The global grab bars market is experiencing steady growth, driven by increasing demand for accessibility solutions in residential and healthcare settings. According to Grand View Research, the global bathroom fixtures market—which includes grab bars—was valued at USD 51.8 billion in 2022 and is expected to expand at a CAGR of 5.2% from 2023 to 2030, fueled by aging populations and rising awareness of universal design. Chrome, in particular, remains a dominant material due to its durability, corrosion resistance, and aesthetic appeal. As demand for reliable and stylish safety hardware grows, manufacturers are innovating to meet stringent safety standards while offering design flexibility. In this competitive landscape, nine leading Chrome grab bars manufacturers have emerged as industry frontrunners, combining quality engineering, compliance with ADA and ISO standards, and scalable production capabilities to capture significant market share.

Top 9 Chrome Grab Bars Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

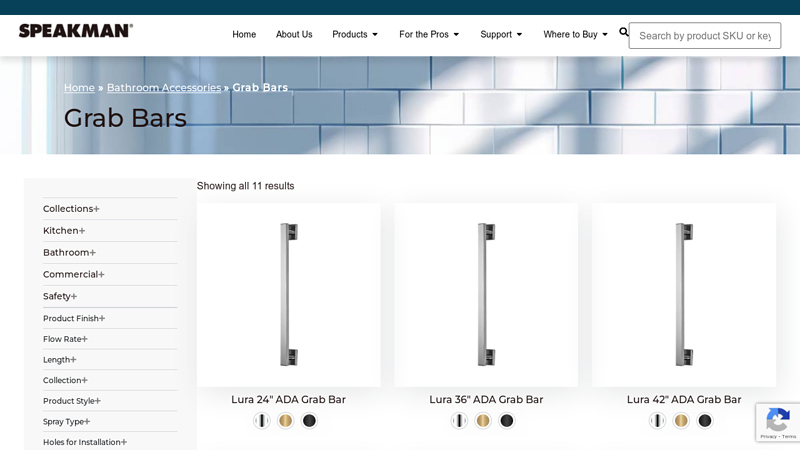

#1 Grab Bars Archives

Domain Est. 1996

Website: speakman.com

Key Highlights: Neo 36″ ADA Grab Bar · Polished Chrome · Brushed Bronze · Brushed Nickel · Matte Black · Oil Rubbed Bronze · +0….

#2 Grab Bars

Domain Est. 1996

Website: binsons.com

Key Highlights: $5 delivery 30-day returnsFind permanent and temporary grab bars so that you can safely navigate your bathroom and shower independently….

#3 Grab Bars

Domain Est. 1996

Website: bobrick.com

Key Highlights: Our slip-resistant grab bars are available in a range of configurations, dimensions, surfaces and finishes….

#4 Grab Bars for Showers, Bathtubs, & Toilets

Domain Est. 1997

#5 Grab bars

Domain Est. 1998

Website: dornbracht.com

Key Highlights: Grab bars and support rails from Dornbracht offer optimum support in every situation. Thanks to the combination of high-quality workmanship and timeless design….

#6 Grab Bars for Shower and Bath Safety

Domain Est. 2000

Website: mrgrabbar.com

Key Highlights: Precision designed residential and commercial Grab Bars | many sizes, finishes and attractive styles. Fabrication | Installation – we are the experts!…

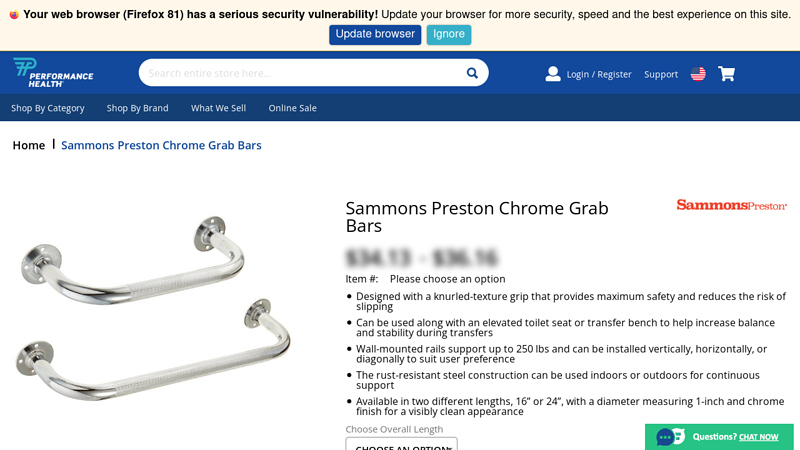

#7 Sammons Preston Chrome Grab Bars

Domain Est. 2002

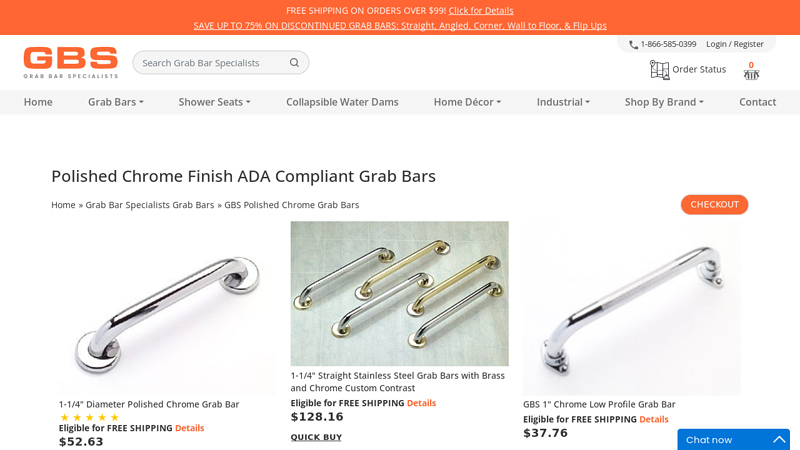

#8 ADA Compliant Grab Bars with Polished Chrome Finish

Domain Est. 2004

Website: grabbarspecialists.com

Key Highlights: Free delivery over $99 30-day returns1-1/4″ Diameter Polished Chrome Grab Bar. Based on 5 ratings. Eligible for FREE SHIPPING. Details Price$52.63…

#9 Grab Bar

Domain Est. 2011

Website: hmebc.com

Key Highlights: Knurled Chrome Grab Bars provide an added safety measure by allowing the user to have a sturdy and easy support to grip….

Expert Sourcing Insights for Chrome Grab Bars

2026 Market Trends for Chrome Grab Bars

Growing Demand in Aging-in-Place Renovations

By 2026, the global population of individuals aged 65 and older will continue to expand significantly, particularly in developed economies. This demographic shift is driving increased demand for home modifications that support independent living. Chrome grab bars, known for their durability, corrosion resistance, and aesthetic appeal, are becoming essential components in aging-in-place bathroom renovations. Homeowners are prioritizing safety without sacrificing style, positioning chrome finishes as a preferred choice over less polished alternatives.

Integration with Universal Design Principles

Universal design—creating spaces accessible to people of all ages and abilities—is gaining mainstream traction in residential construction and remodeling. By 2026, builders and designers are increasingly incorporating grab bars into standard bathroom layouts, even in homes not specifically marketed as accessible. Chrome grab bars align well with this trend due to their sleek, modern appearance that blends seamlessly with a variety of bathroom decors, from minimalist to traditional. This shift is reducing the stigma once associated with safety fixtures.

Rise of Premium and Designer Fixtures

Consumers are moving beyond basic functionality, seeking grab bars that double as design elements. In 2026, the market is witnessing a surge in premium chrome grab bars featuring enhanced finishes (such as spot-resistant or matte chrome), ergonomic shapes, and customizable mounting options. Brands are collaborating with interior designers to offer coordinated collections that match faucets, showerheads, and towel bars, elevating the grab bar from a utilitarian item to a cohesive design feature.

Increased Regulatory and Insurance Incentives

Building codes in several regions are expected to evolve by 2026, mandating grab bar installation in new residential constructions or major renovations, especially in ground-floor bathrooms. Additionally, insurance providers may offer premium discounts for homes equipped with certified safety features, including properly installed chrome grab bars. These regulatory and financial incentives are accelerating adoption across both new builds and retrofit projects.

Sustainability and Longevity Focus

With growing consumer awareness around sustainability, chrome-plated steel grab bars are benefiting from their long lifespan and recyclability. Unlike plastic or lower-grade metal alternatives, high-quality chrome bars resist rust and wear, reducing the need for replacements. Manufacturers are highlighting these environmental advantages in marketing efforts, appealing to eco-conscious buyers who value durability and low lifecycle impact.

E-Commerce and Direct-to-Consumer Sales Growth

Online retail channels are becoming dominant in the grab bar market by 2026. Consumers are leveraging e-commerce platforms to compare styles, read reviews, and purchase certified safety products with home installation guides. Brands are investing in augmented reality (AR) tools that allow users to visualize how chrome grab bars will look in their bathrooms, enhancing confidence in online purchases and expanding market reach beyond traditional hardware stores.

Technological Integration and Smart Features

While still emerging, some innovators are exploring smart grab bars with built-in sensors—such as weight detection or fall alerts—integrated into a chrome-finished frame. Though not yet mainstream, the convergence of safety hardware and home health monitoring is expected to influence premium chrome grab bar designs by 2026, particularly in high-end smart homes and assisted living environments.

In summary, the 2026 market for chrome grab bars is defined by convergence—between safety and design, aging-in-place needs and universal accessibility, and traditional hardware with smart home integration. As consumer expectations evolve, chrome remains a leading finish due to its timeless appeal, performance, and adaptability across diverse market segments.

Common Pitfalls Sourcing Chrome Grab Bars (Quality, IP)

When sourcing chrome grab bars—especially for commercial or healthcare applications—buyers often encounter challenges related to product quality, material integrity, and intellectual property (IP) concerns. Avoiding these pitfalls is essential to ensure safety, compliance, and long-term value. Below are key issues to watch for:

1. Substandard Chrome Plating Quality

One of the most common quality issues is poor chrome plating. Low-quality plating may appear shiny initially but can quickly tarnish, chip, or corrode—especially in humid environments like bathrooms. Look for grab bars with multi-layer plating (e.g., copper-nickel-chrome) and compliance with standards like ASTM B456 to ensure durability.

2. Inadequate Structural Strength

Not all grab bars are built to support required loads. Cheaply sourced products may use thin-wall tubing or weak mounting hardware, failing under stress. Ensure products meet ANSI A117.1 and ICC A117.1 standards for load capacity (typically 250+ lbs) and are tested for pull-out strength.

3. Misrepresentation of Material Composition

Some suppliers claim their grab bars are “solid brass” or “stainless steel” when they are actually made from inferior materials like zinc alloy or plastic with chrome plating. Always request material certifications and consider third-party testing to verify claims.

4. Lack of Compliance with Safety and Accessibility Codes

Grab bars must conform to ADA (Americans with Disabilities Act) and local building codes. Imported or non-certified products may not meet dimensional, placement, or performance requirements, leading to failed inspections or liability risks.

5. Intellectual Property (IP) Infringement Risks

Sourcing from manufacturers that copy patented designs—especially well-known brands—can expose buyers to legal action. Avoid suppliers offering “compatible” or “look-alike” versions of branded grab bars unless they have proper licensing. Conduct due diligence on design origins and request IP indemnification in contracts.

6. Inconsistent Finish and Color Matching

Chrome finishes can vary significantly between batches, especially with overseas manufacturers. This leads to visible mismatches in multi-unit installations. Request physical samples and specify tight tolerances for color and reflectivity (measured via gloss units or delta-E values).

7. Poor Welding and Assembly Quality

Weak welds or misaligned joints compromise both aesthetics and safety. Inspect sample units for smooth, consistent welds and secure base plates. Factory audits or third-party inspections (e.g., pre-shipment inspections) can help catch these issues early.

8. Inadequate or Missing Certifications

Reputable grab bars should carry independent certifications (e.g., ICC-ES, CSA, or UL). Be cautious of suppliers who cannot provide test reports or certifications, as this may indicate non-compliance with industry standards.

9. Hidden Costs from Low-Cost Suppliers

While initial pricing may seem attractive, hidden costs—such as failed inspections, product recalls, or premature replacements—can outweigh savings. Factor in total cost of ownership, including warranty, support, and replacement frequency.

10. Limited Warranty and After-Sales Support

Many low-cost suppliers offer minimal or no warranty. Ensure clear terms are provided for defects, corrosion, and mechanical failure. A strong warranty often reflects confidence in product quality.

By proactively addressing these pitfalls, buyers can source chrome grab bars that are safe, durable, code-compliant, and free from IP risks—protecting both end users and their own reputation.

Logistics & Compliance Guide for Chrome Grab Bars

This guide outlines key logistics and compliance considerations for the distribution, handling, and installation of chrome grab bars. Adhering to these standards ensures product safety, regulatory compliance, and efficient supply chain operations.

Product Specifications and Packaging

Chrome grab bars must be manufactured to meet precise dimensional, load-bearing, and material standards. Each unit should be clearly labeled with product specifications, model number, manufacturer information, and compliance markings. Packaging should provide adequate protection against scratches, corrosion, and impact during transit. Use of foam inserts, plastic wrapping, and sturdy corrugated boxes is recommended. Bulk packaging for wholesale shipments must facilitate easy handling and inventory management.

Regulatory Compliance

All chrome grab bars must comply with relevant safety and accessibility regulations, including:

– ADA (Americans with Disabilities Act) Standards: Grab bars must meet ADA height, placement, diameter, and load requirements (minimum 250 lbs radial and axial load capacity).

– ANSI A117.1: Ensures accessibility in bathing facilities; requires specific grab bar lengths, spacing, and mounting heights.

– ICC/ANSI A117.1-2017 and IBC (International Building Code): Widely adopted in construction projects to ensure universal design principles.

– ASME A112.18.1/CSA B125.1: Covers plumbing fittings and fixtures, including grab bar strength and performance.

Ensure third-party testing and certification (e.g., ICC-ES evaluation reports) are available to validate compliance.

Shipping and Distribution

Coordinate with carriers experienced in handling plumbing and bathroom fixtures to minimize transit damage. Use freight classification appropriate for plumbing fixtures (typically NMFC 100-110). For international shipments, comply with customs documentation, including commercial invoices, packing lists, and product certifications. Label packages with “Fragile,” “This Side Up,” and handling instructions. Track shipments using barcodes or RFID tags to improve inventory visibility.

Import and Export Requirements

For cross-border logistics, verify:

– HTS (Harmonized Tariff Schedule) code: Typically 8302.41.00 (stainless steel mountings) or similar, depending on material and design.

– Country-specific standards (e.g., CE marking for EU, CSA for Canada).

– Documentation: Certificates of Origin, FDA/CPSC declarations (if applicable), and test reports.

Ensure compliance with anti-dumping regulations and trade agreements affecting metal fixtures.

Installation and User Compliance

Provide detailed installation instructions with each unit, including:

– Recommended wall types (tile, drywall, concrete).

– Required fasteners and anchors (e.g., toggle bolts).

– Torque specifications for secure mounting.

Warn against installation in non-load-bearing walls without proper reinforcement. Distribute compliance checklists for contractors to ensure ADA and building code adherence.

Quality Assurance and Recalls

Maintain a traceability system using batch or serial numbers to support quality control and recall management. Monitor customer feedback and field failures. In case of non-compliance or safety issues, follow CPSC (U.S. Consumer Product Safety Commission) guidelines for reporting and initiating recalls.

Sustainability and Disposal

Adhere to environmental regulations regarding chrome plating processes (e.g., EPA standards for hexavalent chromium). Encourage recycling of packaging materials. Provide end-of-life guidance, noting that chrome-plated steel is recyclable through standard metal recovery channels.

By following this logistics and compliance framework, manufacturers, distributors, and installers can ensure chrome grab bars are delivered safely, installed correctly, and meet all regulatory requirements for accessibility and performance.

Conclusion: Sourcing Chrome Grab Bars

Sourcing chrome grab bars requires a strategic approach that balances quality, cost, compliance, and supplier reliability. After evaluating various suppliers, manufacturing processes, and market options, it is evident that selecting the right source involves more than just competitive pricing. Key factors such as material durability (e.g., solid brass or high-grade stainless steel with chrome plating), adherence to safety standards (such as ADA compliance), corrosion resistance, and long-term performance must be prioritized.

Domestic suppliers may offer faster lead times and easier communication, while international manufacturers—particularly in regions like Asia—can provide cost advantages, provided quality control measures are rigorously maintained. Establishing strong supplier relationships, conducting regular quality audits, and obtaining product samples prior to large-scale orders are essential steps in mitigating risks.

Ultimately, the best sourcing strategy for chrome grab bars integrates a lifecycle cost perspective, ensuring that initial savings do not compromise safety, durability, or customer satisfaction. By focusing on certified, reputable suppliers and maintaining clear specifications, businesses can secure reliable, high-performing grab bars that meet both regulatory requirements and end-user expectations.