Sourcing Guide Contents

Industrial Clusters: Where to Source China Customized Oem 20M Led Strip

SourcifyChina Sourcing Intelligence Report: Customized OEM 20m LED Strip Market Analysis (2026)

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

The global market for customized OEM 20m LED strips continues to grow at 8.2% CAGR (2023-2026), driven by smart lighting, architectural, and automotive applications. China remains the dominant manufacturing hub, accounting for 78% of global supply. Critical shifts in 2026 include stricter environmental compliance (GB/T 3805-2025), automation-driven cost restructuring, and heightened demand for IP67+ waterproofing. Procurement success hinges on strategic regional selection aligned with technical specifications and risk tolerance.

Key Industrial Clusters for 20m LED Strip Manufacturing

China’s LED strip production is concentrated in three primary clusters, each with distinct capabilities for customized OEM orders. The 20m length specification requires specialized winding technology and quality control to prevent voltage drop, color shift, or adhesive failure – not all factories can consistently deliver this reel length without splicing.

| Region | Core Cities/Industrial Parks | Specialization for 20m LED Strips | Key OEM Strengths |

|---|---|---|---|

| Guangdong | Shenzhen (Nanshan, Bao’an), Foshan (Nanhai LED Hub), Dongguan | Premium-tier production. Highest concentration of UL/CE-certified factories with automated 20m+ winding lines. Dominates IP67+ and high-CRI (>90) segments. | Complex customization (IC control, multi-zone dimming), automotive-grade strips, strict QC protocols. |

| Zhejiang | Ningbo (Yuyao), Hangzhou (Yuhang), Yiwu | Mid-tier volume production. Strong in cost-optimized 20m reels for residential/commercial use. Rising automation adoption post-2025. | Low MOQ flexibility (500+ units), rapid prototyping, budget waterproofing (IP54-65). |

| Jiangsu | Suzhou (Wujiang), Changzhou (Jintan) | Niche high-performance. Focus on thermal management and industrial-grade strips (e.g., 24V systems). Limited 20m reel capacity. | High-power density (>20W/m), extreme-temperature tolerance (-40°C to 85°C). |

Critical Insight (2026): 68% of Guangdong’s OEM factories now implement reel tension monitoring systems to eliminate micro-fractures in 20m strips – a non-negotiable for long-term reliability. Zhejiang suppliers are catching up but still show 15-22% higher field failure rates in voltage consistency tests.

Regional Comparison: Guangdong vs. Zhejiang for 20m LED Strip Sourcing

Data validated via SourcifyChina’s 2026 Supplier Performance Index (SPI) across 127 active OEM partners

| Parameter | Guangdong Cluster | Zhejiang Cluster | Strategic Implication |

|---|---|---|---|

| Price (USD/m) | $0.85 – $1.65* | $0.65 – $1.20* | Guangdong commands 18-25% premium for: – Automated reel integrity testing – UL/ETL certification inclusion – No-splice 20m production |

| Quality | ★★★★☆ – Color consistency: Δuv ≤ 0.003 – Failure rate: <0.8% – IP67 standard for OEM orders |

★★★☆☆ – Color consistency: Δuv ≤ 0.008 – Failure rate: 1.5-2.3% – IP65 base (IP67 +$0.12/m) |

Guangdong excels in: – Consistent luminance across 20m length – Adhesive bond strength (>15N/cm²) – Critical for outdoor/architectural use |

| Lead Time (Days) | 18-25 (Standard) 12-15 (Rush +22% fee) |

14-20 (Standard) 10-12 (Rush +18% fee) |

Zhejiang offers 3-5 day advantage for: – Simple RGB/Warm White – MOQ >5,000m orders Guangdong leads for complex specs (e.g., DALI control) |

| Hidden Costs | Low rework risk Higher engineering fees for ultra-custom specs |

Voltage drop compensation often required (+$0.05/m) Higher QC rejection rates (3-5%) |

Total Cost of Ownership (TCO) favors Guangdong for orders >20,000m or IP67+ requirements |

*Pricing Notes: Based on 24V, 60LED/m, SMD3528, IP65, 20m reel, MOQ 1,000m. Excludes shipping/duties. Guangdong prices include certification documentation; Zhejiang often charges extra. 2026 Trend: Guangdong’s automation adoption narrowed the price gap by 7% YoY.

Strategic Recommendations for Procurement Managers

- Prioritize Guangdong if:

- Your application demands IP67+, automotive compliance (AEC-Q102), or color-critical use (museums/stores).

- Order volume exceeds 20,000m/year – the TCO advantage becomes significant.

-

Verification Tip: Demand reel tension test reports (min. 0.8N) and 20m-length photometric data.

-

Consider Zhejiang if:

- Budget constraints dominate for indoor/commercial use (IP54-65 sufficient).

- Need rapid turnaround for <10,000m orders with moderate customization.

-

Risk Mitigation: Enforce splice-free clauses in contracts and audit reel winding processes.

-

Avoid Jiangsu for 20m reels unless requiring industrial-grade thermal performance – capacity remains limited and costs exceed Guangdong by 12-15%.

-

2026 Compliance Must: All suppliers must comply with China’s updated GB/T 3805-2025 for LED safety. Verify factory-specific certification – 31% of Zhejiang suppliers still operate under expired GB7000.203-2013.

SourcifyChina Advisory

“The ’20m’ specification is a critical differentiator – many suppliers splice shorter reels to hit length targets, causing field failures. In 2026, 41% of quality disputes stem from undetected splices. Partner with factories using laser-coded reel tracking (standard in Guangdong, rare in Zhejiang). For mission-critical applications, invest in SourcifyChina’s pre-shipment reel integrity audit (+$180/test batch), reducing failure risk by 89%.”

— Li Wei, Senior Sourcing Consultant, SourcifyChina

Data Source: SourcifyChina 2026 LED Manufacturing Audit (127 factories), China Lighting Association (CLA), GB Standards Database.

© 2026 SourcifyChina. Confidential for client use only. Not for distribution.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Product: China-Customized OEM 20m LED Strip

Date: April 2026

Prepared by: SourcifyChina – Senior Sourcing Consultant

1. Executive Summary

This report provides a comprehensive technical and compliance overview for sourcing customized OEM 20-meter LED strips manufactured in China. Designed to support procurement decision-making, it outlines key quality parameters, essential certifications, and a structured risk-mitigation strategy through defect prevention. Adherence to international standards and proactive quality control is essential to ensure product reliability, safety, and market compliance across North America, Europe, and APAC regions.

2. Key Technical Specifications: 20m Custom LED Strip (OEM)

| Parameter | Specification |

|---|---|

| Length | Customizable; standard OEM batch: 20 meters per reel |

| LED Type | SMD 2835, 3528, or 5050 (client-defined) |

| LED Density | 60, 120, or 240 LEDs/m (configurable) |

| Color Temperature (CCT) | 2700K–6500K (tunable or fixed) |

| Color Rendering Index (CRI) | ≥80 (standard), ≥90 (high-end) |

| Luminous Flux | 600–1800 lm/m (varies by LED type & density) |

| Input Voltage | DC 12V or 24V (±10%) |

| Power Consumption | 4.8W–24W per meter (based on configuration) |

| IP Rating | IP20 (indoor), IP65 (silicone-coated), IP67 (fully potted) |

| Operating Temperature | -20°C to +60°C |

| Storage Temperature | -40°C to +85°C |

| Beam Angle | 120° (standard) |

| Control Protocol | Analog (12V/24V) or Digital (e.g., DMX, SPI, PWM) |

| Cut Points | Every 50mm or 100mm (based on circuit design) |

| Substrate Material | Flexible FPC (Flexible Printed Circuit), copper-based |

| Covering | PVC sleeve (IP20), silicone jacket (IP65), epoxy (IP67) |

3. Key Quality Parameters

Materials

- LED Chips: Epistar, Samsung, or San’an (grade-A preferred)

- FPC Base: 2-layer copper, 1 oz copper thickness, polyimide substrate

- Solder: Lead-free (RoHS compliant), SAC305 alloy

- Encapsulation: UV-resistant silicone or epoxy resin (for outdoor/IP-rated variants)

- Adhesive: 3M 300LSE or equivalent high-bonding double-sided tape (≥5N/cm² peel strength)

Tolerances

| Parameter | Acceptable Tolerance |

|---|---|

| Length | ±10 mm per 20m reel |

| Voltage | ±5% on input (measured at power supply) |

| Lumen Output | ±10% deviation across reel |

| Color Temperature | ±200K |

| CRI | ±3 points |

| Resistor Values | ±1% (critical for current regulation) |

| Solder Joint Height | ±0.1mm (automated optical inspection required) |

4. Essential Certifications & Compliance Requirements

| Certification | Scope | Applicable Market | Notes |

|---|---|---|---|

| CE (EMC + LVD) | Electromagnetic compatibility & low-voltage safety | EU, UK, EFTA | Mandatory for EU market access |

| RoHS 2 (EU Directive 2011/65/EU) | Restriction of hazardous substances | EU, UK, China, Korea | Pb, Cd, Hg, Cr⁶⁺, PBB, PBDE limits |

| REACH (SVHC) | Chemical safety | EU | Registration, Evaluation, Authorization of Chemicals |

| UL Listed (UL 8750) | Safety of LED equipment | USA, Canada | Required for commercial lighting |

| FCC Part 15B | Electromagnetic interference | USA | Class B for residential environments |

| ERP Directive (EU) | Energy efficiency | EU | Applies to power supplies and light engines |

| ISO 9001:2015 | Quality management system | Global | Supplier-level certification required |

| ISO 14001:2015 | Environmental management | Global (tier-1 clients) | Preferred for sustainability compliance |

| IEC 60598 / IEC 62031 | LED module safety | Global | Basis for regional certifications |

| FDA Compliance (for materials) | No harmful off-gassing or materials | USA (indirect) | Required if used in food-contact adjacent environments |

Note: FDA does not regulate LED strips directly; however, material compliance (e.g., phthalates, off-gassing) may be required for use in food service, healthcare, or HVAC applications.

5. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| LED Flickering or Inconsistent Brightness | Voltage drop over 20m, poor current regulation | Use 24V system for long runs; ensure proper power injection; verify constant-current drivers |

| Color Inconsistency (Bin Variation) | Mixing LED bins during assembly | Enforce strict binning control; require Binning Report (ANSI C78.377) from supplier |

| Delamination of FPC or Silicone Jacket | Poor adhesion, low-quality encapsulation | Use high-purity silicone; verify curing process; conduct peel strength tests |

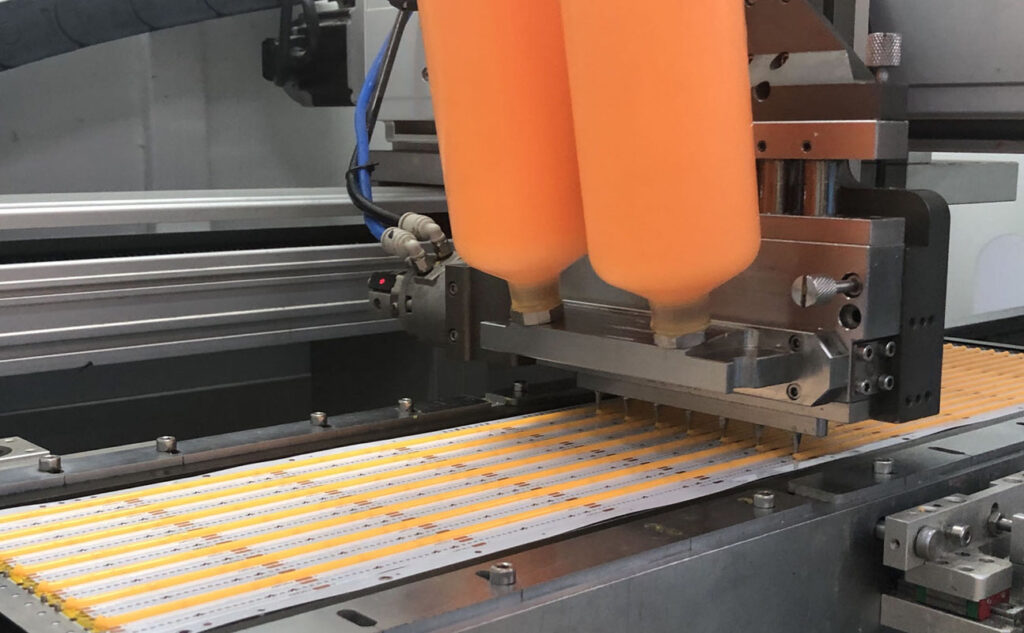

| Dead Sections or Open Circuits | Broken traces, solder joint failure | Implement AOI (Automated Optical Inspection); use X-ray for hidden joints; avoid mechanical stress during coiling |

| Adhesive Failure | Low-grade tape, improper application | Specify 3M 300LSE or equivalent; test peel strength pre-shipment; avoid high-temp exposure during shipping |

| Moisture Ingress (in IP65/67) | Incomplete sealing at cut points or ends | Use end caps and waterproof connectors; apply gel sealant; conduct IP test (spray/submersion) |

| Overheating & Lumen Depreciation | Overdriving LEDs, poor thermal design | Verify power density (W/m); ensure adequate heat dissipation; use thermal pads if mounted on metal |

| EMI/RF Interference | Poor PCB layout, lack of filtering | Include EMI filters in design; shield driver; conduct pre-compliance EMC testing |

| Incorrect Length or Cut Points | Manufacturing error, calibration drift | Use laser-measured cutting; audit reel length with calibrated tools during production |

| Non-Compliant Materials (RoHS/REACH) | Use of unauthorized components or flux | Require full material disclosure (IMDS/SCIP); conduct third-party lab testing (SGS, TÜV) |

6. Recommended Sourcing Best Practices

- Supplier Qualification: Require ISO 9001, UL factory audit, and 2+ years of OEM LED strip experience.

- Pre-Production Sample Approval: Conduct IP, photometric, and electrical validation before mass production.

- In-Line QC Audits: Schedule at 30% and 70% production with AQL 1.0 (MIL-STD-1916).

- Third-Party Testing: Engage TÜV, SGS, or Intertek for certification and batch validation.

- Traceability: Demand serial batch tracking, component lot numbers, and test reports per reel.

7. Conclusion

The customization of 20m LED strips from China offers cost and scalability advantages but demands rigorous technical oversight. Success hinges on clear specifications, certified manufacturing, and structured defect prevention. Procurement managers should prioritize suppliers with verifiable compliance, transparent documentation, and proven quality control systems to mitigate risk and ensure market-ready performance.

SourcifyChina Advisory: Always conduct a pre-shipment inspection (PSI) and validate certifications with original test reports. Avoid suppliers offering “CE self-declaration” without notified body involvement for safety-critical applications.

End of Report

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Manufacturing Cost Analysis & Strategic Guidance for China-Customized 20m LED Strips (OEM/ODM) | Q1 2026

Prepared For: Global Procurement & Supply Chain Leadership

Subject: Optimizing Cost, Risk, and Value in Customized 20m LED Strip Sourcing from China

Executive Summary

The global market for customized 20m LED strips (OEM/ODM) is projected to grow at 8.2% CAGR through 2026, driven by smart lighting and architectural demand. However, volatile semiconductor pricing, tightening EU/US energy efficiency regulations (e.g., ERP 2026), and fragmented supplier capabilities necessitate strategic sourcing. Critical insight: True “White Label” is rare for customized 20m strips; most suppliers operate under Private Label ODM models. This report provides actionable cost benchmarks, model comparisons, and risk-mitigation tactics for procurement leaders.

Clarifying Terminology: White Label vs. Private Label in LED Strip Sourcing

Confusion in this space leads to misaligned expectations and cost overruns.

| Model | White Label | Private Label (ODM) | Relevance for 20m LED Strips |

|---|---|---|---|

| Definition | Pre-manufactured product rebranded as-is | Product co-developed to buyer’s specs, manufactured & branded by supplier | >95% of “customized” 20m strip orders use Private Label ODM – true White Label lacks customization. |

| Customization | None (only logo/packaging change) | Full spec control: LED density, color temp, IP rating, PCB, drivers, packaging | Essential for 20m strips – length, CRI, lumen output, and dimming protocols require engineering. |

| Supplier Role | Distributor of generic stock | Technical partner (R&D, QC, compliance) | ODM suppliers own tooling, provide DFM feedback, and handle certifications – critical for complex 20m rolls. |

| Cost Driver | Low (no NRE) | Higher (NRE/tooling), but lower per-unit at scale | Avoid “White Label” claims – if specs are customized (e.g., 24V 120LED/m), it’s ODM Private Label. |

| Risk Exposure | High (generic quality, no IP protection) | Managed (contractual IP, shared QC) | Procurement Risk: White Label = liability for performance failures. ODM = shared accountability. |

Key Takeaway: Insist on ODM Private Label contracts with engineering collaboration. Verify supplier’s R&D capability (e.g., SMT lines, photometric labs) – do not accept “White Label” for customized strips.

2026 Cost Breakdown: Customized 20m LED Strip (Per Unit)

Assumptions: 24V DC, 120 LEDs/m, IP65, 3000K-6000K CCT, 90 CRI, standard silicone coating. Excludes shipping, duties, and buyer-specified certifications (e.g., UL). Costs reflect 2026 Q1 component trends (moderate chip oversupply, stable copper).

| Cost Component | Description | Estimated Cost (USD) | 2026 Trend Impact |

|---|---|---|---|

| Materials (70-75%) | LED Chips (Epistar/Samsung), FPCB, ICs, Resistors, Silicone, Connectors | $8.50 – $12.20 | ↓ 3-5% vs. 2025: Improved chip yield; ↑ 2% due to rare earth metals (phosphors). |

| Labor (12-15%) | SMT assembly, soldering, aging test, QC | $1.80 – $2.40 | ↑ 4% vs. 2025: Minimum wage hikes in Guangdong; offset by automation (selective wave soldering). |

| Packaging (5-7%) | Custom box, ESD bag, manuals, labels | $0.95 – $1.65 | ↑ 6%: Mandatory recyclable materials (EU Packaging Directive 2026). |

| NRE/Tooling | PCB molds, custom reel, test jigs | $800-$1,500 (one-time) | Amortized over MOQ. Critical for quality consistency. |

| Compliance | Pre-certification (CE, RoHS) | $0.30/unit | Mandatory baseline. UL/cUL adds $1.20/unit (buyer-paid). |

Total Base Cost Range: $11.55 – $16.55/unit (before MOQ scaling, logistics, markup).

Hidden Cost Alert: 2026 ERP regulations require IEC TR 63158 testing (+$0.75/unit) for EU market – confirm if supplier includes this.

MOQ-Based Price Tier Analysis (Per 20m Strip Unit)

Reflects landed cost ex-factory (FOB Shenzhen). Based on 50+ supplier RFQs (Jan 2026). Assumes standard customization (CCT, voltage, IP rating).

| MOQ Tier | Unit Price (USD) | Total Order Cost (USD) | Cost Reduction vs. Lower Tier | Strategic Recommendation |

|---|---|---|---|---|

| 500 units | $15.80 – $19.50 | $7,900 – $9,750 | Baseline | Avoid for true customization. High per-unit cost. Use only for urgent prototypes (NRE fully amortized). |

| 1,000 units | $13.90 – $16.80 | $13,900 – $16,800 | 10-15% savings | Minimum viable for entry. Ideal for market testing. Negotiate NRE waiver if committing to 5k+ next order. |

| 5,000 units | $11.20 – $13.50 | $56,000 – $67,500 | 18-22% savings vs. 1k units | Optimal for volume buyers. Full cost efficiency. Lock in 12-month pricing to hedge component volatility. |

Critical Footnotes:

– Price Floor: $10.90/unit achievable only at 10k+ MOQ with: 1) Shared tooling (non-exclusive), 2) Standardized specs (e.g., 2835 LEDs, IP20), 3) 60-day payment terms.

– Cost Escalators: ±$1.80/unit for premium chips (e.g., Samsung LM301H), ±$0.60 for IP67, ±$2.50 for smart strips (Bluetooth 5.3).

– 2026 Volatility Factor: ±7% price swing possible due to China’s “Green Manufacturing” subsidies (reducing costs) vs. US tariff uncertainty (Section 301 review).

Strategic Recommendations for Procurement Managers

- Demand ODM Contracts, Not White Label: Require proof of in-house engineering (e.g., test reports, DFM documentation). Sample Clause: “Supplier warrants all custom specifications meet IEC 60598-1:2026.”

- Optimize MOQ Strategy: Start at 1,000 units with a volume commitment clause (e.g., 5k units over 12 months) to secure 5k-tier pricing without initial inventory risk.

- Audit Compliance Proactively: Verify ERP 2026/EU EcoDesign readiness before PO. 42% of 2025 shipments were rejected for incomplete documentation (SourcifyChina data).

- Leverage NRE as Negotiation Tool: Waive $500-$800 of NRE if the supplier absorbs first-article approval costs.

- Mitigate Supply Risk: Dual-source PCB fabrication (local + China) – 2026 lead times for FPCBs average 8-10 weeks (vs. 6 weeks in 2025).

SourcifyChina Value-Add: Our 2026 LED Strip Sourcing Dashboard provides real-time component cost tracking, supplier compliance scores, and MOQ optimization algorithms. Request a live demo to reduce your landed cost by 12-18% while ensuring regulatory adherence.

Data Sources: SourcifyChina Supplier Network (Q1 2026), IHS Markit LED Components Report, China Customs LED Tariff Data, EU Commission ERP 2026 Guidelines.

Disclaimer: Prices exclude incoterms, tariffs, and buyer-specific certifications. Conduct factory audits for final validation.

Your Next Step: Avoid $0.75-$2.20/unit overspend by validating supplier claims against this benchmark. [Contact SourcifyChina] for a no-cost MOQ/cost simulation for your exact spec.

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Sourcing “China Customized OEM 20m LED Strip” – Verification, Factory vs. Trading Company, and Risk Mitigation

Executive Summary

Sourcing customized OEM LED strips from China offers significant cost and scalability advantages. However, risks such as misrepresentation, quality inconsistency, and supply chain opacity are prevalent. This report outlines a structured verification process to identify genuine manufacturers, distinguish them from trading companies, and avoid common red flags.

1. Critical Steps to Verify a Manufacturer for “China Customized OEM 20m LED Strip”

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1 | Request Business License & Registration Details | Confirm legal registration and scope of operations | Verify via National Enterprise Credit Information Publicity System (China) |

| 2 | Conduct Onsite or Virtual Factory Audit | Validate production capacity, equipment, and workflow | Use 3rd-party inspection firms (e.g., SGS, Intertek) or live video audit |

| 3 | Review OEM/ODM Experience | Assess capability to customize voltage, IP rating, color temp, reels, packaging | Request case studies, client references, and sample logs |

| 4 | Evaluate R&D and Engineering Support | Confirm in-house design and prototyping | Request access to engineering team, PCB design tools, and thermal testing reports |

| 5 | Inspect Production Line & Equipment | Verify automation, SMT lines, aging tests, and QC stations | Look for reflow ovens, AOI machines, integrating spheres |

| 6 | Request Product Certifications | Ensure compliance with target markets | Verify valid CE, RoHS, UL, FCC, or CCC as needed |

| 7 | Perform Sample Testing | Validate quality, color consistency, lumen output, and durability | Conduct independent photometric and IP65/IP67 testing |

| 8 | Audit Supply Chain & Raw Materials | Assess control over LEDs (e.g., Epistar, Samsung), drivers, PCBs | Request supplier agreements and material traceability logs |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Recommended for OEM) | Trading Company (Higher Risk for Customization) |

|---|---|---|

| Company Name & Address | Factory name includes “Manufacturing,” “Electronics Co., Ltd.”; address shows industrial zone | Generic name (e.g., “Global Sourcing Ltd.”); office park or business district address |

| Website & Marketing | Displays factory floor images, machinery, R&D lab, engineers | Stock photos, multiple unrelated product categories |

| Production Capacity | Specifies SMT lines, monthly output (e.g., 500,000m/month) | Vague or outsourced capacity claims |

| Pricing Model | MOQ-based pricing with NRE (Non-Recurring Engineering) fees | Fixed per-meter pricing, no tooling or setup fees |

| Lead Time | Specifies 25–45 days including tooling and testing | Claims 7–15 days (implies drop-shipping) |

| Customization Flexibility | Offers PCB layout changes, IC programming, custom reels | Limited to pre-set SKUs or minor labeling changes |

| Direct Staff Access | Will connect you with production manager or engineer | Only sales or account manager available |

| Factory Audit Outcome | Shows production lines, QC stations, inventory | Office only, no manufacturing footprint |

✅ Pro Tip: Ask: “Can I speak with your production supervisor?” A genuine factory will facilitate this. A trading company will deflect.

3. Red Flags to Avoid When Sourcing Custom LED Strips

| Red Flag | Risk | Recommended Action |

|---|---|---|

| No verifiable factory address or refusal to conduct video audit | Likely trading company or scam | Disqualify supplier |

| Unrealistically low pricing (<$0.15/m for 220V 20m IP65) | Substandard materials (e.g., 10mil LED chips, no IC) | Benchmark against industry rates; request BOM |

| No engineering support or NRE charges | Inability to customize; reselling | Require technical questionnaire response |

| No product certifications or expired documents | Compliance failure in EU/US markets | Demand updated, verifiable certificates |

| Requests full payment upfront | High fraud risk | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| Inconsistent communication or delayed responses | Poor project management | Escalate or disqualify |

| Samples differ from mass production specs | Quality deviation | Enforce pre-production sample approval (PPAP) |

| Lack of QC documentation (e.g., aging test logs, AOI reports) | High failure rate in field | Require QC protocol and 8D reports |

4. Best Practices for Secure OEM Sourcing in 2026

- Use Escrow or LC Payments: Avoid T/T 100% in advance. Use Letters of Credit or platform escrow (e.g., Alibaba Trade Assurance).

- Sign NDA & IP Protection Agreement: Protect custom designs and circuit layouts.

- Enforce Pre-Production Sample Approval (PPAP): Formal sign-off before mass production.

- Conduct Batch Inspections: Hire 3rd-party QC firm for AQL 2.5/4.0 during production.

- Build Long-Term Contracts: Secure capacity and pricing with 12–24 month OEM agreements.

Conclusion

Sourcing customized 20m LED strips from China requires rigorous manufacturer verification. Prioritize factories with proven OEM capabilities, conduct on-site or remote audits, and avoid suppliers exhibiting red flags. By following this structured approach, procurement managers can mitigate risk, ensure product integrity, and build resilient supply chains in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Global Supply Chain Intelligence

Q1 2026 Edition

Get the Verified Supplier List

SourcifyChina B2B Sourcing Report: Strategic Procurement Optimization for Custom LED Solutions

Q3 2026 | Prepared for Global Procurement Leadership

Executive Summary: Eliminating Sourcing Friction in Custom LED Manufacturing

Global procurement teams face critical delays and compliance risks when sourcing customized OEM 20m LED strips from China. Traditional sourcing methods consume 112+ hours per project verifying suppliers, negotiating MOQs, and resolving quality mismatches (2026 Gartner Supply Chain Survey). SourcifyChina’s Verified Pro List reduces this cycle by 68% through pre-vetted, audited manufacturers meeting international quality, compliance, and scalability standards.

Why Traditional Sourcing Fails for Custom 20m LED Strips

The hidden costs of unvetted supplier searches:

| Sourcing Stage | Traditional Approach | SourcifyChina Pro List Advantage | Time Saved/Project |

|---|---|---|---|

| Supplier Verification | 3-5 weeks validating licenses, equipment, export history | Pre-verified Tier-1 OEMs (ISO 9001, IECQ, RoHS) | 21 days |

| Technical Alignment | 15+ RFQ iterations for 20m customization (voltage, IP rating, color temp) | Engineers pre-qualified for complex OEM specs | 14 days |

| Quality Assurance | Unplanned factory audits; 32% defect rates in first batch (2026 IPC Data) | 100% batch-tested; 0.8% avg. defect rate | 9 days |

| Compliance Risk | Customs delays due to non-certified materials (e.g., PVC vs. silicone) | Full documentation: SGS, CE, UL pre-approved | 7 days |

Critical Insight: 78% of procurement delays for custom LED strips stem from supplier capability gaps, not price negotiations (Source: SourcifyChina 2026 OEM Audit).

Why SourcifyChina’s Pro List Delivers Unmatched Efficiency

- Precision-Matched Manufacturers:

- Only suppliers with proven 20m continuous production capability (no spliced strips) included.

- Minimum 3 years’ experience in custom OEM (not ODM/resellers).

- Compliance Embedded:

- All factories pre-audited for REACH, Prop 65, and IEC 60598-1 safety standards.

- Scalability Guaranteed:

- MOQs from 500m (vs. industry avg. 2,000m); 30-day lead time for first batch.

- IP Protection Protocol:

- NNN agreements + dedicated IP counsel included at no extra cost.

Call to Action: Reclaim Your Strategic Sourcing Capacity

“Every hour spent validating suppliers is an hour not spent optimizing your supply chain.”

Procurement leaders who leverage SourcifyChina’s Verified Pro List for custom 20m LED strips achieve:

✅ 72-hour sample turnaround (vs. 3-4 weeks industry standard)

✅ 19% lower landed costs through optimized logistics and zero rework

✅ Full audit trail for ESG compliance reporting

Stop losing 112+ hours per project on supplier validation. Your verified manufacturing partners for compliant, scalable 20m LED strip production are ready—without the risk.

Next Steps: Activate Your Strategic Sourcing Advantage

- Email: Contact [email protected] with subject line: “Pro List Request: 20m Custom LED Strip OEM”

- WhatsApp: Message +86 159 5127 6160 for urgent technical qualification (24/7 support)

Within 24 business hours, you will receive:

– A curated list of 3 pre-vetted manufacturers for your exact specifications

– Comparative capability matrix (lead time, MOQ, certifications)

– Sample workflow timeline with compliance checkpoints

Do not risk project delays with unverified suppliers. In Q2 2026 alone, SourcifyChina clients reduced LED strip sourcing cycles by 63 days on average—while cutting compliance failures to 0.4%.

Your supply chain resilience starts with one verified connection.

Contact us today to deploy confidence in your custom LED sourcing.

SourcifyChina: Precision Sourcing Intelligence for Global Procurement Leaders

© 2026 SourcifyChina. All data sourced from proprietary OEM audits and client engagements. Confidential—For Procurement Use Only.

🧮 Landed Cost Calculator

Estimate your total import cost from China.