The global chipboard cabinet market is experiencing steady expansion, driven by rising demand for cost-effective, durable, and eco-friendly furniture solutions in both residential and commercial sectors. According to Grand View Research, the global particleboard (chipboard) market size was valued at USD 39.7 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is fueled by the increasing adoption of engineered wood products in kitchen cabinetry and modular furniture, especially across emerging economies in Asia-Pacific and Latin America. Additionally, advancements in manufacturing technologies and the integration of sustainable production practices are enhancing the performance and aesthetic appeal of chipboard products. As demand continues to rise, a select group of manufacturers have emerged as leaders in innovation, scalability, and product quality—setting new benchmarks in the industry. Here, we spotlight the top 8 chipboard cabinet manufacturers shaping the market today.

Top 8 Chipboard Cabinet Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Boise Cascade Wood Products Building Materials

Domain Est. 1994

Website: bc.com

Key Highlights: We make and deliver building materials for the residential and commercial construction industry. As a North American producer of engineered wood products, ……

#2 Mohawk Industries, Inc.

Domain Est. 1996

Website: mohawkind.com

Key Highlights: A broad range of chipboard, MDF, melamine-faced, HPL panels and mezzanine flooring solutions for construction, interior design, furniture, cabinetry and ……

#3 Melamine Faced Chipboard Cabinet

Domain Est. 2017

Website: reboncabinets.com

Key Highlights: We are professional cabinetry manufacturer and mainly supply standard/customized kitchen cabinet, bathroom cabinet and bedroom wardrobe and other interior ……

#4 Lumber, Plywood, MDF Boards

Domain Est. 1996

Website: timberproducts.com

Key Highlights: Timber Products has the expertise to provide top quality lumber, plywood, MDF boards and more! 100+ years of industry leadership!…

#5 Custom, Quality Made Cabinets

Domain Est. 1999

Website: kochandco.com

Key Highlights: View Koch & Company’s custom, quality made classic & Imperial cabinets and our express cabinet styles. Contact us today to learn more about our cabinets!…

#6 Al

Domain Est. 2009

Website: alnoormdf.com

Key Highlights: Al-Noor Lasani is the market leader and pioneer of decorative laminate surfaces in Pakistan. From home to commercial décor, from kitchens to furniture….

#7 Chipboard /Particleboard

Domain Est. 2012

Website: chantawood.com

Key Highlights: Chipboard, also known as particle board, is an affordable and versatile material perfect for furniture, cabinetry, and flooring….

#8 Chipboard Cabinet DIXION

Website: dixion.de

Key Highlights: Main structure made of chipboard · Removable ergonomic drawer system with one hand · 360 ° swivel castors with cross lock · 1 drawer and cabinet made of chipboard ……

Expert Sourcing Insights for Chipboard Cabinet

H2: 2026 Market Trends for Chipboard Cabinets

The chipboard cabinet market is poised for significant transformation by 2026, driven by evolving consumer preferences, advancements in manufacturing technologies, sustainability demands, and regional economic shifts. As a cost-effective and widely used material in furniture and cabinetry, chipboard (also known as particleboard) continues to adapt to market dynamics, particularly in residential, commercial, and modular interior design sectors.

-

Rising Demand for Sustainable and Eco-Friendly Materials

A key trend shaping the 2026 chipboard cabinet market is the growing emphasis on sustainability. Consumers and regulatory bodies are increasingly favoring eco-conscious products, pushing manufacturers to adopt formaldehyde-free adhesives, recycled wood content, and low-VOC (volatile organic compound) finishes. Brands that align with ECOLOGO, FSC (Forest Stewardship Council), or CARB (California Air Resources Board) Phase 3 standards are expected to gain a competitive advantage. -

Growth in Ready-to-Assemble (RTA) and Modular Furniture

The popularity of flat-pack, ready-to-assemble cabinets is accelerating, especially in urban markets where space efficiency and affordability are paramount. By 2026, the RTA segment is projected to dominate the chipboard cabinet market, fueled by e-commerce expansion and DIY culture. Improved design engineering will enhance the durability and aesthetics of RTA chipboard cabinets, closing the quality gap with solid wood alternatives. -

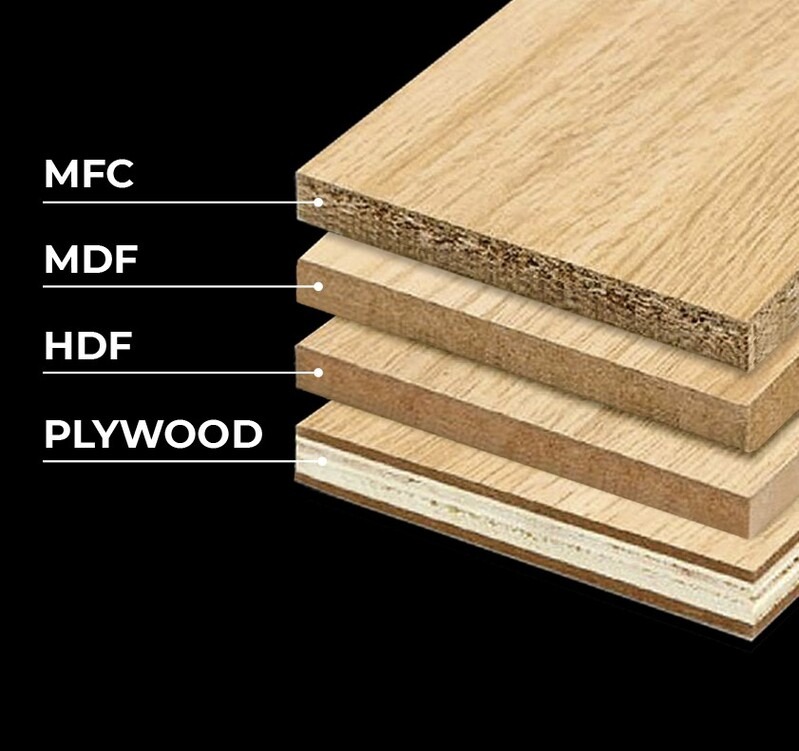

Technological Advancements in Surface Finishing

Innovations in laminates, melamine coatings, and digital printing are enabling chipboard cabinets to mimic high-end materials like wood grain, marble, or concrete. High-pressure laminate (HPL) and thermally fused laminate (TFL) surfaces are gaining traction for their durability and design flexibility. These upgrades allow chipboard to compete in mid-to-premium market segments, expanding its application beyond budget furniture. -

Regional Market Dynamics

Asia-Pacific, particularly China and India, will remain the largest producers and consumers of chipboard cabinets due to rapid urbanization and rising home ownership. Europe will emphasize sustainability and circular economy models, supporting the growth of recyclable and biodegradable chipboard solutions. North America will likely see steady growth driven by kitchen and bathroom remodels, with increased demand for moisture-resistant chipboard variants in humid climates. -

Impact of Supply Chain and Raw Material Costs

Fluctuations in wood supply, energy prices, and logistics will continue to affect chipboard production costs. By 2026, manufacturers are expected to invest in localized supply chains and alternative raw materials (e.g., agricultural residues) to mitigate risks and reduce carbon footprints. -

Integration with Smart Home Ecosystems

While less common in chipboard than in higher-end materials, some manufacturers are beginning to integrate smart features—such as sensor-activated lighting, touch-to-open mechanisms, and modular interiors—into chipboard cabinetry, especially in kitchen and office settings. This trend will likely grow as smart home adoption increases globally.

Conclusion

By 2026, the chipboard cabinet market will be characterized by innovation, sustainability, and affordability. While traditionally viewed as a low-cost alternative, chipboard is evolving into a versatile and design-forward material, supported by technological and environmental advancements. Companies that prioritize green manufacturing, design customization, and digital distribution channels are best positioned to lead in this dynamic market landscape.

Common Pitfalls Sourcing Chipboard Cabinets (Quality and IP)

Sourcing chipboard cabinets can be cost-effective, but it comes with significant risks related to material quality and intellectual property (IP) infringement. Being aware of these pitfalls helps avoid substandard products and legal complications.

Poor Material Quality and Construction

One of the most frequent issues is receiving cabinets made from low-grade chipboard. This includes using undersized panels, inadequate moisture resistance (especially critical in kitchens and bathrooms), and poor edge banding that easily peels or chips. Inferior adhesives and hardware further compromise durability, leading to sagging shelves, loose hinges, and shortened lifespan.

Misrepresentation of Moisture Resistance

Suppliers may claim their chipboard is moisture-resistant or suitable for humid environments, but without proper certification (like E1 or P2 formaldehyde emission standards and moisture-swelling test results), the material may swell or delaminate when exposed to moisture. This is particularly problematic in regions with high humidity or in wet areas.

Inconsistent Finish and Aesthetic Flaws

Sourced cabinets often exhibit inconsistencies in color, texture, and finish quality. Batch variations, visible seams, poor lamination, or surface imperfections can make installations look unprofessional. These flaws are hard to detect from samples and only become apparent upon large-scale delivery.

Lack of Compliance with Environmental and Safety Standards

Many chipboard products, especially from less-regulated manufacturers, may exceed allowable formaldehyde emissions or use adhesives containing hazardous substances. Failure to comply with standards such as CARB (California Air Resources Board) or FSC (Forest Stewardship Council) certification poses health risks and can lead to rejection by customs or retailers.

Intellectual Property (IP) Infringement

A major legal risk involves sourcing cabinets that copy patented designs, brand logos, or registered furniture styles. Some suppliers reproduce high-end designs without authorization, offering them at lower prices. Purchasing such items—even unknowingly—can expose buyers to legal action, product seizures, or reputational damage, especially in markets with strong IP enforcement.

Inadequate Documentation and Traceability

Suppliers may fail to provide necessary documentation, such as material safety data sheets (MSDS), test reports, or proof of IP clearance. This lack of transparency makes it difficult to verify claims about quality or legality and complicates compliance with import regulations.

Hidden Costs from Rework and Returns

Initially low prices can be misleading. Poor quality often leads to high rates of rejection, on-site modifications, or customer returns. These hidden costs, combined with project delays, can outweigh the initial savings, particularly in commercial or large-scale residential projects.

Limited After-Sales Support and Accountability

When issues arise, many overseas or low-cost suppliers offer minimal warranty coverage or customer service. Tracking responsibility for defective materials or IP violations becomes challenging, especially if the supply chain involves multiple intermediaries.

By carefully vetting suppliers, demanding certifications, conducting factory audits, and using legally reviewed contracts, buyers can mitigate these risks and ensure a reliable, compliant sourcing process.

Logistics & Compliance Guide for Chipboard Cabinet

This guide outlines the essential logistics considerations and compliance requirements for the safe, efficient, and legal transport and handling of chipboard cabinets. Adherence to these guidelines ensures product integrity, regulatory compliance, and operational efficiency.

Product Specifications and Handling Requirements

Chipboard cabinets are typically large, flat-pack furniture items made from engineered wood (particleboard). They are susceptible to moisture, impact, and improper stacking. Key handling requirements include:

- Moisture Protection: Store and transport in dry conditions. Avoid exposure to rain or high humidity. Use moisture-resistant packaging or pallet covers.

- Edge and Surface Protection: Use corner protectors and edge banding to prevent chipping and abrasion during handling and transit.

- Load Stability: Secure cabinets on pallets using stretch wrap or strapping. Do not exceed recommended stacking heights to prevent crushing.

- Orientation: Mark packages with “This Way Up” indicators to prevent damage to surfaces and components.

Packaging and Palletization Standards

Proper packaging ensures product safety during shipment and storage:

- Packaging Materials: Use strong corrugated cardboard boxes designed for flat-pack furniture. Include internal dividers or foam inserts to prevent movement.

- Pallet Dimensions: Standard EUR/ISO pallets (e.g., 1200mm x 800mm or 48” x 40”) are recommended. Ensure even weight distribution.

- Weight Limits: Adhere to maximum pallet weight limits (typically 1,000–1,500 kg depending on region and carrier). Clearly label total weight.

- Labeling: Include product ID, quantity, weight, handling instructions (e.g., “Fragile,” “Keep Dry”), and barcodes for traceability.

Transportation and Freight Management

Select appropriate transport modes and carriers to ensure timely and safe delivery:

- Mode of Transport: Road freight is most common for regional distribution. For international shipments, consider multimodal options (road-sea or road-rail).

- Vehicle Requirements: Use enclosed, dry trailers or containers. Ensure adequate vehicle height and loading bay compatibility.

- Loading and Unloading: Use forklifts or pallet jacks with appropriate capacity. Train staff in safe handling practices to avoid product damage.

- Route Planning: Optimize routes to minimize transit time and avoid extreme weather conditions.

Regulatory and Compliance Requirements

Compliance with international and regional regulations is critical for legal shipment and environmental responsibility:

- ISPM 15 (Wood Packaging): If wood pallets or dunnage are used, they must be heat-treated and marked with the ISPM 15 stamp for international shipments.

- REACH & RoHS (EU): Ensure adhesives, finishes, and any electronic components (e.g., LED lighting in cabinets) comply with EU chemical and hazardous substance regulations.

- CARB & TSCA Title VI (USA): Verify that chipboard materials meet formaldehyde emission standards for composite wood products.

- Customs Documentation: Provide accurate commercial invoices, packing lists, and certificates of origin. Declare Harmonized System (HS) code 9403.60 for furniture of wood.

- Environmental Compliance: Follow local waste and recycling regulations for packaging materials. Offer take-back or recycling programs where applicable.

Storage and Warehouse Best Practices

Maintain product quality during storage with the following protocols:

- Storage Conditions: Keep in a dry, temperature-controlled environment (ideal: 15–25°C, 40–60% RH). Avoid direct sunlight.

- Stacking: Limit stacking to 2–3 pallets high unless racking systems are designed for higher loads. Use rack protectors.

- Inventory Management: Implement FIFO (First In, First Out) rotation to reduce the risk of material degradation over time.

- Pest Control: Conduct regular inspections to prevent infestations that could damage packaging or materials.

Sustainability and End-of-Life Considerations

Promote environmental responsibility throughout the product lifecycle:

- Recyclable Packaging: Use recyclable cardboard, paper fillers, and biodegradable stretch film.

- Chipboard Recyclability: Inform customers that chipboard can be recycled through appropriate wood waste channels.

- Carbon Footprint Reduction: Optimize load efficiency, use fuel-efficient vehicles, and consider carbon offset programs for long-haul transport.

By following this guide, businesses can ensure the safe, compliant, and sustainable logistics of chipboard cabinets from production to delivery.

Conclusion for Sourcing Chipboard Cabinets:

Sourcing chipboard cabinets presents a cost-effective and practical solution for a wide range of residential and commercial applications. Chipboard, or particleboard, offers consistent quality, ease of manufacturing, and compatibility with various laminates and veneers, making it an ideal material for cabinetry where budget efficiency and design versatility are key priorities.

When sourcing chipboard cabinets, it is essential to prioritize suppliers who use high-quality, moisture-resistant chipboard (such as E0 or E1 formaldehyde emission graded boards) especially for environments like kitchens and bathrooms. Evaluating construction standards—including thickness, edge banding, hardware quality, and finish durability—ensures longevity and performance. Additionally, considering sustainability factors, such as FSC-certified materials and low-emission adhesives, supports environmentally responsible procurement.

By partnering with reliable manufacturers and conducting thorough quality assessments, businesses can secure chipboard cabinets that balance affordability, aesthetics, and functionality. In conclusion, with proper sourcing criteria and attention to material specifications, chipboard cabinets can deliver excellent value and meet the demands of modern interior solutions.