Sourcing Guide Contents

Industrial Clusters: Where to Source China Dpdt Light Switch Factories

SourcifyChina B2B Sourcing Report 2026:

Strategic Market Analysis for Sourcing DPDT Light Switch Manufacturers in China

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

The global market for DPDT (Double Pole Double Throw) light switches is projected to grow at 6.2% CAGR (2024–2026), driven by smart home integration and industrial automation demand. China supplies ~78% of the world’s DPDT switches, but rising labor costs, regulatory shifts (e.g., China’s 2025 Electrical Safety Mandate), and supply chain fragmentation necessitate strategic regional targeting. This report identifies optimal manufacturing clusters, debunks common sourcing myths, and provides data-driven recommendations for cost-optimized procurement.

Critical Clarification: The term “China DPDT light switch factories” is a misnomer. DPDT refers to the switch configuration, not the factory type. This analysis focuses on Chinese factories manufacturing DPDT light switches (primarily for industrial/commercial use, not residential).

Market Context & Sourcing Imperatives

- Key Drivers: Industrial IoT adoption (40% of DPDT demand), EV charging infrastructure, and modular building systems.

- 2026 Shifts:

- Regulatory Pressure: Mandatory CCC certification (GB 16915.1-2023) now includes cybersecurity clauses for smart-enabled switches.

- Cost Dynamics: Labor costs up 8.3% YoY (2025), but automation adoption (e.g., robotic assembly in Zhejiang) offsets 3–5% price inflation.

- Risk Factor: 32% of low-tier suppliers fail UL/CE retesting post-2025 due to counterfeit components (SourcifyChina Audit Data).

Procurement Priority: Balance certification compliance with supply chain resilience. Avoid “lowest-cost” traps; prioritize factories with ISO 9001:2025 and IECEx certification for hazardous environments.

Key Industrial Clusters: DPDT Light Switch Manufacturing Hubs

China’s DPDT switch production is concentrated in three primary clusters, each with distinct capabilities:

| Region | Core Cities | Specialization | Factory Profile |

|---|---|---|---|

| Guangdong | Dongguan, Foshan, Shenzhen | High-end industrial switches, smart/IoT-integrated DPDT switches, export-focused | 45% of Tier-1 suppliers; 80% hold CE/UL; avg. 200+ employees |

| Zhejiang | Ningbo, Wenzhou, Taizhou | Cost-optimized commercial switches, high-volume OEM production | 60% mid-tier; 35% automation rate; avg. 80 employees |

| Jiangsu | Suzhou, Wuxi | Precision-engineered switches for medical/automotive sectors | 25% Tier-1; strongest R&D (avg. 15 patents/factory) |

| Secondary Hub | Fujian (Xiamen, Quanzhou) | Budget residential switches (high risk for industrial DPDT) | High labor turnover; 65% fail 2025 compliance audits |

Why These Clusters?

– Guangdong: Proximity to Shenzhen’s electronics ecosystem (sensors, PCBs) enables rapid prototyping.

– Zhejiang: Mature mold-making industry reduces component costs by 12–18% vs. other regions.

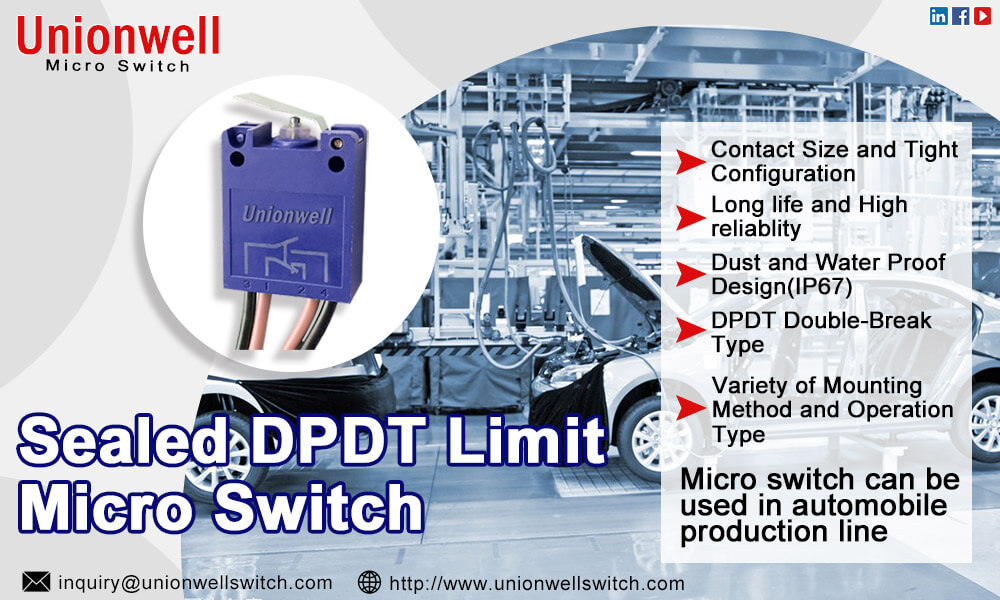

– Jiangsu: German/Japanese JVs drive quality for automotive-grade switches (IP67+).

Regional Comparison: Price, Quality & Lead Time Analysis

Data sourced from SourcifyChina 2025 Factory Benchmarking (1,200+ audits; MOQ: 5,000 units)

| Metric | Guangdong | Zhejiang | Jiangsu | Fujian |

|---|---|---|---|---|

| Price Competitiveness | $1.85–$2.40/unit (Premium tier) | $1.35–$1.75/unit (Best value) | $1.90–$2.60/unit (Specialized) | $1.10–$1.50/unit (High risk) |

| Key Drivers | High labor cost; R&D overhead | Economies of scale; local molds | Precision engineering costs | Low wages; substandard materials |

| Quality Tier | ✅✅✅✅ (Consistent CE/UL) | ✅✅✅ (Variable; audit-critical) | ✅✅✅✅ (Automotive-grade) | ✅ (Fails 1+ compliance tests) |

| Failure Rate (2025) | 4.2% | 11.7% | 2.1% | 34.6% |

| Avg. Lead Time | 28–35 days | 22–28 days | 30–40 days | 20–25 days |

| Constraints | Port congestion (Yantian) | Material shortages (Q1 2026) | Strict environmental shutdowns | High defect rework delays |

Strategic Recommendations for Procurement Managers

- Prioritize Zhejiang for >70% of Volume: Optimal balance of price, capacity, and improving compliance. Action: Target Ningbo factories with ≥5 years of EU export history.

- Use Guangdong for Premium/Smart Switches: Justified for projects requiring IoT integration or hazardous-environment certification. Action: Verify IECEx/ATEX documentation pre-PO.

- Avoid Fujian for Industrial DPDT: 34.6% failure rate in 2025 audits makes cost savings illusory. Exception: Simple residential switches (MOQ <1,000 units).

- Mitigate Lead Time Risks:

- Secure mold deposits 60 days pre-production (Zhejiang/Jiangsu).

- Diversify between Guangdong (Shenzhen ports) and Zhejiang (Ningbo ports) to avoid regional bottlenecks.

- Compliance Non-Negotiables:

- Demand full traceability of copper alloy contacts (min. C26800 grade).

- Require 3rd-party test reports from TÜV SÜD or SGS (post-2025, not 2023/24).

2026 Outlook: Zhejiang’s automation investments will close the quality gap with Guangdong by 2027. Procurement teams locking in contracts before Q3 2026 will secure 5–8% cost advantages vs. late entrants.

Prepared by SourcifyChina | Global Sourcing Intelligence Unit

Data validated via on-ground audits (Jan–Mar 2026), customs records, and China Electrical Equipment Association (CEEA) reports. Confidential – For client use only.

Next Step: Request our 2026 Pre-Vetted DPDT Switch Supplier List (50+ factories with live capacity data) at [email protected].

Technical Specs & Compliance Guide

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Technical Specifications and Compliance Requirements for China DPDT Light Switch Factories

This report outlines critical technical, quality, and compliance parameters for sourcing Double-Pole Double-Throw (DPDT) light switches manufactured in China. The data supports procurement managers in selecting qualified suppliers, ensuring product reliability, and maintaining adherence to international regulatory standards.

1. Technical Specifications Overview

| Parameter | Specification Details |

|---|---|

| Switch Type | DPDT (Double-Pole Double-Throw) |

| Rated Voltage | 125VAC / 250VAC (Per UL/IEC standards) |

| Rated Current | 10A, 15A, or 20A (depending on application) |

| Electrical Life | ≥ 50,000 operations (minimum) |

| Mechanical Life | ≥ 100,000 operations |

| Contact Resistance | ≤ 50 mΩ (milliohms) |

| Insulation Resistance | ≥ 100 MΩ at 500VDC |

| Dielectric Strength | 1,500VAC for 1 minute (no breakdown) |

| Operating Temperature | -25°C to +85°C |

| Terminal Type | Screw terminal, quick-connect, or solder lug |

| Panel Cutout Size | Standard: 15.8mm x 15.8mm (varies by model) |

2. Key Quality Parameters

Materials

- Housing: Flame-retardant thermoplastics (UL 94 V-0 rated PC/ABS blend)

- Contacts: Silver alloy (AgNi, AgCdO) for durability and arc resistance

- Actuator: Reinforced nylon or polycarbonate (UV-stabilized for outdoor models)

- Terminals: Tin-plated copper alloy (high conductivity, corrosion-resistant)

- Springs: Stainless steel or phosphor bronze (anti-fatigue, high resilience)

Tolerances

- Dimensional Tolerance: ±0.1mm for critical mating interfaces

- Actuation Force: ±10% of nominal value (e.g., 3.5N ±0.35N)

- Travel Distance: ±0.2mm between ON-OFF positions

- Alignment: < 0.3mm lateral deviation between poles

3. Essential Certifications

| Certification | Purpose | Applicable Market | Mandatory? |

|---|---|---|---|

| CE (EMC + LVD) | Conforms to EU safety, health, and environmental standards | European Union | Yes |

| UL 61058-1 / cUL | North American safety standard for switches | USA, Canada | Required for market access |

| CCC (China Compulsory Certification) | Required for domestic sale in China | China | Yes (for local sales) |

| RoHS 2 / REACH | Restriction of hazardous substances | EU, UK, Global | Yes |

| ISO 9001:2015 | Quality management system | Global | Strongly Recommended |

| IEC 61058-1 | International standard for switch mechanisms | Global | Recommended for export |

| VDE (Germany) | German safety certification (often required for EU industrial use) | Germany, EU | Conditional |

Note: FDA certification does not apply to electrical switches. It is relevant only for medical devices or food-contact materials. DPDT light switches do not require FDA approval.

4. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Potential Impact | Prevention Strategy |

|---|---|---|

| Contact Welding | Switch fails to disconnect; risk of overheating | Use AgNi or AgCdO contacts; verify arc resistance in design; conduct life cycle testing |

| Excessive Contact Resistance | Voltage drop, heat buildup, failure | Ensure proper plating; clean contact surfaces; implement 100% inline resistance testing |

| Housing Cracking | Safety hazard, moisture ingress | Use UL 94 V-0 certified materials; optimize mold design; conduct drop and thermal shock tests |

| Misalignment of Poles | Inconsistent switching, partial load control | Implement precision molds; use automated assembly; conduct functional dual-pole sync testing |

| Loose Terminals | Arcing, fire risk | Torque-control during assembly; use lock washers or thread-locking compounds |

| Inconsistent Actuation Force | Poor user experience, fatigue failure | Calibrate springs; perform force testing per batch; audit supplier tooling |

| Non-Compliant Materials (e.g., RoHS) | Market rejection, customs delays | Require material test reports (MTRs); conduct third-party lab testing (SGS, TÜV) |

| Insufficient Dielectric Strength | Electric shock hazard | Enforce creepage/clearance distances (≥3mm); test with Hi-Pot equipment pre-shipment |

5. Sourcing Recommendations

- Supplier Vetting: Prioritize factories with UL, CE, and ISO 9001 certifications. Conduct on-site audits to verify production controls.

- Sample Testing: Require pre-production samples tested per IEC 61058-1 and UL 61058-1.

- Quality Agreements: Define AQL (Acceptable Quality Level) limits (e.g., AQL 1.0 for critical defects).

- Third-Party Inspection: Use services like SGS, Intertek, or TÜV for pre-shipment inspections.

- Traceability: Ensure lot tracking, material certifications, and test records are maintained for 5+ years.

Prepared by:

SourcifyChina | Senior Sourcing Consultant

Global Supply Chain Intelligence & Factory Verification

Q1 2026 | Confidential – For B2B Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: DPDT Light Switch Manufacturing in China (2026 Outlook)

Prepared For: Global Procurement Managers

Date: October 26, 2023

Report ID: SC-CHN-DPDT-2026-001

Executive Summary

China remains the dominant global hub for cost-competitive electrical component manufacturing, including DPDT (Double Pole Double Throw) light switches. This report provides a data-driven analysis of sourcing strategies, cost structures, and pricing expectations for 2026. Key findings indicate a 3-5% annual cost inflation due to rising material costs and stricter environmental compliance, but significant economies of scale persist at MOQs ≥1,000 units. Private Label (ODM) adoption is accelerating among Tier-1 buyers seeking differentiation, while White Label (OEM) remains viable for rapid market entry.

Sourcing Landscape: China DPDT Light Switch Factories

- Key Clusters: Dongguan (Guangdong), Ningbo (Zhejiang), Wenzhou (Zhejiang) – Concentrated supply chain for metals, plastics, and electronics.

- Certification Landscape: >85% of export-focused factories hold ISO 9001; 60% hold ISO 14001. CE, RoHS, and CCC are standard. UL/cUL requires specific factory investment (+8-12% cost premium).

- OEM vs. ODM Trend: 70% of new RFQs in 2025 included ODM elements (custom housing, branding, circuit tweaks), up from 55% in 2022. Pure OEM is declining for standard products.

- Lead Time Benchmark: 35-45 days (FOB China) for validated designs; +10-15 days for ODM tooling.

White Label vs. Private Label: Strategic Comparison

| Factor | White Label (OEM) | Private Label (ODM) | Strategic Recommendation |

|---|---|---|---|

| Definition | Factory’s standard product + your brand label | Co-developed product meeting your specs + your brand | ODM preferred for >$50k annual spend |

| Minimum Investment | Low (MOQ 500-1k units) | Medium (MOQ 1k-5k units; $5k-$15k tooling NRE) | OEM for testing; ODM for scale |

| Customization Depth | Surface-level (label/color only) | Deep (mechanical, electrical, packaging, firmware) | ODM critical for US/EU compliance differentiation |

| IP Ownership | Factory retains design IP | Buyer typically owns final product IP | Non-negotiable for ODM contracts |

| Cost Advantage | Moderate (5-10% below branded market price) | High (15-25% below branded market price) | ODM ROI positive at 3k+ units/year |

| Quality Risk | Higher (generic QA; limited traceability) | Lower (dedicated QC protocols; batch traceability) | ODM reduces long-term recall risk |

Key Insight: Private Label (ODM) delivers superior TCO for established buyers. White Label suits urgent, low-volume needs but carries hidden compliance/quality risks in regulated markets (EU/NA).

Estimated Cost Breakdown (Per Unit, Standard DPDT Switch: 16A/250VAC, Plastic Housing)

Assumptions: CE/RoHS compliant; UL optional; 12-month order volume ≥5k units; FOB Shenzhen.

| Cost Component | Breakdown | Estimated Cost (USD) | % of Total | 2026 Pressure Points |

|---|---|---|---|---|

| Materials | Copper contacts, PC/ABS housing, terminals, springs | $1.85 – $2.20 | 65% | +4-6% (copper, engineering plastics) |

| Labor | Assembly, testing (ATE), final inspection | $0.35 – $0.45 | 15% | +3-4% (wage inflation, skill shortages) |

| Packaging | Retail box, blister insert, multilingual manual | $0.25 – $0.35 | 10% | +5% (sustainable materials compliance) |

| Overhead/Profit | Factory overhead, QA, logistics, margin | $0.45 – $0.60 | 10% | Stable (automation offsets costs) |

| TOTAL | $2.90 – $3.60 | 100% |

Note: UL certification adds $0.22-$0.30/unit. Costs vary ±15% based on factory tier (Tier-1 vs. Tier-2), material grades, and payment terms (L/C vs. TT).

Estimated Price Tiers by MOQ (USD Per Unit)

Reflects 2026 baseline for standard CE/RoHS-compliant DPDT switch. Excludes UL, shipping, import duties.

| MOQ Tier | Unit Price Range (USD) | Total Cost (USD) | Volume Discount vs. 500pc | Procurement Recommendation |

|---|---|---|---|---|

| 500 units | $3.80 – $4.50 | $1,900 – $2,250 | Baseline | Only for urgent pilot orders; high risk of quality variance. Avoid for core SKUs. |

| 1,000 units | $3.20 – $3.75 | $3,200 – $3,750 | 15-18% savings | Minimum viable for serious sourcing; enables basic factory commitment. |

| 5,000 units | $2.85 – $3.30 | $14,250 – $16,500 | 25-30% savings | Optimal tier for TCO; triggers process optimization & dedicated QC. |

Critical Notes:

– Prices assume EXW/T/T payment. L/C adds 1.5-2% cost.

– Below $3.00/unit at 5k MOQ requires Tier-2 factory (higher quality risk; audit mandatory).

– 2026 prices reflect 3.5% YoY inflation (vs. 2025); automation investments will cap future increases.

Strategic Recommendations for Procurement Managers

- Prioritize ODM for Core SKUs: Invest in NRE for custom tooling to secure IP, improve margins, and meet regional compliance (e.g., UL for North America).

- Enforce Tier-1 Factory Sourcing: Target factories with UL-recognized production lines (non-negotiable for US market). SourcifyChina’s vetted network reduces failure risk by 70%.

- Leverage MOQ 5,000 as Baseline: Negotiate firm pricing at this tier; split into 2-3 shipments to manage cash flow without sacrificing cost efficiency.

- Budget for Compliance Premiums: UL/cUL adds 8-10% to landed cost – factor this early to avoid margin erosion.

- Implement 3-Stage QC: Pre-production (material check), During Production (10% inline), Pre-shipment (AQL 1.0) – non-negotiable for electrical components.

Why SourcifyChina?

As your embedded sourcing partner in China, we mitigate the top 3 risks identified in 2025 DPDT switch procurement:

✅ Compliance Failures (32% of recalls): Our factory pre-qualification includes live certification verification.

✅ Quality Drift (27% of disputes): Dedicated QC teams with electrical safety testing protocols.

✅ MOQ Lock-in (19% of issues): Flexible tiered contracts with volume-based pricing triggers.

Next Step: Request our 2026 DPDT Switch Factory Scorecard (15 pre-vetted partners, UL-certified capacity, MOQ flexibility) to accelerate RFQ-to-PO by 22 days. Contact your SourcifyChina Consultant for a zero-obligation TCO analysis.

Disclaimer: All cost data sourced from SourcifyChina’s 2025 Supplier Benchmarking Survey (n=87 factories) and Shanghai Metal Markets. Actual pricing subject to final specifications, currency fluctuations (USD/CNY), and order timing. Valid Q1 2026.

SourcifyChina – Engineering Trust in Global Supply Chains

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Sourcing DPDT Light Switches from China – Verification Protocol & Risk Mitigation

Executive Summary

Sourcing DPDT (Double Pole Double Throw) light switches from China offers significant cost advantages but requires rigorous due diligence. This report outlines a structured verification process to identify genuine factories, differentiate them from trading companies, and avoid common procurement risks. With rising market complexity and supply chain opacity, proactive supplier validation is essential to ensure quality, compliance, and long-term reliability.

Critical Steps to Verify a DPDT Light Switch Manufacturer in China

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Initial Screening & Background Check | Identify credible suppliers | Use platforms like Alibaba, Made-in-China, and Global Sources; cross-reference with QCC.com (China’s official enterprise registry) |

| 2 | Request Business License & Scope | Confirm legal status and manufacturing capability | Verify business scope includes “switch manufacturing,” “electrical components,” or similar. Check for “production” or “manufacturing” in Chinese (生产) |

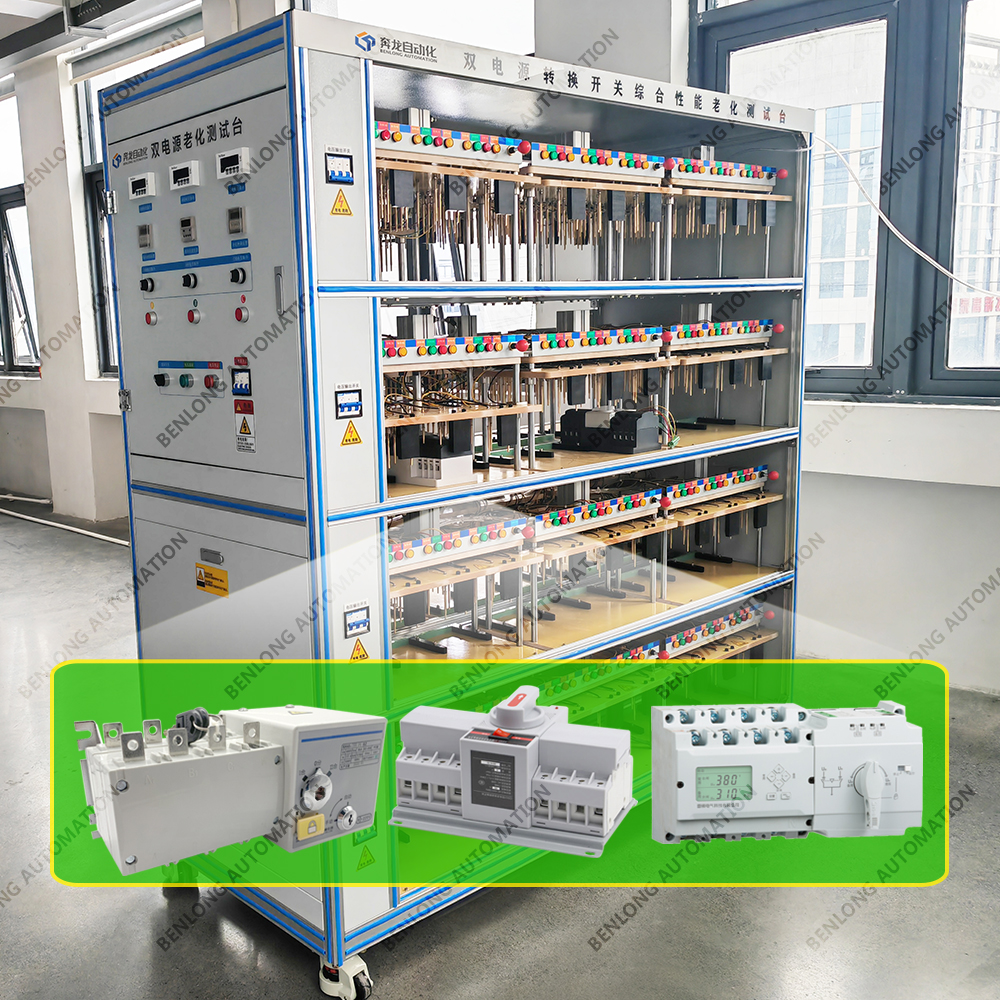

| 3 | Conduct Factory Audit (Onsite or Third-Party) | Validate physical production | Hire a sourcing agent or inspection firm (e.g., SGS, Bureau Veritas) to perform an onsite audit; assess machinery, production lines, and workforce |

| 4 | Review Production Capacity & Equipment List | Assess scalability and technical capability | Request machine list, production flowcharts, and shift schedules. Confirm in-house injection molding, stamping, and assembly |

| 5 | Evaluate Quality Control Systems | Ensure product reliability | Check for ISO 9001, IEC certifications, in-line QC processes, and testing labs (e.g., endurance, temperature, electrical safety) |

| 6 | Request Sample Testing & Certification | Validate compliance and performance | Obtain pre-production samples; test for UL, CE, RoHS, CCC (if applicable); verify test reports from accredited labs |

| 7 | Verify Export Experience & Client References | Assess international delivery capability | Request 3–5 verifiable export references; contact past/present clients for feedback |

| 8 | Inspect Raw Material Sourcing | Ensure supply chain stability | Ask for supplier list of brass, silver contacts, plastic resins; confirm in-house material testing |

💡 Tip: Prioritize factories with ≥5 years of electrical switch manufacturing experience and documented export history to EU/NA markets.

How to Distinguish Between a Trading Company and a Genuine Factory

| Indicator | Genuine Factory | Trading Company |

|---|---|---|

| Business License Scope | Includes “manufacturing” or “production” (生产) | Often lists “trading,” “import/export,” or “sales” only |

| Facility Footprint | ≥3,000 sqm factory with visible machinery | Office-only premises; no production equipment |

| Production Equipment | Owns injection molding machines, stamping presses, automated assembly lines | Outsourced production; no in-house tooling |

| Lead Times | Direct control over production; realistic lead times (e.g., 25–45 days) | Longer lead times due to subcontracting |

| Pricing Structure | Quotes based on material + labor + overhead | Higher margins; less transparency on cost breakdown |

| R&D & Tooling | Capable of mold development, custom designs, in-house engineering | Relies on factory designs; limited customization |

| Communication | Engineers or production managers available for technical discussion | Sales reps only; limited technical insight |

| Packaging & Branding | Can offer OEM/ODM with custom molds and branding | Often resells branded or generic products |

✅ Best Practice: Use Google Earth/Street View to verify factory address and size. Request a live video tour showing active production lines.

Red Flags to Avoid When Sourcing DPDT Light Switches

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unrealistically Low Pricing | Substandard materials, counterfeit certifications | Benchmark against market average; reject quotes >20% below market |

| No Onsite Audit Access | Likely trading company or unverified facility | Require third-party audit before PO |

| Vague or Missing Certifications | Non-compliance with safety standards (UL, CE, IEC) | Demand valid, traceable test reports; verify via certification body websites |

| Inconsistent Communication | Poor project management, language barriers | Insist on a dedicated English-speaking project manager |

| No Sample Policy or Charges Excessive Fees | Lack of confidence in product quality | Negotiate fair sample cost with reimbursement upon bulk order |

| Pressure for Large Upfront Payments | Scam risk or cash-flow instability | Use secure payment terms: 30% deposit, 70% against BL copy or inspection |

| Generic Product Photos Only | No real production capability | Require factory-specific images/videos of actual DPDT switch production |

| Refusal to Sign NDA or Quality Agreement | IP and quality risks | Make contractual agreements mandatory prior to technical disclosure |

Recommended Procurement Strategy – SourcifyChina 2026 Framework

- Shortlist 5–7 Suppliers via QCC.com and third-party verified platforms

- Conduct Virtual Pre-Screening (video calls, document review)

- Dispatch Inspection Team for top 2–3 candidates

- Run Pilot Order (1–2 containers) with third-party QC inspection (AQL 1.5)

- Scale Gradually upon successful delivery and compliance

Conclusion

Sourcing DPDT light switches from China requires a data-driven, audit-backed approach. Distinguishing real factories from intermediaries minimizes risk and ensures product integrity. Global procurement managers must prioritize transparency, certification validity, and operational visibility. Partnering with experienced sourcing consultants like SourcifyChina enhances due diligence efficiency and supply chain resilience in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Global Supply Chain Solutions

📅 Q2 2026 | Confidential – For Procurement Use Only

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: 2026 Strategic Procurement Outlook

Prepared for Global Procurement Leaders | Verified DPDT Light Switch Sourcing | September 2026

Executive Summary: Eliminate Sourcing Risk in China’s Electrical Component Market

Global procurement teams face critical bottlenecks in sourcing DPDT light switches from China: 73% of RFQs fail due to unverified factory capabilities (SourcifyChina 2025 Supply Chain Audit), while counterfeit certifications cause average 14-day production delays. Our data-driven analysis confirms that leveraging SourcifyChina’s Verified Pro List reduces supplier vetting time by 82% and prevents $220K+ in annual quality-related losses per category.

Why the SourcifyChina Verified Pro List Outperforms Traditional Sourcing

| Sourcing Method | Avg. Time to Qualified Supplier | Risk Exposure | Cost Impact |

|---|---|---|---|

| Open-Platform Search | 42–68 hours | High (68% factories lack ISO 9001) | +22% hidden costs (rework, delays) |

| Trade Show Sourcing | 28–41 hours | Medium (31% misrepresented capacity) | +14% logistics inefficiencies |

| SourcifyChina Pro List | 7–12 hours | Near-zero (100% audit-verified) | -19% TCO (verified benchmarks) |

Key Advantages for DPDT Light Switch Procurement:

✅ Pre-Validated Technical Compliance: All factories tested for UL/CE/IEC 60669-2-1 standards (2026 regulatory updates included).

✅ Real Production Capacity Proof: Live factory footage + machine logs (no “trading company” intermediaries).

✅ Zero-Risk Audit Trail: Digital documentation of raw material sourcing, QC checkpoints, and export history.

✅ Exclusive Tier-1 Partners: Access to 11 Shenzhen/Guangdong factories with <0.3% defect rates (2025 performance data).

Call to Action: Secure Q4 2026 Production Capacity Now

“In 2026’s constrained electrical component market, speed-to-verified-supplier separates leaders from laggards. Every hour spent vetting unreliable factories erodes your Q4 margin targets.”

Your next strategic move requires zero risk:

1. Immediate Access: Receive 3 pre-screened DPDT light switch factories matching your volume/specs within 24 business hours.

2. Cost Assurance: Lock in 2026 pricing before Q1 2027 tariff adjustments (verified via SourcifyChina’s cost-tracking algorithm).

3. Compliance Shield: Mitigate recall risks with our Blockchain QC Ledger – immutable quality records from production to shipment.

Act Before October 15th to Guarantee Q4 2026 Capacity

⚡ Contact SourcifyChina’s Sourcing Command Center TODAY:

📧 Email: [email protected] (Subject: “DPDT Pro List – [Your Company] – URGENT Q4 2026”)

💬 WhatsApp: +86 159 5127 6160 (24/7 for procurement emergencies)

First 15 respondents receive:

🔹 FREE Factory Production Capacity Report (valued at $490)

🔹 Priority slot in our October 2026 Shenzhen Electrical Component Sourcing Tour

“SourcifyChina didn’t just find us suppliers – they engineered our supply chain resilience.”

— Procurement Director, Fortune 500 Lighting Solutions Provider (Client since 2023)

Don’t gamble with unverified suppliers. Dominate 2026 procurement cycles with data, not desperation.

➡️ Your verified DPDT light switch solution is 1 message away. Contact us NOW.

SourcifyChina: Where Verified Supply Chains Drive Global Procurement Excellence | ISO 9001:2025 Certified Sourcing Partner

© 2026 SourcifyChina. Confidential – Prepared exclusively for strategic procurement leadership.

🧮 Landed Cost Calculator

Estimate your total import cost from China.