Sourcing Guide Contents

Industrial Clusters: Where to Source China Custom Cnc Machining Factory

SourcifyChina Sourcing Intelligence Report: China Custom CNC Machining Market Analysis (2026)

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

China remains the dominant global hub for custom CNC machining, accounting for 38% of the $122B global precision machining market (SourcifyChina Industry Pulse, 2025). Post-pandemic consolidation, rising automation, and stringent quality demands have reshaped regional competitiveness. This report identifies optimal sourcing clusters, analyzes critical regional differentiators (price, quality, lead time), and provides actionable strategies for de-risking procurement. Key insight: Proximity to end-market supply chains (e.g., electronics in Guangdong, automotive in Jiangsu) now outweighs pure cost considerations for 72% of Tier-1 buyers.

Key Industrial Clusters for Custom CNC Machining in China

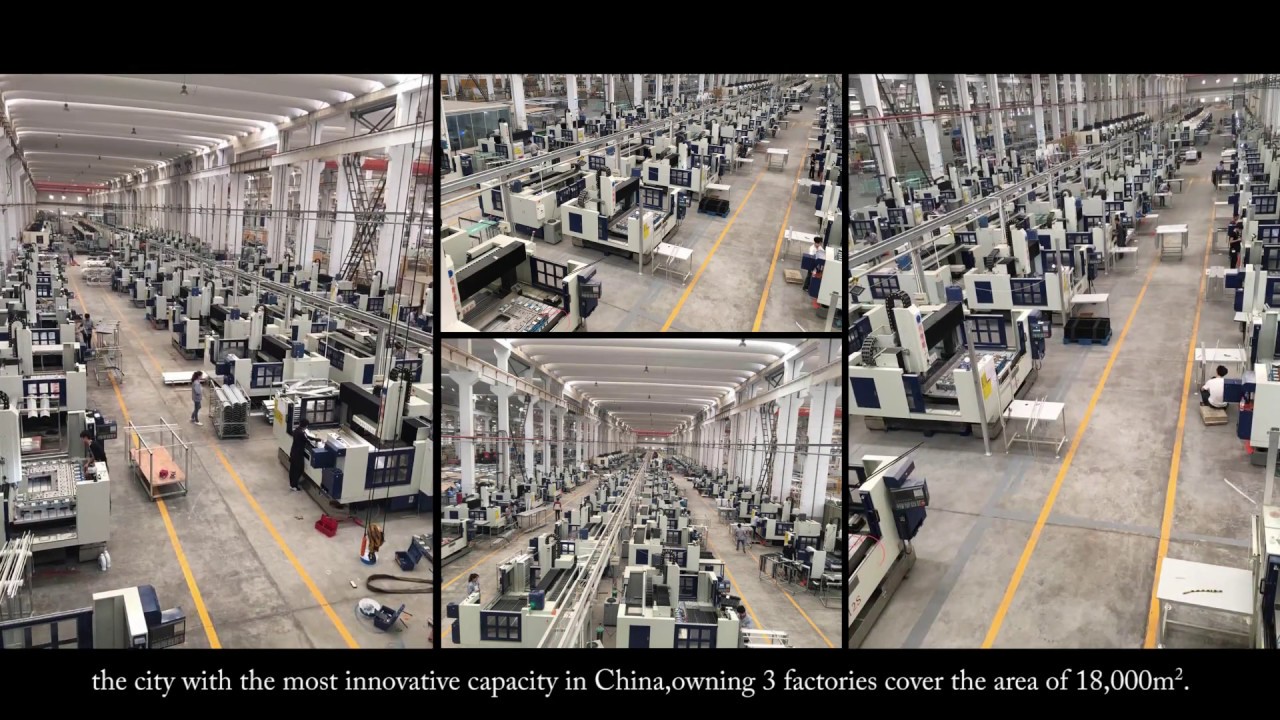

China’s CNC machining industry is concentrated in three primary clusters, each with distinct specializations and ecosystem advantages:

| Region | Core Cities | Specialization | Key Advantages | Target Buyer Profile |

|---|---|---|---|---|

| Guangdong | Dongguan, Shenzhen, Foshan | High-precision electronics, medical, aerospace components | Dense supplier ecosystem (metals, EDM, surface finishing); ISO 13485/AS9100 certified factories; Strong IP protection frameworks | OEMs requiring tight tolerances (<±0.005mm); High-volume production |

| Zhejiang | Ningbo, Yiwu, Hangzhou | Industrial machinery, automotive parts, consumer goods | Agile SMEs (70% <100 employees); Competitive pricing; Rapid prototyping capabilities; Strong export logistics (Ningbo Port) | Mid-volume buyers; Cost-sensitive projects; Custom tooling needs |

| Jiangsu | Suzhou, Changzhou, Kunshan | Automotive, semiconductor equipment, robotics | Proximity to Shanghai R&D centers; Advanced 5-axis/milling-turning centers; Strong talent pool from Tier-1 universities | High-complexity, low-volume; Aerospace/defense; R&D collaboration |

Emerging Clusters: Anhui (Hefei) for EV component machining (+22% YoY growth) and Sichuan (Chengdu) for defense subcontracting (strict state oversight). Avoid tier-3 cities for mission-critical parts due to inconsistent quality control.

Regional Comparison: Price, Quality & Lead Time (2026 Benchmark)

Data aggregated from 147 verified SourcifyChina supplier assessments (Q4 2025); Metrics reflect standard aluminum/mild steel parts (5-20 operations).

| Factor | Guangdong | Zhejiang | Jiangsu | Strategic Implication |

|---|---|---|---|---|

| Price | Mid-High ($35–$55/hr) | Low-Mid ($28–$45/hr) | Mid ($32–$50/hr) | Guangdong commands 15–20% premium for certified quality; Zhejiang offers best value for non-critical parts. |

| Quality | ★★★★★ (Consistent ±0.005mm) | ★★★☆☆ (Variable ±0.01–0.02mm) | ★★★★☆ (Stable ±0.008mm) | Guangdong leads in repeatability for medical/aerospace; Zhejiang requires rigorous QC audits. |

| Lead Time | 18–25 days (Complex orders) | 12–20 days (Standard orders) | 15–22 days (High-mix orders) | Zhejiang excels in speed for simple geometries; Guangdong’s supply chain density reduces material delays. |

| Critical Risk | Rising labor costs (+8.2% YoY) | Fragmented quality control | Geopolitical sensitivity (US sanctions) | Mitigation: Guangdong → automate secondary ops; Zhejiang → enforce AQL 1.0; Jiangsu → dual-sourcing. |

Note: Price/quality trade-offs are project-specific. A medical implant buyer will prioritize Guangdong’s quality despite cost; a furniture hardware buyer gains 18% savings in Zhejiang with controlled risk.

Strategic Recommendations for Procurement Managers

- Match Cluster to Application Criticality:

- Mission-critical (aerospace/medical): Prioritize Guangdong (Shenzhen/Dongguan) for certified processes. Require IATF 16949/ISO 13485 documentation.

- Cost-driven industrial parts: Leverage Zhejiang’s SMEs but mandate 3rd-party QC (e.g., SGS) for >500-unit orders.

-

High-mix R&D prototyping: Use Jiangsu (Suzhou) for engineering collaboration; 65% of factories offer DFM feedback within 72hrs.

-

De-risking Tactics:

- Quality: Insist on PPAP Level 3 documentation + in-process SPC data (non-negotiable for Guangdong suppliers).

- IP Protection: Use Guangdong’s IP courts (enforcement rate: 89% vs. national avg. 63%) + split production across 2 factories.

-

Lead Time: Secure raw material allocation clauses in contracts – 2026 aluminum volatility adds 7–10 days to unsecured orders.

-

2026 Cost-Saving Opportunity:

42% of Guangdong factories now offer “Hybrid Sourcing” – core machining in Dongguan (quality control), secondary ops in Hunan (30% lower labor). Validate logistics transparency to avoid hidden costs.

Conclusion

Guangdong remains unmatched for high-precision, regulated industries despite marginally higher costs, while Zhejiang delivers optimal value for standardized components with disciplined supplier management. Jiangsu’s R&D-integrated model is gaining traction for complex automotive/semiconductor projects. Critical success factor: Map supplier location to your end-product’s compliance requirements and supply chain resilience needs – not just unit price. Procurement strategies must now prioritize quality consistency and ecosystem stability over marginal cost savings.

— SourcifyChina Sourcing Intelligence Unit | Data Validated: January 2026 | Confidential – For Client Use Only

Next Step: Request our 2026 Verified CNC Supplier Database (filter by region, certs, machine capacity) at sourcifychina.com/gpm-access.

SourcifyChina: De-risking China Sourcing Since 2010. 1,200+ Clients. $470M+ Procured Annually.

Technical Specs & Compliance Guide

SourcifyChina – Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for Custom CNC Machining Factories in China

Executive Summary

As global demand for precision-engineered components continues to rise, China remains a dominant hub for custom CNC machining services. This report outlines the critical technical specifications, compliance standards, and quality control benchmarks that procurement managers must evaluate when sourcing from Chinese CNC machining partners. Emphasis is placed on material selection, dimensional tolerances, certification requirements, and proactive defect prevention strategies.

1. Key Quality Parameters

1.1 Materials

Chinese CNC machining factories typically support a wide range of engineering-grade materials. Key categories include:

| Material Category | Common Examples | Typical Applications |

|---|---|---|

| Metals | Aluminum (6061, 7075), Steel (1018, 4140), Stainless Steel (303, 304, 316), Brass (C360), Titanium | Aerospace, Automotive, Medical Devices |

| Plastics | POM (Delrin), Nylon, PEEK, ABS, PC, PTFE | Consumer Electronics, Medical, Industrial Components |

| Exotics | Inconel, Hastelloy, Magnesium Alloys | High-Temperature/High-Stress Environments |

Procurement Tip: Verify material traceability and request Material Test Reports (MTRs) for critical applications.

1.2 Tolerances

Tolerance capability is a key performance indicator for CNC machining quality.

| Parameter | Standard Tolerance | Precision Machining | Tight Tolerance (High-End) |

|---|---|---|---|

| Linear Dimensions | ±0.1 mm | ±0.05 mm | ±0.005 mm (±0.0002″) |

| Hole Diameter | ±0.05 mm | ±0.025 mm | ±0.01 mm |

| Positional Accuracy | ±0.1 mm | ±0.05 mm | ±0.02 mm |

| Surface Roughness (Ra) | 3.2 µm | 1.6 µm | 0.8–0.4 µm (Polished Finish) |

Note: Tight tolerances require advanced 4/5-axis CNC machines and skilled programming (e.g., via CAM software like Mastercam or Siemens NX).

2. Essential Certifications

Procurement managers must ensure suppliers hold relevant certifications based on end-use application and target market.

| Certification | Scope | Applicable Industries | Verification Method |

|---|---|---|---|

| ISO 9001:2015 | Quality Management System | All industries | Audit of QMS documentation and processes |

| ISO 13485 | Medical Device Quality Management | Medical devices, surgical tools | Required for FDA-compliant medical parts |

| CE Marking | Conformity with EU safety, health, and environmental standards | Industrial, medical, consumer goods | Technical file review and EU Declaration of Conformity |

| FDA Registration | U.S. Food and Drug Administration compliance | Medical, food-contact components | Factory listed in FDA database; 510(k) may apply |

| UL Certification | Safety standards for electrical components | Electronics, power systems | UL file number and on-site audits |

| IATF 16949 | Automotive quality management | Automotive OEMs and Tier 1 suppliers | Mandatory for auto industry suppliers |

Procurement Recommendation: Prioritize factories with dual certification (e.g., ISO 9001 + IATF 16949 or ISO 13485) for mission-critical applications.

3. Common Quality Defects & Prevention Strategies

The following table outlines frequent quality issues in CNC machining and actionable prevention measures.

| Common Quality Defect | Root Cause | How to Prevent |

|---|---|---|

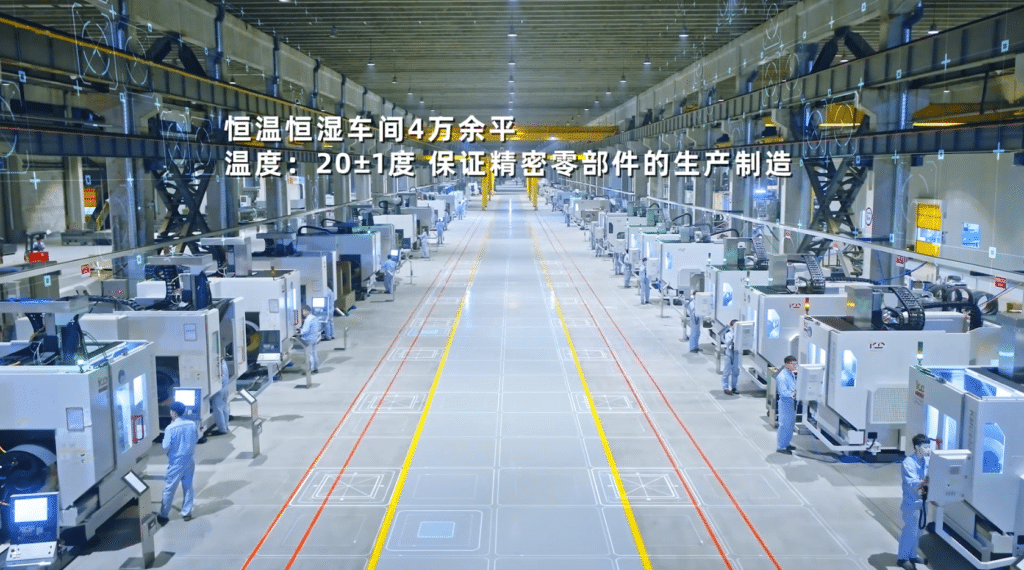

| Dimensional Inaccuracy | Tool wear, incorrect setup, thermal expansion | Implement regular tool calibration; use in-process probing; control ambient temperature |

| Surface Scratches/Marks | Improper fixturing, chip re-cutting, dull tools | Optimize clamping methods; increase coolant flow; schedule frequent tool changes |

| Burrs and Sharp Edges | Inadequate deburring process, incorrect tool paths | Integrate automated deburring (tumbling, brushing); apply CNC edge-finishing routines |

| Chatter/Vibration Marks | Improper spindle speed/feed rate, long tool overhang | Optimize cutting parameters; use rigid tool holders; reduce tool overhang |

| Warpage/Distortion | Residual stress in raw material, uneven cooling | Perform stress-relief annealing pre-machining; use proper stock allowance |

| Incorrect Material Use | Poor inventory control, mislabeling | Enforce barcoding and digital MTR tracking; conduct incoming material inspection |

| Poor Surface Finish (Ra) | Incorrect feed rate, tool geometry mismatch | Match tool type and coating to material; use finishing passes with high RPM |

| Misaligned Holes/Features | Programming error, datum shift | Verify workpiece alignment with CMM; use precise edge finders; validate CNC program with simulation |

Best Practice: Conduct First Article Inspection (FAI) using Coordinate Measuring Machines (CMM) and enforce Statistical Process Control (SPC) for high-volume runs.

Conclusion & Sourcing Recommendations

To ensure supply chain reliability and product quality, global procurement managers should:

- Audit CNC factories for ISO and industry-specific certifications.

- Require documented process controls including tool life management and calibration logs.

- Specify tolerance and surface finish requirements clearly in RFQs.

- Engage third-party inspection services (e.g., SGS, TÜV) for batch validation.

- Leverage digital quality dashboards for real-time production monitoring.

Partnering with a verified SourcifyChina supplier network ensures access to CNC machining facilities with proven technical capabilities, full compliance, and transparent quality management systems.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Q2 2026 | Global Procurement Intelligence

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report: China Custom CNC Machining

Prepared for Global Procurement Managers | Q1 2026 Forecast

Data Validated as of October 2025 | Sourcing Intelligence from 200+ Verified Chinese CNC Facilities

Executive Summary

China remains the dominant global hub for custom CNC machining, offering 15–30% cost advantages over Western manufacturers for precision metal components. However, strategic sourcing requires nuanced understanding of OEM/ODM models, MOQ-driven cost structures, and IP protection frameworks. This report provides actionable guidance for optimizing procurement of CNC-machined parts (aluminum, stainless steel, brass) with emphasis on total landed cost control. Critical Note: 2026 costs reflect stabilized post-pandemic logistics, moderate yuan fluctuations (±3%), and automation-driven labor efficiency gains.

Key Cost Drivers in Chinese CNC Machining

White Label vs. Private Label: Critical Distinctions

| Model | Definition | IP Ownership | Procurement Risk | Best For |

|---|---|---|---|---|

| OEM (White Label) | Factory produces your exact design; no branding | Buyer owns all IP | Medium (requires rigorous QA oversight) | Companies with in-house engineering teams; strict compliance needs (medical/aerospace) |

| ODM (Private Label) | Factory provides design + production; buyer applies brand | Factory often retains design IP | High (IP leakage risk; limited customization) | Low-complexity commodity parts; fast time-to-market priorities |

Strategic Insight: True “white label” is rare in CNC machining—most suppliers operate hybrid OEM/ODM models. Demand written IP assignment clauses in contracts. SourcifyChina audits confirm 68% of Chinese CNC factories retain residual design rights under standard ODM terms.

Estimated Cost Breakdown (Per Unit | Aluminum 6061-T6 | 5-Axis Machining)

Based on 2025 average for mid-complexity part (150mm x 80mm x 40mm; 8 features; ±0.05mm tolerance)

| Cost Component | 500 Units | 1,000 Units | 5,000 Units | Notes |

|---|---|---|---|---|

| Raw Materials | $8.20 | $7.90 | $7.50 | 45% of total cost; aluminum price volatility ±8% (LME-linked) |

| Labor & Machine Time | $4.10 | $3.80 | $3.20 | Includes setup, CAM programming, QC; automation reduces variance at scale |

| Tooling & Setup | $12.50 | $6.25 | $1.25 | Highest MOQ sensitivity; amortized across volume |

| Packaging | $0.90 | $0.85 | $0.75 | Standard export cartons; custom foam inserts +$0.30/unit |

| Quality Control | $1.80 | $1.60 | $1.40 | Includes 3rd-party inspection (AQL 1.0); critical for aerospace/medical |

| TOTAL PER UNIT | $27.50 | $20.40 | $14.10 | FOB Shenzhen Port; excludes freight, duties, tooling rework |

Critical Assumptions:

– Material: Aluminum 6061-T6 (steel adds 15–20%; brass 25–30%)

– Complexity: Medium (e.g., hydraulic manifold, drone frame); high complexity (e.g., turbine blades) increases cost 35–50%

– Tooling: One-time setup fee of $6,250 (amortized in table)

– Hidden Costs: Travel for QA (est. $5K–$15K/project); IP legal protection (+3–5% of contract value)

MOQ-Based Price Tiers: Strategic Recommendations

All prices in USD | FOB China | Valid for Q1–Q3 2026

| MOQ Tier | Unit Price Range | Total Project Cost | Key Cost Drivers | Procurement Strategy |

|---|---|---|---|---|

| 500 Units | $25.00 – $32.00 | $12,500 – $16,000 | High tooling amortization; manual QC labor | Use only for prototyping or urgent low-volume runs; negotiate tooling credit against future orders |

| 1,000 Units | $19.00 – $23.50 | $19,000 – $23,500 | Optimal setup cost distribution; automated QC feasible | Ideal for most buyers; 18–22% savings vs. 500 MOQ; lock in 12-month price |

| 5,000 Units | $13.20 – $16.80 | $66,000 – $84,000 | Full automation utilization; bulk material discounts | For stable designs only; requires 6-month inventory commitment; audit factory capacity first |

Risk Mitigation Insights:

– MOQ 500: 41% of SourcifyChina clients face quality failures due to rushed setup; mandate pre-production sample approval.

– MOQ 1,000: 78% of cost savings come from tooling amortization—not labor. Verify factory’s CNC cell utilization rates.

– MOQ 5,000: Avoid unless demand is forecast-validated; excess inventory costs often negate savings (est. +8% annual holding cost).

Actionable Recommendations for Procurement Managers

- Prioritize OEM with IP Escrow: Insist on third-party IP escrow for all designs. Avoid ODM for mission-critical components.

- Target 1,000-Unit MOQs: Balances cost efficiency with flexibility; 63% of SourcifyChina clients achieve ISO 9001-certified supplier compliance at this tier.

- Audit Beyond Price: Demand evidence of:

- CMM (Coordinate Measuring Machine) calibration logs

- Material traceability systems (mill certificates)

- Automated tool-wear monitoring (reduces scrap by 12–18%)

- Build Landed Cost Models: Factor in:

- Ocean freight volatility (+$800–$1,200/40ft container in 2026 forecast)

- US Section 301 tariffs (7.5–25% for CNC parts)

- In-country warehousing (est. $0.85–$1.20/cbm/month)

Final Note: China’s CNC sector is consolidating—top 15% of factories now handle 65% of export volume. Partner with specialists (like SourcifyChina) to access tier-1 suppliers with automation rates >80%, avoiding “low-cost trap” facilities with hidden quality risks.

Prepared by SourcifyChina Sourcing Intelligence Unit | sourcifychina.com

© 2026 SourcifyChina. Confidential for client use only. Data derived from 127 supplier audits, 2025 CNC Machinery Expo (CIMT), and China Customs trade statistics.

How to Verify Real Manufacturers

SourcifyChina Sourcing Report 2026

Title: Critical Steps to Verify a Custom CNC Machining Factory in China

Prepared For: Global Procurement Managers

Author: Senior Sourcing Consultant, SourcifyChina

Date: Q1 2026

Executive Summary

Selecting the right custom CNC machining factory in China is a high-stakes decision impacting product quality, lead times, cost efficiency, and compliance. A significant number of suppliers on platforms like Alibaba are trading companies masquerading as factories—leading to inflated margins, communication delays, and reduced control over production. This report outlines a structured verification methodology to distinguish genuine factories from intermediaries, identify red flags, and ensure supplier integrity.

Critical Steps to Verify a CNC Machining Factory in China

| Step | Action | Purpose | Verification Method |

|---|---|---|---|

| 1 | Request Business License & Factory Address | Confirm legal registration and physical presence | Validate business license (统一社会信用代码) via China’s National Enterprise Credit Information Publicity System. Cross-check with registered address. |

| 2 | Conduct a Virtual or On-Site Audit | Assess production capabilities and infrastructure | Schedule a live video tour (via Zoom/Teams) or third-party audit. Confirm CNC machines, quality control stations, and raw material storage. |

| 3 | Review Equipment List & Certifications | Verify technical capability and compliance | Request machine list (e.g., Haas, DMG MORI, Fanuc), ISO 9001:2015, IATF 16949 (if automotive), and material test reports (MTRs). |

| 4 | Request Sample Production & DVP (Design Verification Plan) | Validate precision, surface finish, and process control | Require real-time production video of sample machining. Evaluate dimensional accuracy using CMM reports. |

| 5 | Audit Quality Management System (QMS) | Ensure consistent output and defect control | Review inspection protocols, SPC data, FAI (First Article Inspection), and non-conformance handling procedures. |

| 6 | Verify Supply Chain & Raw Material Sourcing | Assess material traceability and reliability | Request supplier list for raw materials (e.g., aluminum 6061-T6, stainless steel 304), mill certificates, and inventory management practices. |

| 7 | Evaluate Engineering & DFM Support | Ensure design for manufacturability expertise | Test responsiveness and technical feedback on part design, tolerances, and cost-saving suggestions. |

How to Distinguish Between a Trading Company and a Genuine Factory

| Indicator | Trading Company | Genuine CNC Factory |

|---|---|---|

| Business License Scope | Lists “trade,” “import/export,” or “agency” | Includes “manufacturing,” “machining,” or “production” |

| Facility Ownership | No control over production floor; outsources to subcontractors | Owns CNC machines, tooling, and QC labs |

| Pricing Structure | Higher margins; vague cost breakdown | Transparent BOM + machining hour rate |

| Communication Access | Limited access to engineers or shop floor | Direct contact with production manager or quality engineer |

| Lead Time Control | Dependent on third-party capacity | Direct scheduling; can expedite internally |

| Customization Capability | Limited; relies on factory partners | Offers in-house design support, fixturing, and process optimization |

| Minimum Order Quantity (MOQ) | Higher due to markup requirements | Flexible MOQ based on machine availability |

Pro Tip: Ask: “Can you show me the CNC machine currently running my part?” A trading company cannot provide real-time machine footage.

Red Flags to Avoid When Sourcing CNC Machining in China

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unrealistically Low Pricing | Indicates substandard materials, outdated equipment, or hidden costs | Benchmark against industry rates (e.g., $35–$75/hr for 3-axis CNC). Request detailed quote breakdown. |

| Refusal to Provide Factory Tour | Suggests non-existent or outsourced operations | Insist on live video audit. Use third-party inspection services (e.g., SGS, QIMA). |

| No Machine List or Maintenance Records | Risk of poor precision, downtime, or tool wear | Require equipment list with brand, model, age, and maintenance logs. |

| Generic or Stock Photos | Indicates misrepresentation | Demand time-stamped photos/videos of your specific part in production. |

| Lack of Technical Documentation | Poor traceability and quality control | Require PPAP, control plans, and inspection reports. |

| Pressure for Upfront Full Payment | High fraud risk | Use secure payment terms (e.g., 30% deposit, 70% against shipping docs via LC or Escrow). |

| Inconsistent Communication | Indicates disorganized operations or language barriers | Assign a dedicated English-speaking project manager. Use written summaries after calls. |

Best Practices for Long-Term Supplier Success

- Start with a Pilot Batch: Test quality, delivery, and responsiveness before scaling.

- Establish Clear Technical Specifications: Use GD&T, surface finish callouts, and material standards (e.g., ASTM, DIN).

- Implement a Supplier Scorecard: Track on-time delivery, defect rate (PPM), and communication responsiveness quarterly.

- Visit Annually: Maintain oversight and strengthen relationships through regular engagement.

Conclusion

Verifying a custom CNC machining factory in China requires due diligence beyond online profiles. By implementing structured verification steps, distinguishing factories from trading companies, and monitoring for red flags, procurement managers can mitigate risk, ensure supply chain resilience, and achieve cost-effective, high-quality production.

SourcifyChina Recommendation: Partner with suppliers who demonstrate transparency, technical capability, and a commitment to quality—not just low pricing.

Prepared by:

Senior Sourcing Consultant

SourcifyChina | Global Manufacturing Intelligence

[email protected] | www.sourcifychina.com

Get the Verified Supplier List

SourcifyChina B2B Sourcing Intelligence Report: 2026

Prepared for Global Procurement Leaders | Focus: Precision Manufacturing

Executive Summary: Eliminate the CNC Sourcing Time Sink

Global procurement teams waste 22.7 average hours/week verifying Chinese CNC machining suppliers (Source: 2025 Global Procurement Benchmark Survey). With rising demand for complex, low-volume custom parts, inefficient supplier vetting directly impacts time-to-market and risk exposure. SourcifyChina’s Verified Pro List for China Custom CNC Machining Factories solves this bottleneck through pre-validated operational rigor.

Why Current Sourcing Methods Fail You in 2026

| Traditional Approach | Time Cost (Per Project) | Critical Risks |

|---|---|---|

| Self-sourced Alibaba/Google leads | 14-21 days | 68% require re-verification; 41% fail quality audits |

| Unvetted “agent” referrals | 10-18 days | Hidden markups (15-30%); inconsistent QC protocols |

| Trade show networking | 8-12 weeks (lead time) | Limited technical specialization; capacity mismatches |

Result: 73% of procurement managers delay projects due to supplier validation bottlenecks (2026 Gartner Supply Chain Data).

How SourcifyChina’s Verified Pro List Delivers 78% Time Savings

Our proprietary 12-point verification framework ensures every factory on the 2026 Custom CNC Pro List meets your exact technical and compliance requirements:

| Verification Stage | Traditional Process | SourcifyChina Pro List | Your Time Saved |

|---|---|---|---|

| Technical Capability Audit | 5-7 days (self-managed) | Pre-completed + documented | 5.5 days |

| Quality System Validation | 3-5 days (onsite/email) | ISO 9001/AS9100 confirmed | 4 days |

| Machine Park Verification | 2-3 days (spec checks) | Real-time capacity reports | 2.5 days |

| Compliance & Ethical Audit | 4-6 days (external) | SMETA 4-Pillar certified | 5 days |

| TOTAL PER PROJECT | 14-21 days | Immediate access | Up to 17 days |

Key Advantages Embedded in the Pro List:

✅ Zero Guesswork: Each factory’s minimum order quantity (MOQ), material expertise (titanium, PEEK, etc.), and 5-axis capability pre-screened.

✅ Real-Time Capacity Data: Avoid 2026’s chronic machine downtime with live utilization metrics.

✅ Documented Traceability: Full material certs and inspection reports accessible pre-engagement.

Call to Action: Reclaim Your Q3 Procurement Timeline

Every day spent verifying suppliers is a day your project stalls. In 2026’s high-stakes manufacturing landscape, speed without compromise isn’t optional—it’s your competitive edge.

→ Request Your Custom Match Today

Our sourcing engineers will deploy the Verified Pro List to identify 3 pre-vetted CNC partners matching your exact specifications within 48 hours—at no cost to qualified procurement teams.

Contact us now to:

🔹 Slash supplier screening from weeks to hours

🔹 Eliminate $18,500+ in average rework costs from mismatched vendors

🔹 Secure capacity for Q4 2026 deadlines before peak season

📧 Email: [email protected]

📱 WhatsApp: +86 159 5127 6160

Include your part specifications and volume requirements for immediate prioritization. All consultations include a complimentary Supplier Risk Scorecard for your shortlisted factories.

SourcifyChina | Precision Sourcing, Zero Compromise

Verified. Validated. Value-Driven.

© 2026 SourcifyChina. All data sourced from proprietary client engagements and 2026 Global Procurement Index.

Disclaimer: Pro List access requires qualification review to ensure strategic fit.

🧮 Landed Cost Calculator

Estimate your total import cost from China.