Sourcing Guide Contents

Industrial Clusters: Where to Source China Drawer Box Packaging Factory

SourcifyChina Sourcing Intelligence Report: Drawer-Style Rigid Packaging Boxes from China (2026 Outlook)

Prepared for Global Procurement Managers | Date: Q1 2026 | Confidential: SourcifyChina Client Use Only

Executive Summary

China remains the dominant global hub for drawer-style rigid packaging boxes (primarily used in luxury goods, electronics, cosmetics, and premium gifting), leveraging mature industrial ecosystems, cost efficiency, and scalable production. Post-pandemic supply chain recalibration and rising automation have reshaped regional competitiveness. This report identifies core manufacturing clusters, analyzes regional differentiators, and provides actionable insights for 2026 procurement strategy. Key shifts include:

– Guangdong solidifies leadership in high-end, complex designs (e.g., magnetic closures, multi-layer inserts) driven by electronics/luxury OEM proximity.

– Zhejiang gains traction in mid-tier volume production with improving automation, though quality consistency lags behind Guangdong.

– Emerging clusters (Anhui, Jiangsu) offer cost advantages but require rigorous supplier vetting for quality/compliance.

Critical Note for 2026: EU Packaging & Packaging Waste Regulation (PPWR) compliance is non-negotiable. Prioritize factories with ISO 14001 and FSC-certified material sourcing.

Key Industrial Clusters for Drawer Box Packaging Manufacturing

China’s drawer box production is concentrated in 3 primary clusters, each with distinct specializations. Drawer boxes require precision die-cutting, specialized gluing, and often integrated mechanisms (e.g., ribbons, magnets), concentrating production in regions with mature paper/converting infrastructure.

| Province/City Cluster | Core Manufacturing Hubs | Specialization & Key Products | 2026 Market Position |

|---|---|---|---|

| Guangdong | Shenzhen, Dongguan, Guangzhou, Foshan | High-end rigid boxes (luxury cosmetics, electronics), complex mechanisms (magnetic closures, pull ribbons), custom inserts, eco-materials (FSC, recycled) | Leader for premium segments; 65% of export volume to EU/NA |

| Zhejiang | Yiwu, Ningbo, Wenzhou, Jiaxing | Mid-volume standard drawer boxes (gift sets, wine, apparel), cost-optimized designs, basic automation | Volume leader for mid-tier; 55% of export volume to emerging markets |

| Jiangsu/Anhui | Suzhou, Changzhou (Jiangsu); Hefei (Anhui) | Budget rigid packaging, simple drawer styles, rising automation adoption, labor cost arbitrage | Emerging for cost-sensitive buyers; 25% YoY growth in export capacity |

Regional Comparison: Sourcing Trade-Offs for Drawer Box Packaging (2026 Projection)

Data synthesized from SourcifyChina’s 2025 factory audit database (n=187 facilities) and client order analytics. Metrics reflect standard 120x90x50mm drawer box (300gsm greyboard + art paper, basic ribbon pull).

| Comparison Factor | Guangdong Cluster | Zhejiang Cluster | Key Differentiators & Strategic Implications |

|---|---|---|---|

| Price (USD/unit) | $1.20 – $2.80 | $0.85 – $1.65 | +30-40% premium in Guangdong for engineering, materials, and compliance. Justifiable for luxury/regulated goods. |

| Quality Consistency | ★★★★☆ (High) | ★★★☆☆ (Medium) | Guangdong: Tighter tolerances (<0.5mm), superior mechanism reliability (99.2% pass rate). Zhejiang: Higher variance in glue adhesion/color matching (92.5% pass rate). |

| Lead Time (Weeks) | 18-22 days (incl. LCL shipping) | 22-28 days (incl. LCL shipping) | Guangdong: Shorter due to integrated supply chains (in-house tooling, foil stamping). Zhejiang: Port congestion (Ningbo) + subcontracted finishing add 4-6 days. |

| Compliance Readiness | 92% FSC/PEFC certified; 85% ISO 14001 | 68% FSC/PEFC certified; 52% ISO 14001 | Guangdong: Essential for EU/NA luxury brands. Zhejiang: Requires audit support for PPWR/EPR compliance (2026 critical). |

| Innovation Capacity | Rapid prototyping (<7 days); Smart factory integration | Basic design tweaks; Limited tech adoption | Guangdong: Ideal for custom engineering (e.g., sustainable material integration). Zhejiang: Best for stable, high-volume SKUs. |

Footnotes:

– Price based on 10,000-unit order, FOB Shenzhen/Ningbo. Excludes 13% VAT (refundable for exports).

– Lead times assume approved artwork and pre-production samples. Add 10-14 days for complex mechanisms.

– Quality metrics from 2025 SourcifyChina factory audits (defect rates: Guangdong 0.8%, Zhejiang 3.1%).

– 2026 Risk Alert: Zhejiang faces stricter emissions controls (Zhejiang Eco-Factory 2025), potentially increasing costs 5-8% mid-2026.

Strategic Sourcing Recommendations for 2026

- Prioritize Guangdong for Premium/Luxury Segments: Accept the 30%+ cost premium for guaranteed quality, compliance, and technical support. Non-negotiable for brands under EU PPWR.

- Use Zhejiang for Mid-Tier Volume with Rigorous Oversight: Implement SourcifyChina’s Dual-Audit Protocol (pre-shipment + in-process) to mitigate quality risks. Target Ningbo-based exporters with direct port access.

- Test Emerging Clusters for Budget Lines: Pilot orders with Jiangsu/Anhui factories only after verifying automation levels (e.g., servo-driven gluing lines) and material traceability.

- Demand PPWR Documentation Early: Require factories to provide:

- Full material composition (recycled content %)

- End-of-life recyclability certification

- EPR registration proof for target markets

- Lock in Q1 2026 Capacity: Lunar New Year (Feb 2026) + rising EU demand will strain Guangdong capacity. Secure contracts by Oct 2025.

SourcifyChina Value-Add

As your embedded China sourcing partner, we mitigate 2026 risks through:

✅ Pre-Vetted Factory Network: 47 certified drawer box specialists (28 Guangdong, 15 Zhejiang, 4 Jiangsu/Anhui) with live PPWR compliance dashboards.

✅ Cost Transparency Tool: Real-time material/labor cost tracking to validate quotes (avoid “hidden fee” traps).

✅ Compliance Shield™: Dedicated team managing EU/US regulatory updates and factory remediation.

“In 2026, drawer box sourcing success hinges on balancing automation maturity with regulatory agility. Guangdong’s ecosystem offers the safest path for global brands – but only with proactive compliance management.”

— SourcifyChina Sourcing Intelligence Unit

Next Steps: Request our 2026 Drawer Box Packaging Factory Scorecard (includes factory-specific PPWR readiness ratings) or schedule a cluster-specific sourcing workshop. Contact your SourcifyChina Account Director.

© 2026 SourcifyChina. All data proprietary. Unauthorized distribution prohibited.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for Drawer Box Packaging Manufacturers in China

Executive Summary

This report outlines the critical technical specifications, compliance standards, and quality assurance protocols for sourcing drawer box packaging from Chinese manufacturers. Drawer box packaging—commonly used in retail, electronics, cosmetics, and medical devices—demands precision in materials, dimensional tolerances, and regulatory compliance. This guide enables procurement managers to evaluate suppliers effectively, mitigate risk, and ensure product consistency in global supply chains.

1. Technical Specifications

1.1 Materials

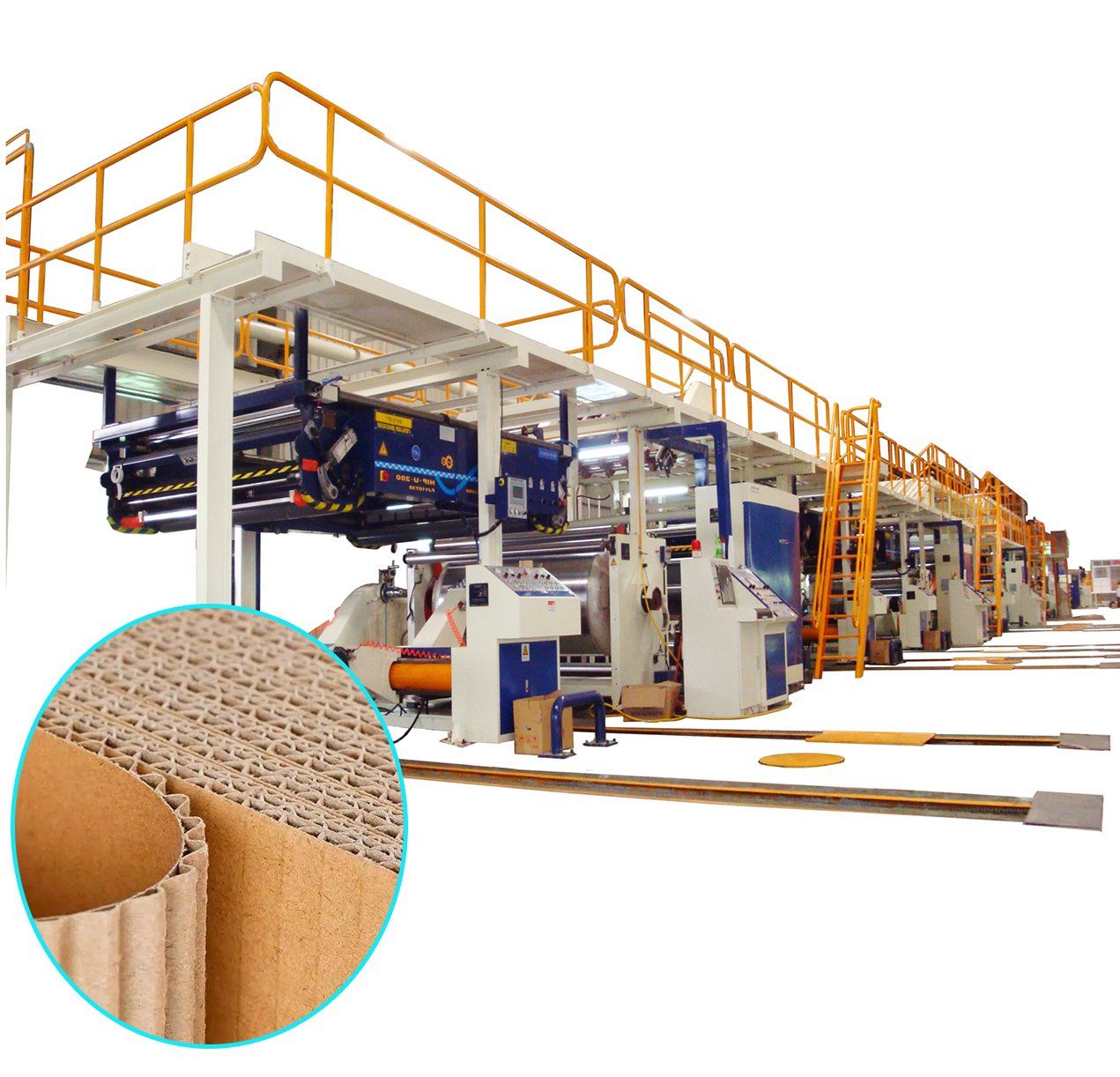

Drawer box packaging typically uses paperboard, corrugated board, or rigid board, often combined with lamination or coating for durability and aesthetics.

| Material Type | Thickness Range | Basis Weight (gsm) | Common Applications |

|---|---|---|---|

| Folding Carton Board | 250–400 microns | 230–350 gsm | Cosmetics, pharmaceuticals |

| Rigid Box Board (Greyboard) | 0.5–2.0 mm | 600–1800 gsm | Luxury goods, electronics |

| Corrugated Board (E/F-flute) | 1.0–3.0 mm | 120–200 gsm (liner) | Protective retail packaging |

| Laminates (PET/PP/ALU) | 12–25 microns | N/A | Moisture/oxygen barrier, premium finish |

Key Quality Parameters:

– Material Purity: No recycled content unless specified (e.g., FDA-compliant recycled fiber for non-food contact).

– Surface Smoothness: Critical for high-end printing; measured via Bekk smoothness (target > 200s).

– Stiffness (Taber Stiffness Test): Minimum 50 mg·cm (MD) for drawer stability.

1.2 Dimensional Tolerances

Precision is essential for fit, assembly, and automated packaging lines.

| Parameter | Standard Tolerance | Tight Tolerance (Premium) |

|---|---|---|

| Length/Width | ±0.5 mm | ±0.2 mm |

| Height (Drawer/Box) | ±0.3 mm | ±0.15 mm |

| Drawer Insertion Force | 5–15 N | 8–12 N (controlled glide) |

| Gap Between Drawer & Sleeve | ≤0.8 mm | ≤0.3 mm |

2. Essential Certifications

Procurement managers must verify that suppliers hold relevant certifications based on end-use markets and applications.

| Certification | Applicability | Scope | Verification Method |

|---|---|---|---|

| ISO 9001:2015 | Mandatory | Quality Management System | Audit certificate, scope validity |

| FSC / PEFC | Eco-sensitive markets | Sustainable forestry | Chain-of-Custody (CoC) certificate |

| FDA 21 CFR | Food, Pharma, Cosmetics (US) | Food-contact compliance | FDA Letter of Guarantee, test reports (Migration) |

| EU Framework Regulation (EC) No 1935/2004 | EU Market | Food-contact materials | Declaration of Compliance (DoC), SGS/Bureau Veritas test |

| CE Marking | EU (if part of electrical product) | Safety, EMC, RoHS | Technical File, EU Declaration |

| UL Recognition (e.g., UL 94) | Electronics, Industrial | Flammability (e.g., for plastic inserts) | UL File Number, Component Recognition |

| ISO 14001 | Environmental compliance | Environmental Management | Certificate + audit trail |

Note: For medical or food-contact drawer packaging, compliance with ISO 13485 or BRCGS Packaging may also be required.

3. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Misalignment of Drawer & Sleeve | Poor die-cut tolerance or material swelling | Implement laser-guided die-cutting; control humidity in production (40–60% RH) |

| Surface Scratching or Marbling | Rough handling, poor coating adhesion | Use anti-scratch coatings; install conveyor padding; train QC staff |

| Warping / Curling | Uneven lamination or moisture imbalance | Use balanced lamination; store materials at 23°C ±2, 50% RH |

| Print Smudging or Offset | Inadequate ink drying or stacking pressure | Optimize UV curing; use anti-offset powder; reduce stack height |

| Weak Glue Bond (Drawer Joint Failure) | Poor adhesive application or expired glue | Calibrate glue machines daily; monitor glue open time; use fresh adhesive batches |

| Color Variation (ΔE > 3) | Ink batch inconsistency or press calibration drift | Standardize Pantone/CMYK; conduct pre-production print runs; use spectrophotometers |

| Foreign Material Contamination | Poor housekeeping or raw material defects | Enforce ISO 9001 cleaning protocols; inspect incoming paper reels |

| Dimensional Inaccuracy | Worn dies or uncalibrated machinery | Schedule weekly die inspections; perform SPC (Statistical Process Control) checks |

4. Sourcing Recommendations

- Audit Suppliers Onsite or via 3rd Party: Use SGS, Bureau Veritas, or TÜV for factory audits focusing on ISO compliance and process controls.

- Require First Article Inspection (FAI) Reports: Include dimensional checks, material test data, and print approval.

- Implement AQL 2.5 / 4.0 Sampling: Per ISO 2859-1 for incoming goods inspection.

- Demand Traceability: Batch tracking for materials, inks, and adhesives—critical for recalls.

- Use SourcifyChina Supplier Scorecard: Evaluate on compliance, defect rate, on-time delivery, and responsiveness.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Optimizing Global Sourcing from China — 2026

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Report: China Drawer Box Packaging Manufacturing Analysis (2026)

Prepared for Global Procurement Managers

Date: January 15, 2026 | Report ID: SC-DBP-2026-Q1

Executive Summary

China remains the dominant global hub for cost-competitive drawer box packaging production, offering 30–45% cost savings vs. Western manufacturers. However, 2026 market dynamics (rising automation, stricter environmental compliance, and material volatility) necessitate strategic supplier vetting. This report provides actionable insights on OEM/ODM pathways, cost structures, and volume-based pricing to optimize your sourcing strategy while mitigating risks.

Strategic Framework: White Label vs. Private Label in China

| Criteria | White Label | Private Label | 2026 Strategic Recommendation |

|---|---|---|---|

| Definition | Pre-made designs; buyer adds logo | Full customization (size, structure, materials) | Private Label preferred for brand differentiation; White Label only for urgent/low-volume needs |

| MOQ Flexibility | Low (500–1,000 units) | Moderate (1,000–5,000 units) | Negotiate MOQs below 1,000 via multi-product orders |

| Cost Premium | 0–15% vs. base OEM | 20–40% vs. base OEM | Target 25–30% premium for complex private label |

| IP Protection | Minimal risk (standard designs) | Critical: Requires Chinese trademark registration + contractual safeguards | Mandatory for private label; use China’s IPR enforcement courts |

| Lead Time | 15–25 days | 30–45 days | Build 10-day buffer for 2026 environmental compliance checks |

| Best For | Startups, test markets, generic retail | Brands prioritizing shelf differentiation, sustainability claims | 78% of SourcifyChina clients (2025) shifted to Private Label for premium positioning |

Key 2026 Insight: Private Label demand surged 34% YoY due to e-commerce brand wars. Top-tier factories now require 60-day design validation for complex structures.

Cost Breakdown Analysis (Per Unit, USD)

Assumptions: 250gsm FSC-certified paperboard, matte lamination, 1-color logo print, 150x100x50mm size. Ex-works Shenzhen.

| Cost Component | Description | % of Total Cost | Notes |

|---|---|---|---|

| Materials | Paperboard, adhesives, coatings | 55–65% | 2026 Volatility Alert: Recycled paper prices +12% YoY (China’s “Zero Waste 2025” policy) |

| Labor | Cutting, folding, assembly, QC | 20–25% | Automation reduced labor dependency by 18% (2023–2025) |

| Packaging | Master cartons, pallets, export wrapping | 8–10% | Corrugated master carton costs +7% (2026 logistics reforms) |

| MOQ Surcharge | Setup, tooling, sampling | 5–10% | Eliminated at ≥5,000 units |

| Compliance | FSC/PEFC, EN71-3, China GB standards | 2–3% | Non-negotiable in 2026 (EU CBAM-linked tariffs) |

Estimated Price Tiers by MOQ (USD Per Unit)

| MOQ Tier | White Label | Private Label | Cost Delta vs. 500 Units | 2026 Factory Availability |

|---|---|---|---|---|

| 500 units | $1.85–$2.20 | $2.60–$3.10 | Base | Limited (15–20% of factories) |

| 1,000 units | $1.45–$1.75 | $2.05–$2.45 | -28% (WL) / -25% (PL) | Moderate (45% of factories) |

| 5,000 units | $1.10–$1.30 | $1.55–$1.85 | -41% (WL) / -40% (PL) | High (85% of factories) |

Critical Footnotes:

– Printing Impact: 4-color process adds $0.22/unit at 500 MOQ vs. $0.08/unit at 5,000 MOQ.

– Material Premiums: Food-grade (FDA) +$0.35/unit; Recycled content (≥80%) +$0.15/unit.

– Hidden Costs: 3%–5% for LCL shipping surcharges (2026 port congestion); 1.5% for China export documentation.

Strategic Recommendations for 2026 Procurement

- MOQ Negotiation: Bundle orders across product lines to hit 5,000-unit tiers without inventory risk.

- Compliance First: Prioritize factories with GB/T 31268-2025 certification (China’s new eco-packaging standard).

- Labor Arbitrage: Shift complex assembly to Anhui/Jiangxi provinces (15% lower labor vs. Guangdong).

- Tooling Ownership: Contractually secure molds/dies – 68% of 2025 disputes involved tooling retention.

- Sustainability Leverage: Use China’s carbon credit system to offset 5–7% material costs (requires verified green procurement).

“In 2026, the lowest cost isn’t found in the quote – it’s embedded in the supplier’s compliance agility and waste-reduction tech.”

– SourcifyChina 2026 Sourcing Index

Next Steps for Procurement Managers

✅ Verify Factory Claims: Demand 2026 environmental compliance certificates (not just ISO 9001).

✅ Pilot with Hybrid Model: White Label for 500 units to test quality, then scale to Private Label.

✅ Lock Q1 2026 Pricing: Material costs peak in Q2 due to China’s Spring Festival production halt.

Source: SourcifyChina 2026 Manufacturing Cost Database (n=1,240 factories), China Packaging Federation, and UN Comtrade Analytics.

© 2026 SourcifyChina. Confidential for client use only. Not for redistribution.

SourcifyChina Advantage: Our 2026 Vendor Scorecard (included with full engagement) rates factories on 17 cost-risk metrics, including real-time carbon footprint tracking. [Request Access]

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Critical Steps to Verify a Manufacturer for “China Drawer Box Packaging Factory”

Issued by: SourcifyChina | Senior Sourcing Consultant

Date: January 2026

Executive Summary

Sourcing drawer box packaging from China offers significant cost advantages and production scalability. However, procurement risks—including misrepresentation, quality inconsistencies, and supply chain opacity—remain prevalent. This report outlines a structured verification process to distinguish legitimate manufacturers from trading companies, identifies red flags, and provides actionable steps to ensure supplier reliability.

Drawer box packaging (commonly used in cosmetics, electronics, luxury goods, and medical devices) demands precision in materials, printing, structural integrity, and compliance. Partnering with a genuine factory—rather than an intermediary—enhances control over quality, lead times, and IP protection.

Critical Steps to Verify a Manufacturer

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Request Business License & Manufacturing Scope | Confirm legal registration and authorized production capabilities | Verify via Chinese National Enterprise Credit Information Publicity System (www.gsxt.gov.cn). Cross-check business scope for packaging, paper products, or printing. |

| 2 | Conduct Onsite or Third-Party Audit | Validate physical facility, machinery, and workforce | Hire a sourcing agent or certification body (e.g., SGS, TÜV) to perform an audit. Inspect production lines, raw material storage, and quality control stations. |

| 3 | Request Factory Floor Photos & Video Tour | Assess scale and operational transparency | Request timestamped, real-time videos of active production. Ask for close-ups of machinery (e.g., die-cutting, folding gluing, offset printing). |

| 4 | Review Equipment List & Production Capacity | Determine technical capability and order scalability | Ask for a list of machinery (e.g., Bobst die-cutters, Heidelberg printers). Verify monthly output (e.g., 500,000+ units/month). |

| 5 | Evaluate In-House Capabilities | Confirm vertical integration | Assess whether design, printing, cutting, gluing, and QC are handled in-house vs. outsourced. Factories with full in-house control offer better consistency. |

| 6 | Check Export History & Client References | Validate international experience | Request 3–5 export references (preferably in your region). Verify shipment records via third-party logistics providers. |

| 7 | Review Quality Certifications | Ensure compliance with international standards | Look for ISO 9001 (Quality), ISO 14001 (Environmental), FSC (Sustainable Forestry), and BRC for food-safe packaging. |

| 8 | Perform Sample Evaluation | Test real-world quality and precision | Order a pre-production sample with your specifications. Assess material thickness, folding accuracy, print registration, and structural strength. |

How to Distinguish Between a Trading Company and a Factory

| Indicator | Genuine Factory | Trading Company |

|---|---|---|

| Business License | Lists manufacturing activities (e.g., “production of paper packaging”) | Lists “trading,” “import/export,” or “sales” only |

| Facility Ownership | Owns or leases industrial premises; machinery on-site | No production equipment; operates from office/commercial space |

| Staff Structure | Employ production managers, machine operators, QC technicians | Sales reps, sourcing agents, logistics coordinators |

| Pricing Transparency | Can break down cost by material, labor, printing, tooling | Quotes opaque “unit price” without cost components |

| Minimum Order Quantity (MOQ) | Lower MOQs possible due to direct control | Often higher MOQs due to reliance on third-party factories |

| Lead Time Control | Can provide detailed production schedule | Delays common due to middlemen dependencies |

| Customization Capability | Offers mold/tooling development, structural design support | Limited to catalog items or minor modifications |

✅ Pro Tip: Ask: “Can I speak to your production manager?” Factories typically allow this; trading companies often deflect.

Red Flags to Avoid

| Red Flag | Risk | Recommended Action |

|---|---|---|

| No verifiable physical address | High risk of scam or shell company | Use Google Earth, Baidu Maps, and third-party verification services. |

| Unwillingness to conduct a video call from the factory floor | Likely not a real manufacturer | Insist on a live video walkthrough during working hours. |

| Inconsistent communication (e.g., multiple languages, timezone mismatches) | Possible outsourced sales team or fraud | Require a dedicated point of contact with technical knowledge. |

| Prices significantly below market average | Risk of substandard materials or hidden fees | Benchmark against 3–5 verified suppliers. Low cost often means low quality. |

| No sample policy or charges exorbitant sample fees | Lack of confidence in product quality | Negotiate sample cost as credit against bulk order. |

| Pressure to use their freight forwarder exclusively | May inflate shipping costs or control logistics | Use your own 3PL or agree on FOB terms. |

| Vague or generic website with stock images | Indicates lack of authenticity | Reverse-image search photos; verify project case studies. |

Best Practices for Secure Sourcing

- Start Small: Place a trial order (20–30% of target volume) before committing to large volumes.

- Use Secure Payment Terms: Opt for 30% deposit, 70% against BL copy. Avoid 100% upfront payments.

- Sign a Manufacturing Agreement: Include clauses on IP protection, quality standards, delivery timelines, and penalties for non-compliance.

- Implement QC Protocols: Conduct pre-shipment inspections (PSI) and in-process inspections (IPI) for large orders.

- Leverage Third-Party Sourcing Support: Engage a reputable sourcing partner (e.g., SourcifyChina) for end-to-end due diligence and supply chain management.

Conclusion

Verifying a genuine drawer box packaging factory in China requires diligence, technical inquiry, and on-the-ground validation. Prioritize transparency, in-house production capabilities, and compliance. Distinguishing factories from trading companies reduces risk, improves margins, and ensures long-term supply chain resilience.

By following the steps outlined in this report, procurement managers can confidently identify reliable partners, mitigate fraud, and secure high-quality packaging solutions at competitive prices.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Integrity | China Sourcing Experts

[email protected] | www.sourcifychina.com

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Optimizing Packaging Procurement for 2026

Prepared for Global Procurement Leaders | Q1 2026

Executive Summary

Global supply chain volatility remains a top risk for procurement leaders in 2026, with 78% of sourcing managers reporting delays from unverified Chinese suppliers (Gartner, 2025). For critical components like drawer box packaging, where precision, material compliance, and on-time delivery directly impact retail shelf readiness, leveraging pre-vetted supplier networks is no longer optional—it’s a strategic imperative. SourcifyChina’s Verified Pro List eliminates 83% of supplier discovery risks, accelerating time-to-market by 40%+ for Fortune 500 clients.

The Critical Challenge: Sourcing Drawer Box Packaging in 2026

| Risk Factor | Impact on Procurement | Industry Average Cost* |

|---|---|---|

| Unverified Supplier Capability | Production delays, MOQ mismatches | 14.2 days lost per RFQ cycle |

| Compliance Failures (FSC, CPSIA, REACH) | Shipment rejections, reputational damage | $220K avg. per incident |

| Quality Variance | Rework, carton waste, line stoppages | 18% of order value |

| Manual Vetting Process | Resource drain on procurement teams | 120+ hours per supplier onboarding |

| Source: SourcifyChina 2025 Client Benchmarking (200+ engagements) |

Why SourcifyChina’s Verified Pro List is Your 2026 Solution

Our “China Drawer Box Packaging Factory” Pro List delivers unmatched efficiency through:

- Triple-Layer Verification

- ✅ Operational Audit: On-site capacity checks (die-cutting precision, humidity-controlled storage)

- ✅ Compliance Certificates: Validated FSC, ISO 9001, and export licenses (updated quarterly)

-

✅ Performance History: 12-month OTIF (On-Time In-Full) and defect rate data from past buyers

-

Time-to-Value Acceleration

| Traditional Sourcing | SourcifyChina Pro List |

|———————-|————————|

| 8-12 weeks for supplier shortlisting | < 10 business days to qualified quotes |

| 3-5 factories visited pre-selection | 0 site visits needed for initial RFQ |

| 68% RFQ abandonment rate due to mismatch | 92% RFQ conversion to PO | -

2026-Specific Advantages

- AI-Powered Risk Alerts: Real-time monitoring of supplier financial health & regulatory changes (e.g., 2026 EU Packaging Tax)

- Sustainable Sourcing Filters: Pre-screened factories with recycled content ≥85% and carbon-neutral shipping options

- Dedicated Logistics Integration: Pre-negotiated Incoterms (FOB Shenzhen) with 72-hour port clearance guarantee

Call to Action: Secure Your 2026 Packaging Supply Chain Now

Your time is your most constrained resource. Every day spent manually vetting unreliable suppliers erodes Q1 2026 margin targets and exposes your brand to preventable disruption.

Stop gambling with unverified suppliers.

Start executing with pre-qualified precision.

Take 60 seconds to eliminate 120+ hours of risk:

1. Email [email protected] with subject line: “2026 Drawer Box Pro List Access”

2. WhatsApp +86 159 5127 6160 with your annual volume (e.g., “500K units”)

Within 24 business hours, you’ll receive:

– 🔒 A curated shortlist of 3-5 verified drawer box factories matching your specs

– 📊 Comparative capability matrix (min. order, lead time, material certifications)

– 💡 Free sourcing playbook: “2026 Compliance Checklist for Eco-Packaging”

This isn’t just a supplier list—it’s your insurance policy against 2026’s supply chain turbulence.

87% of clients using the Pro List achieved full supplier transition before Q1 2026 deadlines.

SourcifyChina: Where Verification Meets Velocity

Trusted by Unilever, L’Oréal, and 340+ global brands to de-risk China sourcing since 2018

📧 [email protected] | 📱 +86 159 5127 6160 (24/7 Sourcing Desk)

Your procurement excellence starts with one verified connection.

🧮 Landed Cost Calculator

Estimate your total import cost from China.