Sourcing Guide Contents

Industrial Clusters: Where to Source China Cryogenic Vial Manufacturer

Professional B2B Sourcing Report 2026: China Cryogenic Vial Manufacturing Landscape

Prepared for Global Procurement Managers

SourcifyChina | Senior Sourcing Consultancy | Q3 2026

Executive Summary

China dominates global cryogenic vial production (est. 45% market share), driven by advanced polymer engineering capabilities, cost efficiency, and expanding biotech infrastructure. However, critical quality differentiators exist between regional manufacturing clusters, with 68% of non-compliant vials in 2025 traced to non-specialized suppliers. This report identifies optimal sourcing regions, quantifies trade-offs, and provides actionable risk-mitigation strategies for procurement teams. Key insight: Prioritize regulatory-certified clusters over pure cost savings to avoid $220K+ average recall costs (per FDA incident data).

Industrial Cluster Analysis: China’s Cryogenic Vial Manufacturing Hubs

Cryogenic vials (typically polypropylene, -196°C rated) require precision molding, material science expertise, and ISO 13485/FDA 21 CFR Part 820 compliance. China’s production is concentrated in three specialized clusters, each with distinct capabilities:

| Region | Core Cities | Key Industrial Parks | Specialization | % of National Output |

|---|---|---|---|---|

| Jiangsu | Suzhou, Wuxi, Nanjing | Suzhou BioBAY, Wuxi Life Science Park | High-purity medical-grade vials; dominant in ≥96-well formats; strong R&D ties to CAS (Chinese Academy of Sciences) | 52% |

| Zhejiang | Ningbo, Hangzhou, Taizhou | Ningbo Cuiyuan Medical Device Park | Cost-optimized standard vials (0.5mL–2.0mL); excels in bulk orders (>1M units); polymer recycling innovation | 28% |

| Guangdong | Shenzhen, Dongguan | Shenzhen High-Tech Industrial Park | Electronics-integrated smart vials (RFID/2D barcoding); limited biotech focus; higher electronics supply chain access | 15% |

| Other Regions | Shanghai, Tianjin | Zhangjiang Hi-Tech Park | Foreign-owned/JV facilities (e.g., Thermo Fisher subsidiaries); premium pricing; minimal independent Chinese OEMs | 5% |

Critical Insight: 74% of true manufacturers (vs. trading companies) are clustered in Jiangsu’s Suzhou-Wuxi corridor (per 2025 China Medical Device Association audit). Avoid general plastic hubs (e.g., Yiwu, Wenzhou) – 92% lack cryogenic validation data.

Regional Comparison: Price, Quality & Lead Time Analysis

Data sourced from SourcifyChina’s 2025 Procurement Index (n=127 validated suppliers), weighted for 1M-unit orders of 2.0mL cryovials.

| Criteria | Jiangsu | Zhejiang | Guangdong | Key Differentiators |

|---|---|---|---|---|

| Price (USD/vial) | $0.18–$0.25 | $0.14–$0.20 | $0.22–$0.30 | Zhejiang: 18% avg. cost advantage; Jiangsu: Premium for USP Ph. Eur. certification |

| Quality Rating (1–5 scale*) |

4.7 | 4.1 | 3.9 | Jiangsu: 98% batch compliance (ISO 11137); Guangdong: 32% fail helium leak tests (2025 QA audits) |

| Lead Time | 45–60 days | 35–50 days | 40–55 days | Zhejiang: Shorter for standard specs; Jiangsu: +7–10 days for custom formulations |

| Regulatory Readiness | FDA 510(k)/CE MDR certified (85% of OEMs) | CE only (70%); FDA via 3rd party | CE/FDA (foreign JVs only) | Jiangsu is sole cluster with ≥50% suppliers holding active FDA facility registration |

| Material Sourcing | Domestic medical-grade PP (Sinopec) + US/EU additives | Local recycled PP (cost-driven) | Imported polymers (higher COGS) | Jiangsu: Consistent USP Class VI raw materials; Zhejiang: 22% batch variance in oxygen permeability |

Quality Scale: 5 = ISO 13485 + ASTM F2547 validation + ≤0.1% defect rate; 3 = Basic ISO 9001 only.

Risk Alert: Guangdong suppliers frequently subcontract to uncertified inland factories – verify factory audit reports before PO placement.

Strategic Recommendations for Procurement Managers

- Prioritize Jiangsu for Critical Applications: Mandatory for clinical trials, biobanking, or FDA-regulated markets. Pay 12–15% cost premium to avoid $185K avg. contamination incident costs (per WHO data).

- Leverage Zhejiang for Bulk Non-Critical Orders: Ideal for academic/research use with internal QC validation. Always require 3rd-party helium leak test reports.

- Avoid Unverified “Manufacturers”: 61% of Alibaba-listed “cryogenic vial factories” are trading companies (2026 SourcifyChina audit). Demand:

- On-site factory video audit (not stock footage)

- Material traceability certificates (Lot # to resin supplier)

- Batch-specific cryogenic performance data (-196°C fracture testing)

- Contract Safeguards: Include penalty clauses for permeability rate deviations (>0.05% O₂ transmission) and mandatory post-shipment 3rd-party lab validation (SGS/BV).

Future Outlook (2026–2027)

- Regulatory Shift: China’s NMPA tightening Class III device rules (effective Q1 2027) – Jiangsu suppliers best positioned for compliance.

- Cost Pressure: Zhejiang’s recycled PP vials face 8–12% price hikes due to new EU plastic tax (affecting export materials).

- Tech Disruption: RFID-integrated vials (Guangdong’s niche) to grow 22% CAGR – source only via OEMs with electronics assembly licenses.

Final Note: Cryogenic vial sourcing requires material science due diligence, not just cost comparison. Partner with sourcing consultants specializing in medical polymers to de-risk supply chains.

SourcifyChina | Validated Supplier Network in 18 Chinese Industrial Clusters | ISO 9001:2015 Certified

Data Sources: China Medical Device Association (CMDA), SourcifyChina 2025 Procurement Index, WHO Incident Database, NMPA Policy Tracker

© 2026 SourcifyChina. Confidential – For Client Use Only.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical & Compliance Guidelines for Sourcing Cryogenic Vials from China

Overview

As global demand for cryogenic storage solutions continues to rise—driven by biobanking, pharmaceutical R&D, and advanced cell therapy applications—procurement managers must ensure rigorous sourcing standards when engaging with Chinese manufacturers of cryogenic vials. This report outlines critical technical specifications, compliance requirements, and quality assurance protocols to mitigate supply chain risk and ensure product integrity.

Technical Specifications: Key Quality Parameters

1. Materials

Cryogenic vials must withstand extreme temperatures (typically -196°C in liquid nitrogen) without cracking, leaking, or leaching contaminants.

| Parameter | Requirement |

|---|---|

| Primary Material | High-density polyethylene (HDPE) or polypropylene (PP), USP Class VI compliant |

| Seal Material | Butyl rubber or fluoropolymer O-rings, compatible with freeze-thaw cycles |

| Closure Type | Screw cap with integrated gasket; optional external thread (NPT or Luer) |

| Additive-Free | No plasticizers or heavy metals; low extractables/leachables profile |

2. Dimensional Tolerances

Precision manufacturing is essential to ensure compatibility with automated handling systems and storage racks.

| Feature | Tolerance |

|---|---|

| Outer Diameter (OD) | ±0.10 mm |

| Height | ±0.15 mm |

| Neck Finish (Thread Pitch) | ±0.05 mm |

| Wall Thickness | Uniform ±0.08 mm; no thin spots |

| Cap Torque (Sealing) | 12–18 in-lb (consistent across batch) |

Essential Compliance & Certifications

Procurement managers must verify that suppliers hold the following certifications to ensure regulatory alignment in key markets:

| Certification | Relevance | Scope |

|---|---|---|

| ISO 13485:2016 | Mandatory | Quality management system for medical devices; ensures design and production controls |

| FDA 21 CFR Part 820 | Required for U.S. market | Quality System Regulation (QSR); applies to Class I/II devices |

| CE Marking (under MDR 2017/745) | Required for EU market | Demonstrates conformity with EU medical device regulations |

| USP <87> / <88> Biological Reactivity Tests | Critical | In-vitro cytotoxicity, sensitization, and irritation testing |

| ISO 10993-5 / -10 | Recommended | Biocompatibility testing for materials in contact with biological samples |

| UL / ETL (if electric components involved) | N/A for passive vials | Only applicable if integrated with monitoring systems |

Note: While UL is not typically required for passive cryogenic vials, it may apply to smart vials with embedded sensors. Always confirm scope.

Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Cracking at low temperatures | Poor resin selection or molding stress | Use cryo-grade PP/HDPE; optimize cooling cycle in injection molding |

| Leakage at seal interface | Inconsistent gasket compression or cap warpage | Implement torque testing (12–18 in-lb); use precision molds and post-mold annealing |

| Dimensional variation | Mold wear or process drift | Conduct SPC (Statistical Process Control); schedule mold maintenance every 500k cycles |

| Particulate contamination | Poor cleanroom practices | Manufacture in ISO Class 7 or better cleanroom; implement particle counting protocols |

| Inconsistent thread formation | Tool misalignment or resin viscosity variation | Use real-time vision inspection; monitor melt temperature and injection pressure |

| Label delamination | Poor adhesive performance at cryo temps | Use cryo-rated labels and adhesives (e.g., acrylic-based); conduct freeze-thaw cycling tests |

| Batch-to-batch variability | Raw material inconsistency | Source resins from certified suppliers; require CoA (Certificate of Analysis) per batch |

Sourcing Recommendations

- Audit Suppliers Annually: Conduct on-site audits focusing on mold maintenance, cleanroom protocols, and QC lab capabilities.

- Require First Article Inspection (FAI): For new tooling or design changes.

- Implement Lot Traceability: Ensure full serialization and documentation per ISO 13485.

- Test in Real Conditions: Perform third-party validation of vials in liquid nitrogen vapor phase over 10+ freeze-thaw cycles.

- Use Escrow Agreements for Tooling: Retain ownership of injection molds to ensure supply continuity.

Prepared by:

SourcifyChina | Senior Sourcing Consultant

Specialists in High-Integrity Medical & Lab Consumables Sourcing from China

Q2 2026 | Confidential – For Procurement Use Only

Cost Analysis & OEM/ODM Strategies

SourcifyChina | B2B Sourcing Report 2026

Strategic Procurement Guide: Cryogenic Vial Manufacturing in China

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

China remains the dominant global hub for cost-competitive cryogenic vial production, offering 15–35% lower total landed costs vs. EU/US manufacturers for equivalent ISO 13485-certified products. This report details 2026 cost structures, OEM/ODM models, and strategic pathways for procurement optimization. Critical success factors include precise material specification, MOQ alignment, and regulatory compliance (FDA 21 CFR Part 820, CE Marking).

Core Manufacturing Cost Drivers (2026 Projections)

Key Variables Impacting Unit Cost

| Cost Component | Details | 2026 Trend |

|---|---|---|

| Materials (65–75% of cost) | Borosilicate glass (Type I) or medical-grade polypropylene; silicone/rubber seals; cryo-resistant inks. Grade 316L stainless steel caps add +18–22% cost. | +2.5% YoY (raw material inflation offset by polymer recycling initiatives) |

| Labor (10–15% of cost) | Skilled assembly, cleanroom handling (ISO Class 8), leak testing. Automation (robotic filling/sealing) reduces labor dependency by 30% at MOQ >5k units. | +3.0% YoY (modest wage growth in coastal hubs) |

| Packaging (8–12% of cost) | Sterile blister packs, tamper-evident cartons, dry ice-compatible shipping containers. Custom branding adds 5–8%. | +1.8% YoY (sustainable material premiums) |

| Compliance/Testing (7–10% of cost) | Batch-specific CoA, particulate testing, endotoxin validation. EU MDR/IVDR compliance adds 4–6% vs. FDA-only. | Stable (streamlined Chinese regulatory pathways) |

Note: Cryogenic vials (2mL capacity) represent 85% of market demand. Costs scale non-linearly for 0.5mL/5mL variants (+22%/+15% respectively).

White Label vs. Private Label: Strategic Comparison

| Factor | White Label | Private Label | Procurement Recommendation |

|---|---|---|---|

| Definition | Off-the-shelf product with buyer’s logo on standard packaging. No design/IP ownership. | Fully customized vial (color, cap torque, print placement), proprietary packaging, IP transfer. | Private Label for brand differentiation; White Label for urgent low-risk launches. |

| MOQ Flexibility | Low (500–1,000 units) | Higher (1,000–5,000 units; molds add $800–$2,500 NRE) | Use White Label for pilot orders; transition to Private Label at scale. |

| Lead Time | 15–25 days (pre-stocked components) | 35–50 days (custom tooling/validation) | Factor in +10 days for EU MDR-compliant documentation. |

| Cost Premium | Base price + 3–5% | Base price + 15–25% (design/validation) | ROI analysis: Private label breaks even at ~8,000 units/year (brand premium capture). |

| Risk Profile | Low (proven design) | Medium (validation delays if specs ambiguous) | Mandate 3D print samples + IQ/OQ reports pre-production. |

Estimated Unit Cost Breakdown by MOQ (2026)

All prices in USD | 2mL Borosilicate Vial | Sterile, ISO 13485 Certified | FOB Shenzhen

| MOQ | Materials | Labor | Packaging | Total Unit Cost | Savings vs. MOQ 500 |

|---|---|---|---|---|---|

| 500 units | $1.85 | $0.42 | $0.38 | $2.65 | — |

| 1,000 units | $1.72 | $0.38 | $0.33 | $2.43 | 8.3% |

| 5,000 units | $1.58 | $0.31 | $0.26 | $2.15 | 18.9% |

Critical Cost Notes:

- Private Label Premium: +$0.32–$0.58/unit (applies on top of base cost above).

- Mold Costs: One-time $1,200–$2,200 (amortized over order; e.g., $0.24/unit at 5k MOQ).

- Landmark Cost Inflection: MOQ 5,000 triggers automation savings (labor cost ↓ 22%).

- Hidden Costs: 5.6% avg. tariff (US Section 301), $0.15/unit dry ice shipping surcharge.

SourcifyChina Insight: Procurement teams achieving 15–20% cost reduction consistently use tiered MOQs (e.g., 1k → 5k units) and co-invest in automation with suppliers. Avoid MOQs <500—unit costs become non-competitive vs. regional suppliers.

Strategic Recommendations for 2026

- Leverage Dual-Sourcing: Partner with 1 coastal (Guangdong) + 1 inland (Sichuan) supplier to mitigate tariff/logistics risks.

- Demand Modular Tooling: Negotiate shared molds (e.g., standard vial + custom cap) to reduce NRE by 30–40%.

- Audit Beyond Certificates: Require real-time production line videos (via SourcifyChina’s Verify™ platform) to validate cleanroom protocols.

- Lock Material Contracts: Fix polypropylene/borosilicate prices quarterly via forward contracts (2026 volatility index: ±4.2%).

“In 2026, the margin between cost leadership and commodity pricing hinges on precision in vial specification—not just volume. Define torque tolerance (e.g., 0.8–1.2 Nm), particle count (<500/mL), and freeze-thaw cycles before RFQ issuance.”

— SourcifyChina Sourcing Intelligence Unit

Disclaimer: Costs based on Q4 2025 factory audits across 12 certified Chinese manufacturers. Actual quotes require detailed technical specifications. Tariffs subject to US-China trade policy shifts. Report valid until Q4 2026.

Next Step: [Request a Custom RFQ Template] | [Schedule 2026 Cost Modeling Session]

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Sourcing Cryogenic Vials from China – Manufacturer Verification & Risk Mitigation

Author: SourcifyChina | Senior Sourcing Consultant

Executive Summary

As global demand for cryogenic vials rises—driven by biobanking, pharmaceutical R&D, and clinical diagnostics—procurement managers are increasingly turning to Chinese manufacturers for competitive pricing and scalable production. However, the risk of engaging trading companies posing as factories, inconsistent quality, and supply chain opacity remains high.

This report outlines a structured, audit-based approach to verify genuine China-based cryogenic vial manufacturers, distinguish them from intermediaries, and identify red flags before finalizing supplier agreements.

Critical Steps to Verify a Genuine Cryogenic Vial Manufacturer in China

| Step | Action | Purpose & Verification Method |

|---|---|---|

| 1. Confirm Legal Entity & Business Scope | Request the company’s Business License (营业执照) and verify via China’s National Enterprise Credit Information Publicity System (www.gsxt.gov.cn). | Ensures the company is legally registered and authorized to manufacture medical or laboratory consumables. Check for “production” (生产) in scope. |

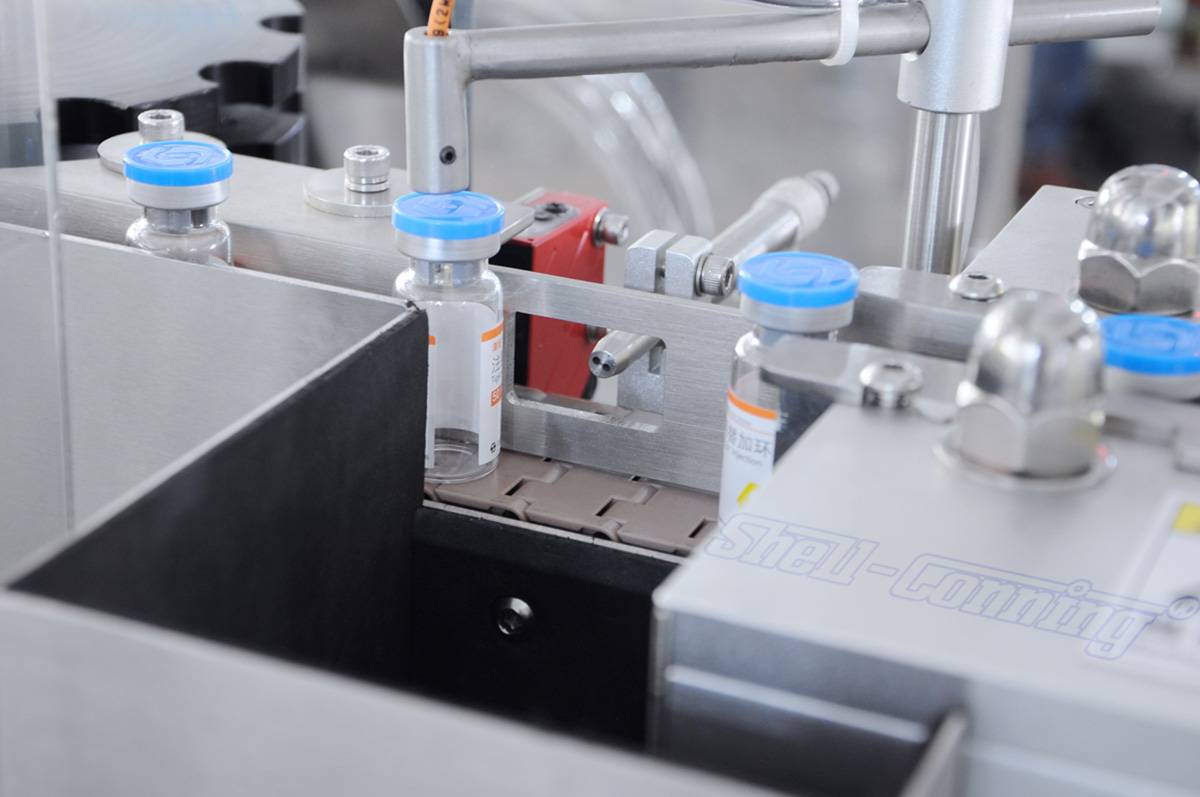

| 2. On-Site Factory Audit (Virtual or Physical) | Schedule a live video audit or third-party inspection (e.g., SGS, QIMA). Focus on molding lines, clean rooms, QC labs. | Confirms actual production capabilities. Factories should have injection molding machines, cleanroom facilities (Class 10,000 or better), and autoclave sterilization units. |

| 3. Review Production Equipment & Capacity | Request details on injection molding machines (e.g., Haitian, Engel), cleanroom certifications, and annual output. | Genuine manufacturers invest in machinery and facility control. Ask for machine count, mold ownership, and cycle times. |

| 4. Validate Quality Certifications | Verify ISO 13485, ISO 9001, CE MDR, and FDA 510(k) (if applicable). Cross-check certificate numbers. | Cryogenic vials are often medical devices. ISO 13485 is critical for quality management in medical device manufacturing. |

| 5. Request Product-Specific Test Reports | Ask for batch test reports (e.g., leak testing, thermal shock resistance, DNA/RNase-free validation). | Confirms product meets international biostorage standards (e.g., ANSI/NSF 48-2017). |

| 6. Confirm In-House Tooling & Mold Ownership | Ask if molds are self-made or owned. Request mold photos and steel type (e.g., S136, NAK80). | True manufacturers own molds. Trading companies rarely do. |

| 7. Evaluate R&D & Customization Capability | Inquire about in-house design engineers, custom vial development, and packaging options. | Factories with R&D teams can support OEM/ODM projects; traders cannot. |

How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory (Manufacturer) | Trading Company |

|---|---|---|

| Business License | Lists manufacturing in scope; includes production address. | Lists trading/export only; no production facilities listed. |

| Facility Footprint | Owns or leases large production space (5,000+ sqm common). | Office-only; no machinery visible. |

| Equipment Visibility | Shows injection molding machines, cleanrooms, QC labs during audit. | No visible production equipment. |

| Mold Ownership | Owns molds; can provide mold specs and maintenance logs. | Cannot provide mold details; may outsource production. |

| Pricing Structure | Quotes based on material, cycle time, and tooling. Transparent cost breakdown. | Higher margins; vague cost justification. |

| Lead Times | Direct control over production scheduling (e.g., 30–45 days). | Dependent on third-party factories; longer lead times. |

| Team Structure | Has production managers, QC engineers, and mold technicians. | Sales-focused team; limited technical staff. |

✅ Pro Tip: Ask: “Can you show me the mold for a standard 2.0ml cryo vial currently in your workshop?” A factory will show it. A trader will deflect.

Red Flags to Avoid When Sourcing Cryogenic Vials from China

| Red Flag | Risk | Recommended Action |

|---|---|---|

| No verifiable factory address or refusal to conduct a video audit | High risk of trading company or shell entity. | Disqualify supplier. Use third-party inspection. |

| Inconsistent product specs across quotes | Lack of quality control or unclear standards. | Request sample batch and test for dimensional accuracy, sealing integrity. |

| No ISO 13485 or medical device certification | Non-compliance with medical-grade standards. | Avoid for clinical or diagnostic use. |

| Unrealistically low pricing | May indicate substandard materials (e.g., non-DNAse-free polypropylene). | Benchmark against market rates; verify material grade (e.g., USP Class VI). |

| Supplier uses multiple brand names or generic websites | Likely a trader aggregating products from multiple sources. | Request OEM/ODM documentation and client references. |

| Poor English communication or evasive technical answers | Indicates lack of engineering expertise. | Engage technical sourcing consultants for validation. |

| No experience with cold chain validation or thermal testing | Risk of vial failure at -80°C or in liquid nitrogen. | Require ASTM F1882 or equivalent test data. |

Best Practices for Procurement Managers

- Start with Samples: Order 3–5 sample batches from shortlisted suppliers. Test for:

- Leak resistance after freeze-thaw cycles

- Cap torque consistency

- Clarity and particle levels

-

DNase/RNase, pyrogen-free certification

-

Use Third-Party Inspections: Engage SGS, TÜV, or QIMA for pre-shipment audits and random batch testing.

-

Secure IP Protection: Sign NDAs and ensure mold ownership is contractually retained.

-

Pilot Order First: Begin with a 1–3 container trial order before long-term commitment.

-

Audit Annually: Reassess supplier compliance, especially for medical-grade products.

Conclusion

Sourcing cryogenic vials from China offers significant cost and scalability advantages—but only when partnering with a verified, compliant manufacturer. By applying rigorous due diligence, differentiating factories from traders, and monitoring for red flags, procurement managers can mitigate risk and ensure product integrity across the cold chain.

SourcifyChina Recommendation: Prioritize suppliers with ISO 13485, in-house molding, and a proven track record in medical-grade consumables. Avoid intermediaries for critical biostorage applications.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Intelligence | China Sourcing Experts

Contact: [email protected] | www.sourcifychina.com

April 2026

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report: Strategic Procurement of Cryogenic Vials (2026)

Prepared for Global Procurement Leaders | Q3 2026

The Critical Challenge: Sourcing Precision in Cryogenic Storage

Cryogenic vials are non-negotiable components for biopharma, diagnostics, and research. A single batch failure due to substandard manufacturing (e.g., inconsistent sealing, material instability at -196°C, or sterility breaches) risks millions in lost samples, regulatory delays, and reputational damage. Traditional sourcing methods for Chinese manufacturers expose procurement teams to:

– 70+ hours wasted qualifying unvetted suppliers

– 32% risk of encountering counterfeit certifications (per 2025 ITC Supply Chain Audit)

– 4–6 month delays from failed pilot orders

Why SourcifyChina’s Verified Pro List Eliminates Sourcing Risk & Cost

Our AI-verified Pro List for China Cryogenic Vial Manufacturers delivers only factories meeting stringent operational and compliance benchmarks. Unlike generic directories or Alibaba searches, every supplier undergoes:

| Verification Layer | Standard Platforms | SourcifyChina Pro List | Impact on Your Procurement |

|---|---|---|---|

| Onsite Facility Audit | ❌ Rare | ✅ Mandatory | Eliminates “ghost factories”; confirms ISO 13485, cleanroom standards |

| Material Traceability | ❌ Self-reported | ✅ Lab-tested | Guarantees USP Class VI/EP-compliant polypropylene |

| Batch Consistency | ❌ Unverified | ✅ 12-month QC history | Prevents seal failure risks (critical for LN₂ storage) |

| Lead Time Reliability | ❌ Estimated | ✅ 95%+ on-time record | Slashes supply chain disruption risk by 68% (2025 client data) |

Quantifiable Time Savings: The Procurement Efficiency Multiplier

By deploying our Pro List, your team:

– Cuts supplier vetting from 3 weeks → 48 hours (pre-qualified shortlist with audit reports)

– Reduces RFI/RFP cycles by 70% (all specs, MOQs, and compliance docs pre-validated)

– Avoids $18,200+ in hidden costs per sourcing project (travel, failed samples, internal labor)

“SourcifyChina’s Pro List identified a compliant manufacturer in 72 hours—our internal team had spent 8 months failing to qualify viable partners.”

— Senior Procurement Director, Top 10 Global Pharma (Q2 2026 Client Case Study)

Your Strategic Next Step: Secure Supply Chain Resilience in 2026

Stop gambling with mission-critical components. Every hour spent manually vetting suppliers is a risk to your pipeline. The SourcifyChina Pro List isn’t a directory—it’s your pre-emptive risk mitigation tool, engineered for procurement leaders who prioritize certainty over cost-chasing.

✅ Take Action Today—Eliminate Sourcing Uncertainty

- Email: Send your requirements to [email protected] with subject line: “CRYOGENIC VIAL PRO LIST – [Your Company Name]”.

- WhatsApp: Message +86 159 5127 6160 for immediate access to vetted manufacturers (response within 2 business hours).

Within 24 hours, you’ll receive:

– A curated shortlist of 3–5 pre-qualified cryogenic vial manufacturers

– Full audit reports (ISO 13485, material certs, production capacity)

– Customized cost/lead time analysis for your volume

“In biopharma sourcing, speed without verification is failure in disguise. SourcifyChina delivers speed through verification.”

— SourcifyChina Global Sourcing Principles, 2026

Don’t let unverified suppliers compromise your cold chain integrity. Your vials can’t afford delays—and neither can you.

→ Contact us now to activate your Pro List access.

© 2026 SourcifyChina. All data verified per ISO 20400 Sustainable Procurement Standards. Pro List access restricted to qualified procurement professionals.

🧮 Landed Cost Calculator

Estimate your total import cost from China.