cim Motor primarily serves industrial markets, the expansion of EV infrastructure and e-mobility is creating indirect opportunities. Motors used in EV charging stations, automated manufacturing lines for EV batteries, and mobile robotics in logistics are driving demand for precision motion control systems.

Implication: Cim Motor can leverage its servo and variable-speed drive expertise to enter adjacent markets. Strategic partnerships with EV equipment manufacturers could unlock new revenue streams by H2 2026.

3. Rise of Smart Motors and IoT Integration

The industrial sector is increasingly adopting Industry 4.0 principles. By 2026, smart motors with embedded sensors, predictive maintenance capabilities, and IoT connectivity are becoming standard in manufacturing and process industries.

Implication: Cim Motor must accelerate its digital transformation by integrating smart features into its motor systems—such as real-time monitoring, remote diagnostics, and cloud-based analytics—to avoid commoditization and add value.

4. Regional Manufacturing Reshoring and Supply Chain Localization

Geopolitical tensions and supply chain disruptions have led to a push for localized production in North America and Europe. In H2 2026, companies are prioritizing suppliers with regional manufacturing and service capabilities.

Implication: Cim Motor can strengthen its foothold by expanding local assembly or service hubs in key markets (e.g., U.S., Germany, Turkey), reducing delivery times and enhancing customer support.

5. Demand for Customized and Modular Motor Solutions

End users across robotics, packaging, and food & beverage industries are seeking modular, customizable motor solutions that can be rapidly deployed and integrated. Off-the-shelf products are losing favor where flexibility and fast time-to-market are essential.

Implication: Cim Motor should enhance its engineering-to-order (ETO) capabilities and adopt modular design platforms to offer tailored solutions without sacrificing scalability.

6. Sustainability and ESG Pressures

Investors and industrial clients are demanding transparent ESG (Environmental, Social, and Governance) reporting. Energy-efficient motors directly contribute to carbon reduction goals.

Implication: Cim Motor can differentiate itself by publishing lifecycle assessments of its products, using recycled materials, and offering motor recycling programs—strengthening brand reputation and meeting corporate sustainability targets.

7. Competitive Pressure from Asian Motor Manufacturers

Low-cost, high-volume motor producers from China and India continue to improve quality and export aggressively. While Cim Motor competes on performance and reliability, price sensitivity in emerging markets remains a challenge.

Implication: Cim Motor should emphasize total cost of ownership (TCO)—highlighting energy savings and durability—over initial purchase price, particularly in B2B marketing and technical sales.

Conclusion: Strategic Outlook for Cim Motor in H2 2026

The second half of 2026 presents both opportunities and challenges for Cim Motor. The company’s future success will depend on its ability to:

- Lead in high-efficiency and smart motor technologies.

- Expand digital integration and data-driven services.

- Localize supply chains and respond rapidly to regional demand.

- Differentiate through sustainability and customization.

By aligning its product development, go-to-market strategy, and customer engagement with these evolving trends, Cim Motor can solidify its position as a forward-looking innovator in the global motion control industry.

Common Pitfalls Sourcing Cim Motors (Quality, IP)

Sourcing Cim Motors, especially from non-authorized distributors or international suppliers, can expose buyers to significant risks related to both product quality and intellectual property (IP) infringement. Being aware of these pitfalls is crucial for ensuring reliability, performance, and legal compliance.

Quality Concerns with Unauthorized Cim Motors

One of the most prevalent risks in sourcing Cim Motors is receiving products that fail to meet the original manufacturer’s rigorous quality standards. Unauthorized suppliers may offer motors labeled as “Cim” that are either counterfeit, refurbished without proper certification, or manufactured using substandard materials and processes. These inferior motors often exhibit reduced efficiency, shorter lifespans, and higher failure rates, leading to increased maintenance costs and operational downtime. Additionally, inconsistent performance can compromise the safety and reliability of the systems in which they are integrated, particularly in industrial or automation applications where precision is critical.

Intellectual Property Infringement Risks

Purchasing Cim Motors from unofficial sources may also involve unknowingly acquiring counterfeit products that violate intellectual property rights. Cim Motors are protected by trademarks, design patents, and technical innovations, and unauthorized replication or sale of these products constitutes IP infringement. Buyers risk legal exposure, especially in regulated industries or jurisdictions with strict IP enforcement. Moreover, using counterfeit components can void warranties on larger systems and damage the reputation of companies associated with non-compliant sourcing practices. Ensuring that motors are sourced through authorized channels is essential to avoid supporting illegal manufacturing and to protect both the buyer and end-users from legal and operational repercussions.

Logistics & Compliance Guide for Cim Motor

This guide outlines the essential logistics and compliance procedures for Cim Motor to ensure efficient operations, regulatory adherence, and supply chain integrity across all domestic and international activities.

Supply Chain Management

Cim Motor must establish a resilient and transparent supply chain. This includes vetting and monitoring suppliers for quality, ethical practices, and compliance with local and international regulations. All suppliers must adhere to Cim Motor’s Supplier Code of Conduct, covering labor standards, environmental responsibility, and anti-corruption policies. Regular audits and performance reviews are required to maintain continuous improvement and risk mitigation.

Transportation & Distribution

All inbound and outbound shipments must comply with applicable transportation regulations, including road, rail, sea, and air freight standards. Cim Motor is responsible for selecting certified logistics partners with proven safety and compliance records. Packaging must meet international standards (e.g., ISTA, ISO) to protect goods during transit. Real-time tracking systems should be implemented for shipment visibility, and delivery timelines must be monitored to meet customer expectations.

Customs Compliance

Cim Motor must ensure full compliance with customs regulations in all operating countries. This includes accurate classification of goods under the Harmonized System (HS), correct valuation, and proper origin certification. All export and import documentation—commercial invoices, packing lists, certificates of origin, and export licenses—must be complete, accurate, and retained for a minimum of five years. Designated personnel must be trained in customs procedures and changes in trade regulations.

Trade Sanctions & Export Controls

Cim Motor is prohibited from engaging in transactions with individuals, entities, or countries subject to international sanctions (e.g., OFAC, EU, UN). Prior to any export, shipments must be screened against global restricted party lists. Products with potential dual-use applications must be evaluated under relevant export control regimes (e.g., EAR, EU Dual-Use Regulation). Licensing requirements must be identified and obtained before shipment.

Product Compliance & Certification

All Cim Motor products must meet applicable technical, safety, and environmental standards in target markets (e.g., CE marking in Europe, E-Mark for automotive components, RoHS, REACH). Compliance documentation, including test reports and conformity certificates, must be maintained and updated regularly. Product labeling must reflect local language, voltage, and safety requirements.

Environmental & Sustainability Compliance

Cim Motor is committed to minimizing its environmental impact throughout the logistics lifecycle. This includes optimizing transport routes to reduce emissions, using recyclable packaging materials, and complying with waste disposal regulations (e.g., WEEE, battery directives). Carbon footprint reporting should be integrated into logistics performance metrics.

Recordkeeping & Audit Preparedness

All logistics and compliance-related records—shipping documents, customs filings, compliance certifications, audit reports, and training logs—must be securely stored and readily accessible. Internal audits should be conducted annually, with external audits performed as required by regulation or certification bodies. Non-conformances must be documented and corrective actions implemented promptly.

Incident Response & Corrective Actions

In the event of a logistics delay, customs seizure, compliance breach, or product recall, Cim Motor must activate its incident response protocol. This includes immediate notification of relevant stakeholders, root cause analysis, reporting to authorities if required, and implementation of corrective and preventive actions to avoid recurrence.

By adhering to this guide, Cim Motor ensures reliable delivery, regulatory compliance, and long-term sustainability in its global operations.

Conclusion for Sourcing CIM Motors:

In conclusion, sourcing CIM (Can-Integrated Motor) motors requires a strategic approach that balances performance requirements, cost, availability, and supplier reliability. These high-performance DC motors are widely used in robotics, industrial automation, and competitive applications such as FIRST Robotics due to their robustness and consistent output. When sourcing CIM motors, it is essential to evaluate authorized distributors and reputable suppliers to ensure authenticity, avoid counterfeit products, and maintain quality standards. Additionally, considering lead times, warranties, and technical support can significantly impact project timelines and long-term success. Establishing relationships with trusted vendors, exploring bulk purchasing options, and staying informed about market availability will help optimize procurement efficiency. Ultimately, a well-planned sourcing strategy ensures reliable access to high-quality CIM motors, supporting the performance and durability of the systems they power.