The global demand for chopper parts—critical components in industries ranging from food processing to recycling and biomass—is on a steady rise, driven by increased automation and processing efficiency requirements. According to a 2023 report by Mordor Intelligence, the global industrial chopper market is projected to grow at a CAGR of 5.8% from 2023 to 2028, reaching an estimated value of USD 2.9 billion by the end of the forecast period. This growth is fueled by expanding applications in meat and vegetable processing, pharmaceuticals, and waste management, where precision and throughput are paramount. As manufacturers strive to meet stringent hygiene standards and performance demands, the role of high-quality chopper part suppliers has become increasingly vital. In this evolving landscape, certain manufacturers have emerged as leaders, combining innovation, durability, and technical expertise to dominate the supply chain. Below, we highlight the top 10 chopper part manufacturers shaping the industry through advanced engineering and reliable performance data.

Top 10 Chopper Part Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

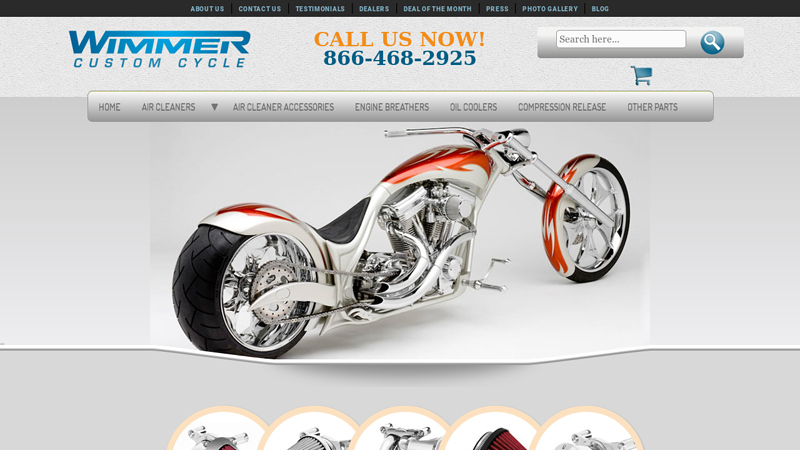

#1 Orange County Choppers

Domain Est. 2000 | Founded: 1999

Website: orangecountychoppers.com

Key Highlights: Orange County Choppers (OCC) is a world famous custom motorcycle manufacturer founded in 1999 by Paul Teutul Sr. Paul Sr. and his team of custom fabricators ……

#2 Chopper Parts

Domain Est. 2016

Website: factory47.com

Key Highlights: Free delivery over $75 Free 30-day returns…

#3 West Coast Choppers

Domain Est. 1998

#4 LA Choppers

Domain Est. 2001 | Founded: 1993

Website: lachoppers.com

Key Highlights: CRAFTED IN LOS ANGELES SINCE 1993! USA-Made • Premium Handlebars • Since 1993 USA-Made • Premium Handlebars • Since 1993. Part Finder 3000™ My Account….

#5 Hardcore Choppers

Domain Est. 2002

Website: hardcorechoppers.com

Key Highlights: We feature certified Harley HD technicians to repair, upgrade, and customize your Harley, custom chopper, Iron Horse, Big Dog, and all American-made V-twin ……

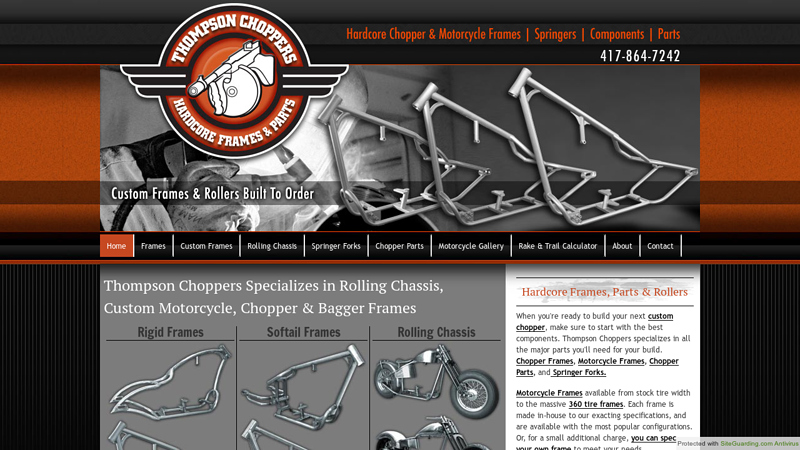

#6 Thompson Choppers

Domain Est. 2003

Website: thompsonchoppers.com

Key Highlights: Thompson Choppers specializes in all the major parts you’ll need for your build. Chopper Frames, Motorcycle Frames, Chopper Parts, and Springer Forks….

#7 Specialist in custom chopper parts

Domain Est. 2005

Website: choppershop.com

Key Highlights: We have parts for all major motorbike brands. You can even easily search for parts that perfectly match your style in the different style categories….

#8 The Chopper Gallery Inventory

Domain Est. 2008

Website: thechoppergallery.com

Key Highlights: Browse and shop Cruiser, Harley-Davidson®, Sportster®, Touring from Big Bear Choppers, Big Dog Motorcycles, BMC Choppers, Custom, Harley-Davidson, Red Neck, ……

#9 Buy Custom Chopper Parts in Bucks and Montgomery County, PA …

Domain Est. 2014

Website: wimmercustomcycle.com

Key Highlights: We supply a broad range of custom Harley Davidson parts that increase your bikes performance and enhance its look. Located in Bucks County, PA….

#10 Choppers

Website: ien.vicon.eu

Key Highlights: Vicon Flail choppers come in many models that suit different operating requirements and provide excellent results in various conditions….

Expert Sourcing Insights for Chopper Part

H2: 2026 Market Trends for Chopper Parts

The global chopper parts market is poised for significant transformation by 2026, driven by evolving consumer preferences, technological advancements, and regulatory shifts. This analysis outlines key trends expected to shape the chopper parts industry in the second half of the decade.

1. Increased Demand for Customization and Aftermarket Upgrades

By 2026, personalization remains a dominant trend in the motorcycle industry, especially among chopper enthusiasts. Riders are increasingly investing in aftermarket chopper parts—such as custom handlebars, exhaust systems, suspension kits, and bespoke seats—to enhance both aesthetics and performance. The aftermarket segment is projected to grow at a CAGR of over 6% from 2023 to 2026, fueled by a strong DIY culture and the rising popularity of chopper customization shows and online communities.

2. Adoption of Lightweight and High-Performance Materials

Manufacturers are shifting towards advanced materials such as carbon fiber, aerospace-grade aluminum, and high-strength composites to improve durability and reduce weight. These materials enhance handling and fuel efficiency, aligning with performance-oriented consumer demands. By 2026, lightweight components are expected to account for over 35% of premium chopper part sales, particularly in North America and Western Europe.

3. Electrification and Hybridization of Chopper Platforms

As electric motorcycles gain traction, traditional chopper manufacturers and aftermarket suppliers are adapting. Harley-Davidson’s LiveWire and other emerging electric chopper models are prompting demand for compatible electric-specific parts—such as battery mounts, motor controllers, and regenerative braking systems. By 2026, the electric chopper parts segment is forecasted to grow at a CAGR of approximately 12%, driven by urban emission regulations and younger, tech-savvy riders.

4. Digital Integration and Smart Components

Smart chopper parts are emerging as a niche but fast-growing category. Features such as Bluetooth-enabled instrumentation, GPS-integrated dashboards, adaptive LED lighting, and ride-mode selectors are being incorporated into aftermarket upgrades. OEMs and third-party suppliers are partnering with tech firms to develop modular smart systems, with connectivity expected to influence over 20% of mid-to-high-end chopper part purchases by 2026.

5. Sustainability and Circular Economy Practices

Environmental concerns are reshaping manufacturing and consumer behavior. By 2026, there is an increasing emphasis on sustainable production methods, recyclable materials, and remanufactured parts. Some leading suppliers are introducing take-back programs and offering refurbished components, appealing to cost-conscious and eco-aware riders. Regulatory pressures in the EU and California are accelerating this shift.

6. Growth in Emerging Markets

While North America remains the largest market for chopper parts, regions such as Southeast Asia, Latin America, and Eastern Europe are witnessing rising demand. Increasing disposable income, growing motorcycle culture, and the influence of global media are driving interest in chopper-style bikes and their accessories. Localized manufacturing and distribution hubs are expected to expand in these regions by 2026.

7. E-Commerce Dominance and Direct-to-Consumer Models

Online platforms have become the primary channel for chopper part sales. By 2026, over 60% of aftermarket transactions are expected to occur via e-commerce, with social media and influencer marketing playing a crucial role in brand engagement. Brands are leveraging augmented reality (AR) tools to allow customers to visualize parts on their bikes before purchase, enhancing the online shopping experience.

Conclusion

The 2026 chopper parts market will be characterized by innovation, personalization, and digital integration. Success for manufacturers and suppliers will depend on agility in responding to electrification trends, embracing sustainable practices, and meeting the demands of a global, digitally connected enthusiast base. Those who align with these H2 trends will be well-positioned to capture growing market opportunities.

Common Pitfalls Sourcing Chopper Parts (Quality, IP)

Sourcing chopper parts—whether for motorcycles, industrial machinery, or specialized equipment—can present significant challenges, particularly concerning quality assurance and intellectual property (IP) risks. Failing to address these pitfalls can lead to costly delays, legal disputes, product failures, or reputational damage. Below are key issues to watch for:

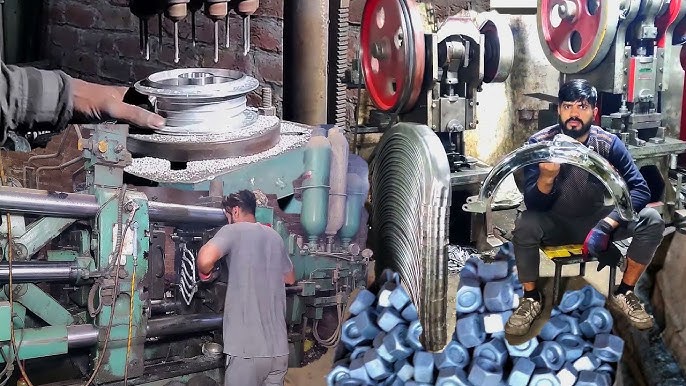

Poor Quality Control and Inconsistent Manufacturing Standards

One of the most frequent issues when sourcing chopper parts is inconsistent quality. Suppliers, especially those from regions with less stringent manufacturing oversight, may deliver parts that do not meet required specifications. This can result in:

- Dimensional inaccuracies affecting fit and function

- Use of substandard materials leading to premature failure

- Lack of proper testing or certification (e.g., ISO, ASTM)

- Inadequate surface finishes or corrosion resistance

To mitigate this, conduct thorough supplier audits, request material certifications, and implement incoming quality inspections or third-party testing.

Counterfeit or Non-OEM Parts Misrepresented as Genuine

Many suppliers offer parts labeled as “OEM equivalent” or even falsely claim to be original equipment. These counterfeit components often mimic branding and packaging but fail to meet the performance or durability standards of authentic parts. Risks include:

- Safety hazards due to part failure

- Voided warranties on end products

- Damage to brand reputation

Always verify supplier credentials, request traceability documentation, and perform authenticity checks (e.g., holograms, serial numbers).

Intellectual Property (IP) Infringement

Sourcing parts that replicate patented or trademarked designs can expose your business to legal liability. Common IP pitfalls include:

- Purchasing parts that copy protected designs, even if slightly modified

- Unknowingly importing components that violate design or utility patents

- Using logos or branding without proper licensing

To avoid IP issues, conduct patent and trademark searches, work with legal counsel to assess designs, and ensure suppliers provide IP indemnification in contracts.

Lack of Traceability and Documentation

Without proper documentation, it’s difficult to verify the origin, materials, or compliance of chopper parts. Missing or falsified paperwork increases risks related to:

- Regulatory non-compliance (e.g., customs, safety standards)

- Difficulty in recalls or root cause analysis

- Inability to prove due diligence in case of litigation

Insist on complete documentation, including certificates of conformance, material test reports, and compliance statements.

Hidden Costs from Rework, Returns, or Downtime

Low upfront pricing can be misleading if parts require rework, fail prematurely, or cause production delays. Hidden costs may include:

- Labor and logistics for replacing defective parts

- Downtime in assembly or repair operations

- Customer dissatisfaction and warranty claims

Adopt a total cost of ownership (TCO) approach when evaluating suppliers, factoring in reliability and support, not just unit price.

Inadequate Supplier Vetting and Due Diligence

Rushing into partnerships without proper due diligence increases exposure to all the above risks. Skipping steps like site visits, reference checks, or sample testing can lead to long-term problems.

Establish a formal supplier qualification process, including technical assessments, financial stability reviews, and ongoing performance monitoring.

By proactively addressing these common pitfalls, businesses can ensure they source chopper parts that are both high-quality and free from intellectual property complications.

Logistics & Compliance Guide for Chopper Part

This guide outlines the key logistics and compliance considerations for the transportation, handling, and regulatory adherence related to the “Chopper Part” throughout the supply chain.

Product Classification and Identification

Ensure the chopper part is accurately classified using standardized systems such as the Harmonized System (HS) Code. Correct classification is critical for determining import/export duties, restrictions, and regulatory requirements. Maintain detailed product specifications, including material composition, dimensions, weight, and intended use, to support accurate classification and traceability.

Export and Import Regulations

Verify export control requirements based on the chopper part’s technical specifications. If the part has potential dual-use applications (civilian and military), it may be subject to export control regimes such as the Export Administration Regulations (EAR) in the U.S. or the EU Dual-Use Regulation. Obtain necessary export licenses or authorizations prior to shipment. Similarly, confirm import regulations in the destination country, including customs documentation, tariffs, and product conformity standards.

Packaging and Labeling Requirements

Package the chopper part to prevent damage during transit, using materials that meet international shipping standards. Clearly label all packages with essential information, including part number, quantity, country of origin, handling instructions (e.g., “Fragile,” “This Side Up”), and any required regulatory markings (e.g., CE, FCC, or RoHS compliance). For controlled or hazardous materials, apply appropriate hazard labels as per IMDG, IATA, or other relevant regulations.

Transportation and Shipping

Select a transportation method (air, sea, road, or rail) based on urgency, cost, and destination. Use carriers experienced in handling industrial components and compliant with international freight standards. Ensure proper documentation accompanies each shipment, including commercial invoice, packing list, bill of lading/air waybill, and any export/import licenses. Track shipments in real time to maintain visibility and respond promptly to delays.

Regulatory Compliance and Certifications

Confirm that the chopper part complies with relevant industry and environmental regulations, such as:

– RoHS (Restriction of Hazardous Substances) – for electronic components

– REACH – for chemical substances in the EU

– ITAR/EAR – if the part is defense-related

Maintain up-to-date compliance certifications and make them available for customs or customer audits upon request.

Recordkeeping and Traceability

Maintain comprehensive records of all logistics and compliance activities for a minimum of five years (or as required by local laws). Records should include shipping documents, compliance certifications, export licenses, and quality inspection reports. Implement a traceability system to track each chopper part from manufacturing to final delivery, enabling efficient recall management if necessary.

Incident Response and Non-Compliance Management

Establish procedures for responding to logistics disruptions (e.g., customs delays, damaged goods) or compliance violations. Designate a compliance officer or team responsible for investigating incidents, notifying relevant authorities if required, and implementing corrective actions to prevent recurrence.

Training and Internal Audits

Provide regular training to logistics, procurement, and operations staff on export controls, shipping regulations, and internal compliance policies. Conduct periodic internal audits to assess adherence to this guide and identify areas for improvement in the logistics and compliance process.

By following this guide, stakeholders can ensure the efficient, legal, and secure movement of the chopper part across global supply chains.

Conclusion for Sourcing Chopper Parts:

In conclusion, sourcing chopper parts requires a strategic approach that balances quality, cost, availability, and reliability. By identifying reputable suppliers, evaluating components based on technical specifications and compatibility, and considering factors such as lead time and after-sales support, businesses can ensure optimal performance and longevity of their chopper systems. Additionally, establishing strong supply chain relationships and exploring both local and global procurement options can enhance flexibility and reduce downtime. Ultimately, effective sourcing not only supports efficient operations but also contributes to overall cost savings and reliability in chopper maintenance and assembly.