The global power tools market is experiencing robust growth, driven by increasing demand across construction, woodworking, and metalworking industries. According to Mordor Intelligence, the global power tools market was valued at USD 36.57 billion in 2023 and is projected to reach USD 50.33 billion by 2029, growing at a CAGR of 5.6% during the forecast period. A significant contributor to this expansion is the rising preference for multifunctional tools that enhance productivity and workspace efficiency—such as combination chop saw and table saw units. These hybrid tools offer precision cutting capabilities for both miter and rip cuts in a single footprint, making them increasingly popular among professionals and serious DIYers. As demand for space-saving, high-performance solutions grows, manufacturers are investing in innovative designs and durable engineering. In this evolving landscape, eight key manufacturers have emerged as leaders in developing reliable, high-quality chop saw and table saw combinations, setting industry benchmarks for performance, safety, and versatility.

Top 8 Chop Saw Table Saw Combination Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Miter Saws

Domain Est. 1995

Website: ridgid.com

Key Highlights: Easily make accurate crosscuts with a variety of blades and save valuable time on the job with RIDGID Miter Saws. Shop here.Missing: combination manufacturer…

#2 Deli Professional Mitre Saw, Heavy Duty Mitre Saw Manufacturer

Domain Est. 2021

Website: delitoolsglobal.com

Key Highlights: The professional picture framing mitre saw is ideal for trim work, molding, and framing. Table Saw: Designed for making straight cuts, rip cuts, and larger ……

#3 JET Tools Compound Miter Saws for Woodworking

Domain Est. 1995

Website: jettools.com

Key Highlights: 10-day returnsBrowse miter saws for woodworking at JET Tools. These high-quality sliding compound miter saws are ideal for making angular cuts on your next project….

#4 Benchtop & Table Saws

Domain Est. 1996

Website: skil.com

Key Highlights: SKIL brings innovation to the table with a range of powerful benchtop and table saws….

#5 Miter Saws

Domain Est. 1996

Website: deltamachinery.com

Key Highlights: Today, DELTA continues to design and manufacture high-quality stationary and benchtop tools — from table saws and band saws to jointers, planers, lathes, and ……

#6 Evolution R8MTS 8

Domain Est. 2000

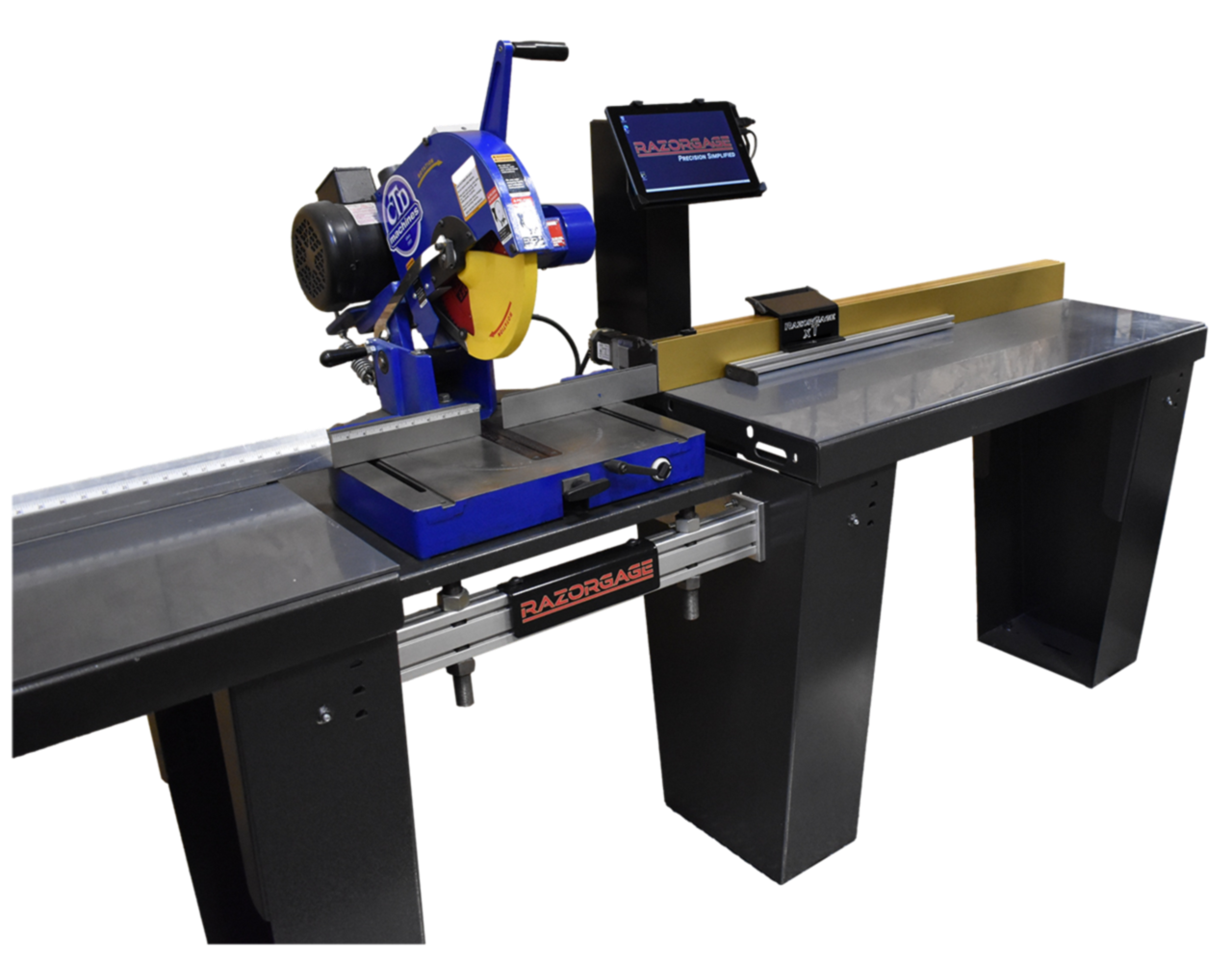

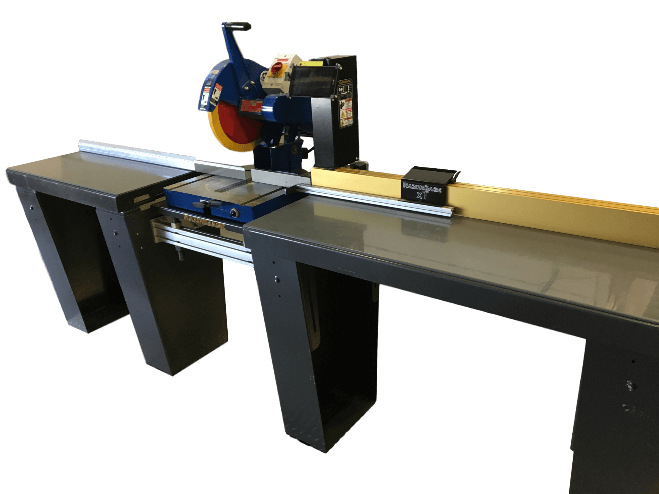

#7 PRO HEAVY DUTY GTM 12 JL Combination Saw

Domain Est. 2008

Website: bosch-professional.com

Key Highlights: 720-day returnsCombines mitre saw and table saw in one, making it versatile in many applications · Powerful 1,800 W motor makes fast progress possible, in both table and mitre ……

#8 BOSCH 0601B15001 GTM 12 JL

Domain Est. 2017

Website: misterworker.com

Key Highlights: In stock Rating 4.4 187 Table saw and mitre saw in one tool. Precise work with integrated laser. Powerful 1800 W motor for fast work progress (up to 95 mm cutting depth – mitre ….

Expert Sourcing Insights for Chop Saw Table Saw Combination

2026 Market Trends for Chop Saw and Table Saw Combination Tools

The market for combination tools—specifically those integrating chop saw (miter saw) and table saw functionalities—is poised for notable evolution by 2026. Driven by technological advancements, shifting consumer preferences, and broader industry dynamics, these hybrid tools are expected to gain increased traction among professional contractors, serious DIYers, and space-constrained workshops. Below is an analysis of key trends shaping this niche segment.

Rising Demand for Space-Efficient, Multi-Functional Tools

As urbanization grows and home workshops become smaller, demand for compact, multi-functional power tools is accelerating. The chop saw and table saw combination addresses this need by consolidating two essential cutting tools into a single footprint. By 2026, this space-saving advantage will be a major selling point, particularly in markets like North America and Western Europe where garage and workshop space is at a premium. Manufacturers are expected to further optimize ergonomics and foldable designs to enhance portability and storage.

Advancements in Safety and Automation

Safety remains a top concern in power tool design. By 2026, combination saws are anticipated to feature enhanced safety mechanisms such as improved blade guards, automatic braking systems, and integrated dust collection. Some models may incorporate smart sensors that detect hand proximity and halt the blade instantly. Additionally, automated alignment systems and digital angle readouts—borrowed from high-end standalone saws—are expected to become standard, improving precision and reducing user error.

Growth in Cordless and Hybrid Power Options

The shift toward cordless tool ecosystems will significantly impact combination saws. While current models are predominantly corded due to high power demands, advancements in lithium-ion battery technology (e.g., 60V and 80V platforms) are making cordless hybrid systems more viable. By 2026, expect to see more combination tools offering dual power options or fully cordless versions, especially from major brands like DEWALT, Milwaukee, and Makita. This will enhance job site flexibility and appeal to contractors working in remote or power-limited environments.

Expansion in Prosumer and Professional Segments

Originally marketed toward hobbyists, combination saws are gaining credibility among professional woodworkers and finish carpenters. As blade technology and motor performance improve, these tools are becoming capable of handling heavier-duty tasks. By 2026, manufacturers will likely position premium models as viable alternatives to owning two separate tools, particularly for small business owners seeking cost and space efficiency. Marketing efforts will increasingly target the prosumer segment—enthusiasts with professional-grade needs.

Integration with Smart Technology and IoT

Smart features are beginning to enter the power tool space, and combination saws are no exception. By 2026, expect integration with mobile apps for cut tracking, maintenance alerts, and usage analytics. Bluetooth-enabled models could allow users to save custom cut settings or receive real-time feedback on blade alignment and performance. While full IoT connectivity may remain limited due to cost, entry-level smart features will become differentiators in mid-to-high-end models.

Sustainability and Eco-Conscious Manufacturing

Environmental considerations are influencing tool design and materials. By 2026, manufacturers may adopt more recyclable components, reduce packaging waste, and improve energy efficiency in motors. Additionally, longer product lifespans and modular designs—allowing for easy part replacement—will appeal to eco-conscious consumers and align with broader circular economy trends in manufacturing.

Competitive Landscape and Pricing Strategies

The market remains relatively niche but is expected to see increased competition. Established brands may launch new combination models, while innovative startups could disrupt the space with novel designs. Pricing will likely stratify: entry-level models under $300 will target DIYers, while pro-grade versions exceeding $600 will compete with high-end standalone saws. Rental and subscription models may also emerge, offering access to premium tools without full ownership costs.

Regional Market Variations

North America will remain the largest market due to high DIY culture and contractor density. However, growth is anticipated in Asia-Pacific—particularly in countries like India and Vietnam—where construction activity is rising and compact tool solutions are gaining favor. European markets will emphasize safety compliance and energy efficiency, influencing product certification and design.

In conclusion, the 2026 landscape for chop saw and table saw combination tools will be defined by innovation in design, power, and connectivity. As these tools become more capable, safer, and smarter, they will transition from niche curiosities to essential solutions for a growing segment of users prioritizing efficiency, versatility, and workspace optimization.

Common Pitfalls When Sourcing a Chop Saw and Table Saw Combination (Quality & IP)

Sourcing a combined chop saw and table saw—often marketed as a multi-function or combo machine—can offer space and cost savings, but it also presents several potential pitfalls related to quality and intellectual property (IP). Being aware of these issues can help you make a more informed and reliable purchase.

Poor Build Quality and Material Durability

Many combo units, especially lower-cost or unbranded models, use substandard materials such as thin-gauge steel, plastic components in load-bearing areas, or inferior bearings and motors. This compromises durability and precision over time. Wobbly blades, inaccurate cuts, and rapid wear are common complaints. Always verify construction materials and look for independent reviews or third-party testing data.

Compromised Performance in Dual Roles

Combination saws often sacrifice performance in one or both functions. A chop saw may lack sufficient power or rigidity for clean crosscuts, while the table saw component may suffer from a smaller blade size, inadequate depth of cut, or poor fence alignment. This dual-purpose design can lead to inconsistent results, especially in professional or high-precision applications.

Lack of Safety Features and Compliance

Some combo saws, particularly imported models, may not meet regional safety standards (e.g., CE, UL, or OSHA requirements). Missing or poorly designed safety guards, absence of emergency stops, or non-compliant dust extraction can increase workplace hazards. Always confirm that the machine complies with safety regulations in your target market.

Inadequate After-Sales Support and Spare Parts Availability

Lower-tier manufacturers may offer limited customer support, short warranty periods, or no access to replacement parts. This becomes a major issue when maintenance or repairs are needed. Ensure the supplier provides clear documentation, service channels, and a parts catalog before purchasing.

Intellectual Property (IP) Infringement Risks

Many budget combo saws mimic the design and branding of well-known industrial tools, potentially violating trademarks, patents, or design rights. Sourcing such products—even unknowingly—can expose your business to legal liability, shipment seizures, or reputational damage, especially in regulated markets. Always vet suppliers for legitimate IP ownership or licensing.

Misleading Specifications and Performance Claims

Exaggerated power ratings (e.g., inflated motor horsepower), inaccurate cutting capacities, or vague technical documentation are common red flags. Some manufacturers list peak power instead of sustained output or omit critical tolerances. Request detailed specs, test reports, or product demonstrations to verify claims.

Poor Dust Collection and Workshop Integration

Effective dust extraction is often an afterthought in combo saw designs. Inadequate shrouds or incompatible ports reduce efficiency and violate air quality standards. This can impact both user health and compliance with environmental regulations.

Conclusion

While a chop saw and table saw combination may seem like a practical solution, due diligence is essential. Assess build quality, verify safety certifications, ensure IP compliance, and scrutinize performance claims to avoid costly mistakes. Prioritize reputable suppliers with transparent sourcing and strong support networks.

Logistics & Compliance Guide for Chop Saw Table Saw Combination

Product Classification and HS Code

The Chop Saw Table Saw Combination is a multi-functional power tool used for cutting wood, metal, and other materials. It typically falls under the following Harmonized System (HS) code:

– HS Code: 8467.21 or 8467.89 (Power-driven hand tools, circular saws)

Accurate classification is essential for international shipping, customs clearance, and duty calculation. Confirm the applicable code based on the tool’s primary function and regional regulations.

Import/Export Regulations

- Export Controls: Check for export restrictions in the country of origin, especially if the tool contains motors or electronic components subject to dual-use regulations.

- Import Requirements: Review destination country rules, including conformity assessments, labeling, and certification needs (e.g., CE, UKCA, EAC, or CCC marks).

- Restricted Destinations: Verify that the destination country does not restrict the import of power tools or electrical equipment.

Packaging and Shipping Requirements

- Packaging Standards: Use sturdy, corrugated cardboard boxes with internal cushioning (foam or molded inserts) to prevent damage during transit.

- Labeling: Include:

- Product name and model number

- Weight and dimensions (gross and net)

- Handling symbols (e.g., “Fragile,” “This Side Up”)

- Manufacturer and importer details

- Shipping Modes: Suitable for air, sea, or land freight. For air transport, ensure compliance with IATA regulations regarding batteries (if applicable) and motor components.

Safety and Compliance Certifications

Ensure the product meets the following regional safety standards:

– CE Marking (EU): Complies with Machinery Directive 2006/42/EC and Low Voltage Directive 2014/35/EU.

– UKCA Marking (UK): Required for sales in Great Britain (post-Brexit).

– UL/CSA Certification (North America): Required for sale in the U.S. and Canada. Must meet ANSI and OSHA safety standards.

– Other Certifications: PSE (Japan), KC (South Korea), CCC (China), as applicable.

Documentation Requirements

Prepare and retain the following documents for customs and compliance:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Product Test Reports and Compliance Certificates (e.g., CE, UL)

– Risk Assessment and Declaration of Conformity (DoC)

Environmental and Disposal Regulations

- RoHS Compliance: Ensure the product complies with RoHS directives (EU 2011/65/EU) limiting hazardous substances (lead, cadmium, etc.).

- WEEE Directive (EU): Provide information on proper end-of-life disposal and recycling. Register with national WEEE authorities if selling in the EU.

- Battery Regulations: If the tool includes a rechargeable battery, comply with local battery disposal and labeling laws (e.g., EU Battery Directive).

Product Labeling and User Instructions

- Mandatory Labels: Include voltage, frequency, power rating, model number, serial number, and safety warnings.

- Language Requirements: User manuals and safety instructions must be provided in the official language(s) of the destination country.

- Safety Symbols: Use ISO-standard safety pictograms for warnings (e.g., blade hazard, electric shock).

Warranty and After-Sales Compliance

- Provide a minimum warranty period as required by local consumer laws (e.g., 2 years in the EU).

- Maintain service and spare parts availability in key markets.

- Comply with right-to-repair regulations where applicable.

Regulatory Updates and Monitoring

- Monitor changes in trade agreements, tariffs, and product safety regulations.

- Subscribe to updates from customs authorities and regulatory bodies (e.g., EU NANDO, U.S. CPSC).

- Conduct periodic compliance audits of supply chain partners and product specifications.

By adhering to this logistics and compliance guide, businesses can ensure smooth international distribution and legal operation of Chop Saw Table Saw Combination units across global markets.

Conclusion: Sourcing a Chop Saw and Table Saw Combination

After evaluating various options for sourcing a combination chop saw and table saw, it is evident that this dual-function tool offers a practical and space-efficient solution for both hobbyists and professionals seeking versatility in their woodworking or metalworking operations. Combining the precision of a miter (chop) saw with the linear cutting capability of a table saw in a single unit enhances productivity, reduces equipment footprint, and can lead to cost savings compared to purchasing two separate machines.

When sourcing such a combination tool, factors such as build quality, safety features, motor power, cutting capacity, brand reputation, and after-sales support should be carefully considered. While standalone chop and table saws may offer superior performance in their individual functions, combination units provide a balanced compromise—ideal for small workshops, job sites, or users with budget and space constraints.

Ultimately, sourcing a reputable model from a trusted manufacturer—whether new or certified pre-owned—ensures reliability, precision, and long-term value. With proper maintenance and safe operation, a well-chosen chop saw and table saw combination can serve as a cornerstone tool for a wide range of cutting tasks, making it a smart investment for efficient and versatile workshop functionality.