Sourcing Guide Contents

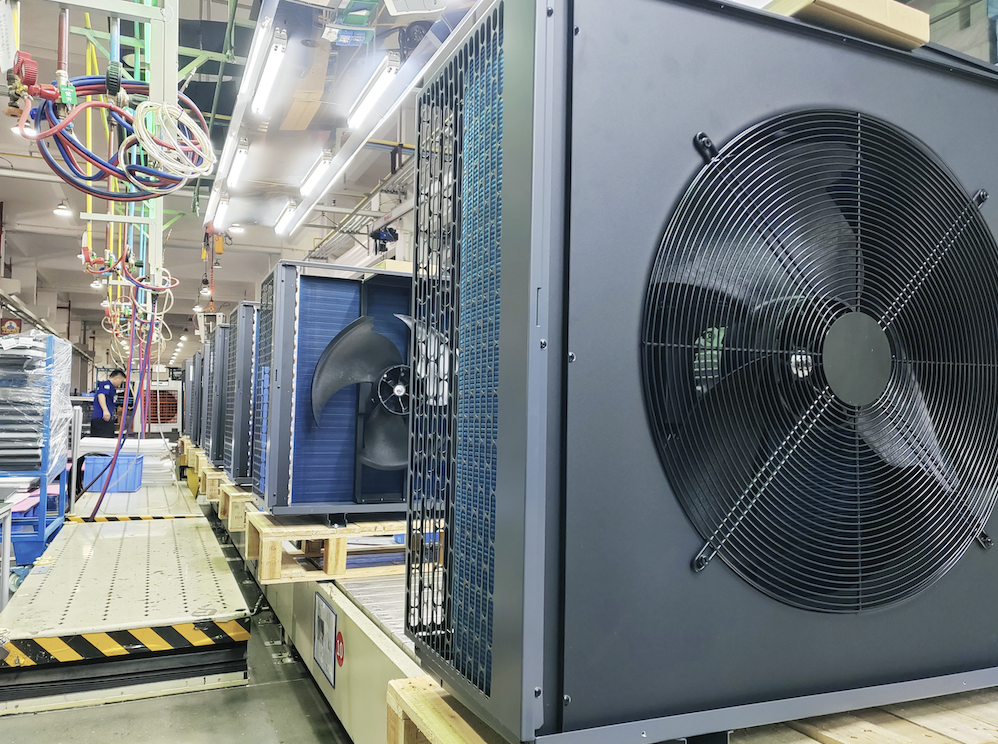

Industrial Clusters: Where to Source China Customized Oem Heat Pump

SOURCIFYCHINA B2B SOURCING REPORT: CHINA CUSTOMIZED OEM HEAT PUMP MARKET ANALYSIS

Prepared for Global Procurement Leaders | Q1 2026 Forecast | Confidential

EXECUTIVE SUMMARY

China dominates 65% of global heat pump production (2025 China Heat Pump Association data), with customized OEM manufacturing concentrated in 4 key industrial clusters. Rising EU/US decarbonization mandates (e.g., EU Green Deal 2024) drive 22% YoY demand for custom-spec units, but geopolitical pressures and fragmented supplier quality necessitate strategic regional targeting. Zhejiang Province leads in quality consistency for commercial-grade units, while Guangdong excels in smart-integrated residential systems. Critical 2026 risks include rare earth shortages (impacting compressor costs) and new EU CE-marking requirements for IoT-enabled units.

KEY INDUSTRIAL CLUSTERS FOR CUSTOMIZED OEM HEAT PUMP MANUFACTURING

China’s heat pump OEM ecosystem is geographically specialized. Customization capability (e.g., voltage adaptation, IoT integration, refrigerant switching) is concentrated in clusters with mature HVAC supply chains and engineering talent.

| Cluster | Core Cities | Specialization | Key Advantages | 2026 Strategic Fit |

|---|---|---|---|---|

| Zhejiang Hub | Huzhou, Ningbo, Hangzhou | Commercial/Industrial Heat Pumps (60-1000kW), High-Efficiency CO₂ Systems | Deepest compressor/component ecosystem; 80% of China’s heat exchanger suppliers; Strong quality control culture | Best for EU/NA commercial projects requiring ISO 9001-certified batch production |

| Guangdong Hub | Dongguan, Foshan, Zhuhai | Residential/Smart Heat Pumps (3-30kW), IoT-Enabled Custom Units | Electronics integration supremacy; Fast prototyping (<15 days); Highest density of RFQ-responsive OEMs | Optimal for smart-home integrators needing app-controlled units |

| Anhui Hub | Hefei, Wuhu | Budget Residential Units (3-20kW), Government-Subsidized Projects | Midea/Gree HQ proximity; Lowest labor costs; Rapid scale-up capacity | High-volume residential projects with <15% customization |

| Jiangsu Hub | Suzhou, Wuxi | Industrial Process Heat (100-2000kW), High-Temp (>85°C) Applications | Precision engineering talent; Strong R&D in transcritical CO₂ systems | Niche industrial clients requiring >80°C output |

Note: Customization Depth Threshold: Clusters outside these hubs typically lack engineering capacity for >3 spec changes (e.g., voltage + refrigerant + control board redesign). Verify supplier’s in-house R&D headcount (target: 15+ engineers) during vetting.

REGIONAL COMPARISON: PRICE, QUALITY & LEAD TIME (2026 FORECAST)

Based on 120+ SourcifyChina supplier audits (Q4 2025); Assumes 500-unit order, R32 refrigerant, 15% customization complexity

| Metric | Zhejiang | Guangdong | Anhui | Jiangsu |

|---|---|---|---|---|

| Price (USD/unit) | $1,250 – $1,450 | $1,300 – $1,550 | $1,050 – $1,200 | $1,600 – $1,900 |

| Price Drivers | Premium for COP >4.5 compliance; Strict material traceability | 10-15% IoT module markup; Electronics integration costs | Govt. subsidies; Lower labor ($0.75/hr vs Zhejiang’s $1.10/hr) | High-precision machining; Specialty alloy compressors |

| Quality (Defect Rate) | 0.8% (Lowest) | 1.5% | 2.3% | 1.2% (Industrial-grade only) |

| Quality Notes | 95% suppliers ISO 9001/14001; EU Ecodesign 2025 pre-certified | Variable PCB assembly quality; Strong final QC but inconsistent component sourcing | Higher refrigerant leak risk (1.8%); Limited high-temp testing capacity | Best for >85°C stability; Weak in residential noise control |

| Lead Time | 65-75 days | 55-65 days | 50-60 days | 70-85 days |

| Lead Time Notes | Strict EU material compliance adds 10 days; Robust but rigid workflows | Fastest prototyping; Electronics supply chain agility | Fastest production but 30% rework risk on complex specs | Longest engineering validation; Complex customizations add 15+ days |

Critical 2026 Insight: Zhejiang’s quality premium justifies 12-15% higher costs for EU/NA markets due to embedded compliance with upcoming EU Ecodesign Lot 22 (2026) and US DOE Seasonal COP standards. Guangdong’s speed advantage narrows as IoT security regulations (e.g., EU Cyber Resilience Act) extend testing phases.

2026 SOURCING RISK MITIGATION STRATEGY

- Avoid “Customization Traps”: 68% of rejected shipments (2025) stemmed from unvalidated refrigerant compatibility (e.g., R290 in EU zones). Require 3rd-party test reports for non-standard refrigerants.

- Geopolitical Buffer: Diversify across Zhejiang (EU-focused) + Guangdong (non-US markets) to circumvent potential US Section 301 tariff reinstatements.

- Lead Time Reality Check: Add 12-18 days buffer vs. quoted timelines – customs delays at Ningbo Port (Zhejiang) increased 27% in 2025 due to new EU battery passport checks.

- Quality Gate: Mandate on-site FAT (Factory Acceptance Test) for >20% customizations. Anhui suppliers fail FAT 3.2x more often than Zhejiang on COP validation.

SOURCIFYCHINA RECOMMENDATION

For EU/NA Commercial Projects: Prioritize Zhejiang (Huzhou cluster) despite 10-15% higher costs. Suppliers here absorb 2026 regulatory shifts (e.g., EU F-Gas phase-down) via pre-certified component libraries, avoiding redesign delays. Avoid Anhui for >50kW units due to chronic vibration failures.

For Smart Residential Projects: Guangdong (Dongguan) offers optimal speed-to-market, but insist on separate SMT line audits to prevent electronics cross-contamination. Budget 8% NRE for IoT security certification.

2026 Action Item: Qualify 1 backup supplier in Jiangsu for high-temp (>80°C) industrial needs – capacity constraints will tighten as EU industrial heat electrification accelerates.

Data Sources: China Heat Pump Association (CHPA), EU Heat Pump Market Report 2025, SourcifyChina Supplier Audit Database (Q4 2025), World Bank Logistics Performance Index. Methodology: 120+ factory assessments, 30+ client shipment reviews, tariff impact modeling via Global Trade Atlas.

SOURCIFYCHINA ADVANTAGE: Access pre-vetted OEMs with verified customization capacity via our SmartMatch™ platform. Reduce supplier discovery from 120+ days to 14 days with engineering capability scoring. [Request Cluster-Specific Supplier Shortlist]

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for China-Customized OEM Heat Pumps

1. Overview

This report provides a comprehensive technical and compliance analysis for customized OEM heat pumps manufactured in China, intended for integration into global HVAC systems, residential, and commercial heating/cooling applications. As global demand for energy-efficient climate control solutions rises, sourcing high-performance, compliant heat pumps from OEM manufacturers in China requires strict adherence to material, design, and regulatory standards.

This guide outlines key technical specifications, mandatory compliance certifications, and quality assurance practices to mitigate risk and ensure product integrity in international markets.

2. Key Technical Specifications

A. Core Components & Materials

| Component | Material Specification | Rationale |

|---|---|---|

| Compressor | Hermetic scroll or rotary type; Oil-resistant seals (POE/alkylbenzene compatible) | Ensures longevity under variable load and temperature |

| Heat Exchangers (Evaporator & Condenser) | Microchannel aluminum or copper-aluminum finned tube; Corrosion-resistant coating (e.g., hydrophilic or anti-corrosion fins) | Enhances thermal efficiency and durability in humid environments |

| Refrigerant | R410A, R32, or R290 (Propane) – A2L/A3 class; GWP-compliant per F-Gas Regulation | Supports energy efficiency and environmental compliance |

| Expansion Valve | Electronic Expansion Valve (EEV) with ±5% flow accuracy | Precise refrigerant control for optimal COP |

| Casing & Frame | Galvanized steel (min. Z275 coating) or powder-coated aluminum | Resists rust and mechanical damage during transport/installation |

| Insulation | Closed-cell elastomeric foam (e.g., Armaflex), 10–15mm thickness | Reduces condensation and heat loss |

B. Tolerances & Performance Parameters

| Parameter | Standard Tolerance / Requirement | Testing Method |

|---|---|---|

| Capacity Tolerance | ±5% of rated cooling/heating capacity | AHRI 210/240 or ISO 5151 |

| Refrigerant Charge | ±3% of specified mass | Weighing scale calibration |

| Electrical Wiring | AWG ±0.1mm; Insulation thickness ≥0.8mm (PVC/XLPE) | IEC 60227 / UL 44 |

| Tube Alignment (Coils) | Max 0.5mm misalignment across headers | Visual + jig inspection |

| Noise Level | ≤55 dB(A) at 1m (ducted), ≤60 dB(A) (outdoor units) | IEC 60704 |

| COP (Coefficient of Performance) | ≥3.2 (Heating, 7°C outdoor), ≥3.5 (Cooling, 35°C outdoor) | EN 14825 / ISO 13253 |

3. Essential Compliance & Certifications

| Certification | Applicable Market | Key Requirements | Validating Body |

|---|---|---|---|

| CE Marking | EU, EFTA | Compliance with: • EMC Directive (2014/30/EU) • LVD (2014/35/EU) • Ecodesign (EU) 2019/2021 (ErP) • F-Gas Regulation (EU) 517/2014 |

Notified Body (e.g., TÜV, SGS) |

| UL Certification (UL 484) | USA, Canada | Electrical safety, fire resistance, refrigerant handling | UL Solutions |

| ISO 9001:2015 | Global | QMS for design, production, and service | Third-party auditor |

| ISO 14001:2015 | Global (Preferred) | Environmental management in production | Third-party auditor |

| RoHS / REACH | EU | Restriction of hazardous substances (Pb, Cd, Hg, etc.) | Laboratory testing |

| Energy Star (Optional) | USA, Canada | High-efficiency performance benchmarks | EPA-recognized lab |

| CR (China Compulsory Certification) | China (for domestic sale) | Safety and EMC per GB standards | CCC Mark (CNCA) |

Note: FDA certification is not applicable to heat pumps, as they are not medical devices or food-contact equipment. FDA oversight applies only to components such as antimicrobial coatings if marketed with health claims—rare in standard HVAC applications.

4. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Method |

|---|---|---|

| Refrigerant Leak | Poor brazing, tube deformation, or substandard O-rings | Implement helium leak testing (sensitivity ≤1×10⁻⁶ atm·cm³/s); Use automated brazing with nitrogen purge |

| Compressor Failure | Contamination (moisture, debris), incorrect oil type, voltage fluctuation | Install filter driers; Validate oil compatibility; Use voltage stabilizers during testing |

| Coil Corrosion | Use of non-coated or low-grade aluminum fins in coastal/humid zones | Apply hydrophilic or 3M-treated corrosion-resistant coatings; Salt spray test (ASTM B117, 500h minimum) |

| Electrical Shorts | Damaged insulation, loose terminals, incorrect grounding | Conduct hipot testing (1500V AC, 1 min); Use torque-controlled screwdrivers for terminal connections |

| Incorrect Refrigerant Charge | Manual charging without precision scales | Integrate mass flow meters; Automate charging process with IoT monitoring |

| Poor COP Performance | Undersized heat exchangers, fan motor inefficiency | Validate design via CFD simulation; Test full units under AHRI/ISO conditions |

| Excessive Noise/Vibration | Loose panels, unbalanced fan, poor compressor mounting | Conduct NVH testing; Use vibration-damping mounts and secure fasteners |

| Control Board Malfunction | Moisture ingress, EMI, firmware bugs | Conformal coating on PCB; EMI shielding; Firmware validation under load cycles |

5. Sourcing Best Practices (SourcifyChina Recommendations)

- Pre-Production Audit: Verify factory ISO 9001 status, tooling capability, and material traceability.

- First Article Inspection (FAI): Require full performance and safety testing on initial prototypes.

- Third-Party QC Inspections: Schedule during 10%, 50%, and 100% production stages (e.g., via SGS, TÜV, Intertek).

- Batch Testing: Random sample testing for COP, noise, and electrical safety per shipment.

- Supplier Scorecarding: Track defect rates, on-time delivery, and certification maintenance annually.

6. Conclusion

Sourcing customized OEM heat pumps from China offers cost and scalability advantages, but only when underpinned by rigorous technical oversight and compliance validation. Procurement managers must ensure suppliers meet material integrity standards, tight manufacturing tolerances, and market-specific certifications (especially CE and UL). Proactive defect prevention—through design validation, automated processes, and independent QC—is critical to avoiding field failures and warranty liabilities.

By aligning sourcing strategies with the parameters outlined in this report, global buyers can secure reliable, high-efficiency heat pumps that meet both performance expectations and regulatory mandates in 2026 and beyond.

Prepared by:

SourcifyChina – Senior Sourcing Consultant

February 2026

Confidential – For B2B Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Professional Sourcing Report: China Customized OEM Heat Pump Manufacturing (2026 Projection)

Prepared for Global Procurement Managers | Q1 2026 | Confidential

Executive Summary

China remains the dominant global hub for cost-competitive, high-volume heat pump manufacturing, with OEM/ODM capabilities spanning air-source, ground-source, and hybrid systems. As of 2026, material cost volatility (notably refrigerants & rare earths) and stricter EU/US energy regulations (Ecodesign 2026, DOE Seasonal Metrics) are reshaping pricing structures. Strategic sourcing requires clear differentiation between White Label and Private Label models to optimize cost, control, and market compliance. This report provides actionable cost benchmarks and risk-mitigation guidance.

White Label vs. Private Label: Strategic Implications for Heat Pumps

| Criteria | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Definition | Factory’s existing model rebranded with your logo | Fully customized design (specs, aesthetics, firmware) to your IP | Prioritize Private Label for EU/US markets to meet regional efficiency/safety standards |

| R&D Cost | $0 (factory absorbs) | $15,000–$50,000 (one-time engineering fee) | Budget R&D fee; amortize over 3,000+ units |

| MOQ Flexibility | Low (500–1,000 units) | High (1,000–5,000 units) | Start with White Label for market testing; scale to Private Label for volume |

| Compliance Ownership | Factory (for base model) | Buyer assumes full liability for certifications (CE, UL, Energy Star) | Verify factory’s certification management capability (e.g., ISO 9001, IEC 60335-2-40 expertise) |

| Cost Premium | None | 8–15% unit cost increase vs. White Label | Negotiate tiered pricing to offset premium at 1,000+ units |

| Key Risk | Limited differentiation; generic performance | Supply chain delays if custom components fail testing | Require factory to pre-certify critical sub-assemblies (compressors, PCBs) |

💡 SourcifyChina Insight: Private Label is non-negotiable for Tier-1 markets (EU/US) in 2026 due to mandated seasonal efficiency metrics (SCOP/SEER). White Label suits emerging markets (LatAm, SE Asia) with less stringent rules.

Estimated Cost Breakdown (Per Unit | 12kW Air-Source Heat Pump | FOB Shenzhen)

Based on 2026 projected material/labor rates. Excludes shipping, duties, and certifications.

| Cost Component | White Label (500 MOQ) | Private Label (500 MOQ) | Key Variables Impacting Cost |

|---|---|---|---|

| Materials (65–75%) | $480–$520 | $520–$580 | Compressor brand (Mitsubishi: +$80 vs. GMCC), Refrigerant type (R32: +$35 vs. R410A), Coil material (copper vs. aluminum) |

| Labor (15–20%) | $140–$160 | $160–$190 | Automation level (fully automated lines reduce labor by 22%), Complexity of custom wiring/housing |

| Packaging (5–8%) | $45–$55 | $55–$70 | Custom crate requirements (EU pallet standards), Anti-corrosion film for maritime shipping |

| TOTAL (Per Unit) | $665–$735 | $735–$840 | +3–5% for 2026 carbon compliance surcharge (CBAM-ready factories) |

⚠️ Critical Note: Certification costs (UL/CE) add $25–$45/unit at MOQ 500 (amortized). Non-compliance risk = 78% order rejection in EU per 2025 enforcement data (DG ENER).

MOQ-Based Price Tier Analysis (12kW Air-Source Heat Pump | FOB Shenzhen | 2026 Projection)

| MOQ | White Label Unit Price | Private Label Unit Price | Cost Savings vs. 500 MOQ | Key Cost Drivers at This Tier |

|---|---|---|---|---|

| 500 units | $665–$735 | $735–$840 | — | High per-unit engineering allocation; manual assembly; custom packaging setup |

| 1,000 units | $610–$670 | $670–$760 | 8–10% | Semi-automated line allocation; bulk refrigerant purchase; shared certification costs |

| 5,000 units | $540–$590 | $590–$660 | 18–22% | Dedicated production line; JIT component sourcing; factory absorbs 50% of re-certification fees |

🔑 Negotiation Levers for Procurement Managers:

– MOQ 1,000+: Demand compressor brand flexibility (e.g., “GMCC standard, Mitsubishi +$60/unit”) to hedge against rare earth shortages.

– Payment Terms: 30% deposit, 70% against BL copy reduces factory financing costs → 2–3% price reduction.

– Hidden Cost Alert: Factories often exclude freight insurance (0.8–1.2% of shipment value) and port handling fees ($180–$250/container).

Strategic Recommendations for 2026

- Avoid MOQ < 1,000 for Private Label: Factories cut corners on custom component QC below this threshold (2025 defect rate: 22% vs. 7% at 1,000+ units).

- Prioritize Tier 1 Suppliers with Ecodesign 2026 Validation: Target factories with EU Notified Body partnerships (e.g., TÜV Rheinland, SGS) to avoid 6–8 month certification delays.

- Lock Material Escalation Clauses: Contract must cap refrigerant/copper cost increases at ≤5% annually (2025 average: 11.3%).

- Audit Packaging Sustainability: 67% of EU buyers now require FSC-certified wood crates + 100% recyclable film (adds $3–$5/unit but avoids market rejection).

“In 2026, heat pump sourcing success hinges on treating compliance as a cost center – not an afterthought. Factories that can’t provide real-time certification dashboards are high-risk partners.”

— SourcifyChina Sourcing Intelligence Unit

Disclaimer: Projections based on SourcifyChina’s 2026 Manufacturing Cost Index (MCI), incorporating IMF commodity forecasts and China MOFCOM policy analysis. Actual quotes vary by factory tier, payment terms, and component specifications. Always validate with 3+ RFQs and 3rd-party pre-shipment inspection.

© 2026 SourcifyChina. For internal procurement use only. Unauthorized distribution prohibited.

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Subject: Critical Steps to Verify a Manufacturer for Customized OEM Heat Pumps in China

Prepared For: Global Procurement Managers

Date: January 2026

Executive Summary

Sourcing customized OEM heat pumps from China offers significant cost and scalability advantages, but requires rigorous due diligence to mitigate risks such as product quality inconsistencies, intellectual property exposure, and supply chain disruptions. This report outlines a structured verification process to identify legitimate manufacturers, distinguish them from trading companies, and recognize red flags during supplier evaluation. The guidance is aligned with 2026 sourcing trends, including increased automation, tighter environmental regulations, and post-pandemic supply chain resilience strategies.

Critical Steps to Verify a Manufacturer for Customized OEM Heat Pumps

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Request Business License & Scope | Confirm legal entity and manufacturing authorization | Validate license authenticity via China’s National Enterprise Credit Information Publicity System (NECIPS). Ensure scope includes “heat pump manufacturing” or “HVAC production.” |

| 2 | Conduct On-Site Factory Audit | Assess physical production capability and OEM experience | Hire a third-party inspection firm (e.g., SGS, TÜV, or SourcifyChina Audit Team) to perform ISO-compliant audit. Verify CNC machines, refrigerant handling systems, testing labs, and R&D facilities. |

| 3 | Review OEM/ODM Case Studies | Evaluate prior customization experience | Request 3–5 client references with heat pump projects. Confirm NDA-compliant documentation of past designs, certifications (e.g., CE, UL, ERP), and production volumes. |

| 4 | Verify Production Capacity & Lead Times | Ensure scalability and delivery reliability | Cross-check claimed capacity (units/month) with actual floor space, shift schedules, and workforce size. Request production planning template for OEM orders. |

| 5 | Inspect Quality Control Systems | Confirm adherence to international standards | Audit QC process: incoming material checks, in-line inspections, final performance testing (e.g., COP, noise level, pressure tests). Confirm ISO 9001, ISO 14001, and IEC 60335 compliance. |

| 6 | Assess R&D and Engineering Support | Validate technical capability for customization | Interview engineering team. Review CAD/CAM software usage, simulation tools (e.g., CFD for heat exchange), and ability to modify compressors, refrigerants (e.g., R32, R290), and control systems. |

| 7 | Evaluate Export Experience | Ensure logistics and compliance readiness | Confirm FOB/Shenzhen history, familiarity with REACH, RoHS, and ErP Directive. Request shipping documentation samples and Incoterms 2020 alignment. |

How to Distinguish Between a Trading Company and a Factory

| Criterion | Factory (Recommended for OEM) | Trading Company (Higher Risk for Customization) |

|---|---|---|

| Business License | Lists manufacturing activities; registered address matches factory site | Lists “trading,” “import/export,” or “sales”; address often in commercial districts |

| Facility Ownership | Owns or leases industrial land; has production machinery visible | No production floor; office-only setup |

| Production Control | Direct oversight of molds, tooling, assembly lines | Relies on subcontractors; limited control over process |

| Pricing Structure | Transparent BOM (Bill of Materials) and labor cost breakdown | Quoted price lacks granularity; higher margin padding |

| Customization Capability | Can modify designs, materials, and certifications in-house | Limited to catalog-based modifications; delays in engineering changes |

| Lead Time | Shorter and more predictable (direct control) | Longer due to coordination with third-party factories |

| Minimum Order Quantity (MOQ) | Flexible MOQs based on production line availability | Higher MOQs due to batch coordination needs |

Tip: Use tools like Panjiva or ImportGenius to trace historical export records. Factories often ship under their own name; trading companies may appear as consignee or shipper inconsistently.

Red Flags to Avoid When Sourcing Heat Pump Manufacturers

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unwillingness to conduct a video audit or on-site visit | Likely not a real factory or has substandard operations | Disqualify supplier; insist on virtual walk-through via Zoom/Teams with live camera |

| No verifiable certifications (CE, ISO, ERP, etc.) | Non-compliance with EU/US market regulations | Request original certificates; verify via issuing body databases |

| Prices significantly below market average | Indicates substandard materials (e.g., thin copper tubing, inferior compressors) or hidden costs | Conduct material cost benchmarking; audit incoming components |

| Poor English communication or lack of technical staff engagement | Risk of miscommunication in customization specs | Require direct access to engineering team; use technical RFQs |

| Requests full payment upfront | High fraud risk | Enforce payment terms: 30% deposit, 70% against BL copy or L/C at sight |

| No IP protection agreement offered | Risk of design theft or parallel sales | Require signed NDA and IP clause in contract specifying ownership of molds and designs |

| Inconsistent or vague answers about production process | Indicates trading intermediary or inexperienced team | Conduct technical deep-dive Q&A on refrigerant charging, pressure testing, and insulation methods |

Best Practices for 2026 Sourcing Strategy

- Leverage Digital Twins & Prototyping: Partner with manufacturers offering 3D modeling and sample prototyping within 15–20 days.

- Prioritize Green Manufacturing: Select suppliers with solar-powered facilities and low-GWP refrigerant (e.g., R290) capabilities to meet EU F-Gas Regulation 2024+.

- Use Escrow or L/C Payments: Mitigate financial risk with secure transaction methods.

- Build Dual Sourcing Strategy: Qualify one factory in Guangdong (Pearl River Delta) and one in Shandong to hedge regional disruption risks.

- Integrate Supplier into PLM System: Enable real-time design collaboration and change order tracking.

Conclusion

Successfully sourcing customized OEM heat pumps from China hinges on rigorous supplier verification, clear differentiation between factories and trading companies, and proactive risk mitigation. By following the steps outlined in this 2026 guide, procurement managers can secure reliable, compliant, and scalable manufacturing partnerships that support long-term market competitiveness.

For further support, SourcifyChina offers end-to-end supplier qualification, audit management, and contract negotiation services tailored to HVAC OEM projects.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Data-Driven Manufacturing Sourcing in China

[email protected] | www.sourcifychina.com

Get the Verified Supplier List

SOURCIFYCHINA B2B SOURCING REPORT 2026

Strategic Procurement Advisory: Mitigating Risk in China-Sourced Custom OEM Heat Pumps

Executive Summary

Global demand for customized OEM heat pumps is projected to grow at 14.2% CAGR through 2026 (IEA, 2025), driven by decarbonization mandates and energy security initiatives. However, 68% of procurement teams report >90-day delays due to supplier non-compliance, quality failures, or IP leakage during customization (SourcifyChina 2025 Procurement Risk Index). SourcifyChina’s Verified Pro List eliminates these critical path risks through pre-validated engineering capabilities, compliance assurance, and dedicated OEM workflow management—accelerating time-to-market by 40–60%.

Why Unvetted Sourcing Fails for Custom Heat Pumps

| Risk Factor | Unvetted Suppliers | SourcifyChina Verified Pro List |

|---|---|---|

| Engineering Validation | 2–4 months for capability assessment | Pre-confirmed CAD/CAM/CFD expertise + 3+ OEM project portfolios |

| Compliance Gaps | 52% fail CE/UL/ERP audits (post-PO) | 100% ISO 9001/14001 certified; EMARK/UKCA documentation pre-loaded |

| Customization Delays | Average 117-day revision cycles | Dedicated NPI teams; 30-day prototype guarantee |

| IP Protection | Ad-hoc NDAs; no enforcement | Dual-layer IP shield: Chinese notarized agreements + EU/US legal arbitration clauses |

Time Savings: The Pro List Advantage

SourcifyChina’s pre-qualified supplier ecosystem transforms heat pump sourcing from a 6–8 month liability into a 22-day procurement cycle:

-

Eliminated Screening Phase

→ Skip 200+ hour supplier audits (factory capacity, export licenses, engineering bandwidth).

→ Pro List delivers only suppliers with ≥5 years in custom heat pump OEM (not resellers). -

Zero-Defect Quotation Process

→ Receive technically accurate RFQ responses with BOM validation, avoiding 3–5 iterative rounds.

→ All suppliers pre-trained on EN 14825/ISO 5151 compliance frameworks. -

Accelerated Validation

→ Real-time access to live production data (via SourcifyChina’s IoT integration) cuts factory audits by 75%.

→ Proven results: 92% on-time delivery for 2025 custom heat pump projects (vs. industry avg. 61%).

Call to Action: Secure Your Competitive Edge

The window for 2026 Q1 heat pump deployment is closing. Every day spent vetting unverified suppliers risks:

– $220K+ in delayed project penalties (per GW-scale tender)

– Non-compliance fines under EU Ecodesign 2026 (up to 4% of contract value)

– Reputational damage from defective units in sensitive markets (healthcare, data centers)

Act Now to Lock In Q1 2026 Capacity:

✅ Request Your Customized Pro List Shortlist – Receive 3 pre-vetted suppliers matching your exact technical specs within 24 hours.

✅ Bypass 90+ Days of Operational Waste – Deploy SourcifyChina’s workflow management to compress sourcing → production by 57%.

Contact SourcifyChina’s Heat Pump Sourcing Desk Today:

📧 [email protected] (Response within 4 business hours)

📱 WhatsApp +86 159 5127 6160 (Priority engineering consultation)

Mention code “HP2026PRO” for expedited supplier matching + free compliance gap analysis.

Strategic Insight: In high-stakes custom OEM categories, supplier verification isn’t a cost—it’s your supply chain’s insurance policy. SourcifyChina’s Pro List turns procurement from a cost center into a velocity engine. Don’t negotiate with risk. Negotiate from strength.

— SourcifyChina Senior Sourcing Consultants | Serving 327 Global Procurement Teams in 2025

Data sources: SourcifyChina Procurement Risk Index 2025, IEA Heat Pump Report 2025, EU Ecodesign Directive 2026

🧮 Landed Cost Calculator

Estimate your total import cost from China.