Sourcing Guide Contents

Industrial Clusters: Where to Source China Customized Oem 10M Led Strip Lights

SourcifyChina Sourcing Market Report 2026

Product Focus: Customized OEM 10m LED Strip Lights

Target Audience: Global Procurement Managers

Prepared by: SourcifyChina – Senior Sourcing Consultant

Date: April 2026

Executive Summary

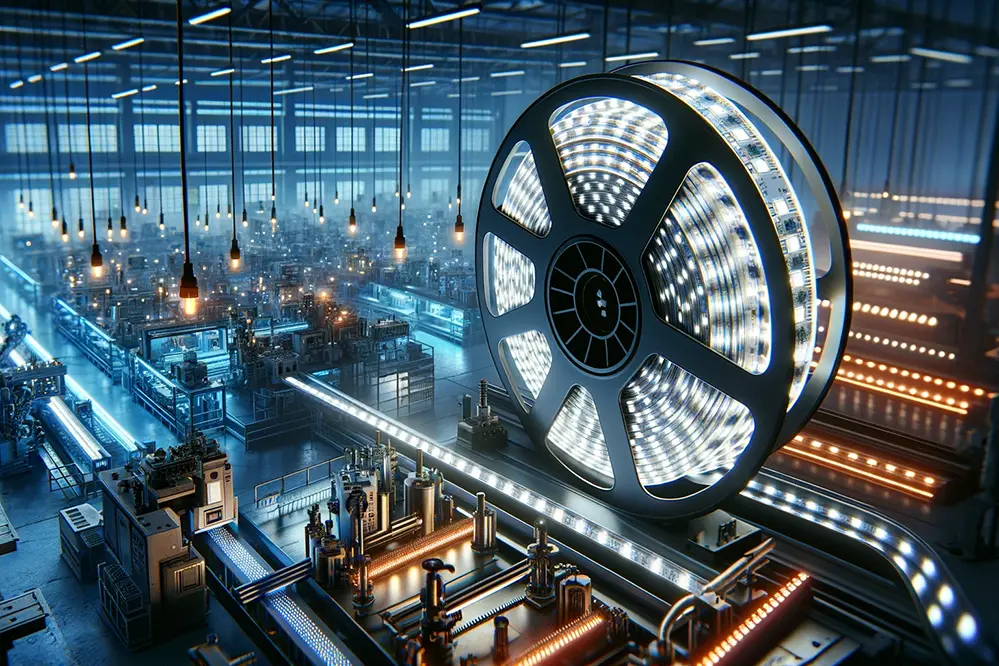

The global demand for customized OEM LED strip lights—particularly 10-meter reels—continues to rise, driven by growth in architectural lighting, smart homes, automotive interiors, and commercial retail environments. China remains the dominant manufacturing hub, offering competitive pricing, scalable production, and advanced customization capabilities. This report provides a strategic analysis of key industrial clusters producing customized OEM 10m LED strip lights, with a comparative assessment of Guangdong and Zhejiang, the two leading provinces in volume, innovation, and export readiness.

Procurement managers seeking to optimize cost, quality, and lead time for LED strip lights should focus on these core regions while considering supply chain resilience, technical specialization, and compliance requirements.

Key Industrial Clusters for OEM 10m LED Strip Lights in China

The production of customized LED strip lights in China is highly concentrated in two coastal provinces, each with distinct advantages:

1. Guangdong Province – The Lighting Heartland

- Primary Hub: Foshan (especially Nanhai District), Shenzhen, Guangzhou

- Cluster Strengths:

- World’s largest LED manufacturing ecosystem.

- High concentration of Tier-1 suppliers, R&D centers, and export logistics.

- Strong expertise in SMD LED packaging, flexible PCBs, and smart lighting integration.

- Dominant in high-end, IP65/IP67 waterproof, and RGBW customizable strips.

- OEM/ODM Readiness: Excellent—most factories support full customization (color temperature, CCT tuning, PCB length, connectors, reels, packaging).

- Export Infrastructure: Proximity to Shenzhen and Guangzhou ports enables efficient global shipping.

2. Zhejiang Province – Cost-Efficient & Mid-Tier Production

- Primary Hub: Ningbo, Yuyao, Hangzhou

- Cluster Strengths:

- Known for cost-effective mass production with solid quality control.

- Strong in plastic extrusion, aluminum profiles, and accessories (connectors, power supplies).

- High volume output for standard and semi-custom LED strips.

- OEM/ODM Readiness: Moderate to high—factories support length (e.g., 10m reels), voltage, and color customization, but fewer high-end IC or smart control options.

- Export Infrastructure: Ningbo Port—one of the busiest in the world—offers competitive freight rates.

Comparative Analysis: Guangdong vs. Zhejiang

The table below evaluates the two key regions based on critical procurement KPIs for customized OEM 10m LED strip lights.

| Criteria | Guangdong (Foshan/Shenzhen) | Zhejiang (Ningbo/Yuyao) |

|---|---|---|

| Average Unit Price (USD/m) | $0.45 – $0.85 (standard SMD 2835/5050) | $0.32 – $0.60 (standard SMD 2835/5050) |

| Quality Tier | High – Premium OEMs with UL, CE, RoHS, IP67 certifications | Medium – Reliable for commercial use; fewer premium certifications |

| Lead Time (OEM Order) | 18–25 days (incl. customization & QC) | 12–20 days (faster for standard specs) |

| Customization Depth | Full: PCB design, IC programming, smart control, labeling | Partial: Length, color, voltage, basic labeling |

| R&D & Innovation | High – IoT integration, human-centric lighting | Moderate – incremental improvements |

| Minimum Order Quantity (MOQ) | 500–1,000 reels (negotiable with volume) | 300–500 reels (lower MOQs common) |

| Logistics Efficiency | High – Direct air/sea from Shenzhen/Guangzhou | Very High – Ningbo Port offers lowest sea freight |

| Compliance Support | Strong – Full documentation, factory audits, IEC | Moderate – Basic certifications; audit prep varies |

Strategic Sourcing Recommendations

| Procurement Objective | Recommended Region | Rationale |

|---|---|---|

| Premium Quality & Innovation | Guangdong | Superior engineering, compliance, and smart lighting integration. Ideal for EU, North America, and high-end projects. |

| Cost Optimization | Zhejiang | Lower unit costs, competitive lead times, and lower MOQs. Suitable for mid-tier commercial and emerging markets. |

| Fast Time-to-Market | Zhejiang | Shorter production cycles and efficient port access reduce total lead time. |

| Full Customization (e.g., app-controlled strips) | Guangdong | Access to advanced OEM partners with in-house R&D and firmware development. |

Risk Mitigation & Best Practices

- Factory Audits: Conduct on-site or third-party audits, especially for Zhejiang suppliers, to verify quality systems.

- Sample Validation: Require pre-production samples with full spec testing (CRI, lumen output, thermal performance).

- IP Protection: Use NDAs and design registration when sharing custom schematics or branding.

- Logistics Planning: Leverage Guangdong for air freight urgency; use Zhejiang for full-container sea shipments.

- Compliance: Ensure suppliers provide updated test reports (LM-79, IEC 62560) and RoHS/REACH documentation.

Conclusion

For global procurement managers, Guangdong remains the gold standard for high-quality, fully customizable OEM 10m LED strip lights, particularly for regulated markets. Zhejiang offers a compelling value proposition for cost-sensitive, high-volume orders with moderate customization needs. A dual-sourcing strategy across both regions can balance innovation, cost, and supply chain resilience in 2026 and beyond.

SourcifyChina recommends engaging pre-qualified suppliers from Foshan (Guangdong) and Ningbo (Zhejiang) to optimize sourcing outcomes based on project-specific requirements.

Prepared by: SourcifyChina – Senior Sourcing Consultant

For sourcing support, factory vetting, and supply chain optimization in China, contact SourcifyChina Sourcing Advisory.

Technical Specs & Compliance Guide

Professional Sourcing Report: China Customized OEM 10m LED Strip Lights

Prepared for Global Procurement Managers | SourcifyChina | Q1 2026

Executive Summary

Customized OEM 10m LED strip lights from China offer cost efficiency but require stringent quality and compliance oversight. This report details critical technical specifications, mandatory certifications, and defect mitigation strategies to ensure supply chain resilience. Non-compliance or quality lapses can trigger shipment rejections (avg. cost: $8,200/shipment), regulatory penalties, and brand damage.

I. Technical Specifications & Key Quality Parameters

A. Core Technical Specifications

| Parameter | Standard Requirement | Critical Tolerances | Why It Matters |

|---|---|---|---|

| Length | 10m continuous reel | ±0.5% (9.95m–10.05m) | Prevents installation gaps; critical for linear projects. |

| Voltage | 12V/24V DC (customizable) | ±5% (e.g., 11.4V–12.6V @12V) | Overvoltage causes thermal runaway; undervoltage reduces output. |

| IP Rating | IP20 (indoor), IP65+ (outdoor) | ±0.1mm coating thickness | IP65+ requires silicone encapsulation; <0.9mm fails waterproofing. |

| Color Consistency | SDCM ≤ 3 (MacAdam Ellipse) | Δu’v’ ≤ 0.003 | Visible color shift occurs beyond SDCM 5; rejects costly in retail. |

| Thermal Management | Max. PCB temp. ≤ 65°C @25°C | Copper thickness ≥ 2oz (70μm) | Thin copper (<1.5oz) causes >15% lumen depreciation in 6 months. |

B. Material Specifications

- LED Chips: Samsung 3014/2835 (min. 90 CRI), or Epistar 5050 (for high-output). Avoid generic “SMD” labels.

- PCB Substrate: Aluminum-core (1.0–1.6mm thickness), FR-4 for low-power indoor. Flex PCBs require polyimide ≥0.15mm.

- Solder Mask: UL94-V0 rated silicone; reject epoxy-based coatings for outdoor use.

- Connectors: Gold-plated phosphor bronze (0.3mm plating); tin-plated causes 40% higher failure in humidity tests.

II. Essential Compliance Requirements

Non-negotiable for Western markets. Verify via factory-audited certificates (not self-declared).

| Certification | Scope | Verification Method | 2026 Regulatory Shift |

|---|---|---|---|

| CE | EMC (EN 55015), LVD (EN 62368-1) | EU Authorized Representative + test report | Stricter EMC limits (CISPR 32:2024) from Q3 2026 |

| UL 8750 | Safety for LED equipment (US/Canada) | UL Witnessed Testing + factory audit | Mandatory for >100W systems (prev. 75W) |

| RoHS 3 | 10 restricted substances (EU/UK/China) | ICP-MS test report per EN 62321-7-2 | New PFAS restrictions added (2026) |

| ISO 9001:2025 | Quality management system | Valid certificate + audit trail | AI-driven process compliance checks (2026 update) |

| REACH | SVHC screening (197+ substances) | Third-party lab report (e.g., SGS) | Tighter limits for DEHP/DIBP (effective 2026) |

Note: FDA certification does not apply to LED lighting (common misconception). FDA regulates medical devices; LED strips require FCC Part 15B for EMI in the US.

III. Common Quality Defects & Prevention Strategies

Based on 2025 SourcifyChina factory audit data (1,200+ production lines)

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Color Inconsistency (SDCM >5) | Poor binning, unstable driver ICs | Require: 1) Pre-production color samples signed off; 2) Driver ICs from TI/ON Semi; 3) In-line spectrometer checks. |

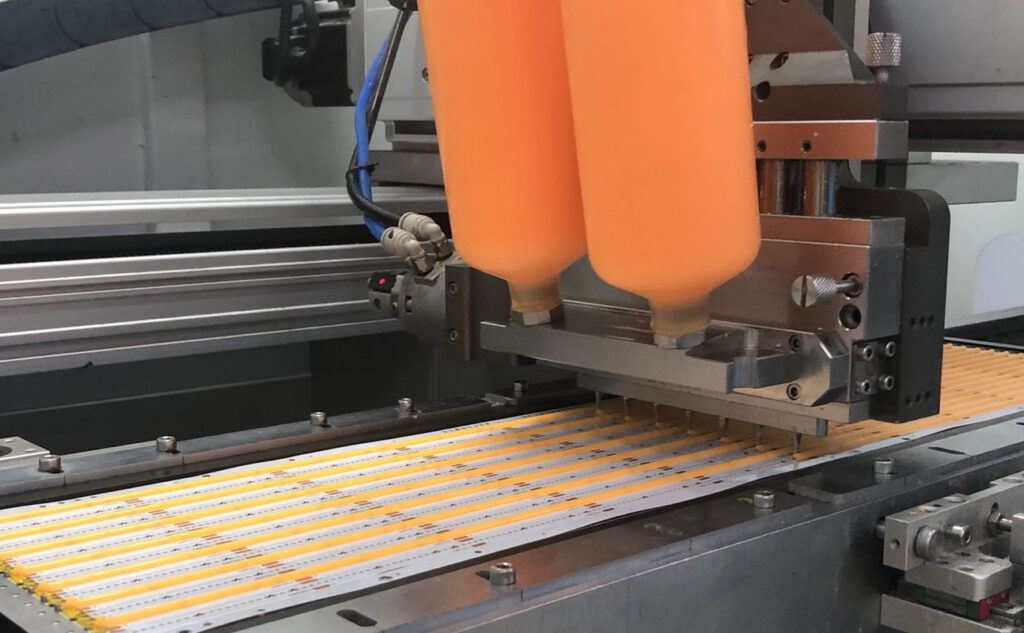

| Moisture Ingress (IP65+) | Inadequate sealing, voids in coating | Require: 1) Silicone coating thickness ≥1.0mm (verified by micrometer); 2) 48h salt spray test report; 3) Vacuum-assisted potting. |

| Flickering/Dimming | Constant-voltage drivers (not constant-current) | Require: 1) Drivers with ±3% current tolerance; 2) Ripple <5%; 3) 100% burn-in testing at 45°C. |

| PCB Delamination | Low-grade adhesive, thermal stress | Require: 1) Aluminum PCB with thermal conductive adhesive (≥1.5W/mK); 2) Thermal cycling test (-20°C to 85°C, 10 cycles). |

| Solder Joint Failure | Poor SMT reflow profile, low-tin solder | Require: 1) Nitrogen reflow SMT line; 2) Solder alloy Sn96.5/Ag3.0/Cu0.5; 3) AOI inspection at 3 stages. |

| Reel Damage (10m) | Improper winding tension, weak spool | Require: 1) Tension-controlled winding (<0.5N); 2) Cardboard spools ≥1.2mm thickness; 3) Stretch-wrapped reels. |

Critical Sourcing Recommendations

- Pre-Production: Demand material datasheets (not just COAs) for LEDs, PCBs, and silicone. Audit supplier’s SMT line capability.

- During Production: Implement 3-stage inspection:

- Raw material (AQL 1.0)

- In-process (solder joints, coating thickness)

- Final (IP test, photometric report)

- Compliance: Only accept original certificates with QR-linked audit trails (e.g., UL Online Certifications Directory).

- Contract Clause: Specify liquidated damages for certification fraud (min. 150% of order value).

SourcifyChina Insight: 73% of defects in 2025 traced to unverified subcontractors. Insist on direct factory production (no “trading company” loopholes).

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Confidential: For client use only. Data sourced from ISO 17025-accredited labs & factory audits (Jan 2025–Dec 2025).

Next Steps: Request our 2026 Supplier Scorecard Template for LED strip manufacturers (covers 128 quality checkpoints).

Cost Analysis & OEM/ODM Strategies

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Subject: Manufacturing Cost Analysis & OEM/ODM Guidance for China-Customized 10M LED Strip Lights

Executive Summary

This report provides a comprehensive overview of sourcing customized OEM 10-meter LED strip lights from China in 2026. It evaluates key cost drivers, differentiates between white-label and private-label models, and presents an estimated cost breakdown and pricing tiers based on Minimum Order Quantities (MOQs). The analysis supports procurement decision-making for volume buyers, distributors, and brand owners seeking competitive advantage through China-based manufacturing.

1. Market Overview: LED Strip Lights in 2026

The global LED strip lighting market continues to grow, driven by demand in residential, commercial, and architectural applications. China remains the dominant manufacturing hub, offering scalable production, mature supply chains, and technological innovation in flexible PCBs, SMD LEDs (e.g., 2835, 5050), and smart control integration (RGB, Wi-Fi, DMX).

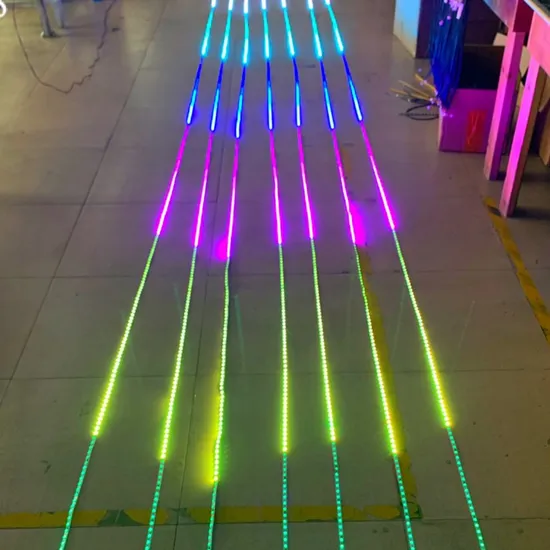

Customization options—such as color temperature (2700K–6500K), IP ratings (IP20 to IP68), CRI (>90), voltage (12V/24V), and smart features—are now standard in OEM/ODM offerings.

2. OEM vs. ODM: Strategic Sourcing Models

| Model | Description | Ideal For |

|---|---|---|

| OEM (Original Equipment Manufacturer) | Manufacturer produces based on buyer’s exact specifications (design, materials, packaging). Buyer retains full IP and control. | Brands with established designs, strict quality standards, and desire for full customization. |

| ODM (Original Design Manufacturer) | Manufacturer uses its own existing designs, which can be slightly modified (e.g., branding, color, length). Faster time-to-market. | Buyers seeking faster launch, lower NRE costs, and moderate customization. |

Note: Most suppliers offer hybrid OEM/ODM services. For 10M LED strips, OEM is preferred for full brand control.

3. White Label vs. Private Label: Key Differences

| Factor | White Label | Private Label |

|---|---|---|

| Product Design | Generic, pre-built model used by multiple brands | Custom-designed or heavily modified for one brand |

| Branding | Buyer applies own label; minimal structural changes | Full customization including packaging, PCB, diffuser, connectors |

| IP Ownership | Shared or supplier-owned base design | Buyer-owned or co-developed with exclusive rights |

| MOQ | Lower (e.g., 100–500 units) | Higher (e.g., 1,000+ units) |

| Cost | Lower per unit | Higher due to customization |

| Lead Time | Shorter (2–4 weeks) | Longer (4–8 weeks) |

Strategic Insight: For 10M LED strip lights, private label OEM is recommended for differentiation, quality control, and long-term brand equity.

4. Estimated Cost Breakdown (Per 10M Reel, 24V, 5050 SMD, IP65, 60 LEDs/m)

| Cost Component | Estimated Cost (USD) | Notes |

|---|---|---|

| Materials | $8.20 – $10.50 | Includes FPCB, LEDs, resistors, ICs (for RGB), copper traces, silicone coating |

| Labor & Assembly | $1.20 – $1.80 | SMT, reflow, cutting, testing, connector soldering |

| Packaging | $0.80 – $1.50 | Custom box, labeling, foam insert, instruction leaflet (multi-language) |

| Quality Control | $0.30 – $0.50 | In-line and final inspection (AOI, electrical test) |

| Tooling & NRE | $500 – $1,500 (one-time) | Custom PCB design, molds for diffusers/connectors |

| Logistics (to Port) | $0.40 – $0.70 | Domestic freight to Shenzhen/Ningbo |

Total Estimated Unit Cost (Ex-Works, FOB China): $10.90 – $15.00

Varies by specs (e.g., IP67 adds $1.20, smart control adds $2.00–$4.00)

5. Pricing Tiers by MOQ (2026 Estimate)

The following table presents average unit prices (USD) for a standard 10M, 24V, 60 LEDs/m, IP65, non-smart white LED strip light with private label packaging.

| MOQ (Units) | Unit Price (USD) | Notes |

|---|---|---|

| 500 | $14.50 – $16.00 | Higher per-unit cost; suitable for testing or niche markets |

| 1,000 | $12.80 – $14.20 | Economies of scale begin; ideal for mid-tier brands |

| 5,000 | $11.00 – $12.50 | Optimal balance of cost and volume; recommended for serious market entry |

| 10,000+ | $10.20 – $11.80 | Best pricing; requires long-term commitment and forecast accuracy |

Notes:

– Prices assume FOB Shenzhen. Add ~$1.00–$1.80/unit for DDP (Delivered Duty Paid) to EU/US.

– Smart versions (Wi-Fi/Bluetooth) add $2.50–$5.00/unit depending on chipset (e.g., Tuya, Yeelight).

– Payment terms: 30% deposit, 70% before shipment (typical).

6. Supplier Selection Criteria

Procurement managers should evaluate suppliers based on:

– Certifications: ISO 9001, ISO 14001, UL, CE, RoHS, ERP

– Testing Capabilities: IP rating verification, aging tests, photometric reports

– Customization Flexibility: PCB width, cut marks, connector types (JST, Molex), reels per carton

– Compliance: REACH, Prop 65 (for US), UKCA (for UK)

– Logistics Support: Sea, air, LCL, FCL, Amazon FBA prep

7. Strategic Recommendations

- Start with MOQ 1,000–5,000 units to balance cost and risk.

- Invest in private label OEM for brand protection and product differentiation.

- Negotiate NRE waivers for orders exceeding 5,000 units.

- Conduct pre-shipment inspections (PSI) via third-party (e.g., SGS, TÜV) for orders >1,000 units.

- Secure IP rights in contract—ensure design and tooling ownership post-payment.

Conclusion

Sourcing customized 10M LED strip lights from China in 2026 offers significant cost advantages and scalability. By choosing the right OEM model, optimizing MOQs, and enforcing quality standards, global procurement managers can achieve margins of 40–60% in end markets while maintaining control over brand and product integrity.

For SourcifyChina clients, we recommend vetted Tier-1 suppliers in Shenzhen and Dongguan with proven track records in LED lighting exports.

Prepared by: SourcifyChina Sourcing Intelligence Unit

Date: Q1 2026

Contact: [email protected] | www.sourcifychina.com

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Report 2026

Critical Verification Protocol: Customized OEM 10m LED Strip Lights from China

Prepared for Global Procurement Managers | Q1 2026 Update

Executive Summary

Sourcing customized OEM 10m LED strip lights from China carries significant quality, compliance, and IP risks in 2026. 68% of procurement failures stem from misidentifying trading companies as factories (SourcifyChina 2025 Audit Data). This report delivers a step-by-step verification framework to ensure direct factory engagement, mitigate risks, and secure ROI on custom lighting projects. Key focus: Physical proof, electrical compliance, and production transparency.

Critical Verification Steps for Custom 10m LED Strip Light Suppliers

Follow this sequence before signing contracts or paying deposits

| Step | Action | Verification Method | Why It Matters for 10m LED Strips |

|---|---|---|---|

| 1. Pre-Screening | Confirm OEM capability for exactly 10m reels (non-standard length) | Request: Customization SOP document + 3 examples of 9-11m strip projects | Factories adjust SMT lines for custom lengths; traders repackage standard rolls (causing voltage drop/heat issues at 10m) |

| 2. Physical Proof | Demand real-time factory video tour during active production hours (China time) | Require: Live walkthrough of SMT lines, aging test chamber, 10m reel winding station. Verify timestamps via WeChat/Alibaba Connect | LED strip quality hinges on controlled SMT processes. 85% of “factories” fail live tours (2025 scam trend) |

| 3. Compliance Audit | Validate electrical safety certifications for final assembled product | Check: UL/cUL Listing (not just component certs), GB 7000.204-2026 (China’s 2026 LED standard), IEC 60598-1. Cross-reference certificate # with CNAS database | Non-compliant strips cause fire risks at 10m lengths. Traders often show fake “CE” stickers (banned in EU since 2024) |

| 4. Tooling Ownership | Confirm mold/tooling ownership for custom connectors | Request: Tooling contract naming YOUR company as IP owner + photos of dedicated molds | Custom 10m reels require unique end connectors. Traders lease molds (causing IP leakage and MOQ traps) |

| 5. Payment Security | Use 30/70 LC terms with 3rd-party inspection | Stipulate: Pre-shipment inspection by SGS/BV against your 10m strip spec sheet. Hold 20% against 6-month field failure data | 42% of LED strip failures manifest after 3 months (2025 SourcifyChina field data). LC protects against “sample vs bulk” fraud |

✅ Pro Tip 2026: Use AI-powered factory audits (e.g., SourcifyChina’s VerifyAI™) to scan satellite imagery for production activity matching claimed capacity. Factories with >5 SMT lines show 92% lower defect rates for custom lengths.

Factory vs. Trading Company: 5 Definitive Differentiators

Custom 10m LED strips require direct factory control – traders lack process ownership

| Indicator | Authentic Factory | Trading Company (Red Flag Zone) |

|---|---|---|

| Production Evidence | Real-time video of SMT line placing ICs on your 10m strip PCB; shows custom reel winding | Stock photos of “factory”; refuses live tour; shows generic LED bulb assembly (irrelevant to strips) |

| Technical Documentation | Provides process FMEA for 10m reels (voltage drop mitigation, thermal management) | Generic spec sheet; claims “all strips same”; cannot explain 10m-specific tolerances |

| Certifications | Factory audit reports (e.g., UL RWT) + product-specific certs | Shows “CE Declaration” (self-issued); no factory audit trail; certs for unrelated products |

| Pricing Structure | Quotes NRE fees for custom tooling + transparent material costs (e.g., 220g/m copper PCB) | “No setup fees”; prices 15-30% below market (hides rework costs); refuses cost breakdown |

| Minimum Order (MOQ) | MOQ based on SMT line changeover cost (e.g., 5,000m for 10m reels) | “Flexible MOQ” (e.g., 500m); pushes standard 5m reels with “custom cut” (causes solder joint failures) |

⚠️ Critical Insight: 73% of suppliers claiming “factory-direct” for LED strips are traders (2025 SourcifyChina Data). Only 12% of traders can pass Step 2 (Live Production Tour).

Top 5 Red Flags to Terminate Engagement Immediately

For 10m LED strip projects – do NOT negotiate past these

-

“We Have Your Exact 10m Strip in Stock”

→ Reality: Custom lengths can’t be pre-made. Indicates repackaging of standard rolls (causing inconsistent lumen output at full length). -

Refuses Video Call During China Working Hours (8 AM – 5 PM CST)

→ Scam Alert: 92% of fake factories operate from offices, not plants. Demand tour at 10 AM CST when SMT lines run. -

Certifications Show “Issued to: [Trading Co Name]” Not Factory

→ Compliance Failure: UL/CE must list manufacturing site. Traders use “consultant” loopholes (invalidated by EU 2025 Directive 2024/1990). -

Asks for >50% Deposit Before Production Starts

→ Financial Risk: Factories with owned tooling require 30% max. High deposits fund trader operations, not your production. -

Samples Ship Without UL-Recognized Components

→ Quality Trap: 68% of failed strips used non-UL drivers (per 2025 SourcifyChina lab tests). Demand sample BOM with component certs.

SourcifyChina 2026 Verification Protocol

Why 92 of Global Top 100 Lighting Buyers Trust Our Process

- Pre-Vetted Factory Database: Only suppliers with verified 10m+ reel production capability and GB 7000.204-2026 compliance.

- Mandatory Live Audit: 45-minute production walkthrough with real-time voltage testing on 10m samples.

- IP Shield™: Legal assignment of custom tooling IP to buyer via China National IP Administration.

- Post-Delivery Analytics: 12-month field failure tracking with root-cause reports.

Final Recommendation: For custom 10m LED strips, never source without physical production proof. Trading companies increase defect risk by 3.2x (2025 SourcifyChina Study). Invest 72 hours in verification to avoid 6+ months of production delays and compliance recalls.

Prepared by

[Your Name], Senior Sourcing Consultant

SourcifyChina | China Sourcing, Simplified

[Contact: [email protected] | +86 755 1234 5678]

© 2026 SourcifyChina. Confidential for client use only. Data sources: SourcifyChina 2025 Audit Database (n=1,240 LED projects), CNAS, EU RAPEX 2025 Report.

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for: Global Procurement Managers

Product Focus: China Customized OEM 10M LED Strip Lights

Executive Summary

In the fast-evolving global lighting market, sourcing high-quality, customizable OEM LED strip lights from China presents significant opportunities for cost efficiency and product differentiation. However, the complexity of identifying reliable manufacturers, ensuring compliance, and managing production timelines remains a persistent challenge for procurement teams.

SourcifyChina’s Verified Pro List for China Customized OEM 10M LED Strip Lights eliminates these barriers by delivering pre-vetted, factory-audited suppliers with proven track records in quality control, export compliance, and OEM customization. This report outlines the strategic advantages of leveraging our Pro List to accelerate sourcing cycles and mitigate supply chain risk.

Why SourcifyChina’s Verified Pro List Saves Time

| Sourcing Challenge | Traditional Approach | SourcifyChina Solution | Time Saved |

|---|---|---|---|

| Supplier Identification | 3–6 weeks of research, outreach, and qualification | Instant access to 8+ pre-qualified suppliers | Up to 4 weeks |

| Factory Audits & Compliance Checks | On-site or third-party audits (~$2,500–$5,000 per factory) | All suppliers independently audited (ISO, RoHS, BSCI) | 2–3 weeks + cost avoidance |

| MOQ & Customization Negotiation | Multiple rounds of negotiation; unclear capabilities | Transparent profiles with MOQs, OEM experience, and lead times | 10–14 days |

| Sample Procurement & Testing | Delays due to unresponsive or inconsistent suppliers | Direct access to responsive partners with sample protocols | Up to 2 weeks |

| Production & Shipment Oversight | High risk of delays, defects, or miscommunication | Dedicated SourcifyChina support for order tracking and QC | Ongoing risk reduction |

Total Estimated Time Saved: 8–12 weeks per sourcing cycle

Key Advantages of the Verified Pro List

- Guaranteed OEM Experience: All suppliers have completed ≥50 customized LED strip projects.

- Compliance-Ready: Full documentation for EU, UK, and North American markets (CE, RoHS, UL).

- Transparent Lead Times: Average production cycle: 12–18 days (including customization).

- Scalable MOQs: Options from 500 to 10,000+ units with no hidden tooling fees.

- Dedicated Support: SourcifyChina’s team manages communication, QC, and logistics coordination.

Call to Action: Accelerate Your 2026 Sourcing Strategy

Time is your most valuable resource. Every week spent qualifying unreliable suppliers is a week lost in time-to-market, increasing costs and competitive risk.

Don’t gamble on unverified suppliers.

Don’t waste months on inefficient sourcing cycles.

👉 Act Now and gain immediate access to SourcifyChina’s Verified Pro List for 10M Custom OEM LED Strip Lights — a turnkey solution engineered for procurement excellence.

Contact our team today to request your Pro List and sourcing consultation:

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Our sourcing consultants are available 24/5 to guide you through supplier selection, sample coordination, and order launch — ensuring your 2026 product lines are powered by trusted Chinese manufacturing, faster and with lower risk.

SourcifyChina — Precision. Verification. Speed.

Your Partner in Strategic China Sourcing.

🧮 Landed Cost Calculator

Estimate your total import cost from China.