The global packaging materials market is undergoing rapid transformation, driven by rising demand for sustainable, cost-effective, and lightweight solutions across industries such as e-commerce, consumer goods, and logistics. According to Mordor Intelligence, the global cardboard and paper packaging market is projected to grow at a CAGR of over 4.5% from 2023 to 2028, reaching a valuation of more than USD 500 billion by the end of the forecast period. A key driver behind this expansion is the increasing preference for recyclable materials like cardboard and chipboard, especially as environmental regulations tighten and corporate sustainability goals intensify.

Within this growing market, the distinction between chipboard and cardboard—two widely used paper-based materials—has become increasingly significant for manufacturers and buyers alike. While both offer eco-friendly profiles and structural versatility, their applications, durability, and production methods differ substantively, influencing sourcing decisions across supply chains. As demand surges, particularly in emerging economies and digital retail sectors, leading manufacturers are innovating in terms of material composition, production efficiency, and environmental impact.

This evolving landscape has given rise to a competitive field of top-tier producers who dominate both regional and global supply networks. From multinational corporations with integrated recycling systems to specialized regional players focusing on high-performance grades, the industry reflects a diverse ecosystem shaping the future of sustainable packaging. Below, we explore the top nine chipboard and cardboard manufacturers driving innovation, scaling output, and setting sustainability benchmarks in a market poised for continued growth.

Top 9 Chipboard Vs Cardboard Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Chipboard vs Cardboard

Domain Est. 2004

Website: feeds.gmsindustries.com

Key Highlights: Chipboard is a single-layer, dense paperboard used for retail packaging. Cardboard, often corrugated, has multiple layers and provides more ……

#2 Chipboard vs Cardboard

Domain Est. 1995

Website: arka.com

Key Highlights: This analysis dissects the features of cardboard and chipboard to determine the best packaging choice for various purposes….

#3 Corrugated Cardboard vs. Chipboard

Domain Est. 1996

Website: americanpaper.com

Key Highlights: Chipboard is a single-ply paperboard made from recycled paper fibers, typically thinner and more flexible. Cardboard is a broader term often used to describe ……

#4 4 Types of Paperboard

Domain Est. 1996

Website: paperbox.org

Key Highlights: Non-Bending Chipboard. Manufactured from recycled newsprint and old corrugated, this thick paperboard grade is often used as the “body stock” ……

#5 Sustainable Advantage

Domain Est. 1998

Website: adcomfg.com

Key Highlights: Cardboard and Chipboard Offer Stronger Packaging Solutions. Options like corrugated packaging, chipboard, and paper tape packaging for your products have never ……

#6 4 Reasons to Choose Chipboard Instead of Corrugated Cardboard

Domain Est. 2000

Website: badgerpaperboard.com

Key Highlights: Chipboard is more cost-effective than corrugated. And that’s not only for the reasons mentioned above, but it’s cheaper overall….

#7 Cardboard vs Chipboard

Domain Est. 2004

Website: hammondpaper.com

Key Highlights: Chipboard and cardboard are both types of paperboard, but chipboard is generally considered better than cardboard for slip sheets in certain applications….

#8 Chipboard vs. Corrugated Cardboard For Packaging

Domain Est. 2006

Website: customboxesnow.com

Key Highlights: Chipboard packaging is often more affordable, requiring less material and processing. Corrugated cardboard boxes have higher upfront costs but are reusable….

#9 Chipboard Vs Corrugated Cardboard

Domain Est. 2022

Website: boxagency.co

Key Highlights: A chipboard is usually cheaper to make because it uses less material and is simpler to create. It is a good choice for brands that want to keep ……

Expert Sourcing Insights for Chipboard Vs Cardboard

2026 Market Trends: Chipboard vs Cardboard

Market Overview

As global demand for sustainable packaging solutions continues to grow, the competition between chipboard and cardboard is expected to intensify by 2026. Both materials are widely used across industries such as e-commerce, food and beverage, consumer goods, and electronics, but their differing properties, production costs, and environmental footprints are shaping market dynamics. This analysis explores key trends influencing the chipboard and cardboard markets leading up to 2026.

Rising Sustainability Pressures

Environmental regulations and consumer preferences are driving a shift toward recyclable and biodegradable materials. By 2026, cardboard—particularly corrugated cardboard—is anticipated to maintain a dominant position due to its high recyclability rate (over 90% in regions like North America and Europe) and lower carbon footprint during production. In contrast, chipboard, made from recycled paper waste and often containing binders, faces challenges in recycling due to potential contamination and lower fiber quality. As brands commit to net-zero goals and circular economy models, cardboard is likely to be favored in eco-conscious supply chains.

E-Commerce Expansion Driving Demand

The continued growth of e-commerce is a major driver for packaging materials. By 2026, global e-commerce sales are projected to exceed $8 trillion, fueling demand for durable, lightweight, and protective packaging. Corrugated cardboard excels in shipping applications due to its strength, cushioning properties, and ease of customization. Chipboard, being less rigid and moisture-resistant, is typically used for lightweight retail packaging (e.g., cereal boxes, notepads) but is less suited for direct-to-consumer shipping. As a result, cardboard is expected to capture a larger share of the e-commerce packaging market.

Cost and Production Efficiency

Chipboard generally has a lower production cost compared to corrugated cardboard, as it requires less energy and simpler manufacturing processes. This cost advantage makes chipboard attractive for short-run, low-cost packaging in industries like cosmetics and small electronics. However, advancements in automated corrugation and recycled fiber processing are reducing the price gap. By 2026, economies of scale and innovations in cardboard production are expected to enhance cost competitiveness, potentially eroding chipboard’s price advantage in certain segments.

Technological and Material Innovations

Both materials are benefiting from R&D investments aimed at improving performance and sustainability. In the cardboard sector, developments include water-resistant coatings without PFAS, enhanced printability, and smart packaging integration (e.g., QR codes, RFID). Chipboard manufacturers are exploring bio-based binders and denser fiber formulations to improve strength and moisture resistance. However, cardboard’s adaptability to automation and digital printing gives it an edge in high-volume, branded applications.

Regional Market Dynamics

In emerging markets, chipboard may retain a stronger foothold due to lower infrastructure for recycling and cost sensitivity. However, in regions with strict environmental regulations—such as the EU and North America—cardboard is expected to dominate due to regulatory support for recyclable materials and extended producer responsibility (EPR) schemes. Asia-Pacific, particularly China and India, will see rising demand for both materials, but government sustainability initiatives are likely to favor cardboard expansion.

Conclusion

By 2026, corrugated cardboard is poised to outperform chipboard in overall market growth, driven by e-commerce, sustainability mandates, and technological advancements. While chipboard will maintain relevance in niche, low-cost packaging applications, its limitations in durability, recyclability, and scalability may restrict broader adoption. Companies investing in packaging solutions should prioritize cardboard for forward-looking, sustainable strategies, while evaluating chipboard for specific, cost-driven use cases.

Common Pitfalls Sourcing Chipboard vs Cardboard (Quality, IP)

When sourcing packaging or structural materials, confusion between chipboard and cardboard can lead to significant quality and intellectual property (IP) issues. Understanding the key differences and associated risks is crucial for making informed procurement decisions.

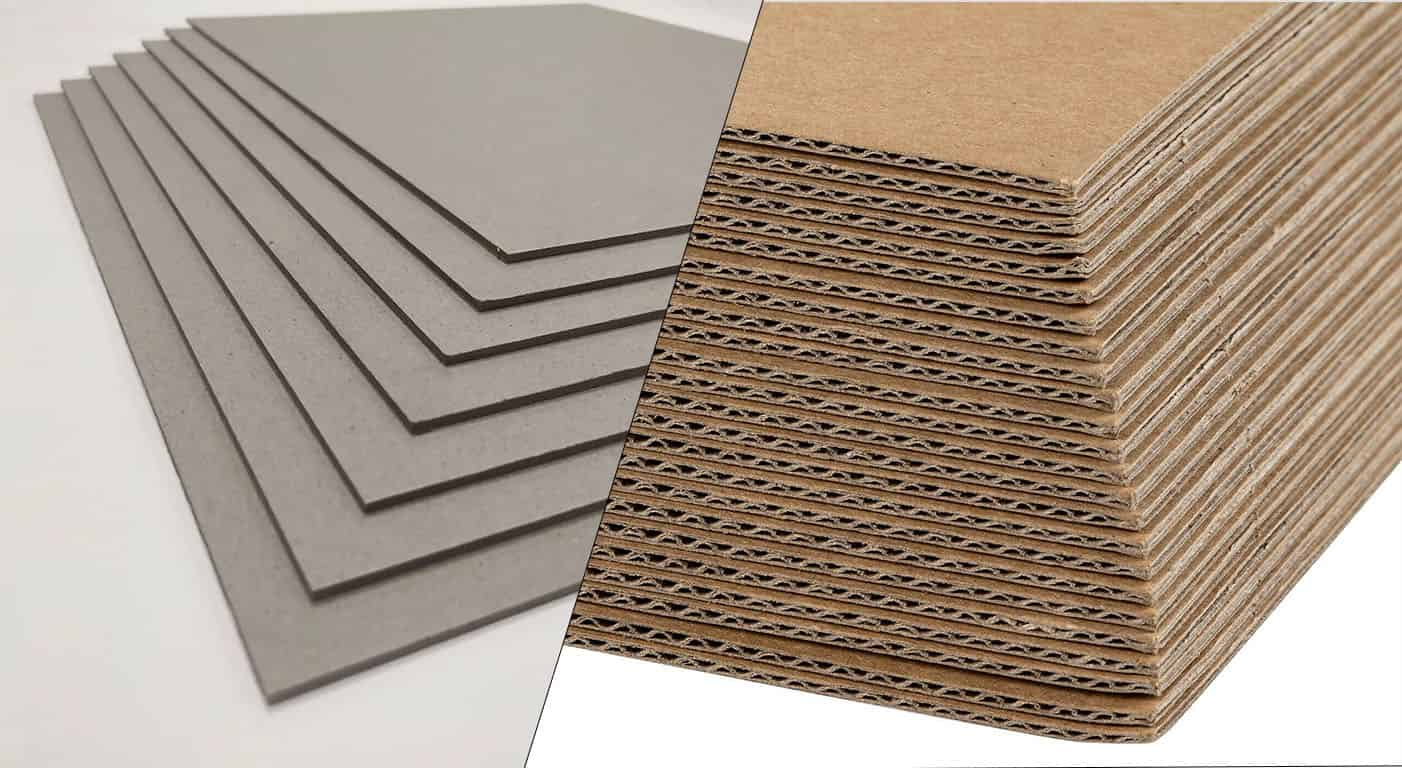

Misidentifying Material Specifications

One of the most common pitfalls is incorrectly identifying chipboard and cardboard due to overlapping terminology. Chipboard is a dense, paper-based material made from recycled paper fibers, typically used in rigid boxes, binders, or backing boards. Cardboard, often referring to corrugated fiberboard, consists of a fluted corrugated sheet sandwiched between linerboards, designed for durability and shock absorption in shipping. Sourcing the wrong material can result in inadequate protection, structural failure, or poor fit for end-use applications.

Overlooking Performance Requirements

Chipboard lacks the cushioning and stacking strength of corrugated cardboard, making it unsuitable for shipping heavy or fragile items. Conversely, using corrugated cardboard for applications requiring a smooth, rigid surface (e.g., retail packaging inserts) may result in excess bulk or poor print quality. Failing to match material properties to functional needs leads to product damage, increased shipping costs, or customer dissatisfaction.

Assuming Equivalent Print and Finish Quality

Chipboard typically offers a smoother surface than corrugated cardboard, making it better suited for high-quality printing and premium finishes. Corrugated cardboard, especially with coarse fluting, may cause print distortion or require additional liners for professional results. Sourcing the wrong material can compromise branding efforts and reduce perceived product value.

Ignoring Intellectual Property and Design Rights

When sourcing custom-designed packaging, particularly for retail or branded products, using chipboard or cardboard designs that mimic patented or trademarked structures can lead to IP infringement. For example, replicating a unique folding carton design protected by design patents—even if made from different materials—can result in legal disputes. Buyers must verify that their packaging designs do not violate existing IP rights, regardless of the base material used.

Relying on Vague Supplier Descriptions

Suppliers may use terms like “cardboard” or “paperboard” loosely, leading to miscommunication. Without clear specifications—such as material type (solid bleached board, recycled chipboard, E-flute corrugated), caliper (thickness), weight (gsm or points), and performance standards—buyers risk receiving substandard or incorrect materials. Always request technical data sheets and physical samples before bulk ordering.

Neglecting Sustainability Claims and Certifications

Both chipboard and cardboard are often marketed as eco-friendly, but sourcing decisions must verify these claims. Recycled content, FSC or PEFC certifications, and compostability vary significantly between products. Misrepresenting sustainability credentials can damage brand reputation and lead to regulatory scrutiny, especially in markets with strict environmental labeling laws.

Conclusion

To avoid these pitfalls, clearly define material requirements upfront, distinguish between chipboard and corrugated cardboard based on application needs, validate supplier specifications, and conduct due diligence on IP and sustainability claims. Proper sourcing ensures product integrity, legal compliance, and brand consistency.

Logistics & Compliance Guide: Chipboard vs. Cardboard

When selecting packaging materials for shipping, storage, or retail display, understanding the differences between chipboard and cardboard is critical for ensuring logistical efficiency and regulatory compliance. This guide outlines key considerations for both materials in terms of handling, transportation, environmental regulations, and industry standards.

Material Definitions and Structural Differences

Chipboard is a dense, paper-based material made from recycled paper fibers. It is often gray or brown, lacks structural strength, and is typically used for lightweight packaging such as cereal boxes, notepads, or backing in packaging.

Cardboard, more accurately referred to as corrugated cardboard, consists of a fluted corrugated sheet sandwiched between two flat linerboards. This structure provides strength, cushioning, and durability, making it ideal for shipping boxes and protective packaging.

Understanding these structural differences is essential for determining appropriate use cases and load-bearing capabilities in logistics operations.

Load Capacity and Durability

Chipboard offers minimal load-bearing capacity and is unsuitable for heavy or fragile items. It is prone to bending, warping, and moisture damage, making it inappropriate for long-distance or multi-stage shipping.

Corrugated cardboard, by contrast, is engineered for strength. Its fluted design provides excellent compression resistance and shock absorption. Depending on the flute type (e.g., A, B, C, E, or F), cardboard can support varying weights and stacking loads—critical for warehouse stacking and transport safety.

Logistics planners must choose corrugated cardboard for any shipment involving weight, stacking, or variable environmental conditions.

Moisture and Environmental Resistance

Chipboard is highly susceptible to moisture, which can cause warping, weakening, and mold growth—posing risks during transit in humid or wet conditions.

Corrugated cardboard performs better but can still degrade when exposed to prolonged moisture. However, moisture-resistant coatings or wax treatments can enhance its performance. For international shipping or outdoor storage, moisture barriers and proper packaging protocols are advised.

Compliance with shipping standards (e.g., ISTA, ASTM) often requires moisture resistance testing, especially for products transported in non-climate-controlled environments.

Sustainability and Recycling Compliance

Both chipboard and cardboard are recyclable and made from renewable or recycled materials, supporting sustainability goals.

Chipboard is typically made from 100% recycled content, contributing to waste reduction but often cannot be recycled again after use due to fiber degradation.

Corrugated cardboard has a high recycling rate (over 90% in the U.S., per the EPA) and is widely accepted in municipal recycling programs. Many regions have regulations requiring or incentivizing the use of recyclable packaging, such as Extended Producer Responsibility (EPR) laws in the EU and Canada.

Ensure packaging is labeled with proper recycling symbols (e.g., Mobius loop) and avoid non-recyclable coatings or laminates to maintain compliance.

International Shipping and Regulatory Standards

For cross-border shipments, compliance with international packaging regulations is crucial. ISPM 15, for instance, applies to wood packaging but indirectly influences cardboard use by promoting non-wood alternatives.

Corrugated cardboard is exempt from ISPM 15, making it a preferred material for export packaging. However, certain countries may require phytosanitary certificates or restrict the use of recycled materials if contaminants are suspected.

Chipboard’s lack of structural integrity makes it unsuitable for most export applications, especially for heavy or valuable goods.

Always verify destination country requirements regarding material sourcing, labeling, and chemical treatments (e.g., PFAS restrictions in food-contact packaging).

Cost and Storage Efficiency

Chipboard is low-cost and lightweight, reducing initial material expenses. However, its fragility may increase damage-related losses, handling labor, and returns—negatively impacting total logistics cost.

Corrugated cardboard has a higher upfront cost but offers superior protection, reducing product loss and improving supply chain reliability. It is also easy to assemble, store flat, and customize—enhancing warehouse efficiency.

From a total cost of ownership perspective, cardboard often proves more economical for logistics-heavy operations.

Best Practices for Selection and Use

- Use chipboard for lightweight, non-shipped items such as retail boxes, displays, or internal packaging where structural strength is not required.

- Use corrugated cardboard for all shipping, storage, and protective packaging applications.

- Ensure all packaging is clearly labeled with contents, handling instructions (e.g., “This Side Up”), and compliance marks.

- Train staff on proper boxing techniques, including correct sealing and cushioning.

- Regularly audit packaging performance to minimize waste and improve compliance.

By aligning material choice with logistical demands and regulatory frameworks, businesses can enhance efficiency, reduce risk, and support environmental compliance.

In conclusion, the choice between sourcing chipboard and cardboard depends on the specific requirements of the application, including strength, durability, cost, and sustainability goals. Chipboard, being denser and more rigid, is better suited for structural packaging, backing materials, and products requiring added stiffness. However, it is less eco-friendly due to its composition and lower recyclability compared to cardboard. On the other hand, cardboard—particularly corrugated cardboard—offers superior strength-to-weight ratio, excellent cushioning properties, and high recyclability, making it ideal for shipping, e-commerce, and protective packaging. While cardboard may come at a slightly higher cost, its environmental benefits and versatility often justify the investment. Ultimately, businesses should evaluate their packaging needs, environmental commitments, and supply chain logistics when deciding between chipboard and cardboard, aiming for a balance of performance, sustainability, and cost-efficiency.