The global technical textiles market, which includes chino and performance-oriented cotton-blend materials, is witnessing robust growth driven by rising consumer demand for durable, versatile, and comfortable apparel. According to a 2023 report by Mordor Intelligence, the technical textiles market is projected to grow at a CAGR of 5.8% from 2023 to 2028, with performance cotton derivatives like chino fabric playing a significant role in casualwear and workwear segments. Factors such as urbanization, increasing spending on lifestyle apparel, and advancements in fabric finishing technologies are accelerating adoption across North America, Europe, and Asia-Pacific regions. As brands prioritize sustainable sourcing and performance functionality, the demand for premium chino materials has intensified—putting leading manufacturers at the forefront of innovation, scalability, and eco-conscious production. Here are the top 7 chino material manufacturers shaping the future of this evolving textile landscape.

Top 7 Chino Material Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Theory

Domain Est. 1995

Website: theory.com

Key Highlights: Out of stock Rating 4.5 (19) Produced by a leading Italian cotton mill, the fabric has a soft hand and added stretch for exceptional comfort and utility. Style #: P0804213. Fit….

#2 Chino – Cotton

Domain Est. 2000

Website: thefabricofourlives.com

Key Highlights: Chino is a durable cotton fabric which uses a steep twill construction, and is mercerized for a slight sheen. Chino has a storied past of being used for ……

#3 Men

Domain Est. 2011

#4 JOE McCOY CHINO TROUSERS

Domain Est. 2013

Website: therealmccoys.com

Key Highlights: The JOE MCCOY CHINO TROUSERS are crafted from a chino cloth that is historically associated with The United States Military Academy at West Point….

#5 The History And Benefits Of Chino Fabric

Domain Est. 2015

Website: fabriclore.com

Key Highlights: Chino fabric is a sturdy made form 100 % cotton and dyed khaki or tan colors most commonly. As the cloth itself was originally made in China ……

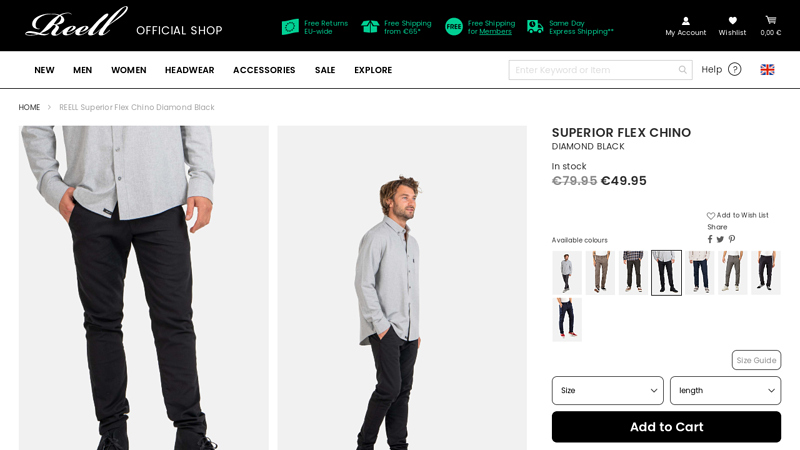

#6 REELL Superior Flex Chino Diamond Black

Domain Est. 2022

Website: reellworld.com

Key Highlights: 14-day returnsTailored for the office and the street; classic Chino details, tonal top-stitching and logo embroidery complete the clean design of this wardrobe essential….

#7 Best Mens Chinos

Website: paulbrownengland.com

Key Highlights: Rating 5.0 · Review by Mark TOur luxury mens chinos by Paul Brown are hand cut and sewn to order using the finest materials available and unlike many chino brands including Ga…

Expert Sourcing Insights for Chino Material

H2 2026 Market Trends for Chino Material

As we move into the second half of 2026, the market for Chino material—primarily a cotton-blend twill fabric known for its softness, durability, and versatility—reflects a convergence of evolving consumer preferences, sustainability demands, and advancements in textile technology. Below is an analysis of key trends shaping the Chino material market during this period.

1. Rising Demand for Sustainable and Eco-Friendly Fabrics

Environmental consciousness continues to drive innovation in the Chino material sector. Consumers and brands alike are prioritizing fabrics made from organic cotton, recycled fibers, and low-impact dyes. By H2 2026, a significant portion of Chino fabric production incorporates traceable, sustainably sourced raw materials. Certifications such as GOTS (Global Organic Textile Standard) and OEKO-TEX are increasingly expected, especially in North America and Europe.

2. Growth in Performance-Enhanced Chino Fabrics

The traditional Chino has evolved into performance-driven apparel. Blends incorporating elastane, moisture-wicking fibers, and anti-odor technologies are gaining traction. These upgraded Chino materials are popular in hybrid workwear, athleisure, and travel-friendly clothing. Brands are marketing “smart Chinos” with stretch, wrinkle resistance, and UV protection, catering to consumers seeking comfort and functionality.

3. Shift Toward Localized and Resilient Supply Chains

Geopolitical uncertainties and supply chain disruptions have prompted manufacturers to reevaluate sourcing strategies. In H2 2026, there is a noticeable shift toward regional production hubs in Southeast Asia, Latin America, and North America. This localization improves lead times, reduces carbon footprint, and enhances responsiveness to fast-changing fashion cycles.

4. Influence of Circular Fashion and Recycling Initiatives

The circular economy is gaining momentum. Textile recyclers are developing processes to reclaim cotton-polyester blends used in Chino pants, reducing landfill waste. Several major apparel brands have launched take-back programs and are incorporating recycled Chino material into new product lines—a trend expected to grow as regulations on textile waste tighten globally.

5. Digitalization and Customization in Fabric Development

Advancements in digital textile printing and on-demand manufacturing are enabling greater customization of Chino materials. Designers can now order small batches with unique finishes, weights, or colorations, reducing overproduction. AI-driven trend forecasting is also helping mills anticipate demand for specific Chino variants, optimizing inventory and reducing waste.

6. Expansion in Non-Apparel Applications

Beyond traditional use in pants and chinos, the fabric is finding applications in upholstery, accessories, and even automotive interiors due to its durability and aesthetic appeal. This diversification is opening new revenue streams for Chino material producers.

Conclusion

By H2 2026, the Chino material market is characterized by innovation, sustainability, and adaptability. As consumer expectations evolve and environmental regulations tighten, manufacturers who invest in eco-conscious production, digital agility, and functional enhancements are best positioned to lead the market. The Chino fabric, once a staple of casual menswear, is undergoing a transformation into a high-performance, sustainable textile with broad cross-industry appeal.

Common Pitfalls Sourcing Chino Material (Quality, IP)

Sourcing chino material, a popular cotton-blend fabric known for its durability and comfort, involves navigating several potential pitfalls—particularly concerning quality consistency and intellectual property (IP) risks. Overlooking these areas can lead to production delays, increased costs, legal disputes, and brand damage.

Quality Inconsistencies

One of the most frequent challenges in sourcing chino fabric is maintaining consistent quality across batches. Variations in fiber composition, weave density, dye lots, and finishing treatments can result in noticeable differences in color, hand feel, shrinkage, and durability. Buyers may receive fabric that meets initial specifications but performs poorly in garment production or after consumer use, such as excessive wrinkling, pilling, or fading. This often stems from suppliers using alternate raw materials or subcontracting production without approval, especially when cost pressures mount. To mitigate this, brands should enforce strict quality control protocols, conduct pre-production sampling, and perform third-party lab testing for performance metrics like colorfastness and tensile strength.

Intellectual Property Infringement

Another critical risk is the inadvertent sourcing of chino fabric that infringes on protected textile designs, patented finishes, or branded fiber technologies (e.g., moisture-wicking or anti-odor treatments). Some suppliers may replicate popular finishes or use uncertified “look-alike” performance fibers without proper licensing, exposing the buyer to legal liability. For example, using a fabric labeled as “similar to Cordura®” or incorporating unlicensed stretch technology could trigger IP claims from patent holders like INVISTA (LYCRA®) or Schoeller Technologies. Brands must verify suppliers’ certifications, require IP indemnification clauses in contracts, and audit supply chains to ensure all components are legitimately sourced and compliant with global IP regulations.

Proactively addressing these pitfalls through due diligence, clear specifications, and strong supplier relationships is essential for ensuring both the quality and legal safety of chino material sourcing.

Logistics & Compliance Guide for Chino Material

This guide outlines the essential logistics and compliance considerations for handling, transporting, and managing Chino material—a durable cotton fabric commonly used in apparel and workwear. Adherence to these guidelines ensures regulatory compliance, supply chain efficiency, and product quality.

Material Classification and Documentation

Chino material is typically classified under textile regulations. Ensure accurate classification using the Harmonized System (HS) code—commonly 5208.xx.xx for cotton woven fabrics. Maintain detailed documentation including commercial invoices, packing lists, certificates of origin, and fabric test reports (e.g., fiber content, flammability, and colorfastness).

Regulatory Compliance

Comply with regional and international textile regulations. In the U.S., adhere to FTC labeling requirements specifying fiber content and country of origin. In the EU, ensure compliance with REACH and the Textile Regulation (EU) No 1007/2011. Monitor Restricted Substances Lists (RSLs) to confirm the absence of banned dyes, heavy metals, or formaldehyde.

Packaging and Labeling Standards

Package Chino material in moisture-resistant, durable wrapping to prevent damage during transit. Clearly label each roll or bundle with product ID, fabric composition, weight, width, color, batch number, and handling instructions (e.g., “Keep Dry,” “This Side Up”). Include barcodes or RFID tags for inventory tracking where applicable.

Transportation and Handling

Use clean, dry, and pest-free containers or trucks for transport. Protect fabric from direct sunlight, extreme temperatures, and physical abrasion. Stack rolls securely to avoid crushing or deformation. For international shipments, comply with ISPM 15 standards for wooden pallets and utilize freight partners experienced in textile logistics.

Import and Export Requirements

Verify import duties, quotas, and customs procedures for destination countries. Submit required documentation promptly to avoid delays. Leverage free trade agreements where applicable (e.g., USMCA, EU-GSP) to reduce tariffs. Engage a licensed customs broker for complex shipments.

Environmental and Sustainability Practices

Source Chino material from mills with environmental certifications (e.g., OEKO-TEX®, GOTS). Minimize packaging waste and prioritize recyclable materials. Track carbon footprint across the supply chain and seek opportunities for sustainable logistics, such as consolidated shipments and low-emission transport.

Quality Assurance and Traceability

Implement a traceability system to track Chino material from raw cotton to finished fabric. Conduct regular quality inspections for consistency in color, weight, and weave. Retain batch samples and test reports for audit readiness and customer inquiries.

Incident Reporting and Corrective Actions

Establish procedures for reporting compliance breaches, material defects, or logistics disruptions. Conduct root cause analysis and implement corrective actions promptly. Maintain records of non-conformances and resolutions for continuous improvement.

By following this guide, stakeholders can ensure reliable, compliant, and sustainable management of Chino material throughout the supply chain.

Conclusion for Sourcing Chino Material:

After a thorough evaluation of potential suppliers, material quality, cost, sustainability, and lead times, it is concluded that sourcing chino fabric requires a balanced approach that prioritizes durability, consistency, and ethical production practices. High-quality cotton-blend chino fabrics from vertically integrated mills in regions such as China, India, and Turkey offer competitive pricing and reliable performance, provided that stringent quality control measures are in place. Additionally, an increasing number of eco-conscious suppliers now offer sustainable options, such as organic cotton or recycled fiber blends, which align with growing consumer demand for environmentally responsible apparel.

To ensure a successful supply chain, it is recommended to partner with pre-vetted suppliers with proven track records, conduct regular fabric testing, and maintain open communication to address variability and delivery timelines. Ultimately, the most effective sourcing strategy combines cost-efficiency with long-term reliability and sustainability, ensuring the chino material meets both product specifications and brand values.