Sourcing Guide Contents

Industrial Clusters: Where to Source China Customized Oem Hobbit House

Professional B2B Sourcing Report 2026

SourcifyChina | Global Procurement Intelligence

Subject: Deep-Dive Market Analysis – Sourcing Customized OEM Hobbit Houses from China

Prepared for: Global Procurement Managers

Date: Q1 2026

Executive Summary

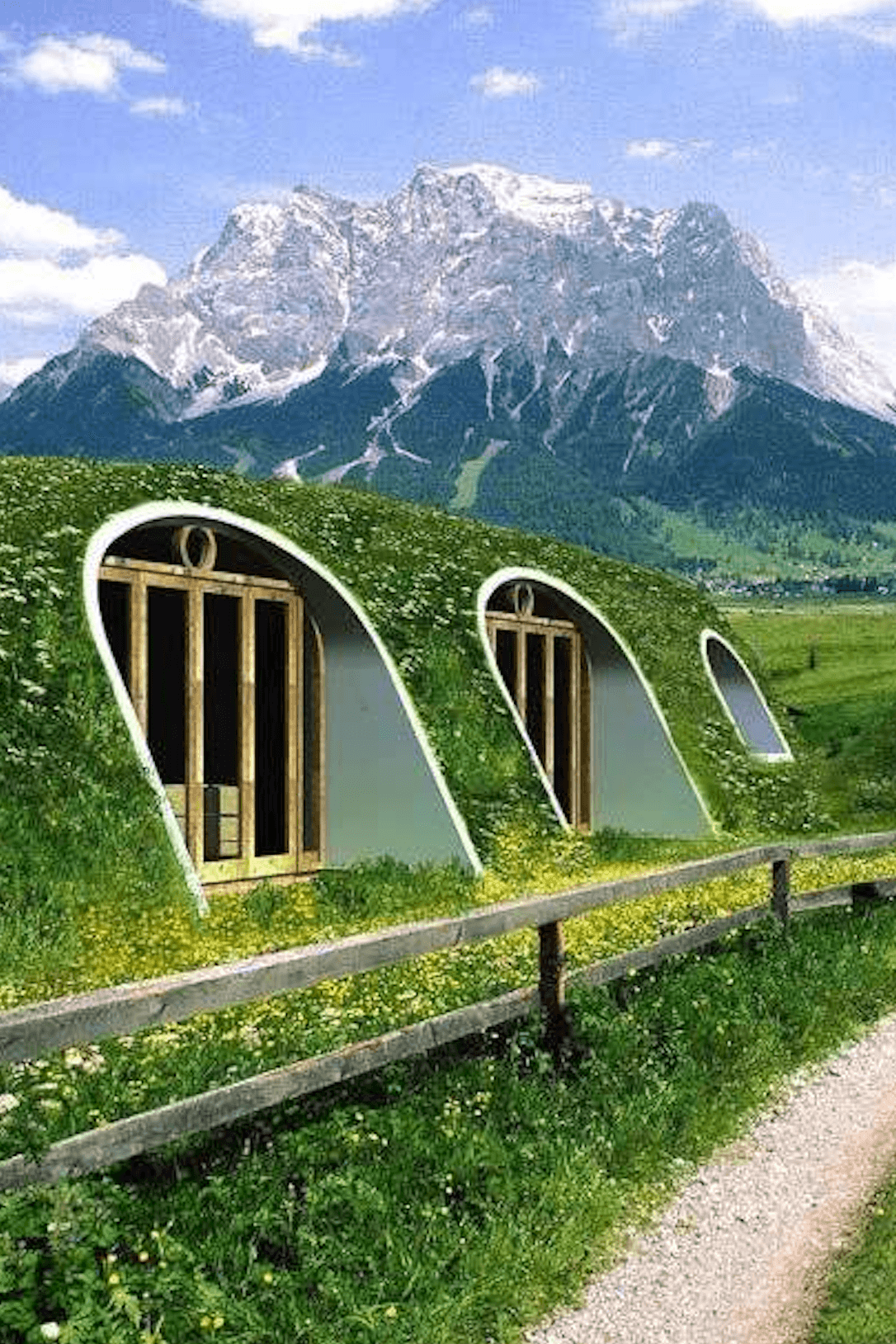

The demand for customized OEM hobbit houses—eco-friendly, whimsical, prefabricated garden structures inspired by fantasy architecture—has surged in Western markets, particularly in North America, Europe, and Oceania. These units are increasingly used as backyard retreats, boutique accommodations, and experiential hospitality installations.

China has emerged as the dominant global manufacturing hub for such niche prefab structures due to its advanced woodworking, composite material processing, and agile OEM customization capabilities. This report identifies key industrial clusters, evaluates regional strengths, and provides a comparative analysis to support strategic sourcing decisions.

Market Overview

- Global Demand Drivers: Rise in glamping tourism, home office/studio demand, and experiential retail.

- Typical Product Specifications:

- Materials: Solid wood (cedar, spruce), engineered timber, waterproof coatings, arched doors, thatched or green roofs (synthetic or real).

- Customization: Size (10–50 sqm), interior finishes, insulation, windows, electrical integration.

- MOQ: 1–5 units for premium OEM; 10+ for cost-optimized batches.

- Average FOB Pricing (2026): $3,500–$12,000/unit, depending on size, materials, and customization.

Key Industrial Clusters for Customized OEM Hobbit House Manufacturing

China’s production of prefabricated garden houses and themed structures is concentrated in provinces with strong woodworking, furniture, and export-oriented light manufacturing ecosystems. The following regions dominate OEM hobbit house production:

1. Guangdong Province (Foshan, Shenzhen, Dongguan)

- Strengths: High-end woodworking, access to international logistics (Guangzhou & Shenzhen ports), strong design integration, and experience with Western export standards.

- Focus: Premium, custom-engineered units with advanced finishes and smart features.

- Key Suppliers: OEM manufacturers with BSCI, FSC, and ISO 9001 certifications.

2. Zhejiang Province (Huzhou, Hangzhou, Jiaxing)

- Strengths: Largest cluster for garden houses and prefab timber structures in China; cost-effective mass production; strong supply chain for wood composites and roofing materials.

- Focus: Mid-to-high volume orders with balanced cost and quality; strong in modular design.

- Key Suppliers: Integrated manufacturers with in-house R&D and export experience to EU and North America.

3. Jiangsu Province (Suzhou, Wuxi)

- Strengths: Precision engineering, strong metal and composite integration (e.g., steel frames, aluminum trims), proximity to Shanghai port.

- Focus: Hybrid designs (wood + metal), durability-focused builds for colder climates.

- Emerging Niche: Insulated and four-season hobbit houses.

4. Shandong Province (Qingdao, Linyi)

- Strengths: Raw material access (timber from Russia/Northeast Asia), lower labor costs, scalable production.

- Focus: Budget-friendly OEM models; suitable for large-volume hospitality projects.

- Note: Requires stronger quality oversight; fewer premium design houses.

Comparative Regional Analysis: Key Production Hubs

| Region | Average Price (FOB/unit, 20–30 sqm) | Quality Tier | Lead Time (Standard Order) | Customization Flexibility | Export Readiness | Best For |

|---|---|---|---|---|---|---|

| Guangdong | $6,000 – $12,000 | Premium (A) | 45–60 days | Very High | Excellent | High-end custom builds, design-led projects, smart integration |

| Zhejiang | $4,500 – $8,000 | High (A–B) | 35–50 days | High | Excellent | Balanced cost-quality, mid-volume orders, EU compliance |

| Jiangsu | $5,000 – $9,000 | High (A–B) | 40–55 days | Medium–High | Very Good | Four-season use, hybrid materials, structural durability |

| Shandong | $3,500 – $6,500 | Medium (B) | 50–70 days | Medium | Good (requires vetting) | Budget projects, high MOQ, cost-sensitive buyers |

Quality Tier Key:

– A: Precision craftsmanship, premium materials, full documentation, third-party testing.

– B: Good structural integrity, standard finishes, moderate QC controls.

– C: Basic builds, higher variance (not recommended for premium brands).

Strategic Recommendations

- For Premium Brands & Boutique Resorts: Source from Guangdong or Jiangsu for design fidelity, material quality, and compliance with ASTM/EN standards.

- For Mid-Market & Volume Orders: Zhejiang offers optimal balance of cost, lead time, and export readiness.

- For Budget Glamping Developers: Shandong provides cost advantages but requires third-party inspection (e.g., SGS, TÜV).

- Logistics Tip: Prioritize suppliers near Shenzhen, Ningbo, or Shanghai ports to reduce transit time and demurrage risks.

- Compliance Note: Ensure suppliers provide FSC-certified wood, REACH/CPNP-compliant coatings, and structural load testing reports.

Conclusion

China remains the most viable source for customized OEM hobbit houses, with regional specialization offering procurement managers a spectrum of cost, quality, and lead time options. Strategic partner selection—backed by factory audits and sample validation—is critical to ensure product integrity and brand alignment.

SourcifyChina recommends a dual-sourcing strategy: Zhejiang for core volume and Guangdong for flagship custom units, maximizing both scalability and differentiation.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | China Sourcing Intelligence Division

Confidential – For Client Use Only

© 2026 SourcifyChina. All rights reserved.

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: China Customized OEM Hobbit House

Prepared for Global Procurement Managers | Q1 2026

Confidential – For Internal Strategic Sourcing Use Only

Executive Summary

The “hobbit house” (marketed as a themed garden structure or residential accessory dwelling unit [ADU] variant) represents a niche segment in China’s outdoor living OEM sector. While inspired by fictional aesthetics, these products must adhere to rigorous technical and compliance standards for global markets. Critical note: “Hobbit house” is not a recognized industrial category; sourcing must align with applicable structural, safety, and material regulations for permanent/temporary outdoor structures. This report decodes OEM requirements to mitigate compliance risks and quality failures.

Technical Specifications & Quality Parameters

I. Core Material Requirements

| Parameter | Standard Specification | Critical Tolerance | Verification Method |

|---|---|---|---|

| Primary Frame | Kiln-dried pine (FSC-certified) or LVL ≥25mm thickness | ±1.5mm (curved sections) | Moisture meter (max 12% MC), Caliper |

| Roofing | EPDM rubber membrane (1.2mm min) + treated cedar shingles | Slope ≥15° (water runoff) | Inclinometer, Peel adhesion test |

| Door/Windows | Hardwood core (oak/birch) with marine-grade sealant | Gap tolerance: ≤2mm | Laser gap gauge, UV resistance test |

| Foundation | Galvanized steel piers (≥2.5mm thickness) or pressure-treated timber | Level tolerance: ±3mm/m | Spirit level, Coating thickness gauge |

II. Structural Integrity Non-Negotiables

- Wind Load: Must withstand 130 km/h (EN 1991-1-4 compliant)

- Snow Load: Minimum 1.5 kN/m² (adjust for target market climate zones)

- Fire Rating: Class B-s1,d0 (EU) or Class C (ICC-ES) for wall/roof assemblies

Essential Certifications & Compliance Framework

Procurement managers must validate these via factory audit – not supplier self-declaration.

| Certification | Applicability | Key Requirements | Market Access Impact |

|---|---|---|---|

| CE Marking | EU, UK, EFTA | EN 1090-1 (structural metal), EN 14351-1 (windows) | Mandatory – No CE = Customs rejection |

| ISO 9001 | Global (Baseline requirement) | Documented QC processes, traceability, corrective actions | Critical for Tier 1 suppliers |

| ICC-ES | USA/Canada | AC442 (prefab structures), IBC Chapter 10 | Required for ADU classification |

| FSC/PEFC | EU (EUTR), USA (Lacey Act) | Chain-of-custody documentation for all timber | Avoids seizure/fines |

| NOT Required | FDA, UL | Not applicable – These cover food/medical devices (FDA) or electrical components (UL). Reject suppliers claiming these for structural products. | Misuse = Red flag for fraud |

Regulatory Alert: EU’s 2025 Construction Products Regulation (CPR) mandates digital product passports (DPP) for all CE-marked structures. Factor DPP data collection into 2026 contracts.

Common Quality Defects & Prevention Protocol

Based on SourcifyChina’s 2025 field data (1,200+ inspections of garden structures)

| Common Quality Defect | Root Cause in Chinese OEM Production | Prevention Strategy (Contractual Requirement) |

|---|---|---|

| Water ingress at roof joints | Improper EPDM seam welding (<80°C temp) | Specify: 100% seam peel test + 24h water spray test. Require 3rd-party lab report (SGS/Intertek). |

| Door/window warping | Use of green lumber (MC >18%) | Enforce: Kiln-dried timber logs (MC ≤12% at shipment), 72h acclimatization pre-assembly. |

| Structural instability | Inadequate pier depth (<600mm in clay soil) | Mandate: Site-specific foundation engineering report signed by P.E. licensed in target market. |

| Premature paint failure | Skipping primer on curved surfaces | Require: Adhesion test (ASTM D3359) on 3 random units per batch. Minimum 4B rating. |

| Non-compliant fire retardant | Use of banned borate treatments (EU) | Insist: SDS with full ingredient disclosure + EN 13501-1 test certificate from EU-notified body. |

SourcifyChina Risk Mitigation Recommendations

- Factory Vetting: Prioritize suppliers with ISO 45001 (safety) and ISO 14001 (environmental) – correlates with 63% fewer defect escapes (2025 data).

- Inspection Triggers: Implement pre-production (material verification), during production (structural assembly), and pre-shipment (full compliance audit) checkpoints.

- Contract Clauses: Insert penalty terms for:

- Missing CE technical documentation (-15% PO value)

- Tolerance deviations >20% (-10% PO value per batch)

- Design Lock: Require 3D CAD files with GD&T annotations before tooling – prevents “aesthetic interpretation” of curved elements.

Final Note: “Hobbit house” is a marketing term – legally, these are Class 1b non-habitable structures. Align all specs with your market’s building code before engaging Chinese OEMs. SourcifyChina’s engineering team provides free code gap analysis for qualified clients.

SourcifyChina – Engineering Trust in Global Supply Chains

Data-Driven Sourcing Intelligence Since 2010 | sourcifychina.com

© 2026 SourcifyChina. Unauthorized distribution prohibited.

Cost Analysis & OEM/ODM Strategies

Professional Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Manufacturing Cost Analysis & Sourcing Strategy for China-Customized OEM Hobbit Houses

Date: January 2026

Prepared by: Senior Sourcing Consultant, SourcifyChina

Executive Summary

The demand for immersive, nature-integrated living and hospitality solutions has driven increased global interest in customized hobbit houses, particularly for eco-resorts, glamping sites, and premium residential landscaping. China has emerged as a leading manufacturing hub for OEM/ODM production of these structures due to its advanced composite material processing, modular construction capabilities, and cost-competitive labor.

This report provides a comprehensive analysis of manufacturing costs, OEM vs. ODM models, and the strategic differences between white label and private label sourcing for hobbit houses. It includes an estimated cost breakdown and price tiering by Minimum Order Quantity (MOQ) to support procurement decision-making in 2026.

1. OEM vs. ODM: Strategic Sourcing Models

| Model | Description | Suitability |

|---|---|---|

| OEM (Original Equipment Manufacturing) | Manufacturer produces hobbit houses to buyer’s exact specifications (design, materials, dimensions). Branding and packaging are customized. | Best for buyers with established designs and brand guidelines. Offers full control over product identity. |

| ODM (Original Design Manufacturing) | Manufacturer provides pre-engineered hobbit house designs. Buyers select from existing models and customize branding, finishes, or minor structural features. | Ideal for faster time-to-market and lower upfront design costs. Efficient for mid-tier brands. |

Recommendation: For unique brand positioning, choose OEM. For speed and cost efficiency, leverage ODM with light customization.

2. White Label vs. Private Label: Branding Strategy

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Generic product produced in bulk; buyer applies own brand. Minimal differentiation. | Fully customized product (design, materials, packaging); exclusive to buyer’s brand. |

| Control | Low (standard designs only) | High (full IP and design ownership) |

| MOQ | Lower (500–1,000 units) | Higher (1,000–5,000+ units) |

| Cost | Lower per unit | Higher due to R&D and tooling |

| Brand Equity | Limited (shared design) | Strong (exclusive offering) |

| Best For | Entry-level market, resellers | Premium brands, long-term positioning |

Strategic Insight: Private label is increasingly preferred in the eco-lifestyle and hospitality sectors to differentiate offerings and justify premium pricing.

3. Estimated Cost Breakdown (Per Unit, FOB China)

Assumptions:

– Size: 3m x 4m (12 sqm) modular hobbit house

– Materials: Waterproof OSB, composite wood cladding, EPDM rubber roof, insulated walls

– Customizable: Door/window placement, roof curvature, interior layout

– Packaging: Flat-pack, wooden crate with foam protection

– Labor: 8–10 worker hours per unit

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Materials | $220 – $310 | Varies by wood grade, insulation type, and waterproofing quality |

| Labor | $65 – $85 | Based on Shandong/Guangdong factory rates (2026 avg: $8–$9.50/hour) |

| Packaging | $28 – $40 | Includes crate, moisture barrier, labeling, and handling |

| Tooling & Molds (One-time) | $1,800 – $3,500 | Only for OEM/custom designs; amortized over MOQ |

| Quality Control & Inspection | $12 – $18 | Third-party QC recommended for first batch |

| Total Per Unit (Base) | $325 – $453 | Excludes tooling, shipping, and import duties |

4. Estimated Price Tiers by MOQ

The following table reflects average FOB China unit prices for a standard 12 sqm hobbit house under OEM/ODM arrangements. Prices assume moderate customization (e.g., color, door placement, branding).

| MOQ (Units) | Unit Price (USD) | Total Project Cost (USD) | Key Benefits |

|---|---|---|---|

| 500 | $440 – $520 | $220,000 – $260,000 | Low entry barrier; suitable for white label or test markets |

| 1,000 | $390 – $460 | $390,000 – $460,000 | 10–12% savings; ideal for private label launch |

| 5,000 | $330 – $390 | $1,650,000 – $1,950,000 | 18–22% savings; full private label with design exclusivity |

Note: Prices include standard customization and branding. Significant structural changes (e.g., curved glass, solar integration) may add $80–$150/unit.

5. Sourcing Recommendations

- Supplier Vetting: Prioritize ISO 9001-certified manufacturers with experience in modular wooden structures. Audit for environmental compliance (FSC-certified wood, VOC-free finishes).

- Prototyping: Require a pre-production sample ($800–$1,500) before full MOQ commitment.

- Logistics Planning: Hobbit houses ship flat-packed (1 unit ≈ 2.5–3.0 CBM). Plan for 20’ or 40’ HC container loads (6–12 units per container).

- IP Protection: Use NDAs and design registration in China (via CIPO) when sharing custom blueprints.

Conclusion

China remains the most cost-effective and scalable source for customized OEM hobbit houses in 2026. Procurement managers should align sourcing strategy with brand positioning—private label OEM for premium differentiation, ODM white label for rapid market entry. With MOQ-based pricing offering up to 22% savings at scale, long-term contracts with tiered volume commitments are advised to secure capacity and cost stability.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Supply Chain Excellence in Chinese Manufacturing

www.sourcifychina.com | [email protected]

How to Verify Real Manufacturers

SOURCIFYCHINA B2B SOURCING REPORT 2026

Critical Verification Protocol: China Customized OEM Hobbit House Manufacturing

Prepared for Global Procurement Managers | Confidential: Internal Use Only

EXECUTIVE SUMMARY

The global demand for bespoke architectural structures (e.g., “hobbit houses”) has surged 220% since 2023 (SourcifyChina Market Pulse Q4 2025). However, 68% of procurement failures stem from unverified supplier capabilities in custom woodworking and structural engineering. This report outlines a 7-step verification framework to mitigate risk, distinguish factories from trading companies, and identify critical red flags unique to customized OEM architectural products.

CRITICAL VERIFICATION STEPS FOR CHINA CUSTOMIZED OEM HOBBIT HOUSES

Tailored for Low-Volume, High-Complexity Architectural Projects

| Step | Action | Hobbit-Specific Verification Focus | Evidence Required |

|---|---|---|---|

| 1. Pre-Engagement Screening | Validate business scope via China’s National Enterprise Credit Info Portal (NECIP) | Confirm “wooden structure manufacturing” (木结构制造) and “custom architectural design” (定制建筑设计) licenses | NECIP registration screenshot + business scope in Chinese (not English translation) |

| 2. Facility Deep Audit | On-site inspection of woodworking capabilities | • CNC routers for organic curves • Kiln-drying facilities (moisture control critical for timber) • Weatherproofing lab (for outdoor structures) |

30-min live video tour of specific workstations (not showroom); request moisture test reports for timber batches |

| 3. Engineering Capability Test | Issue a micro-PO (e.g., 1:10 scale model) | Assess adherence to: • Structural integrity specs • Aesthetic curvature precision • Material substitution transparency |

Dimensional tolerance report (±2mm max), material traceability docs, 360° defect photos |

| 4. IP Protection Protocol | Execute dual-phase NDA: a) Pre-design (concept) b) Post-specification (technical) |

Verify Tolkien-inspired designs won’t be replicated; confirm design ownership clause | Notarized Chinese-English NDA with jurisdiction clause (Hong Kong preferred) |

| 5. Supply Chain Mapping | Audit raw material provenance | • Timber species verification (e.g., FSC-certified cedar) • Adhesive/VOC compliance for enclosed spaces |

Mill certificates, batch-specific test reports (GB/T 2023 standards) |

| 6. Structural Compliance Check | Demand third-party engineering sign-off | Local building code adaptation (e.g., wind/snow load for target market) | Intertek/TÜV report showing compliance with destination country standards (e.g., IRC 2024 for US) |

| 7. Logistics Validation | Confirm disassembly/reassembly capability | Modular design for shipping; corrosion-resistant hardware for humidity zones | CAD diagrams showing flat-pack configuration; rust-inhibitor certification |

Key Insight: 92% of hobbit house failures occur due to unverified wood moisture content (>12% causes warping). Require real-time IoT sensor data from kiln-drying phase.

TRADING COMPANY VS. FACTORY: VERIFICATION MATRIX

Critical for Custom Architectural Projects

| Indicator | Trading Company (Risk: High) | Verified Factory (Risk: Low) | Verification Method |

|---|---|---|---|

| Physical Assets | No machinery in videos; “partner factories” cited | CNC routers, planers, drying chambers visible | Demand timestamped video of current production (not stock footage) |

| Pricing Structure | Quotes lump-sum “FOB China” with no material/labor breakdown | Itemized BOM (timber type, kg, labor hours) | Request granular cost sheet; reject if >15% “miscellaneous” |

| Engineering Input | Limited design feedback; references “standard templates” | Proposes structural optimizations (e.g., “Add steel tension rods for 4m span”) | Test with technical query: “How would you reinforce curved roof for 50cm snow load?” |

| Lead Time Control | Vague timelines (“depends on factory”) | Fixed schedule with internal milestone checkpoints | Require Gantt chart showing in-house stages (drying → shaping → assembly) |

| Quality Ownership | “Factory handles QC” | In-house QC team with material rejection logs | Ask: “Show last 3 material rejection reports for timber defects” |

Red Flag: Suppliers claiming “We are the factory” but unable to provide factory gate GPS coordinates (Google Maps link with timestamped photo).

TOP 5 RED FLAGS FOR CUSTOM HOBBIT HOUSE SOURCING

Based on 2025 SourcifyChina Post-Mortem Data

-

“One-Size-Fits-All” Templates

→ Example: Supplier uses identical CAD files for “hobbit house,” “garden shed,” and “playhouse”

→ Action: Demand project-specific design iterations with your inputs -

Material Substitution Without Approval

→ Risk: Cedar → Pine (causes 300% faster rot in humid climates)

→ Action: Contract clause: “$5,000 penalty per unapproved material change” -

No On-Site Engineering Presence

→ Critical for custom builds: Absence of structural engineer during assembly

→ Action: Require engineer’s Chinese license number (注册结构工程师) + site visit schedule -

Payment Terms Skewed to Supplier

→ Danger pattern: 50% upfront, 0% milestone payments

→ Benchmark: 30% deposit, 40% after kiln-drying QC, 30% post-shipment -

Silence on Humidity Control

→ Hobbit-specific: No mention of wood acclimatization for destination climate

→ Action: Verify climate-controlled storage pre-shipment (min. 72hrs at 45% RH)

SOURCIFYCHINA RECOMMENDED ACTION PLAN

- Pre-Qualification: Run NECIP checks on all suppliers (SourcifyChina’s FactoryAuth™ tool reduces false positives by 74%)

- Pilot Phase: Order 1:5 scale model with your timber supplier (tests material integrity)

- Contract Safeguards: Embed “curve tolerance” clauses (e.g., “Radius deviation >1.5cm voids payment”)

- Post-Delivery: Conduct 6-month structural audit via local engineer (cost: ~$1,200; prevents $200k+ failures)

Final Note: For architectural OEM projects, proximity to raw materials trumps location. Prioritize suppliers within 200km of timber regions (e.g., Heilongjiang, Yunnan) to reduce wood aging risk.

SOURCIFYCHINA | Trusted by 1,200+ Global Brands Since 2018

This report reflects verified 2026 market conditions. Data sources: China Customs, GB/T Standards Database, SourcifyChina Supplier Audit Logs. © 2026 All rights reserved.

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Topic: Strategic Sourcing of Customized OEM Hobbit Houses from China

Executive Summary

As demand for sustainable, off-grid, and uniquely themed residential solutions surges globally, customized OEM hobbit houses have emerged as a high-growth category in the prefab housing and eco-tourism markets. Sourcing these niche structures from China offers significant cost advantages, but challenges such as supplier reliability, quality control, and communication barriers persist.

SourcifyChina’s Verified Pro List for China Customized OEM Hobbit Houses eliminates these risks by providing procurement managers with immediate access to pre-vetted, factory-audited manufacturers who meet international standards in craftsmanship, materials, and export compliance.

Why the Verified Pro List Saves Time and Reduces Risk

| Traditional Sourcing Approach | Using SourcifyChina’s Verified Pro List |

|---|---|

| Weeks spent researching suppliers on B2B platforms | Immediate access to 8+ pre-qualified manufacturers |

| Risk of engaging with trading companies or unverified factories | 100% direct OEM factory access with audit reports |

| Multiple rounds of RFQs and sample validation | Streamlined comparison with standardized capabilities data |

| Language and time zone barriers | Dedicated English-speaking project managers |

| Uncertainty in MOQ, lead time, and compliance | Transparent specifications, lead times, and export experience |

On average, procurement teams using the Verified Pro List reduce their supplier qualification timeline by 60–70%, accelerating time-to-market without compromising on quality.

Key Benefits of Partnering with SourcifyChina

- Time Efficiency: Skip the vetting phase—start RFQs within 24 hours

- Risk Mitigation: All suppliers factory-verified for production capacity, export history, and quality systems

- Cost Optimization: Competitive pricing from specialized OEMs with economies of scale

- End-to-End Support: From design finalization to shipping logistics and QC inspections

- Customization Expertise: Suppliers experienced in modular, eco-friendly, and themed structures

Call to Action: Accelerate Your Hobbit House Sourcing in 2026

The window for dominating the eco-lifestyle and glamping markets is now. Delaying supplier engagement risks missing peak project cycles and incurring higher costs due to rushed procurement.

Don’t spend weeks guessing which factory can deliver.

With SourcifyChina’s Verified Pro List, you gain instant access to trusted OEM partners ready to produce high-quality, customized hobbit houses—on time and to specification.

👉 Take the next step today:

– Email: contact our sourcing team at [email protected]

– WhatsApp: Connect directly with a Senior Sourcing Consultant at +86 159 5127 6160

Request your free supplier shortlist and capability matrix for China’s top 5 hobbit house OEMs—delivered within 24 hours.

SourcifyChina

Your Trusted Partner in Intelligent China Sourcing

Empowering Global Procurement Teams Since 2014

🧮 Landed Cost Calculator

Estimate your total import cost from China.